📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Strategic Imperative: Why a Precision-Engineered Narrow Aisle Pallet Racking Setup is the Cornerstone of Modern Warehousing

In the global logistics arena, dominated by demands for speed and efficiency, the warehouse has transformed from a static storage facility into a dynamic, high-velocity throughput engine. At the heart of this transformation lies a critical, often underestimated decision: the selection and implementation of the storage infrastructure. For operations targeting sustainable growth in emerging markets—from the bustling ports of Southeast Asia to the industrial hubs of the Middle East and the expanding distribution networks of Latin America—this decision crystallizes around one concept: investing in a meticulously planned narrow aisle pallet racking setup.

This is not merely about saving space; it is about constructing a high-performance, adaptable backbone capable of integrating with and empowering the next generation of material handling technology. A properly executed narrow aisle pallet racking setup is the definitive foundation upon which automation, whether immediate or future, is successfully built.

The distinction between a conventional storage solution and a forward-thinking narrow aisle pallet racking setup is profound. The former addresses present-day volume requirements; the latter is engineered for future-state operational paradigms. It transcends basic functionality, incorporating precision engineering, rigorous tolerance controls, and intrinsic compatibility with robotic systems.

For businesses navigating the complexities of rising land costs, labor volatility, and escalating customer service expectations, opting for a sophisticated narrow aisle pallet racking setup represents a strategic maneuver to lock in long-term operational resilience and competitive advantage. This approach directly translates to quantifiable gains in storage density, picking accuracy, and system uptime, forming a compelling return on investment narrative for stakeholders.

Deconstructing the Automation-Ready Paradigm: Core Tenets of a Next-Generation System

The term “automation-ready” is frequently used but seldom fully defined. In the context of a narrow aisle pallet racking setup, it signifies a holistic set of physical, digital, and operational characteristics engineered to interface seamlessly with automated guided vehicles (AGVs), robotic forklifts, and warehouse management systems (WMS). It implies that the storage infrastructure is not a passive asset but an active, predictable participant in the automated workflow.

Precision as a Non-Negotiable Standard:

The fundamental principle governing an automation-optimized narrow aisle pallet racking setup is extreme precision. While a human-operated reach truck can compensate for minor rack lean or beam misalignment, an AGV cannot. These machines operate on pre-programmed paths and depend on millimeter-level consistency. Any deviation—a column out of plumb, a beam height inconsistency, or an aisle width variation—forces the vehicle into error recovery mode, halting productivity.

Therefore, the engineering specifications for such a narrow aisle pallet racking setup demand tolerances far exceeding those of traditional racking. Upright frame plumb is held to ±3mm over 10 meters; beam levels are consistent within ±1.5mm; and the critical aisle width is maintained within a ±10mm window throughout the entire warehouse floor. This unwavering consistency is the bedrock upon which reliable, high-speed automation operates.

Structural Integrity for Dynamic Loads:

An automated warehouse subjects its racking to different stress profiles compared to a manual one. The movements of AGVs and robotic forklifts, while precise, are frequent and can impart unique dynamic forces. Furthermore, the loading and unloading cycles are often faster. The narrow aisle pallet racking setup designed for this environment must therefore be built with enhanced structural rigidity. This involves specifying high-yield-strength steel, employing robust welded connections at critical stress points, and utilizing bolt-through or advanced interlocking beam connectors that cannot be accidentally dislodged. The system is calculated not just for static pallet weight, but for the cumulative effects of continuous, automated material flow, ensuring longevity and safety in high-cycle environments.

The Digital-Physical Interface: Embedded Intelligence:

A truly advanced narrow aisle pallet racking setup incorporates its own layer of “intelligence” to communicate with machines. This goes beyond basic labeling. It involves the strategic placement of machine-readable location identifiers—such as barcodes, QR codes, or RFID tags—at standardized, optimized positions on the rack structure. These identifiers are positioned for clear line-of-sight from AGV-mounted scanners, regardless of the vehicle’s approach angle. The layout of the narrow aisle pallet racking setup itself is also designed to avoid creating radio frequency (RF) dead zones that could disrupt communication between the AGV fleet and the central control system. In essence, the racking becomes a readable map for the automated fleet.

