📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Optimizing Warehouse Potential: The Strategic Imperative of Custom Narrow Aisle Shelving Systems in Growth Economies

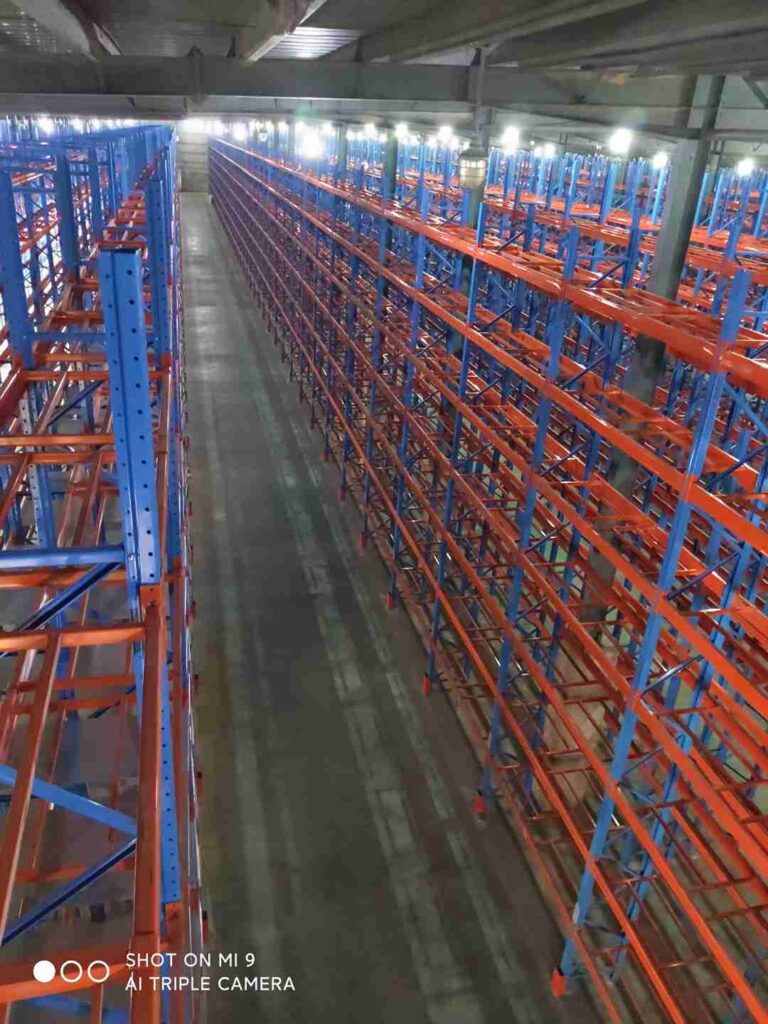

In the dynamic and often unpredictable landscapes of Southeast Asia, the Middle East, Africa, and Latin America, logistics and warehouse operators face a universal conundrum: escalating operational costs against the pressing need for rapid scalability. Conventional storage solutions frequently become bottlenecks, stifling growth and eroding profitability. The strategic implementation of narrow aisle shelving systems represents a paradigm shift, offering a proven pathway to dramatic gains in storage density and operational throughput.

However, the critical differentiator between success and failure in these diverse markets lies not in the generic concept of narrow aisle shelving systems, but in their meticulous, expert-led customization. This extensive treatise articulates why a deeply tailored approach is non-negotiable for emerging markets. It will dissect the unique infrastructural, environmental, and human-centric challenges, demonstrating how a truly custom-engineered narrow aisle shelving system transforms these challenges into competitive advantages.

The discussion extends beyond static storage, exploring seamless integration with automation technologies like AGVs and smart warehousing software, and underscores the vital importance of local partnership networks for sustained performance. For decision-makers seeking not just equipment but a resilient, high-return logistics asset, this analysis provides the essential framework for evaluating and investing in narrow aisle shelving systems engineered for the future.

The Foundational Logic: Why Off-the-Shelf Solutions Fail in Complex Markets

The global warehousing equipment catalogue, filled with standard specifications, is a seductive trap for the unprepared manager in Jakarta, Dubai, Lagos, or Bogotá. It promises efficiency but often delivers fragility. Standard designs for narrow aisle shelving systems presuppose conditions rarely found in fast-growing economies: consistently high-specification construction, stable environmental controls, readily available specialist technicians, and predictable inventory profiles. Decades of field experience across these continents reveal a different reality—one where the winning solution is always a bespoke one.

