📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Definitive Guide to Engineering and Operating a High-Performance Narrow Aisle Racking System for Heavy Loads

For distribution centers, manufacturing plants, and third-party logistics (3PL) providers operating in space-constrained, high-growth regions, the strategic implementation of a narrow aisle racking for heavy loads system represents a transformative investment. This comprehensive guide delves beyond superficial specifications to explore the intricate engineering principles, operational synergies, and total cost of ownership calculations that define a successful high-density storage project.

Mastering the deployment of narrow aisle racking for heavy loads is not merely about purchasing racks and forklifts; it is about architecting a cohesive, resilient, and scalable storage ecosystem. This resource provides facility managers, operations directors, and logistics planners with the critical knowledge required to navigate the complexities of such a system—from foundational concrete slab specifications and seismic considerations for regions like Southeast Asia and Latin America, to the nuanced integration of guided very narrow aisle (VNA) trucks and automated guided vehicles (AGVs).

By prioritizing structural integrity, workflow optimization, and proactive safety protocols, businesses can unlock unprecedented storage density and throughput efficiency. The ultimate goal is to transform capital expenditure into a rapid, measurable return on investment (ROI) through space savings, labor productivity gains, and enhanced inventory control.

The Imperative for Density: Solving Spatial and Economic Constraints in Emerging Markets

The logistical landscapes of industrial hubs in the Middle East, Southeast Asia, and Africa share a common pressure point: the escalating cost and scarcity of available land. Expanding a warehouse footprint is often prohibitively expensive or geographically impossible. Concurrently, supply chain demands necessitate holding broader and deeper inventory stocks. The traditional wide-aisle warehouse, reliant on counterbalance forklifts, becomes an unsustainable model of inefficiency, wasting valuable cubic space on transit aisles. This is precisely where the paradigm shift to narrow aisle racking for heavy loads becomes a strategic imperative, not just a storage option.

A properly engineered narrow aisle racking for heavy loads system directly addresses this spatial arithmetic. By reducing aisle widths from the standard 3.5-4 meters down to 1.6-2.2 meters, facilities can achieve a dramatic increase in storage capacity—often by 40% to 50% within the same building envelope. However, the crucial insight for decision-makers is that this density must be engineered for performance, not just occupancy. Every decision, from the steel grade in the upright frames to the training protocol for operators, must support the overarching goal of storing more without sacrificing speed, safety, or accessibility. The journey to implementing a world-class narrow aisle racking for heavy loads system begins with a holistic understanding of its interconnected components.

Structural Engineering Excellence: The Non-Negotiable Foundation for Safety and Stability

The paramount consideration for any narrow aisle racking for heavy loads installation is unwavering structural integrity. When palletized loads exceeding 1,000 kg are stored at heights of 10, 12, or even 15 meters, the racking transitions from a storage medium to a critical piece of industrial infrastructure. Its design must account for static loads, dynamic forces from forklift operations, and potential seismic activity.

Upright Frame Design: Combatting Torsion and Sway in Confined Spaces

The upright frame is the spinal column of the system. For narrow aisle racking for heavy loads, engineers specify high-yield, cold-rolled steel (typically S350GD+Z) formed into closed or reinforced open profiles. The profile geometry is optimized to resist the unique stress vectors present in a tall, narrow configuration: primarily down-aisle bending and, more critically, cross-aisle torsion induced by forklift mast movement during side-loading. Bracing patterns are intensified, utilizing a matrix of horizontal and diagonal braces that create a rigid triangulated structure, minimizing any potential for rack “walking” or sway over time.

The Beam-to-Upright Connection: Precision Engineering for Unyielding Load Transfer

