📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Decoding the True Investment Behind Warehouse Efficiency

In the dynamic hubs of Bangkok, Dubai, Mexico City, and Lagos, logistics executives face a universal challenge: maximizing storage throughput while minimizing operational expenditure. The search for “narrow aisle racking cost” is often the first step toward a transformative solution, yet it unveils a complex equation far beyond a simple price per pallet position. The genuine narrow aisle racking cost encompasses a strategic calculus balancing capital outlay against long-term gains in density, speed, and control.

For operations spanning diverse sectors from booming e-commerce fulfillment to heavy industrial manufacturing, understanding this total investment is paramount. A meticulously planned narrow aisle system does not merely store goods; it re-engineers material flow, turning square footage into a potent competitive advantage. This guide dismantles the components of narrow aisle racking cost, providing a blueprint for supply chain leaders to make informed, high-return decisions that resonate across emerging markets.

The Multifaceted Anatomy of Narrow Aisle Racking Cost

Deconstructing the Quote: From Unit Price to Integrated System Value

A quotation for narrow aisle racking often presents a line-item total, but the intelligent buyer scrutinizes what each component represents. The foundational narrow aisle racking cost is governed by material volume, profile strength, and finish quality. However, the system’s true price tag emerges from its integration capabilities and operational design. A selective racking configuration designed for 10-meter heights with 1.8-meter aisles will command a different narrow aisle racking cost profile than a system built for 15-meter automated storage and retrieval (AS/RS) compatibility.

The former focuses on optimized manual or semi-automated access, while the latter embeds precision tolerances and guidance interfaces for robotic pallet handlers. Suppliers with deep automation experience, offering integrated solutions from AGV小车 to automated conveyor systems, structure their narrow aisle racking cost to reflect this engineered synergy, ensuring the storage structure is not a passive asset but an active participant in the automation ecosystem.

The Steel Core: How Material Specifications Dictate Durability and Price

The backbone of any racking system is its steel. The narrow aisle racking cost is directly influenced by the metallurgical grade, profile design, and protective coatings employed. Commercial-grade steel with a yield strength of 235 MPa may offer a lower initial ticket, but for the dynamic loads and occasional impacts of narrow aisle operations, structural-grade steel (S355JR or equivalent) is the prudent minimum. High-caliber suppliers often utilize S500MC or similar high-tensile steel for upright frames in systems exceeding 12 meters, significantly reducing column cross-section for better visibility while increasing load capacity—a critical factor in the overall narrow aisle racking cost calculation for high-bay warehouses.

The manufacturing process further refines this cost. Roll-formed columns with customized cross-sections (like a “dog-bone” or “omega” shape) offer superior strength-to-weight ratios compared to standard C-channel profiles. Beams undergo a similar scrutiny; step-beam designs with integrated locking mechanisms provide vastly safer and more robust connections than straight beams with bolt-on clips.

The finish—typically a robust electrostatic epoxy powder coating applied at 70-80 microns—is a non-negotiable line item in the narrow aisle racking cost. In the humid climates of Southeast Asia or the corrosive coastal air of the Middle East, this coating is the primary defense against rust, ensuring a 20+ year lifespan. Opting for a cheaper, thinner paint finish is a direct compromise on the system’s longevity, effectively increasing its long-term narrow aisle racking cost through premature replacement or repair.

Engineering for Precision: The Cost of Safety and Compliance

Safety is not an add-on; it is engineered into the system from the first CAD drawing. Reputable providers factor comprehensive safety features into the narrow aisle racking cost. This includes structural safety factors exceeding 1.5 per FEM 10.2.02 standards, detailed Load Application and Rack Design (LARD) drawings, and integrated physical protections. Key components that influence narrow aisle racking cost for safety include:

Column Guards & Post Protectors: Heavy-duty steel guards anchored to the floor prevent catastrophic damage from forklift impact, a common risk in tight aisles.