A custom-engineered narrow aisle shelving system in this context is an exercise in precision adaptation. It begins with a forensic analysis of site-specific variables that standard suppliers overlook. Engineers must account for the variable composition and load-bearing capacity of local concrete, which can differ between industrial zones in the same city. They must design for the relentless humidity of a Ho Chi Minh City monsoon season, the abrasive, silica-rich dust of a Riyadh logistics park, and the thermal expansion cycles in the high-altitude warehouses of the Andes.

Furthermore, the design must integrate with the available material handling equipment (MHE) and the skill level of local operators, building in intuitive safety and ease of use. Ultimately, an effective narrow aisle shelving system in an emerging market is not a purchased product; it is a co-created asset, born from a collaboration between a knowledgeable supplier and a forward-thinking operator. The following sections deconstruct the pillars of this collaborative, custom-creation process.

Navigating the Terrain: Core Challenges Informing Custom Design

The superiority of a tailored narrow aisle shelving system is most evident in how it addresses and overcomes the endemic challenges of developing logistics hubs. A generic system ignores these factors; a custom system is designed because of them.

1. Infrastructure Realities: Building on Existing Conditions

The assumption of a perfect, warehouse-grade slab is a luxury many operations lack. A pragmatic narrow aisle shelving system supplier must adapt to the actual site, not an idealized one.

Suboptimal Floor Conditions: Existing facilities often have floors with poor flatness (deviating from critical FF/FL standards) or uncertain load-bearing capacities. A sophisticated supplier will conduct detailed laser-levelling surveys and then engineer the narrow aisle shelving system accordingly. This may involve specifying adjustable, heavy-duty baseplates with large bearing areas, designing integrated levelling shims, or modifying the structural load distribution to compensate for weak spots—all to avoid the prohibitive cost and downtime of slab replacement.

Irregular Building Fabrics: Warehouses, especially repurposed or older structures, frequently feature obstructive column grids, low ceiling clearances, or irregular bay sizes. A custom narrow aisle shelving system is artfully configured to navigate these obstacles. It turns constraints into a optimized layout, maximizing every cubic meter of available space by designing specific rack modules that fit around columns or under low-hanging services, ensuring no potential storage volume is wasted.

Utility and Power Volatility: In regions with less stable electrical grids, the design of a narrow aisle shelving system must consider operational continuity. This can influence the placement of high-density storage zones relative to natural light sources or the specification of manual backup systems for critical retrieval processes, ensuring graceful degradation rather than total shutdown during outages.

2. Environmental Adversaries: Engineering for Resilience

The local environment actively tests the mettle of storage equipment. A narrow aisle shelving system must be clad in a form of armor specific to its climatic battlefield.

Corrosion Warfare in Tropical Climates: For coastal operations in Vietnam, the Philippines, or Brazil, a standard paint finish is a prelude to rapid failure. A responsible supplier implements a multi-layered corrosion defense protocol for the narrow aisle shelving system. This begins with the selection of hot-dip galvanized structural components for critical upright frames. The coating process itself involves multi-stage phosphating, epoxy-priming, and finishing with advanced polyurethane or polyester powders applied at specified thicknesses (e.g., 80-120 microns) to withstand constant high humidity and salt-air exposure.

The Assault of Dust and Sand: In the arid logistics corridors of the Middle East and Central Asia, fine particulate matter is an insidious enemy. It accelerates wear on moving parts, clogs sensors for guided systems, and contaminates goods. A well-engineered narrow aisle shelving system for these regions incorporates features like sealed bearing wheels for carts, protective canopies for top-level storage, and easy-clean designs for guide rails and beams to mitigate dust accumulation and its damaging effects.

Thermal Dynamics: In markets with significant diurnal or seasonal temperature swings, the steel in a narrow aisle shelving system expands and contracts. Custom engineering accounts for this thermal movement in the structural calculations, ensuring that critical clearances in very narrow aisle (VNA) systems remain within safe and functional limits year-round, preventing operational issues like mast binding in high-level trucks.

3. Human-Centric Design: Safety, Skill, and Productivity

Technology must serve the people who use it. The most robust narrow aisle shelving system is ineffective if operators cannot use it safely and efficiently.

Bridging the Skills Gap: Designing for operational intuitiveness is paramount. This includes clear, durable aisle markings, color-coded picking levels, and ergonomically considered load placement to reduce strain and error. This design philosophy is then cemented by comprehensive, on-site training programs delivered in the local language, focusing on the safe and efficient operation of the specific MHE within the custom-configured narrow aisle shelving system.

