📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Unlocking Your Warehouse’s Vertical Potential: A Strategic Guide

In the high-stakes world of logistics and inventory management, the constant pressure to do more with less is a universal challenge. Expansion is costly, disruptive, and often geographically impossible. The most innovative and cost-effective solution isn’t found by looking outward, but upward. The answer lies in the sophisticated integration of a pallet racking mezzanine floor. This transformative structural solution is the definitive method for capitalizing on the unused cubic airspace within an existing facility, effectively creating a new level of operational capacity without the exorbitant costs and timelines associated with new construction.

The critical distinction between a mere installation and a genuine strategic asset hinges on one factor: expert execution. The marriage of structural engineering, material science, and logistical workflow design requires a specialized skill set. This is where the value of true design & installation experts becomes paramount. A professionally engineered pallet racking mezzanine floor is a masterclass in efficiency, safety, and future-ready planning.

It demands a partner who views the project not as a simple product drop-off, but as a holistic integration into the client’s unique operational ecosystem. The offer of a free consultation is the first step in this rigorous process, a commitment to understanding client challenges from the ground up—literally and figuratively—before a single beam is ever designed.

Deconstructing the Powerhouse: What Exactly is a Pallet Racking Mezzanine Floor?

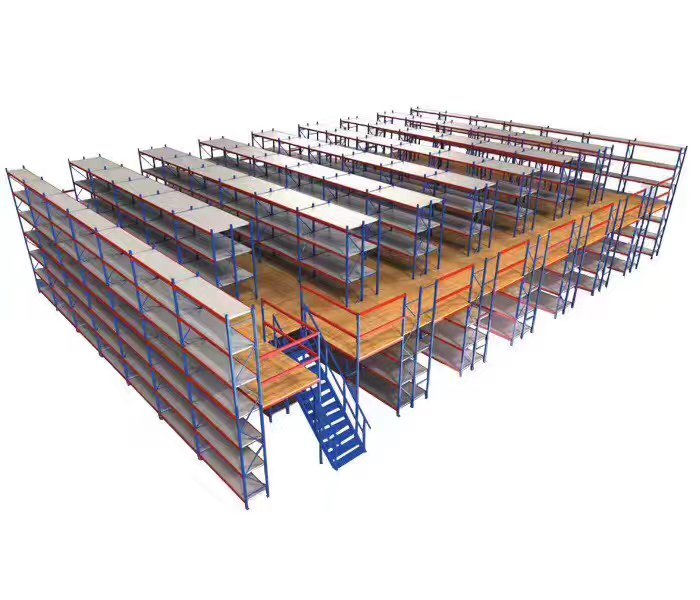

At its core, a pallet racking mezzanine floor is a freestanding, multi-tiered structural system engineered to create one or more additional working levels within a warehouse or industrial building. It is a testament to vertical efficiency. Unlike traditional construction, which relies on a building’s perimeter walls for support, this system typically utilizes the inherent strength of the client’s existing or new pallet racking infrastructure as its primary support, or it employs a network of independent structural columns. This creates a robust intermediate deck, a “floor in the air,” that dramatically expands usable square footage.

The Anatomy of a Superior Mezzanine System

The integrity of any pallet racking mezzanine floor is defined by the sum of its parts. Each component must be meticulously engineered and harmonized.

Primary Structural Supports: The backbone of the entire structure. In a rack-supported design, the pallet racking upright frames are reinforced and upgraded to bear the immense additional loads of the deck above. In a structurally-supported design, heavy-duty steel columns are installed independently, offering unparalleled flexibility for the layout below.

Secondary Beams & Decking Solutions: Horizontal beams connect the primary supports, creating a grid that holds the decking. The choice of decking is critical and varies based on application: from open-grating for light-duty use and ventilation to solid, heavyweight steel bar grating for durability and under-deck lighting, all the way to concrete-filled metal decking for maximum fire resistance and the ability to support extreme point loads from heavy machinery.

The Integrated Pallet Racking: This is where the magic of space multiplication happens. The system is designed so that the lower levels continue to function as high-density storage, seamlessly supporting the new mezzanine floor above. This symbiotic relationship is the hallmark of an efficient design.

