📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Cold Storage & Manufacturing Ready: The Definitive Guide to Heavy-Duty Narrow Aisle Racking for Extreme Environments

For logistics directors, warehouse managers, and operations executives overseeing facilities in the cold chain, heavy manufacturing, or chemically demanding sectors, the selection of a storage system transcends a simple procurement decision. It represents a strategic investment in operational resilience, asset protection, and long-term profitability. Standard warehouse racking, when deployed in harsh environments, becomes a liability—succumbing to premature corrosion, structural fatigue, and catastrophic failure. This authoritative guide delves into the engineering philosophy, material science, and integrative design behind a truly robust narrow aisle racking system built for extreme duty.

It explores why a specialized heavy-duty narrow aisle racking solution is non-negotiable for maximizing density in cold storage and industrial settings, how it forms the critical backbone for AGV-compatible racking systems and automated storage and retrieval systems (AS/RS), and outlines the pathway from concept to operational reality. Grounded in decades of global project experience from the humid coastlines of Southeast Asia to the arid industrial zones of the Middle East and the bustling manufacturing hubs of Latin America, this resource is designed to equip decision-makers with the knowledge to specify a storage infrastructure that not only survives but thrives under duress, enabling precision, efficiency, and growth.

The Inherent Limitations of Standard Racking in Hostile Environments

A conventional pallet racking system is engineered for a stable, temperate, and relatively clean warehouse environment. Its design calculus assumes consistent temperatures, minimal corrosive agents, and predictable, static loading. Introduce the variables present in a -30°C freezer, a seafood processing plant with daily high-pressure washdowns, a fertilizer storage warehouse, or a foundry storing cast metal components, and the system’s vulnerabilities are quickly exposed.

The failure of a standard narrow aisle racking system in such conditions is rarely instantaneous. It is a progressive degradation: microscopic cracks form in embrittled steel under thermal stress; chloride ions from salt air or washdown water initiate pitting corrosion at bolt holes and welded joints; constant minor impacts from busy operations slowly deform beam end connectors. This gradual compromise erodes the system’s stated load capacity and alignment integrity long before visible signs of distress appear, creating an unseen safety hazard and a major operational risk.

The fundamental difference with a purpose-built heavy-duty narrow aisle racking system lies in its foundational engineering principles. It is designed from the component level upward to resist specific environmental stressors:

Thermal Dynamics in Cold Storage: Steel contracts significantly at deep-freeze temperatures. A narrow aisle racking system not accounting for this thermal movement can experience loosened connections, induced stresses, and misalignment, which in turn jeopardizes the precise clearances required for very narrow aisle (VNA) forklift operation. Furthermore, the cyclic thermal loading from repeated transfer of pallets from ambient to frozen zones accelerates metal fatigue.

Corrosion: The Silent Capacity Killer: In harsh environments, corrosion is multifaceted. Beyond general humidity, it involves chemical exposure—from acidic food products and alkaline cleaning agents to industrial vapors. Coastal climates, prevalent in many target markets, present a severe challenge with salt spray. This corrosion directly reduces the material cross-section of uprights and beams, diminishing their load-bearing capacity. A rack may look intact while its structural safety margin has been dangerously compromised.

Dynamic and Impact Loads in Industrial Settings: In manufacturing and heavy industry, narrow aisle racking is part of the active production workflow. It must withstand not just the static weight of palletized raw materials or finished goods but also the dynamic forces from sideloaders, the vibration of adjacent machinery, and occasional incidental contact. The system requires a higher design safety factor and more robust connection details than a standard warehouse narrow aisle racking installation.

Therefore, specifying a narrow aisle racking solution for these conditions begins not with a catalog, but with a forensic understanding of the operational environment. It demands collaboration with a supplier whose expertise encompasses metallurgy, structural engineering, and corrosion science, ensuring the heavy-duty narrow aisle racking system is a custom-engineered asset, not a commodity product.

Metallurgy and Coatings: The First Line of Defense in Harsh-Environment Racking

The longevity and safety of any narrow aisle racking system in a demanding application are determined by the inherent properties of its steel and the efficacy of its protective finish. For cold storage pallet racking and industrial manufacturing racking, these are not ancillary features but core functional requirements.