Designing for Maintenance Accessibility: A system that cannot be easily maintained will fail. Custom designs prioritize serviceability. This means ensuring that critical wear components, guide rail attachment points, and structural connectors are accessible for inspection and replacement. Partnering with a supplier who establishes a local spare parts inventory and trains in-country technicians creates a sustainable ecosystem that guarantees the long-term health of the narrow aisle shelving system.

The Anatomy of Customization: A Step-by-Step Engineering Methodology

The journey to an optimized warehouse is a structured, data-driven process. For a leading supplier, customization is a disciplined methodology, not an abstract promise.

Phase 1: Immersive Discovery and Digital Twin Creation

The process commences with a detailed site audit, increasingly leveraging advanced 3D laser scanning technology. This tool captures a millimeter-accurate “digital twin” of the existing warehouse, documenting every structural element, utility line, and floor imperfection. This rich dataset forms the uncontestable foundation for all subsequent design work, eliminating assumptions and ensuring the proposed narrow aisle shelving system fits the real-world space with precision.

Phase 2: Dynamic SKU and Throughput Analysis

Effective design hinges on understanding what is being stored and how it moves. Analysts profile not only current pallet types (wooden, plastic, regional standard sizes) but also forecast future SKU mixes and their velocity. This analysis directly dictates the configuration of the narrow aisle shelving system. Fast-moving items are positioned in the “golden zone” for optimal pick times, while slower-moving inventory is allocated to higher or lower storage levels. The system’s layout is a direct physical manifestation of the client’s unique supply chain rhythm.

Phase 3: Structural Calibration for Safety and Compliance

Using sophisticated finite element analysis (FEA) software, engineers simulate every conceivable load scenario—uniformly distributed loads, point loads, and seismic forces. For facilities in seismically active zones like parts of Indonesia, Chile, or the Philippines, the narrow aisle shelving system is specifically designed to meet local seismic codes (e.g., IBC, NZS 1170.5), incorporating bracing systems and connection details that absorb and dissipate energy. This phase results in certified load notices and engineering stamps, providing documented assurance of safety and regulatory compliance.

Phase 4: Designing for the Automated Future

A forward-looking narrow aisle shelving system is conceived as the foundational grid for automation. This is critical for future-proofing the investment.

AGV/AMR Integration: When automation is planned, the narrow aisle shelving system is engineered as the “roadway” and “landing pad” for robots. Aisle widths are calculated to the millimeter based on the AGV’s turning radius and safety sensor fields. The system design includes reinforced uprights at aisle ends, consistently positioned target pallet locations, and interface points that are compatible with automated lift mechanisms.

Semi-Automated Picker Synergy: For systems using man-up order pickers, the vertical profile of the narrow aisle shelving system is optimized to match the machine’s lift speed and height, placing high-activity SKUs within the most productive reach zones. The integration of high-precision guide rails ensures smooth, stable travel for the operator at elevation, directly enhancing both safety and pick rates.

The Integrity of Build: Material Science and Precision Manufacturing

The durability and performance of a narrow aisle shelving system are determined long before installation, in the mill and the factory. Customization extends to the very composition and fabrication of the components.

Strategic Material Selection and Forming

High-tensile, low-carbon steel is the material of choice, sourced to precise metallurgical specifications. This steel is then roll-formed on computer-numeric-controlled (CNC) lines into consistent profiles. For the upright frames that bear the critical column loads, a closed-section design (such as a tubular or hat-shaped profile) is often employed. This design offers superior torsional stiffness and resistance to impact forces compared to open-channel sections, a vital safety feature in high-traffic, high-bay narrow aisle shelving systems. The consistency of the formed shape is paramount for the reliable function of safety-lock beam connections.

Advanced Fabrication and Protective Finishing

Key structural joints, particularly where uprights meet baseplates and in integral beam connectors, are welded using automated MIG/MAG processes. This ensures deep, consistent penetration and repeatable strength across thousands of components. Post-fabrication, the parts undergo a surface preparation and coating process tailored to the environmental analysis. This may involve shot blasting, a multi-stage phosphating pre-treatment, and the application of advanced epoxy or polyester powders in controlled, oven-cured layers to achieve the specified corrosion resistance. Each component is then tagged with a unique identifier, linking it to its quality documentation.