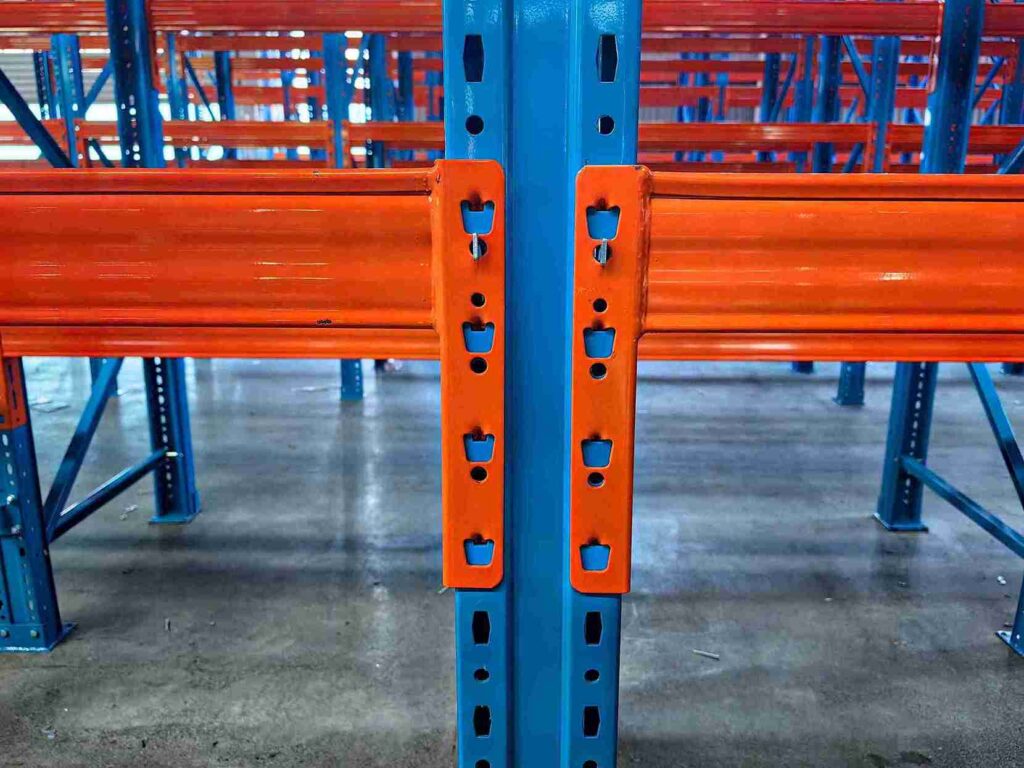

The connection point between the horizontal load beam and the upright is the most critical interface in any narrow aisle racking for heavy loads system. It must perform flawlessly under repeated cyclic loading. Industry-leading systems employ a positive, mechanical locking mechanism. The twin-tube safety lock, featuring two independent locking devices (a primary gravity lock and a secondary spring-loaded safety latch), is considered best practice. This design ensures that an accidental impact from a forklift cannot dislodge a beam. Furthermore, the beam’s torsional rigidity is paramount; box-beam or deep truss designs prevent deflection under full capacity, ensuring pallets remain secure and level, which is especially vital for automated retrieval systems.

Base Plates and Anchor Bolts: Creating an Immovable Foundation

The entire load path terminates at the concrete floor. Therefore, the anchorage system for narrow aisle racking for heavy loads is designed for maximum pull-out and shear resistance. Large, welded base plates distribute the concentrated load, while high-tensile anchor bolts (e.g., M20, property class 8.8) are specified based on rigorous calculations considering rack load, potential seismic forces per local building codes, and the compressive strength of the concrete slab (a minimum of 30 MPa is typically recommended). Professional installation teams use calibrated torque wrenches to ensure each anchor bolt provides the specified clamping force, transforming the freestanding structure into a permanent, integrated part of the building’s stability.

The Symbiotic Relationship: Selecting Material Handling Equipment for Your Narrow Aisle Racking for Heavy Loads

The aisle width in a narrow aisle racking for heavy loads system is a direct function of the material handling equipment’s turning radius and mast dimensions. Selecting the right equipment is therefore a co-engineering exercise with the rack design.

Very Narrow Aisle (VNA) Turret Trucks: The Pinnacle of Density and Speed

For facilities with high-volume, unit-load handling (full pallet in/out), the turret truck is the optimal partner for a narrow aisle racking for heavy loads system. Operating in aisles as tight as 1.6 meters, these trucks do not turn within the aisle. Instead, a rotating fork carriage (the turret) allows them to store or retrieve pallets from either side. This requires an exceptionally flat floor (FF50/FL40 specification or better) and often a guidance system—either wire-guided or rail-guided—to maintain perfect mast alignment and prevent contact with the racking. The investment is significant, but the payoff in terms of storage density and operator productivity is unmatched.