Low-Temperature Steel Alloys: The base material for a heavy-duty narrow aisle racking system destined for freezing environments is specialized steel manufactured with enhanced toughness properties. This steel is formulated and processed to maintain its ductility and resist brittle fracture at temperatures far below freezing. The fabrication process—including cutting, drilling, and welding—is meticulously controlled to preserve these critical material properties, ensuring the narrow aisle racking structure behaves predictably under extreme thermal stress.

Advanced Powder Coating Systems: While standard powder coating offers good protection, harsh environments require enhanced formulations. For narrow aisle racking in coolers or mildly corrosive settings, a high-performance epoxy-polyester hybrid powder with superior adhesion and flexibility is specified. The pretreatment process—typically a multi-stage zinc or iron phosphate bath—is crucial to create a surface that chemically bonds with the coating, preventing underfilm corrosion creep. For food and pharmaceutical applications, the coating must be non-porous, chemically inert, and compliant with relevant FDA, EU, or other international food contact regulations, facilitating rigorous hygiene protocols.

Hot-Dip Galvanizing (HDG) for Maximum Protection: In the most aggressive environments—such as blast freezers, seafood processing, chemical storage, or tropical coastal facilities—hot-dip galvanizing is the preferred defense. This process involves immersing fabricated narrow aisle racking components in a bath of molten zinc, forming a metallurgical bond that provides robust barrier and sacrificial cathodic protection. Even if damaged, the surrounding zinc sacrificially protects the exposed steel. A duplex system, combining HDG with a powder coat top layer, offers the ultimate protection: the galvanizing provides long-term corrosion resistance, while the color coating adds aesthetics, easy identification, and an additional barrier.

Specialized Finishes for Unique Challenges: Certain manufacturing processes may involve exposure to oils, solvents, or other specific chemicals. In these cases, chemical-resistant coating systems, such as epoxy primers with polyurethane topcoats, can be specified for the narrow aisle racking system. The key is matching the finish technology precisely to the environmental contaminant profile.

Selecting the appropriate protective system for a heavy-duty narrow aisle racking project is a critical cost-of-ownership decision. An under-specified finish leads to exponential maintenance costs, unscheduled downtime for repairs, and potential safety incidents, far outweighing the marginal initial savings.

Deconstructing the Heavy-Duty Narrow Aisle Racking System: An Engineering Perspective

A narrow aisle storage system achieves its renowned space efficiency—typically a 40-60% increase in pallet positions over conventional wide-aisle designs—by operating within aisles as narrow as 1.5 to 2.0 meters. This feat requires not only specialized material handling equipment but, more fundamentally, a rack structure of exceptional precision, rigidity, and durability. The margin for error is virtually nonexistent; any significant deflection or misalignment in the narrow aisle racking can lead to equipment damage, operational delays, and safety hazards.

Component-Level Engineering for Extreme Performance

Every element of a heavy-duty narrow aisle racking system is optimized for strength, precision, and longevity:

Upright Frames (Columns): As the primary load-bearing vertical elements, columns in a harsh-environment narrow aisle racking system are fabricated from high-tensile, cold-rolled steel with increased material thickness. Profiles often feature a closed tubular or reinforced open-back design for superior torsional stiffness. Connection holes are precision laser-cut (not punched) to maintain material integrity and ensure perfect beam level alignment. Base plates are substantial, engineered to distribute concentrated column loads effectively to the concrete floor and accommodate high-strength anchoring. A critical design detail often incorporated is a raised drip ridge on the base plate to prevent moisture accumulation and wicking into the column section—a simple yet vital feature for washdown and high-humidity areas.

