📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Heavy-Duty Push Back Pallet Racking for Cold Storage & Harsh Environments

For logistics managers and warehouse operators in cold storage, chemical processing, and other demanding sectors, standard warehouse racking is a liability. It’s not a question of if it will fail, but when. Corrosion, constant thermal cycling, and heavy, dynamic loads create a perfect storm that can compromise structural integrity, product safety, and your bottom line. [Geelyracks/Jiliracks] specializes in engineering heavy-duty push back pallet racking systems that are not just installed in these environments, but are specifically built to thrive in them.

This isn’t off-the-shelf racking with a thicker coat of paint; it’s a fully integrated storage solution designed from the ground up with one goal: to provide unmatched durability, reliability, and productivity in the world’s most challenging storage conditions. Our corrosion-resistant push back racking systems leverage advanced metallurgy, precision engineering, and a deep understanding of material flow to ensure your operation remains efficient, safe, and cost-effective, even when the environment is working against you. The fundamental design of the push back pallet racking system, with its dynamic cart-and-rail mechanism, is re-engineered here to withstand extremes that would cripple a conventional setup.

<h2>Understanding the Unique Challenges of Harsh Environment Warehousing</h2>

Before delving into the engineering specifics, it’s critical to define what constitutes a “harsh environment.” Many operations face conditions that dramatically accelerate wear and tear, and standard storage solutions simply aren’t equipped to handle them. A standard push back pallet racking system might be rated for the load, but without the correct material and finish, its lifespan can be measured in months, not years.

<h3>The Relentless Assault of Cold Storage Facilities</h3>

Freezers and blast chillers present a triple threat to storage infrastructure. First, the constant sub-zero temperatures make standard steel brittle, increasing the risk of catastrophic failure under impact. Second, the high humidity levels, which condense and freeze on surfaces, create a perpetually wet environment. Third, the thermal expansion and contraction from defrost cycles and door openings put repeated stress on the racking’s structural connections. A system not designed for this will see its protective coatings crack and peel, exposing the base metal to rapid corrosion. This is why a specialized push back pallet racking for cold storage is not a luxury but an operational necessity. The repeated loading and unloading cycles in these conditions demand a system that maintains its mechanical smoothness and structural integrity where others seize and weaken.

<h3>Chemical Exposure in Industrial Settings</h3>

Industries like agriculture (fertilizers), food processing (salts, acids), and chemicals deal with airborne particulates and spills that are highly corrosive. Even in climate-controlled warehouses, these substances can quickly degrade standard powder coatings and compromise the zinc layer of pre-galvanized steel, leading to rust and structural weakening. The design of a push back pallet racking system in these contexts must account for chemical resistance not just on the beams and uprights, but on every moving part, every cart, and every wheel. A single point of failure in the coating can halt the entire lane’s functionality.

<h3>High-Humidity and Coastal Environments</h3>

Warehouses in tropical regions of Southeast Asia, Latin America, and coastal areas in the Middle East and Africa are constantly battling salt-laden, humid air. This salty moisture is exceptionally effective at penetrating microscopic pores in standard finishes, initiating rust from the inside out. For a push back pallet racking system, this environment is particularly punishing. The inclined rails and carts, critical to the system’s operation, are under constant threat. Without sealed bearings and specially formulated coatings, the mechanism will corrode, increasing rolling resistance and eventually jamming completely, defeating the purpose of this high-density storage solution.

<h2>Beyond Standard Coatings: Our Multi-Layered Defense Against Corrosion</h2>

The foundation of our corrosion-resistant push back pallet racking is a protection system that goes far beyond a simple paint job. We employ a multi-stage, industrial-grade process to create a barrier that is both physically resilient and chemically inert. This comprehensive approach is what sets our heavy-duty push back pallet racking apart in the global market.

<h3>Step 1: Advanced Surface Preparation – The Key to Longevity</h3>

Long-lasting corrosion protection is impossible without perfect surface preparation. Every component of our push back pallet racking undergoes a thorough chemical pretreatment process. This involves:

Degreasing: Removing all oils and contaminants from the steel.

Rinsing: Ensuring a perfectly clean surface for the next stage.

Phosphating: Creating a micro-crystalline zinc or iron phosphate layer that dramatically enhances paint adhesion and provides a secondary corrosion-inhibiting barrier. This step is what prevents under-film corrosion, the primary failure point of inferior coatings on any push back pallet racking system. Without this, even the best coating will eventually blister and peel.