Man-Up Order Pickers and Reach Trucks: Flexibility for Selective Access

When operations require broken-case picking or frequent access to individual pallets within a selective racking bay, a man-up order picker or a specialized narrow aisle reach truck is the ideal solution. These machines allow the operator to elevate with the load or the picking platform. They typically operate in slightly wider aisles (1.8-2.2m) than turret trucks but offer superior flexibility for multi-SKU environments. Integrating these with a narrow aisle racking for heavy loads system requires careful planning of pick paths and potential traffic management with other equipment.

The Automated Frontier: AGVs and Robotic Forklifts in the Narrow Aisle

The ultimate evolution in operating a narrow aisle racking for heavy loads system is the removal of the human operator from the vehicle. Automated Guided Vehicles (AGVs) or robotic forklifts can operate 24/7, following pre-programmed or dynamically optimized routes. Integrating automation with narrow aisle racking for heavy loads demands another level of precision:

Dimensional Tolerance: The racking installation must have near-perfect alignment to serve as a navigation landmark for the AGV’s sensors (LiDAR, cameras).

Load and Pallet Standardization: Consistency is key. Pallets must be within strict dimensional and weight tolerances, and loads must be stable.

System Integration: The Warehouse Management System (WMS) must communicate seamlessly with the AGV’s Fleet Management System (FMS), orchestrating a synchronized dance of storage and retrieval tasks. For businesses targeting uninterrupted multi-shift operations in competitive markets, automating the narrow aisle racking for heavy loads environment is a decisive step towards logistical superiority.

The Critical, Often Underestimated Component: Warehouse Floor Specification and Preparation

Perhaps the most common and costly oversight in planning a narrow aisle racking for heavy loads project is underestimating the importance of the warehouse floor. The floor is the first point of contact and the reference plane for the entire system. A VNA turret truck or AGV operating in a 1.6-meter aisle has zero tolerance for slopes, dips, or bumps.

Floor Flatness (FF) and Levelness (FL): These are scientifically measured indices. A standard industrial floor might be FF20/FL15. A floor suitable for a high-performance narrow aisle racking for heavy loads system with VNA equipment typically requires FF50/FL40 or superior. Achieving this demands laser-guided screeding and power floating during construction or a comprehensive diamond grinding retrofit for existing slabs.

Consequences of Non-Compliance: Operating sensitive equipment on an inadequate floor leads to chronic problems: excessive vibration, premature wear on wheels and guidance components, operator fatigue, inaccurate positioning leading to rack impacts, and most dangerously, mast oscillation that can compromise load stability at height. The floor is not a place to cut corners; it is the foundational investment that protects all other capital expenditures in the narrow aisle racking for heavy loads ecosystem.

A Culture of Safety: Engineering and Operational Protocols for a Secure Environment

Safety in a narrow aisle racking for heavy loads warehouse is not merely about compliance; it is a system-wide philosophy engineered into every component and procedure. The confined spaces and significant heights create unique hazards that must be proactively managed.

Physical Protection Systems: Every aisle entrance in a narrow aisle racking for heavy loads system should be guarded by substantial impact barriers—steel column guards, reinforced concrete bollards, or crash gates. Continuous upright protectors (heavy-gauge steel channels) should line the lower sections of the aisle to absorb incidental impacts. Pallet stops on every beam level are mandatory to prevent pallets from being pushed through the rack face.

Forklift Guidance and Control Systems: To maintain perfect alignment in the tight confines of a narrow aisle racking for heavy loads system, guidance is essential. Rail guidance offers the most positive physical control, while wire guidance provides a reliable electronic path. These systems prevent the truck from drifting into the rack structure.

Comprehensive Training and Certification: Operators of narrow aisle equipment require specialized training beyond a standard forklift license. This training must cover the unique handling characteristics of the truck, load stability at height, specific procedures for the narrow aisle racking for heavy loads environment, and emergency protocols.

Regular Racking Inspections: A formal, documented rack inspection program is critical. Daily visual checks by warehouse staff should be supplemented by quarterly or semi-annual professional inspections conducted by a qualified engineer. These inspections look for impact damage, alignment issues, loose connectors, and any signs of overloading or deflection.

The Implementation Blueprint: A Phased Approach to Success

Deploying a robust narrow aisle racking for heavy loads system is a complex project that benefits from a disciplined, phased methodology.