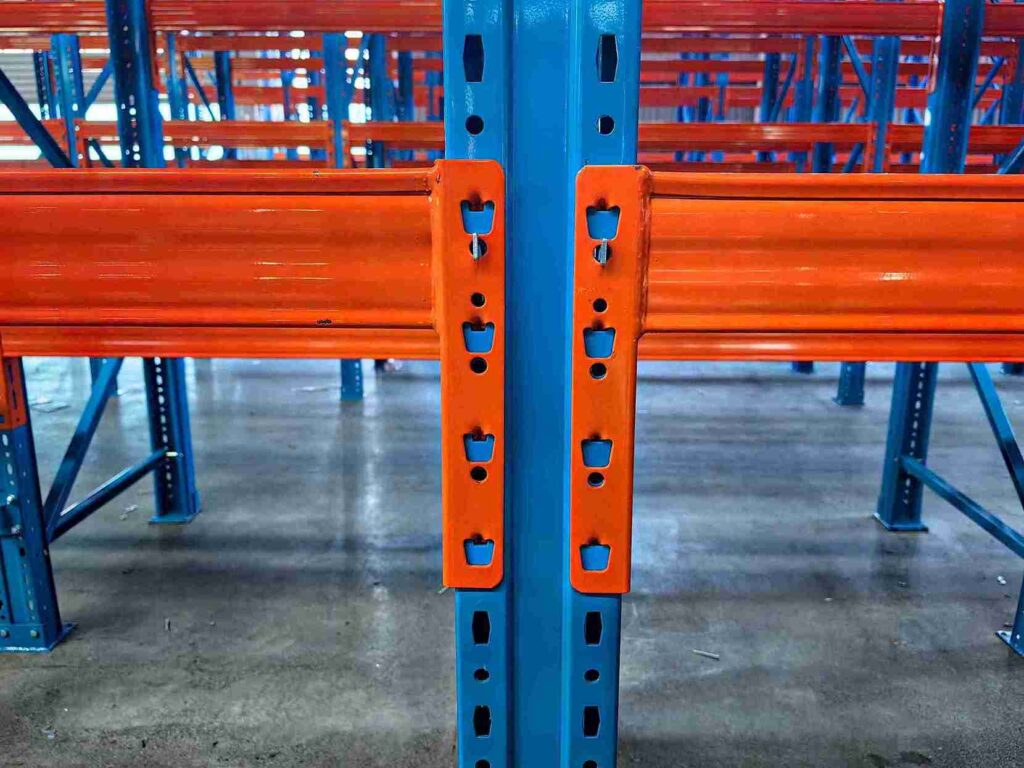

Beams and Connectors: The horizontal beams in a heavy-duty narrow aisle racking system are the workhorses, directly supporting the palletized loads. They feature a robust double-step or teardrop design for secure engagement with the column. The locking mechanism is a critical safety component; premium systems use a positive, mechanical anti-disengagement device that provides both audible and visual confirmation of secure engagement. Beam end connectors are often hot-forged for superior grain structure and strength, not merely welded onto the beam tube.

- For the most demanding applications involving automated storage and retrieval systems (AS/RS) or ultra-heavy loads, bolt-on beam configurations are employed. This design provides the highest possible load capacity and rigidity, as the connection transfers load through shear bolts rather than friction-based locks.

Bracing and Structural Stabilization: The bracing system provides lateral stability to the narrow aisle racking structure, resisting forces from seismic activity, impacts, and operational dynamics. In heavy-duty applications, bracing is substantial—utilizing heavy-gauge channel or solid bar stock connected with high-tensile bolts. The design ensures the rack can withstand not only design loads but also unforeseen lateral forces. For installations exceeding 12 meters in height, additional stabilization measures, such as longitudinal tie-backs to the building structure or portal bracing systems, are often engineered into the narrow aisle racking design to guarantee global stability.

The Critical Interface: Floor Flatness, Anchoring, and Installation Precision

The most perfectly engineered narrow aisle racking system is critically dependent on its foundation. The performance and safety of a narrow aisle storage system are directly tied to floor flatness and anchoring integrity.

Floor Flatness Tolerances: Very narrow aisle (VNA) equipment and automated guided vehicles (AGVs) operate with clearances of just millimeters. Consequently, the floor flatness requirement for a narrow aisle racking installation is exceptionally stringent, often specified as Floor Flatness (FF) numbers exceeding 50 or with a tolerance of ±3mm over a 3-meter span. An uneven floor causes rack lean, reduces effective aisle width, accelerates wear on guide wheels and rails, and can cause automated systems to fault. A professional site survey using specialized equipment is a mandatory first step to assess existing conditions or specify requirements for new slabs.