Safety and Access Infrastructure: No pallet racking mezzanine floor is complete without comprehensive access and safety systems. This includes code-compliant staircases with safety gates, full-perimeter guardrail systems with toe-boards, and specialized loading equipment like material lifts or even integrated ramps for automated guided vehicles (AGVs).

Beyond Storage: The Multifaceted Applications of a Mezzanine Floor

The versatility of a pallet racking mezzanine floor is its most compelling feature. While creating additional bulk storage is a common driver, the highest return on investment often comes from more strategic, operational applications.

Revolutionizing High-Density Storage and Order Fulfillement

Imagine a warehouse where slow-moving, long-term storage is elevated to the mezzanine floor level, accessed only periodically. This frees up the entire, highly valuable ground floor for high-velocity goods and optimized order picking zones. This configuration can be integrated with pick modules and conveyor systems, slashing walk times and supercharging fulfillment speed.

Creating Distinct, Multi-Tiered Operational Zones

Manufacturing and Assembly Overheads: Light manufacturing, sub-assembly lines, kitting stations, and packaging operations are perfect candidates for relocation to a pallet racking mezzanine floor. This clears the main floor for heavy machinery, raw material staging, and finished product shipping, dramatically improving workflow and safety.

Administrative and Human-Focused Spaces: The need for quiet, clean, and safe office space, quality control laboratories, or employee break rooms can be elegantly solved by a mezzanine floor. These enclosed spaces provide a productive environment away from the hustle and noise of the warehouse floor, all without sacrificing a single square foot of productive storage or manufacturing space.

Showroom and Client-Facing Areas: For distributors and wholesalers, a well-finished pallet racking mezzanine floor can serve as a pristine, professional showroom. Clients can view products in an organized, clean setting while the operational chaos of inventory management continues efficiently below, out of sight.

The Blueprint for Success: The Indispensable Expert Design Phase

This phase is where professional design & installation experts separate themselves from simple equipment vendors. It is a rigorous, data-driven process where assumptions are replaced by calculations.

Phase 1: The In-Depth Facility Audit and Load Analysis

The process begins with a comprehensive on-site assessment conducted by seasoned experts. This audit gathers critical data that forms the foundation of the entire project:

Dimensional Mapping: Precise measurements of the building’s clear height are taken, noting all overhead obstructions like sprinkler heads, lighting, HVAC ductwork, and electrical conduits.

Slab Analysis: The existing concrete floor is evaluated for thickness, compressive strength, and reinforcement to ensure it can handle the new concentrated point loads imposed by the pallet racking mezzanine floor structure.

Load Requirement Engineering: Meticulous calculation of all potential loads is paramount. This includes the dead load (the weight of the structure itself), the live load (the weight of stored goods, personnel, and equipment), and dynamic loads (the impact and vibration from forklifts or AGV小车 moving on the deck above). Factors like seismic activity and wind loads are also considered where applicable.

Workflow Diagnostics: Understanding how goods and people move through the facility is crucial. Experts analyze traffic patterns, picking paths, and material flow to strategically place access points, columns, and aisles. The goal is to enhance efficiency, not just create space.

Phase 2: Precision Engineering and Conceptualization

Using state-of-the-art CAD (Computer-Aided Design) and structural analysis software, engineers translate the audit data into a safe, compliant, and efficient design. This design must adhere to a stringent set of international standards and local building codes, including:

IBC (International Building Code)

OSHA (Occupational Safety and Health Administration) regulations, particularly for fall protection and load management.

RMI (Rack Manufacturers Institute) specifications governing the pallet racking components.

The result is a comprehensive set of detailed fabrication and installation drawings, which are used for client approval, manufacturing, and securing necessary building permits.

The Installation Imperative: Precision, Safety, and Operational Continuity

The value of expert design is fully realized only through flawless execution. Professional installation is characterized by precision, safety, and a disciplined approach to minimizing disruption.

A Methodical Approach to Installation

Pre-Fabrication and Staging: All components for the pallet racking mezzanine floor are pre-cut, pre-welded, and pre-finished in a controlled factory environment. They are then kitted, labeled, and shipped to the site, ensuring quality and reducing on-site assembly time.