Phase 1: Data Analysis, Simulation, and Master Planning

Success begins with data. A deep analysis of SKU profiles (dimensions, weight, turnover velocity using ABC analysis), historical and forecasted throughput, pallet types, and growth projections forms the basis of the design. Advanced warehouse simulation software is then used to create a digital twin of the proposed narrow aisle racking for heavy loads system. This allows planners to stress-test different layouts, equipment types, and picking strategies in a virtual environment, optimizing for both storage capacity and peak throughput before any physical investment is made.

Phase 2: Custom Engineering and Load Documentation

Following simulation, the system is fully engineered. This phase produces the crucial Load Application and Rack Configuration (LARC) drawings. These are not simple layouts; they are legally and operationally binding documents that specify the exact capacity of every beam position, the overall load configuration, and compliance with international standards like FEM 10.2.02 or RMI. For a narrow aisle racking for heavy loads system, these documents are the definitive guide for safe operation and future modifications.

Phase 3: Precision Installation and Systematic Commissioning

Installation of a narrow aisle racking for heavy loads system requires specialized teams using laser levels and optical alignment tools. Every component is assembled to exacting tolerances. Post-installation, a full commissioning process is undertaken, including a final plumb and alignment survey, torque verification on all critical connections, and a functional test with the intended material handling equipment.

Phase 4: Lifecycle Management: Audits, Maintenance, and Adaptation

A narrow aisle racking for heavy loads system is a dynamic asset. Implementing a lifecycle management program ensures its longevity and safety. This includes scheduled professional engineering audits, routine preventive maintenance for both racking and equipment, and a clear process for managing any system modifications or expansions. This proactive approach safeguards the investment and maintains optimal performance for decades.

The Financial Justification: A Detailed Total Cost of Ownership (TCO) Analysis

Justifying the capital outlay for a high-end narrow aisle racking for heavy loads system requires a comprehensive TCO model that captures both direct costs and strategic savings.

Capital Expenditure (CapEx): This includes the narrow aisle racking for heavy loads structure itself, specialized forklifts (VNA trucks, order pickers), floor preparation/upgrading, guidance systems, and any WMS/software integration costs.

Operational Expenditure Savings (OpEx) & Value Creation:

Real Estate Efficiency: Storing the same inventory in 40-50% less space defers or eliminates the need for costly facility expansion, a major factor in high-rent districts.

Labor Productivity: Reduced travel distances, faster cycle times, and the potential for operator-to-equipment ratios to improve can lead to a 25-40% increase in pallet moves per operator hour.

Energy and Overhead: A smaller, denser footprint reduces lighting, heating, and cooling costs.

Inventory Accuracy and Control: A well-organized, system-directed narrow aisle racking for heavy loads environment reduces mis-ships, lost inventory, and stock discrepancies.

ROI Scenario: Consider a beverage distributor in Vietnam facing a 30% annual sales growth. By implementing a narrow aisle racking for heavy loads system with guided reach trucks, they accommodated 5 years of projected growth within their existing building, avoided a $2M expansion, reduced their forklift fleet by 4 units, and increased order fulfillment speed by 30%. The project achieved payback in under 3 years through hard cost savings alone.

Future-Proofing the Investment: Designing for Flexibility and Scalability

A world-class narrow aisle racking for heavy loads system is designed not just for today’s needs, but for tomorrow’s challenges. Key future-proofing strategies include:

Modular Design Philosophy: Specifying racking components from a system that allows for easy reconfiguration of beam levels and upright frames to accommodate changing pallet sizes or product profiles.

Vertical Expansion Capability: Ensuring the original upright frames are rated for additional height and that the building structure can support future mezzanines or higher rack elevations.

Automation-Ready Infrastructure: Designing aisles with the clearances and tolerances necessary for future AGV integration, and considering the placement of conduit for data and power to support emerging technologies like drone-based inventory scanning or IoT load sensors.

Conclusion

The decision to implement a narrow aisle racking for heavy loads system is a strategic commitment to operational excellence and financial prudence. It is a sophisticated engineering undertaking that synthesizes advanced metallurgy, precision logistics planning, and human-factor management into a single, high-performance asset. For businesses across the dynamic markets of the Middle East, Africa, Southeast Asia, and Latin America, mastering this technology is key to overcoming spatial constraints, escalating real estate costs, and intensifying service-level demands.