Anchoring Systems: The anchoring system permanently secures the narrow aisle racking to the concrete floor, resisting uplift and shear forces. For heavy-duty narrow aisle racking, this involves high-capacity, cast-in-place or mechanical expansion anchors designed for the specific concrete strength and anticipated loads. Anchor bolt grade, embedment depth, and installation torque are precisely specified and rigorously verified during installation. In retrofit projects, pull-out testing is conducted to confirm the existing floor’s capacity. This meticulous approach to the rack-floor interface is a cornerstone of a safe and durable narrow aisle racking installation, particularly one destined to interface with precision automation.

Sector-Specific Applications: Tailoring Narrow Aisle Racking for Maximum Impact

Cold Storage and Frozen Logistics: Engineering for the Deep Freeze

In cold storage, operational efficiency is measured in energy savings per pallet and footprint optimization. A cold storage pallet racking system must achieve maximum storage density without impeding crucial airflow or compromising safety in a physically demanding environment.

Layout Synergy with Refrigeration: The design of a narrow aisle racking layout for cold storage is conducted in close consultation with refrigeration engineers. Rack rows are typically oriented parallel to the airflow from ceiling evaporators to prevent creating stagnant air pockets. The use of wire mesh or perforated decking is standard to promote vertical air circulation through the rack structure itself, ensuring uniform temperature distribution and product integrity.

Cold-Optimized Materials and Design: Beyond the low-temperature steel, every ancillary component of the narrow aisle racking system and its associated equipment must be rated for cold service. This includes the seals on forklift hydraulics, the polymers in guide wheel coatings, and even the lubricants used. The narrow aisle racking safety locks are tested to function reliably when frosted over.

Automation Integration for Efficiency: Minimizing human presence in freezers is a key driver for automation. A modern cold storage pallet racking system is often designed as the static partner to dynamic automation. This requires:

Dimensional Precision: AS/RS cranes or shuttles running on mast guides attached to the narrow aisle racking demand extraordinary alignment tolerances, often within ±5mm over the entire system height. This dictates controlled manufacturing and laser-guided installation processes.

System Interfacing: The narrow aisle racking design includes detailed interface points for guide rails, sensor mounts, and communication cabling, provided to the automation supplier for seamless integration.

Throughput-Driven Design: The configuration of the narrow aisle racking—lane depth, number of storage levels, and picking face arrangement—is optimized using warehouse data to match the I/O profile and speed of the AS/RS, creating a cohesive high-performance system.

Project Spotlight: Multi-Temp Facility in a High-Humidity Climate

A recent project for a regional food distributor in Vietnam involved a facility with ambient, chilled (+2°C), and frozen (-25°C) zones. A unified heavy-duty narrow aisle racking system was implemented throughout, but with zone-specific specifications. The ambient area used a standard powder coat. The chill zone used a chemical-resistant epoxy. The critical freezer zone narrow aisle racking was fabricated from low-temperature steel and finished with a hot-dip galvanized duplex system. The entire narrow aisle racking structure was designed to be compatible with both current man-up VNA trucks and a future-phase, high-density AS/RS, protecting the client’s long-term investment.

Manufacturing and Heavy Industry: Storage as a Production Tool

In a plant, storage is a dynamic buffer within the production flow. The industrial manufacturing racking must accommodate diverse, often non-standard loads and withstand a more physically aggressive environment.

Handling Non-Standard and Extreme Loads: Manufacturing deals with rolls of steel, engine blocks, large molds, and raw material ingots. A heavy-duty narrow aisle racking system here often incorporates custom elements: reinforced cantilever arms, structural shelving inserts, or specially engineered decking to handle high point loads. Load calculations account for both uniformly distributed and concentrated load scenarios.

Impact Resistance and Durability: While operational discipline minimizes impacts, the narrow aisle racking system must be resilient. Features like bolt-on, replaceable column guards made of high-density polyethylene or steel, reinforced post protectors, and extra-strong lower beam levels are common. The design philosophy acknowledges that in a busy plant, some degree of contact is inevitable, and the system should be easily repairable.