<h3>Step 2: The Power of Hot-Dip Galvanizing</h3>

For the most extreme environments, such as chemical plants or coastal ports, we recommend a hot-dip galvanized finish for the entire push back pallet racking structure. This process involves immersing the fabricated steel components into a bath of molten zinc. The result is a metallurgical bond that creates a zinc-steel alloy coating. This coating is not only incredibly hard and abrasion-resistant but also provides cathodic protection. If the coating is scratched, the surrounding zinc sacrificially protects the exposed steel, preventing rust from forming. This is the gold standard for industrial corrosion protection and is highly recommended for the structural frames of a push back pallet racking system in a Class IV harsh environment as defined by the American Institute of Steel Construction.

<h3>Step 3: Epoxy-Polyester Hybrid Powder Coating</h3>

For cold storage and many high-humidity applications, we utilize a thick, durable epoxy-polyester hybrid powder coating on our push back pallet racking. After pretreatment, an electrostatically charged powder is applied to the components, which are then cured in an oven, creating a smooth, uniform, and exceptionally resilient finish. We specify coatings with high resistance to impact, moisture, and a wide range of chemicals. The color isn’t just for aesthetics; it’s the final, robust shield in our defensive system for the push back pallet racking. For the carts and rails, we often use a nylon-based or other polymer coating to reduce friction and prevent galvanic corrosion.

<h2>Heavy-Duty Structural Engineering for Uncompromising Load Capacity</h2>

A finish is only as good as the structure it protects. Our heavy-duty push back pallet racking is engineered with the structural integrity to handle the immense stresses of high-density storage in demanding conditions. The dynamic nature of the push back pallet racking system, where loads are constantly moving on an incline, imposes unique forces that must be calculated by experienced engineers.

<h3>High-Strength, Low-Alloy (HSLA) Steel</h3>

We don’t use generic mild steel. Our push back pallet racking systems are fabricated from High-Strength, Low-Alloy (HSLA) steel. This material offers a superior strength-to-weight ratio, meaning we can use less material to achieve the same load capacity as a bulkier, standard steel beam, or use the same volume of material for a much higher capacity. This inherent strength is crucial for withstanding the dynamic loads of pallets being pushed and pulled on the rails, as well as the constant weight in high-bay applications. The use of HSLA steel in a push back pallet racking system directly translates to a slimmer profile for the same capacity, allowing for better visibility and light penetration within the warehouse.

<h3>Beam and Upright Design: Where Precision Meets Power</h3>

Uprights (Frames): The uprights for our heavy-duty push back pallet racking are manufactured with reinforced column designs and often feature additional bracing to resist the lateral forces inherent in push-back systems. The bolt holes are precision-punched to ensure perfect alignment, which is critical for maintaining the system’s overall structural stability over thousands of load cycles.

Beams: Our heavy-duty pallet rack beams for the push back pallet racking system feature a robust roll-formed or structural tube design. They are equipped with patented safety locks that securely engage with the upright, preventing accidental dislodgement, a critical feature in high-traffic or automated environments. The beam end-plates are designed to distribute load stress evenly across the upright column.

<h2>The Push Back System: Maximizing Density Without Sacrificing Selectivity</h2>

The push back racking system is a dynamic pallet storage solution that offers a superb balance between high-density storage and good selectivity. Understanding its mechanics is key to appreciating its value in a harsh environment setting. The reliability of the push back pallet racking mechanism is paramount; a jammed cart in a -30°C freezer is more than an inconvenience—it’s a major operational disruption.

<h3>How the Cart-and-Rail System Works</h3>

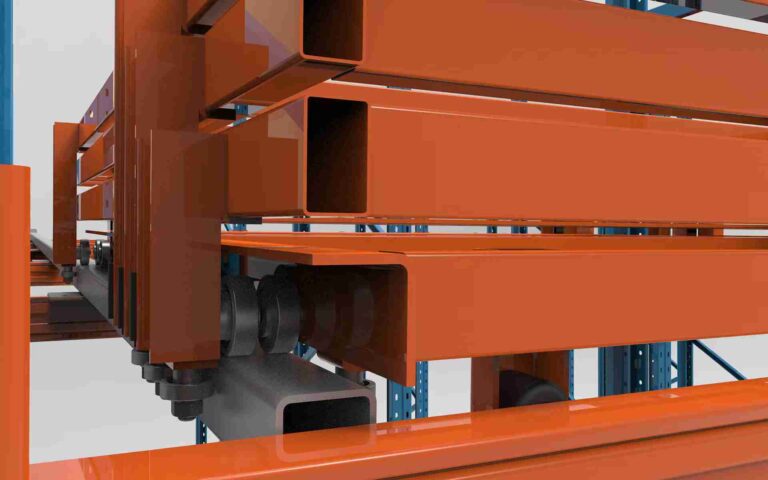

Each level of our push back pallet racking system consists of a pair of inclined rails on which specially designed carts travel. Pallets are loaded from the aisle onto these carts. When a new pallet is loaded, it pushes the previous pallets back along the rails. This creates a Last-In, First-Out (LIFO) inventory system. Unloading is the reverse process; when the front pallet is removed, the next pallet automatically rolls forward to the aisle position, ready for picking. This entire mechanism—the carts, wheels, and rails—is built with sealed bearings and corrosion-resistant materials to prevent freeze-ups and seizing in cold or corrosive atmospheres. The precision of the incline is what makes the push back pallet racking system work flawlessly; too steep and the pallets roll too fast, too shallow and they won’t return. Our engineering accounts for pallet weight and bottom condition to perfect this angle.