Phased and disciplined Execution: Installation teams work to a precise schedule, often coordinating with the client to perform work during off-shifts or weekends to avoid interrupting critical daytime operations. The process is streamlined and efficient.

Uncompromising Quality Assurance: Every connection, from the base plates anchored to the concrete floor to the bolts securing the decking, is torqued to specification and inspected. The project is not signed off until it passes a multi-point final inspection against the original engineering drawings.

True Turnkey Responsibility: Experts manage the entire project lifecycle. This includes pulling permits, coordinating with other trades such as electricians for lighting and sprinkler contractors for fire system modifications, and providing a single point of accountability for the entire pallet racking mezzanine floor project.

A Critical Choice: Rack-Supported vs. Structurally-Supported Mezzanine Floors

Selecting the appropriate type of support system is a fundamental decision that impacts flexibility, cost, and long-term utility.

The Rack-Supported Mezzanine Floor

The Ideal Scenario: This design is perfect for applications where the primary goal is to maximize storage density in a dedicated area. The pallet racking system itself is engineered to act as the support structure for the deck above.

Inherent Advantages: This can be a highly space-efficient and cost-effective solution for pure storage applications, as it eliminates the need for independent columns, allowing for completely clear spans beneath the structure.

Important Considerations: The main trade-off is flexibility. Future reconfiguration of the ground-level pallet racking layout is intrinsically linked to the mezzanine floor above, making changes more complex and costly.

The Structurally-Supported Mezzanine Floor

The Ideal Scenario: This is the solution for heavy-duty industrial applications, spaces that require large open areas beneath the deck, or multi-level mezzanine structures. It uses its own network of steel columns for support, independent of any storage racking.

Inherent Advantages: This design offers superior flexibility. It can support significantly heavier loads, making it suitable for supporting automated automated conveyors or light industrial machinery on the deck. Crucially, it allows the ground-floor layout, including any pallet racking, to be reconfigured, moved, or expanded at any time without affecting the integrity of the mezzanine floor above.

Important Considerations: The presence of independent support columns will slightly impact the layout and aisle space on the main floor level, a factor that must be expertly planned during the design phase.

Building for Tomorrow: Integrating the Mezzanine Floor with Automation

A modern warehouse is an automated ecosystem. Therefore, a pallet racking mezzanine floor must be designed not as a standalone structure, but as a fully integrated component of this ecosystem. Forward-thinking design & installation experts bake automation readiness into their blueprints.

Facilitating Autonomous Material Movement

The future of warehousing is autonomous. A well-designed pallet racking mezzanine floor can include gently sloped ramps with reinforced decks and integrated safety sensors to allow AGV (AGVs) and unmanned forklifts to travel between levels autonomously. This creates a truly continuous, high-density storage and retrieval system that operates around the clock with minimal human intervention.

Seamless Interface with Conveyor and Sortation Systems

To truly connect operational levels, the mezzanine floor design can include strategically placed openings and reinforced edges for vertical reciprocating conveyors (VRCs), spiral conveyors, or even chute systems. This enables automated, continuous vertical movement of goods between the mezzanine floor and the main level, which is essential for feeding into a main sortation system and is a key feature of advanced ASRS concepts.

The Non-Negotiable Priority: Engineering Safety into Every Aspect

Any discussion about a pallet racking mezzanine floor is incomplete without an unwavering focus on safety. Professional experts engineer safety into the very DNA of the structure, far exceeding the minimum requirements of the code.

Perimeter Protection: High-strength steel guardrail systems are mandatory on all open sides and ends of the mezzanine floor. These systems include a top rail, mid-rail, and a solid toe-board to prevent tools or materials from falling to the level below.

Staircase and Access Safety: Industrial-grade staircases are designed for safe and easy access. They are equipped with handrails on both sides and safety gates that swing shut automatically to prevent falls from the top landing.

Clear and Unambiguous Load Signage: Professional installers fix durable, easy-to-read placards at all access points to the mezzanine floor. These signs clearly state the maximum permissible load capacity in terms of weight per square foot, preventing dangerous overloading.