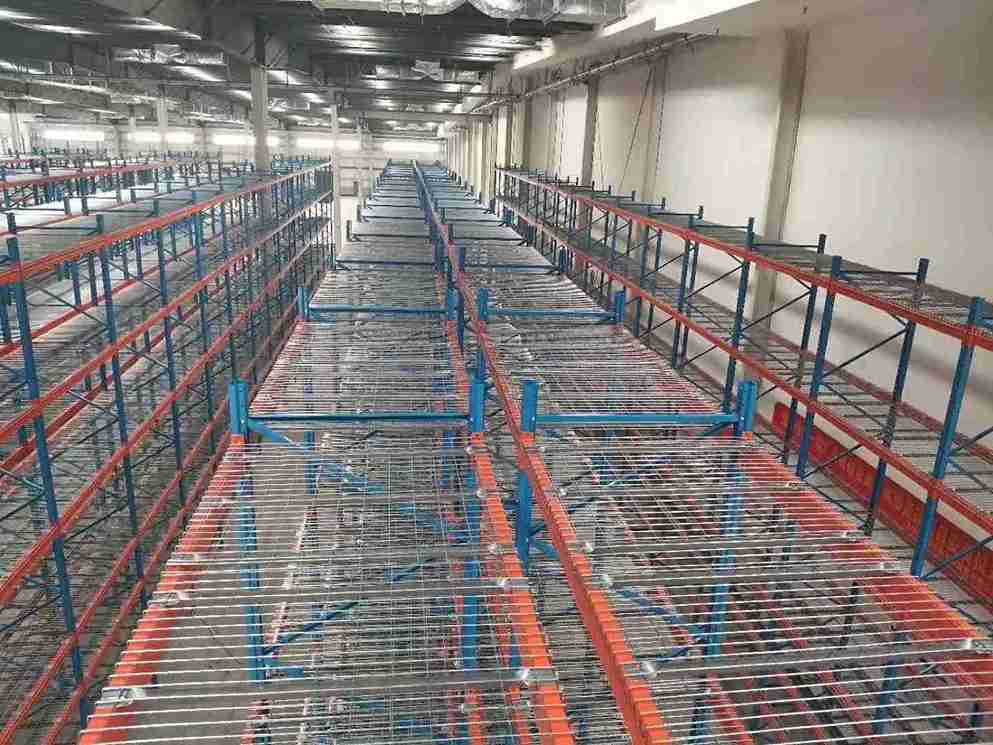

Pallet Supports & Wire Mesh Decking: These prevent pallets or products from dislodging, a critical feature in food & beverage or pharmaceutical warehousing where product integrity is paramount.

Seismic Bracing Kits: For regions in Latin America or Southeast Asia with seismic activity, specialized cross-bracing and base plates are essential, adding a specific, non-optional component to the regional narrow aisle racking cost.

Professional Installation & Certification: The final, crucial element of the safety narrow aisle racking cost is certified installation. A crew trained by the manufacturer ensures every anchor bolt is torqued to specification and every frame is plumb, delivering a system that performs as engineered.

Operational Economics: Calculating the ROI of a Narrow Aisle Conversion

The Space Multiplication Effect: Quantifying Density Gains

The primary driver for evaluating narrow aisle racking cost is the dramatic increase in storage density. By reducing aisle width from a traditional 3.5 meters to 1.6-1.8 meters, facilities can often increase pallet positions by 40-50% within the same footprint. The financial translation of this is profound. Instead of leasing or constructing additional warehouse space—a capital-intensive and time-consuming process—the business effectively “creates” new space internally.

The narrow aisle racking cost must therefore be compared against the alternative cost of real estate acquisition, construction, and the ongoing overhead of a second facility (utilities, security, management). For a 10,000 sqm warehouse in a premium logistics park in Poland or Malaysia, the avoidance of expansion can represent a savings in the millions of dollars, making the narrow aisle racking cost a highly attractive investment.

A detailed case study illustrates this: A distributor in Santiago, Chile, was facing a 30% annual growth rate. A new 5,000 sqm warehouse would have cost approximately $1.2 million USD in construction and taken 18 months. Instead, a $350,000 investment in a high-density narrow aisle system, which included a modest narrow aisle racking cost for the structure and new narrow aisle forklifts, increased their existing warehouse’s capacity by 45%. The project was completed in 12 weeks. The ROI was calculated not just on the narrow aisle racking cost, but on the capital and opportunity costs avoided, resulting in a payback period of under 14 months.

Labor and Productivity: The Hidden Savings Engine

Beyond real estate, labor productivity is where narrow aisle systems generate continuous operational savings. Wider aisles mean longer travel distances for order pickers. By condensing the storage arena, narrow aisle designs drastically reduce non-productive travel time. When paired with the right Material Handling Equipment (MHE)—such as man-up turret trucks that allow operators to travel at height—pick rates can improve by 25-35%.

The analysis of narrow aisle racking cost must, therefore, include a thorough review of MHE options and their associated costs:

Option A: New Narrow Aisle Forklifts. This increases the upfront narrow aisle racking cost package but delivers optimal performance. Modern units feature lithium-ion batteries for fast charging, programmable lift/lower speeds, and cameras for precise alignment.

Option B: Articulated Forklifts. These can be a versatile middle-ground, capable of working in narrow aisles but also maneuvering in standard receiving areas. Their cost profile is part of the total system narrow aisle racking cost analysis.