<h3>Operational Advantages in Demanding Conditions</h3>

Reduced Aisle Footprint: By storing pallets 2-5 deep per side, a push back pallet racking system significantly reduces the number of aisles, maximizing your valuable cubic storage space. In expensive cold storage construction, this directly translates to lower energy costs and a higher ROI on the push back pallet racking investment.

Enhanced Safety: With no forklift entry required into the rack structure (as with drive-in racks), the risk of damaging uprights and sprinkler systems is drastically reduced. This is a major safety and maintenance advantage of the push back pallet racking design.

Improved Productivity: Operators spend less time traveling by having multiple SKUs accessible from a single aisle. In a -25°C freezer, minimizing an operator’s exposure time is not just an efficiency gain; it’s a worker safety issue, making the push back pallet racking system a strategic asset.

<h2>Integration with Automated Systems: The Future-Proof Warehouse</h2>

A modern warehouse is rarely a static entity. Our heavy-duty push back racking is designed to be the perfect partner for automation, creating a seamless, high-throughput storage and retrieval system. The compatibility of a push back pallet racking system with automation is a key consideration for businesses looking to scale.

<h3>Compatibility with AGVs and Unmanned Forklifts</h3>

The precise and consistent dimensions of our push back pallet racking make it ideally suited for integration with Automated Guided Vehicles (AGVs) and unmanned forklifts. These systems rely on millimeter-perfect alignment to operate safely and efficiently. Our push back pallet racking provides that stable, predictable environment. We can work with your automation team to specify load tolerances, aisle widths, and interface points to ensure a flawless integration. The robust construction of our push back pallet racking ensures it can withstand the occasional minor impact from an automated vehicle without compromising the system’s integrity.

<h3>Linking to a Broader Automated Storage and Retrieval System (AS/RS)</h3>

For the highest level of efficiency, a push back pallet racking system can be integrated into a larger Automated Storage and Retrieval System (AS/RS). In this setup, a fully automated crane or shuttle system services the push back lanes, completely removing the human element from the harsh environment. This maximizes throughput, accuracy, and worker safety while ensuring the equipment operates in its ideal, designed conditions. The push back pallet racking acts as the high-density buffer within a fully automated workflow.

<h2>Case Study: Transforming a Southeast Asian Seafood Exporter’s Cold Chain</h2>

A leading seafood exporter in Vietnam was struggling with their existing racking in their -30°C blast freezer. The standard powder-coated racking was showing significant rust after just 18 months, and weld points were failing due to embrittlement. Forklift drivers were nervous about collisions, fearing a structural collapse. Their throughput was suffering due to manual, single-deep selective racking.

The Solution: We designed and installed a fully hot-dip galvanized heavy-duty push back pallet racking system. The structural beams and uprights were specified with HSLA steel to handle the shock loads from rapid freezing and the heavy, water-soaked pallets. The carts were fitted with polymer wheels and sealed bearings specifically rated for ultra-low temperatures. This custom push back pallet racking solution was designed for 4-pallet depth, dramatically increasing storage within the same footprint.

The Result:

Eliminated Corrosion: After three years of continuous operation, the push back pallet racking system shows zero signs of rust or coating degradation.

Increased Capacity: The push back pallet racking design increased storage density by 60% within the same footprint, deferring the need for a costly facility expansion.

Improved Safety & Morale: The robust structure gave operators confidence, and the reduced aisle count minimized risky maneuvers in the cramped, cold space. The reliability of the push back pallet racking mechanism eliminated the downtime previously caused by jammed pallets.

<h2>Selecting the Right Partner: More Than Just a Supplier</h2>

Choosing a racking provider for a harsh environment is a critical capital decision. It’s not about finding the lowest cost per component; it’s about finding the lowest cost of ownership over a 15-20 year lifespan. The provider of your push back pallet racking must act as a consultant and engineer, not just a vendor.