A Rigorous Quality Assurance Regimen

Every production batch is subjected to a stringent validation protocol: 1) Verification of material mill certificates, 2) Dimensional accuracy checks, 3) Weld integrity inspection (visual and non-destructive spot testing), 4) Coating thickness measurement, 5) Adhesion testing, 6) Beam load-deflection verification, 7) Connector engagement force testing, 8) Final assembly and load certification, 9) Finish quality audit, 10) Export-grade packaging inspection. This meticulous process guarantees that the narrow aisle shelving system delivered to the dock is identical in quality and performance to the one engineered in the digital model.

Execution Excellence: Project Management Grounded in Local Partnership

The transition from digital design to physical operation is the crucible where projects succeed or fail. For a narrow aisle shelving system supplier serving global markets, excellence in project management is inextricably linked to local empowerment.

The Strategic Value of Local Integration Partners

A true partner operates through an ecosystem of vetted and certified local integrators. These firms are far more than installers; they are the supplier’s permanent hands, eyes, and ears in the market. They possess deep understanding of local business practices, permit acquisition, and labor regulations. They maintain strategic inventories of critical spare parts and provide the first line of rapid, in-territory technical support. This model ensures clients receive responsive, culturally attuned, and linguistically accessible service, turning a one-time purchase into an enduring support relationship for the narrow aisle shelving system.

Phased Implementation with Business Continuity

Acknowledging that most warehouses cannot afford complete shutdowns, installation is meticulously phased. Work often begins in a new extension or a designated section, allowing for pilot operations and staff training to proceed in parallel with ongoing warehouse activities in other areas. Experienced site supervisors coordinate closely with client management to sequence work, manage safety perimeters, and minimize daily disruption, ensuring a smooth, low-risk rollout of the new narrow aisle shelving system.

Commissioning, Knowledge Transfer, and Asset Handover

Physical completion is followed by systematic commissioning: load testing to verify performance, alignment checks for guided systems, and full functional testing. Concurrently, structured training programs are delivered for all user levels—from forklift operators to warehouse managers. The project culminates in a formal handover, delivering a comprehensive dossier including as-built drawings, certified load notices, maintenance manuals, warranty certificates, and training records. This transforms the installed narrow aisle shelving system into a fully documented, company-owned asset.

The Automation Trajectory: From Static Storage to Intelligent Hub

For businesses aiming to achieve a definitive competitive edge, a narrow aisle shelving system is the essential physical infrastructure upon which intelligent warehousing is built. It provides the order and density that make automation both feasible and financially compelling.

Engineering the Infrastructure for AGVs

When the roadmap includes AGVs, the narrow aisle shelving system is designed as their critical operating environment. This involves:

Precision Aisle Architecture: Determining aisle width based on the AGV’s kinematic model, including its safety scanner ranges and mast dimensions, to ensure flawless navigation and operation.

Floor-System Interface: Specifying and verifying the required floor flatness tolerance to guarantee navigation accuracy and mast stability for the AGVs operating within the narrow aisle shelving system.

Rack-Robot Interface: Designing pick faces with consistent, predictable geometries and incorporating subtle fiducial markers or reinforced target zones that assist the AGV’s vision systems in achieving precise fork placement.

Interfacing with Broader Automated Ecosystems

A high-density narrow aisle shelving system frequently acts as the dynamic buffer or high-speed picking module within a larger automated storage and retrieval system (AS/RS). Custom engineering ensures seamless interfaces with conveyor transfer cars, automated palletizers, and sortation systems. The steelwork and the automation controls are designed in concert, ensuring mechanical and digital harmony from the outset and avoiding the costly inefficiencies of retrofitted integration.

The True Metric of Investment: Total Cost of Ownership Analysis

In procurement decisions for capital equipment like a narrow aisle shelving system, the lowest initial price tag is a notoriously poor indicator of long-term value. A sophisticated evaluation employs a Total Cost of Ownership (TCO) model, which accounts for:

Capital Expenditure (Capex): The initial design, manufacturing, and installation cost of the custom narrow aisle shelving system.

Operational Expenditure (Opex): The ongoing costs. A superior custom narrow aisle shelving system actively reduces opex by: dramatically increasing storage density (lowering cost per pallet position), accelerating order cycles (reducing labor cost per pick), minimizing product damage through stable, secure storage, and optimizing energy use through efficient material flow.

Risk Mitigation Cost: The cost of business interruption from failure. The robust engineering, quality manufacturing, and local technical support inherent in a premium narrow aisle shelving system directly minimize this often-catastrophic cost.

Lifecycle and Residual Value: A properly designed and fabricated narrow aisle shelving system has a functional lifespan measured in decades, often outlasting the MHE that serves it. Its durable construction ensures high residual value and adaptability for future reuse.