The journey to a successful narrow aisle racking for heavy loads installation is paved with detailed planning, rigorous engineering standards, and a partnership-focused approach. By moving beyond a simplistic product purchase to embrace a holistic systems philosophy—where the floor, the rack, the forklift, the software, and the people are all seamlessly integrated—organizations can build a logistics infrastructure that is not only dense but also dynamic, safe, and supremely efficient. This is the definitive path to transforming the warehouse from a cost center into a powerful, data-driven, and resilient competitive advantage.

Frequently Asked Questions (FAQs)

1. How does humidity and coastal air in tropical regions (e.g., Philippines, Indonesia, Gulf states) affect the longevity of a narrow aisle racking for heavy loads system, and what special coatings or materials are recommended?

In high-humidity and saline environments, corrosion is a primary concern. For a narrow aisle racking for heavy loads system in such conditions, specifying hot-dip galvanized steel components is strongly advised over standard powder coating. The galvanization process creates a metallurgical bond that provides superior sacrificial protection against rust, even if the coating is scratched. For extreme environments, additional coatings like a zinc-rich primer with a polyurethane topcoat can be applied over the galvanization. Regular inspections should focus on weld points and connection areas for any early signs of corrosion.

2. For a facility with a mix of very heavy loads (e.g., 2,000 kg metal coils) and standard palletized goods, can a single narrow aisle racking for heavy loads system accommodate both, or are separate zones required?

A single narrow aisle racking for heavy loads system can be engineered to handle the mix, but it will be zoned and configured differently. The racking for the heavy coil storage area would require a distinct structural specification: likely closer upright spacing (narrower bay widths), heavier-duty beam profiles (e.g., 150mm x 50mm box beams), and potentially integrated coil cradles or specialized arms instead of standard wire decking. The WMS would be configured to direct the ultra-heavy loads only to these specifically rated locations. This approach is common in manufacturing and steel service centers utilizing narrow aisle racking for heavy loads for mixed inventory.

3. What are the fire protection and sprinkler system considerations for a high-bay narrow aisle racking for heavy loads installation that exceeds 12 meters in height?

Standard ceiling-mounted sprinklers are ineffective for tall, dense storage. A narrow aisle racking for heavy loads system in a high-bay facility typically requires an in-rack sprinkler system. These are dedicated sprinkler lines and heads installed within the rack structure itself, typically at every 3-4 vertical meters. They are designed to create a water curtain that penetrates the dense storage array to control a fire at its source. The design must comply with NFPA 13 or equivalent local standards and requires careful coordination between the rack designer, sprinkler contractor, and local fire authority. This is a critical safety and insurance requirement.

4. In regions with intermittent or unstable power supply, what backup or operational contingency plans are feasible for an automated narrow aisle racking for heavy loads system reliant on AGVs?

Contingency planning is essential. Solutions include: 1) Uninterruptible Power Supply (UPS) Systems for the AGV charging stations and central control server to allow for a graceful shutdown and data preservation during short outages. 2) On-site generator capacity sized to support the critical automation and WMS infrastructure for longer outages. 3) System Design for Manual Override: The narrow aisle racking for heavy loads layout should allow for temporary, safe access by a manual forklift (e.g., a standard reach truck) in a critical aisle during an extended AGV downtime. This requires designing aisles to be slightly wider in key areas or having a “breakaway” section of guidance rail.

5. How does the cost and lead time for a custom-engineered narrow aisle racking for heavy loads system compare to a standard wide-aisle solution, and what are the key drivers?

Initially, the CapEx for a narrow aisle racking for heavy loads system is 20-40% higher than a basic selective racking system. This accounts for the heavier-gauge steel, more complex components (like safety locks), and the engineering design work. Lead times are also longer, typically 10-16 weeks for manufacturing and delivery, compared to 6-8 weeks for standard racking. The key cost drivers are steel volume per pallet position, the complexity of the seismic design (if required), and the level of customization for special load types.

However, the financial analysis must focus on TCO. The significantly higher storage density (more pallet positions per square meter) often means the cost per pallet position is competitive or even lower, while the operational savings on real estate and labor deliver the compelling ROI that justifies the upfront investment and wait.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com