Auxiliary System Integration: The design proactively includes planning for adequate lighting on the mezzanine floor deck to eliminate dark spots and shadows. It also coordinates with fire safety professionals to ensure sprinkler coverage meets code requirements for the new level created.

The Hallmarks of a True Industry Expert Partner

Choosing the right partner for a pallet racking mezzanine floor project is the most critical decision a warehouse manager can make. The distinguishing factors of a true expert are clear.

Single-Source Accountability: A top-tier provider manages both the pallet racking and structural mezzanine floor design & installation under one roof. This eliminates the risk of finger-pointing between different subcontractors and ensures seamless integration and total accountability.

Holistic, Systems-Based Thinking: Experts see the bigger picture. They design the pallet racking mezzanine floor to work in perfect harmony with the client’s existing material handling equipment, workflow patterns, and future automation goals, whether that involves AGV or automated.

A Proven and Documented Track Record: Expertise is demonstrated through a robust portfolio of successful projects across diverse industries—from e-commerce fulfillment centers and cold storage warehouses to complex manufacturing plants. Case studies and client testimonials are a testament to their capability.

The Value of the Free Consultation: This initial offering is far more than a sales call. It is a diagnostic session. It represents an expert’s commitment to listening, understanding pain points, and performing a preliminary assessment to determine the true feasibility and potential ROI of a pallet racking mezzanine floor for that specific operation. It is the foundation of a trusted partnership.

Conclusion: Elevate Your Operations, Not Your Expenses

The ceiling of a warehouse is no longer a limit; it is the next frontier for growth. A professionally engineered and installed pallet racking mezzanine floor represents one of the smartest strategic investments a business can make in its logistical infrastructure. It is a powerful, pragmatic, and proven solution to the universal challenges of space constraints, rising real estate costs, and the need for agile, efficient operations.

The success of this endeavor—its safety, its efficiency, and its return on investment—is entirely dependent on the expertise of the partner chosen for the journey.

By prioritizing precision engineering, seamless integration, uncompromising safety, and a future-ready mindset, industry leaders provide more than just a structure—they deliver a transformative and lasting competitive advantage. The space is there, waiting to be claimed.

Frequently Asked Questions (FAQs)

1. How does the presence of a mezzanine floor affect our warehouse’s fire suppression system?

A professionally installed pallet racking mezzanine floor will always require an upgrade to the facility’s fire sprinkler system. Code requires that the new level created by the mezzanine floor be protected. This typically involves relocating existing sprinkler heads to the underside of the new deck and adding new heads on the mezzanine floor level itself. A expert partner will coordinate this entire process with a licensed sprinkler contractor as part of the turnkey service.

2. What are the weight capacity limits for a typical mezzanine floor installation?

The capacity of a pallet racking mezzanine floor is not “typical”; it is custom-engineered. Capacities can range from 125 pounds per square foot (psf) for light-duty office or storage use to 250 psf, 500 psf, or even more for heavy industrial applications supporting machinery or very dense storage. The final capacity is a result of the structural design, the decking choice, and the underlying concrete slab’s strength.

3. Can a mezzanine be installed in a building with a sloped floor or other irregularities?

Yes, experienced design & installation experts can overcome site irregularities. For sloped floors, the steel columns can be custom-cut to specific lengths to create a level mezzanine floor deck above. Other obstacles, like support posts or machinery, can be engineered around. The initial audit is crucial for identifying these challenges and developing solutions.

4. How does the cost of a mezzanine floor compare to building a new warehouse addition?

The cost savings are significant. Generally, a pallet racking mezzanine floor can create new operational space at a fraction of the cost per square foot of constructing a new building addition. There are also substantial savings in terms of time (avoiding lengthy construction timelines), property taxes (in many jurisdictions), and avoiding the business disruption of a major construction project.

5. What kind of lead time is involved from the initial consultation to project completion?

While every project is unique, a general timeline from a free consultation to completion can range from 8 to 14 weeks for a standard project. This timeline includes the detailed engineering and permitting phase (2-4 weeks), the fabrication of all components (3-5 weeks), and the on-site installation (1-3 weeks, depending on size and complexity). Experts provide a detailed project schedule after the initial assessment.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com