Supporting Lean Manufacturing: To feed production lines efficiently, narrow aisle racking is often integrated with dynamic flow systems. Gravity flow racking lanes or carton live storage units can be incorporated at the picking face of a narrow aisle racking structure, creating first-in-first-out (FIFO) inventory management and drastically reducing picker travel time for high-volume components.

The Automation-Ready Racking System: Designing for Tomorrow’s Warehouse Today

The evolution towards lights-out warehouses and labor-optimized operations makes automation compatibility a paramount concern. A modern heavy-duty narrow aisle racking system is no longer a passive structure; it is the foundational grid upon which automation operates.

Engineered for AGV and Robotic Interaction

The rise of AGV-compatible racking systems demands a paradigm shift in racking design, emphasizing precision, consistency, and structural predictability.

Navigation and Guidance Integration: AGVs using LiDAR or natural feature navigation rely on the rack structure as a fixed reference point. A narrow aisle racking system for AGVs must exhibit extreme dimensional stability and may have reflective targets or specific profiles integrated to aid navigation. The consistency of the narrow aisle racking aisle width and upright alignment is critical for reliable AGV path planning and execution.

Interface for Robotic Handling: Robotic pallet handlers, whether mounted on AGVs or stationed at transfer points, require highly repeatable pick/place positions. The narrow aisle racking openings are engineered with clearances optimized for the end-effector’s geometry, ensuring reliable operation over millions of cycles. This may involve custom beam heights, specific pallet support bar configurations, and reinforced upright faces at contact points.

Dynamic Load Considerations: The interaction forces between an AGV and the narrow aisle racking during docking and load transfer differ from human-operated equipment. The narrow aisle racking structure must be designed to accommodate these dynamic loads without excessive deflection, which could cause pallet handling errors or system faults.

The Symbiosis with Automated Storage and Retrieval Systems (AS/RS)

For ultimate density and throughput, particularly in cold storage or high-value parts storage, an automated storage and retrieval system (AS/RS) represents the pinnacle. In this scenario, the narrow aisle racking is an integral part of the machine itself.

Tolerance as a Fundamental Specification: An AS/RS operates on rails mounted to the narrow aisle racking structure. The required tolerances for straightness, plumb, and level are aerospace-level, often exceeding those of the building itself. This demands a dedicated Quality Management System governing the entire process from fabrication to installation, utilizing jigs, templates, and laser alignment tools.

Holistic Project Coordination: Successful AS/RS projects involving narrow aisle racking are executed using Building Information Modeling (BIM). This digital twin allows for clash detection between the racking, building services, and automation equipment long before installation, preventing costly on-site modifications. The narrow aisle racking supplier must act as a structural systems integrator within this collaborative model.

Load Handling Device (LHD) Specific Design: The narrow aisle racking design is wholly dependent on the AS/RS LHD—whether it is a unit-load crane, a mini-load shuttle, or a robotic gantry. Pallet support details, rail mounting points, and clearances are all custom-engineered for that specific technology, making the narrow aisle racking and the AS/RS a single, co-engineered system.

The Implementation Roadmap: From Initial Consultation to Operational Handover

Deploying a harsh-environment warehouse solution based on heavy-duty narrow aisle racking is a phased, collaborative process that ensures alignment with business objectives and technical requirements.

Phase 1: The Free Design Review – A Strategic Discovery

The offered Free Design Review is a consultative engagement designed to uncover value and define scope. It involves:

Operational Analysis: Reviewing SKU data, pallet specs, throughput patterns, and growth forecasts to understand storage profiles.

Site Evaluation: Assessing building dimensions, column locations, floor conditions, door placements, and environmental control systems.

Workflow Consultation: Mapping current and future material flows to identify bottlenecks and optimization opportunities.

Conceptual Design & ROI Analysis: Producing 2D/3D layout options illustrating capacity gains and workflow improvements. Providing a comparative analysis of different narrow aisle racking scenarios (e.g., manual VNA vs. semi-automated) with projected ROI.

Phase 2: Detailed Engineering and Project Planning

Upon project approval, detailed engineering commences:

Production of full structural calculations sealed by a professional engineer, complying with local building and seismic codes (essential for regions like the Philippines, Chile, or Turkey).