Option C: Automation Integration. The highest initial narrow aisle racking cost scenario involves designing the racking for unmanned forklifts or AGV小车. However, this eliminates labor costs for specific tasks (like night replenishment) and boosts accuracy to 99.99+%. The narrow aisle racking cost here includes precision leveling, guidance targets, and communication interfaces.

The ongoing narrow aisle racking cost of labor is thus transformed. Fewer forklifts may be needed to achieve higher throughput. Training costs are focused on specialized, efficient equipment operation. The reduction in congestion and travel also lowers the risk of accidents, indirectly affecting insurance premiums—a subtle but real factor in the total narrow aisle racking cost of ownership.

Strategic Procurement: Navigating the Global Market for Narrow Aisle Solutions

Sourcing Strategies: Local Manufacture vs. Global Import

For a procurement manager in Nigeria or the Philippines, the decision on where to source significantly impacts the final narrow aisle racking cost. There are two primary models:

Fully Imported Systems: High-quality racking from specialized manufacturers in Europe or China may offer excellent engineering but carries the narrow aisle racking cost additions of international freight, import duties (which can be 15-25% in some markets), and longer lead times. This model is often chosen for highly complex, automated projects where specific engineering expertise is paramount.

Local or Regional Fabrication: Partnering with a global supplier that has established quality-controlled manufacturing partnerships within a region (e.g., a facility in Thailand serving ASEAN, or in Turkey serving the Middle East) can optimize the narrow aisle racking cost. It reduces shipping costs and tariffs, shortens lead times, and facilitates easier after-sales support. The key is ensuring the local partner adheres to the parent company’s stringent material and production standards.

A sophisticated supplier will perform a narrow aisle racking cost-benefit analysis for the client, presenting both options. For a large project in Colombia, it might recommend importing the high-precision beam connectors and safety components from its core factory while fabricating the upright columns locally under strict supervision, achieving an optimal balance of quality, narrow aisle racking cost, and delivery time.

Total Cost of Ownership (TCO) Modeling: The Ultimate Financial Tool

The most critical service a provider can offer is a comprehensive TCO model that transcends the initial narrow aisle racking cost quote. This dynamic financial tool projects costs and savings over a 5-to-10-year horizon. It contrasts the proposed narrow aisle system against the client’s current baseline or alternative solutions (like drive-in racking or a new warehouse).

A robust TCO model for narrow aisle racking cost analysis includes:

Capital Costs: The racking system, new MHE, required building modifications (floor grinding, sprinkler relocation).

Operational Costs: Estimated labor hours (before/after), energy consumption for MHE, preventive maintenance contracts, and insurance.

Soft Cost Savings: Value of recovered space, reduced error rates, improved inventory accuracy, and enhanced scalability.

Risk Mitigation: Quantifying the value of reduced product damage and improved safety records.

By modeling these factors, the abstract narrow aisle racking cost becomes a clear financial statement. It shows, for instance, that while Option A has a 20% higher upfront narrow aisle racking cost than Option B, its superior density and lower energy MHE will result in a lower TCO by Year 3. This level of analysis is what empowers executives to make board-level decisions with confidence, moving the conversation from “What is the narrow aisle racking cost?” to “What is the net present value of this logistics investment?”

Implementation and Beyond: Ensuring Your Investment Delivers

The Critical Path: From Design to Operational Handover

The realization of the projected ROI depends entirely on flawless execution. The narrow aisle racking cost proposal should include a detailed project management plan. This plan outlines the journey from the initial site survey—where engineers measure floor flatness (FΔ tolerance) and check roof clearances—to the final performance validation.

A key phase often underestimated in the narrow aisle racking cost is site preparation. The required floor flatness for narrow aisle operations (e.g., ±5mm over 3 meters) may necessitate professional grinding or a new topping slab. The cost for this is sometimes excluded from initial narrow aisle racking cost quotes, leading to budget overruns. Transparent suppliers include a site audit and a clear delineation of responsibilities, ensuring the narrow aisle racking cost presented is comprehensive.

Installation is another variable. A crew employed directly by the manufacturer or its certified local partner, trained on the specific system, will work more efficiently and accurately than a general contractor. This expertise, while factored into the narrow aisle racking cost, prevents costly errors and ensures the system’s design integrity and safety are maintained.

Lifecycle Support: Protecting Your Investment Post-Installation

The relationship with the supplier should not end at installation. The long-term narrow aisle racking cost of ownership is heavily influenced by maintenance and support. Leading providers offer annual inspection services to check anchor integrity, upright verticality, and beam connections. They also provide easy access to spare parts—from replacement beam locks to additional wire decking panels—ensuring the system can adapt to changing needs without a complete redesign.