<h3>The Critical Role of a Professional Site Assessment and Load Audit</h3>

We never sell a push back pallet racking system without first conducting a thorough on-site assessment. Our engineers analyze your specific environmental conditions (temperature, humidity, chemical exposure), measure your pallet loads (including dynamic load factors), and understand your material flow. This data is the foundation of a safe and effective design for your push back pallet racking. An off-the-shelf solution is a gamble you cannot afford.

<h3>Importance of Certified Load Calculations and Drawings</h3>

You receive a complete set of engineered drawings and certified load calculations for your push back pallet racking system. This documentation is not just for installation; it’s for your safety records, insurance compliance, and future planning. It provides peace of mind that the push back pallet racking is designed to recognized engineering standards like those from the Rack Manufacturers Institute (RMI). This level of documentation is non-negotiable for a professional push back pallet racking installation.

<h2>Installation and Lifelong Maintenance in Harsh Conditions</h2>

Even the best-designed push back pallet racking system can fail if installed incorrectly. Our approach to installation and maintenance ensures long-term performance, protecting your investment for decades.

<h3>Specialized Installation Protocols</h3>

Our installation teams are trained in the unique challenges of working in cold storage and industrial environments. This includes understanding thermal expansion, using appropriate tools in low temperatures, and ensuring all safety protocols are followed. The installation of a push back pallet racking system requires precise leveling of the rails to ensure smooth cart operation, a task that requires skill and patience in challenging environments.

<h3>Proactive Maintenance and Inspection Schedules</h3>

We provide our clients with a customized maintenance and inspection schedule for their push back pallet racking investment. In a harsh environment, a semi-annual inspection is mandatory. We check for any coating damage (which can be touched up with our provided specialized paint), structural integrity, and the smooth operation of all moving parts in the push back carts. This proactive approach for your push back pallet racking system prevents small issues from becoming catastrophic failures. We also recommend regular cleaning of the rails to remove debris that could impede cart movement.

<h2>Conclusion: An Investment in Resilience and Efficiency</h2>

In the demanding world of cold storage and harsh industrial environments, your storage racking is a critical piece of operational infrastructure. It directly impacts safety, productivity, and profitability. Opting for a standard system is a false economy that leads to premature failure, safety hazards, and costly replacements. The specialized heavy-duty push back pallet racking offered by [Company Name] represents a fundamental shift in approach.

It is a precision-engineered, corrosion-resistant solution built to deliver decades of reliable, high-performance service where ordinary racking fails. By investing in a push back pallet racking system designed specifically for your challenges, you are not just purchasing steel; you are investing in the resilience, efficiency, and future-proofing of your entire logistics operation. The right push back pallet racking system is the backbone of a robust and modern supply chain.

Frequently Asked Questions (FAQs)

1. What is the typical lifespan of your heavy-duty push back racking in a corrosive environment compared to a standard system?

While standard push back pallet racking in a harsh environment may begin to show significant corrosion and require replacement in 3-5 years, our systems are engineered for a lifespan of 15-20 years or more. The combination of HSLA steel and our multi-stage corrosion protection (hot-dip galvanizing or industrial powder coating) is designed to withstand continuous assault, offering a significantly lower total cost of ownership for your push back pallet racking investment.

2. Can your push back systems be retrofitted into an existing warehouse structure, or do they require a new building?

We specialize in both greenfield (new building) and brownfield (retrofit) projects. Our engineering team can design a push back pallet racking system to fit within your existing warehouse footprint, often working around live operations. We conduct a detailed site survey to ensure the new push back pallet racking integrates seamlessly with your building’s structure, floor conditions, and existing logistics flow.

3. How does the load capacity of your harsh-environment racking differ from your standard models?

The structural design principles for load capacity remain the same; however, the materials are superior. By using High-Strength, Low-Alloy (HSLA) steel, we can often achieve higher load capacities with similar beam and upright profiles in our push back pallet racking. More importantly, the load capacity is guaranteed over the long term because the structural integrity is protected from corrosion, which weakens standard steel over time and compromises any push back pallet racking system.

4. Are the moving parts (carts, wheels) in the push back system also corrosion-resistant?

Absolutely. The entire push back pallet racking system is designed for the environment. The carts and wheels are typically manufactured from high-impact, corrosion-resistant polymers or coated metals and are equipped with sealed bearings to prevent moisture and contaminants from entering the rolling mechanism. This prevents freezing and seizing, ensuring smooth operation of the push back pallet racking in cold storage and corrosive atmospheres.

5. Do you offer fire protection or seismic design for these specialized racking systems?

Yes, we can engineer our heavy-duty push back pallet racking to meet local fire protection codes and specific seismic zone requirements. This can include the integration of in-rack sprinkler systems and the use of specialized, ductile structural components and bracing designed to absorb and dissipate seismic energy, which is a critical consideration for a push back pallet racking installation in many regions across Latin America and Asia.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com