When analyzed through the TCO lens, the investment in a custom-engineered narrow aisle shelving system from an expert supplier consistently demonstrates a superior return on investment, frequently paying for itself within the first few years of operation through relentless efficiency gains.

Conclusion: Forging a Resilient and Scalable Logistics Foundation

Across the thriving yet demanding commercial landscapes of the world’s growth economies, the warehouse has evolved from a passive storage space into the active, pulsating heart of the supply chain. The decision to implement a narrow aisle shelving system is, therefore, a strategic choice that will define operational agility, cost structure, and growth capacity for the long term.

The evidence is unequivocal: the path to success is paved with customization. It requires partnering with a narrow aisle shelving system supplier who possesses the engineering depth to translate local complexities into robust designs, the manufacturing integrity to build for durability, and the project execution ethos to deliver a flawless operational asset. It demands a collaborator who views the narrow aisle shelving system not as an end product, but as the foundational layer of a scalable, automated, and intelligent logistics ecosystem.

For leaders who envision a warehouse that is not merely a cost center but a source of competitive advantage, the mandate is clear. Move beyond standardized offerings. Engage with partners who demonstrate proven expertise in tailoring narrow aisle shelving systems to the unique fabric of your market and operation. Initiate a consultative dialogue grounded in your specific challenges and ambitions, and embark on the journey to construct the high-density, high-efficiency, and future-ready storage infrastructure that will power your enterprise for the next generation.

Frequently Asked Questions (FAQs)

1. Our facility handles a wide mix of palletized goods and smaller carton picking. Can a narrow aisle shelving system efficiently accommodate both?

Yes, a versatile narrow aisle shelving system can be expertly configured for mixed SKU profiles. The design typically incorporates a combination of standard selective pallet racking for full-pallet loads and integrated carton-flow lanes or shelving modules on the lower levels for smaller item picking. This “pick module” design within the narrow aisle shelving system allows order pickers to efficiently consolidate both pallet and piece-pick items in a single pass, dramatically improving order assembly productivity and accuracy.

2. What are the key differences between a standard narrow aisle system and a very narrow aisle (VNA) system, and how do we choose?

The primary distinction lies in aisle width and the required MHE. A standard narrow aisle shelving system typically requires aisles of approximately 1.5 to 2 meters and is served by guided reach trucks. A Very Narrow Aisle (VNA) system reduces aisles to 1.2 to 1.5 meters and requires specialized turret trucks or swing-mast trucks that operate within fixed guide rails. The choice hinges on a cost-benefit analysis: VNA narrow aisle shelving systems offer roughly 20-30% higher storage density but involve higher equipment costs and more stringent floor flatness requirements. The decision should be based on your specific space constraints, SKU profile, and budget.

3. How does the fire protection strategy (e.g., sprinklers) integrate with a high-bay narrow aisle shelving system?

This is a critical safety and compliance consideration. A custom narrow aisle shelving system design must be fully coordinated with the warehouse’s fire protection engineering. For systems exceeding 12 meters in height, in-rack sprinkler heads are often mandated by local codes. The rack layout must include vertical and horizontal sprinkler piping runs, with heads positioned at specific intervals within the rack structure to ensure water can penetrate dense storage. The design of the narrow aisle shelving system incorporates dedicated space for this infrastructure without compromising storage positions or load capacity.

4. We are concerned about damage from forklift impacts. How is a custom system designed to be more resilient?

Impact resistance is a key focus of custom engineering. A robust narrow aisle shelving system employs several protective strategies: 1) Specifying heavier-gauge steel for lower upright frames, 2) Installing substantial, bolt-on column guards or post protectors at aisle ends and corners, 3) Using closed-section upright designs that offer better torsional strength, and 4) Ensuring all critical beam connectors are positive-locking and designed to withstand minor shocks. Furthermore, proper operator training, facilitated by the supplier, is the most effective preventative measure.

5. Can the layout of a narrow aisle shelving system be reconfigured if our business needs change in a few years?

A hallmark of a well-designed selective pallet racking-based narrow aisle shelving system is its inherent flexibility. The beams are typically mounted on adjustable clips or locks, allowing you to easily change shelf heights to accommodate different product sizes. While the overall footprint and guide rail positions are fixed, the internal configuration of storage levels within the narrow aisle shelving system can be modified with relative ease. For major layout changes, a consultation with the original supplier is recommended to ensure structural integrity is maintained.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com