For automated systems linked to AGV小车 or unmanned forklifts, this support extends to software updates and remote diagnostics. This proactive approach to managing the ongoing narrow aisle racking cost of maintenance minimizes unplanned downtime, which for a high-throughput distribution center can cost tens of thousands of dollars per hour.

Conclusion: The Intelligent Calculus of Warehouse Transformation

The pursuit of an accurate narrow aisle racking cost is, in essence, the beginning of a strategic supply chain optimization project. It is a multi-variable equation where quality, density, productivity, and future-readiness intersect. In the fast-growing markets of the world, where logistics efficiency is a direct correlate of market share, the decision to invest in a narrow aisle system is a decision to build operational resilience and scalability.

The most competitive businesses will not seek the lowest initial narrow aisle racking cost. They will seek the most compelling value proposition—a solution whose total narrow aisle racking cost over its lifecycle delivers the highest return on intelligence, transforming their warehouse from a cost center into a dynamic, data-driven asset that powers growth across continents.

Frequently Asked Questions (FAQs)

Q1: For a multi-client 3PL warehouse with constantly changing SKU profiles, is the higher initial narrow aisle racking cost justified compared to more flexible but less dense systems?

Absolutely. The dynamic nature of a 3PL operation makes selectivity and access speed paramount. While systems like drive-in racking have a lower pallet position narrow aisle racking cost, they operate on LIFO (Last-In, First-Out) principles and are terrible for SKU variety. A narrow aisle selective system provides 100% immediate access to every pallet. This allows 3PLs to optimize storage based on velocity for each client, maximize space utilization across diverse product shapes, and fulfill orders faster. The higher narrow aisle racking cost per position is offset multiple times over by the ability to serve more clients more efficiently within the same building, directly increasing revenue per square meter.

Q2: How does the narrow aisle racking cost structure differ for a cold storage facility versus a dry warehouse?

The narrow aisle racking cost for cold storage is inherently higher due to several critical factors. First, the steel must be specified for low-temperature performance, often using special grades to prevent brittleness. Second, the design must account for thick insulation on walls and ceilings, which can reduce clear height. Third, all components—especially safety decks and pallet supports—must be designed to prevent ice buildup and ensure drainage. Fourth, installation is more complex and expensive due to the working environment. Finally, the MHE must be cold-rated. Therefore, the narrow aisle racking cost analysis for cold storage must integrate these premium requirements, but the ROI argument is even stronger due to the exorbitant cost of building and operating refrigerated space.

Q3: What is the typical lead time variance in narrow aisle racking cost between a standard system and a fully automated one?

Lead time is a significant, though often hidden, component of project narrow aisle racking cost through its impact on time-to-value. A standard, manually operated narrow aisle system from a regional fabricator might have a lead time of 10-14 weeks from order to installation-ready. A fully automated system, integrating 立体仓库货架 concepts with AGV小车, can extend this to 20-30 weeks. This longer timeline accounts for the detailed software integration engineering, prototyping of robotic interfaces, manufacture of precision-guided components, and extended commissioning. The narrow aisle racking cost proposal should clearly state these timelines, as a delay in an automation project has a higher narrow aisle racking cost impact due to the greater anticipated productivity gains being postponed.

Q4: Can existing Wide-Aisle racking be economically converted to a Narrow Aisle system, or is a complete replacement always necessary?

This is a common query aiming to reduce narrow aisle racking cost. A partial conversion is sometimes possible but fraught with risk. It typically involves replacing beams with longer ones to create deeper bays and using the existing uprights. However, this is only feasible if:

1) The existing uprights are structurally sound, perfectly plumb, and of a compatible profile.

2) The load capacity and seismic ratings of the old frames meet the new design requirements.

3) The floor condition and layout support the new, tighter aisle spacing. In 80% of cases, a complete replacement is recommended. Mixing old and new components jeopardizes system integrity and voids warranties. A professional audit can determine viability, but the narrow aisle racking cost savings from a hybrid approach are often outweighed by the performance and safety compromises.

Q5: How are ongoing energy costs factored into the narrow aisle racking cost TCO, especially with different MHE options?

Energy consumption is a major OpEx factor. A comprehensive narrow aisle racking cost TCO model will include MHE energy analysis. Traditional lead-acid battery forklifts have lower upfront narrow aisle racking cost but require long charging times and dedicated space. Modern lithium-ion equipped narrow aisle forklifts have a higher acquisition narrow aisle racking cost but can opportunity charge during breaks, use 30-40% less energy, and have no battery replacement costs.

For automated systems (AGV), energy use is highly predictable and optimized through scheduling. The model will calculate estimated kWh consumption per shift based on travel distances (optimized by the narrow aisle design) and compare the total energy narrow aisle racking cost over 5 years for each MHE scenario, providing a complete financial picture.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com