Generation of manufacturing and assembly drawings for every unique narrow aisle racking component.

Development of a comprehensive project plan, including delivery schedules, installation sequencing, and coordination with other trades.

Phase 3: Precision Installation and Commissioning

Installation of a heavy-duty narrow aisle racking system is a specialized task:

Verification of floor conditions against specification.

Laser-guided setting of anchor bolt patterns.

Systematic erection with continuous quality checks for plumb, level, and alignment.

Final torque audit of all critical connections.

Load application testing and formal system sign-off, accompanied by operational training.

Phase 4: Lifecycle Support and Future Scalability

A true partnership extends beyond installation. Provision of as-built drawings, maintenance guides, and ongoing support for system expansion or reconfiguration ensures the narrow aisle racking investment continues to deliver value for its entire lifecycle.

Conclusion: The Strategic Imperative of Engineered Storage Resilience

Selecting a heavy-duty narrow aisle racking system for demanding environments is a decisive strategic move. It is an investment in safeguarding product quality, ensuring workforce safety, maximizing valuable real estate, and building a scalable operational platform. The allure of a lower-cost, standard narrow aisle racking solution is a false economy, inevitably leading to higher total cost through maintenance, unplanned downtime, premature replacement, and elevated operational risk.

By engaging with a specialist provider that masters the intersection of advanced engineering, material science, and automation integration, organizations procure more than narrow aisle racking. They secure a custom industrial storage solution—a resilient, high-density, and intelligent backbone engineered to transform challenging storage spaces into reliable, high-performance assets. In the competitive global landscapes of logistics and manufacturing, such an infrastructure is not merely an operational necessity; it is a formidable source of competitive advantage and business resilience.

Frequently Asked Questions (FAQs)

1. What is the typical lead time for a custom heavy-duty narrow aisle racking system for a cold storage facility?

Lead times are project-dependent. A standard powder-coated narrow aisle racking system may have an 8-12 week lead time from finalized design. For large, hot-dip galvanized heavy-duty narrow aisle racking projects with AS/RS interface requirements, lead times can extend to 16-20 weeks due to the specialized processing and stringent quality controls. A detailed project schedule is always provided during the initial design phase.

2. Can your narrow aisle racking be retrofitted into an existing building with a lower ceiling height or uneven floors?

Retrofits are common. For lower ceilings, the narrow aisle racking design focuses on optimizing vertical space with tight beam level spacing and potentially integrating mezzanine levels. For uneven floors, solutions include adjustable base plates, selective shimming, or designing the narrow aisle racking layout to avoid severely out-of-tolerance areas. A pre-installation survey is critical to identify and plan for these constraints.

3. How do you ensure the narrow aisle racking meets the specific seismic codes for our region, for example, in parts of the Philippines or Chile?

Seismic design is integral to our engineering. Our structural engineers design the heavy-duty narrow aisle racking system to the specific seismic zone and soil parameters of your site, applying relevant international (IBC, Eurocode 8) or local national standards. This results in specific bracing configurations, connection details, and anchorage designs to ensure structural integrity during a seismic event.

4. What are the ongoing maintenance requirements for a galvanized narrow aisle racking system in a washdown environment?

Hot-dip galvanized narrow aisle racking is low-maintenance. Primary tasks are periodic visual inspections for mechanical damage to the zinc layer (e.g., deep scratches from impacts). Any damaged areas should be touched up with a zinc-rich paint. Regular rinsing with fresh water is beneficial to remove surface contaminants. Harsh acidic or alkaline cleaners should be avoided as they can degrade the zinc over time.

5. We are considering automation but need to start manually. How do you “future-proof” the narrow aisle racking design?

Future-proofing is a core design principle. For clients anticipating automation, we engineer the narrow aisle racking to the higher tolerances and structural specs required by AGVs or AS/RS from the outset. This includes using more robust components, ensuring exceptional plumb and alignment, and designing aisle layouts compatible with automated vehicle paths. We can also pre-install mounting interfaces for future guidance rails or sensors. This approach safeguards the initial investment, making the future transition to automation a matter of adding equipment, not replacing the core narrow aisle racking infrastructure.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com