Component-Level Excellence: Building Blocks of a Superior Narrow Aisle System

The performance of any narrow aisle pallet racking setup is dictated by the quality and design of its individual components. When the goal is automation readiness, every element is scrutinized and often upgraded from standard specifications.

Upright Frames: The Backbone of Stability:

The upright frame is the primary load-bearing component, and its design is paramount. For an automation-grade narrow aisle pallet racking setup, frames are fabricated from higher-grade, consistently galvanized steel to resist the environmental challenges prevalent in many target markets, such as coastal humidity in Vietnam or abrasive dust in the UAE. Column profiles are often heavier gauge, and connector holes are precision-punched or laser-cut to ensure perfect alignment during assembly. Footplates are larger and designed for multi-bolt chemical anchoring, providing exceptional moment resistance to prevent any leaning in tall, narrow configurations. This level of stability is non-negotiable for ensuring the long-term geometric integrity of the aisles that AGVs will navigate.

Load Beams: The Critical Interface Point:

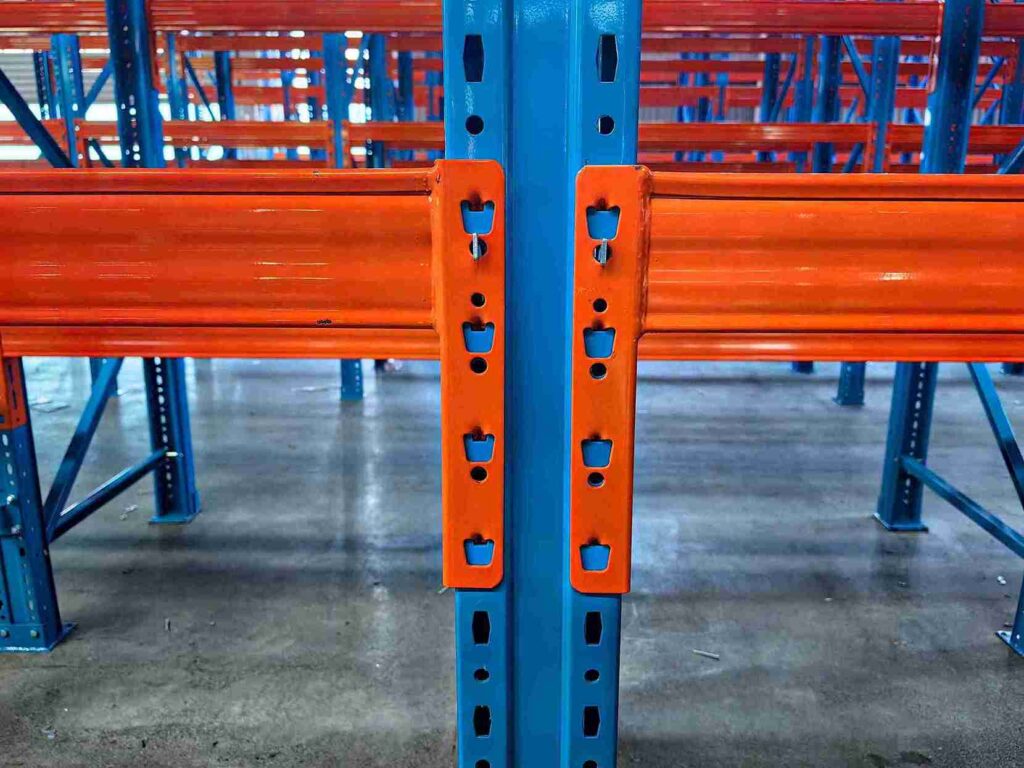

Beams in an automation-focused narrow aisle pallet racking setup serve as the direct interface for automated handling equipment. The fork entry, pallet support, and overall beam deflection characteristics are carefully engineered. For medium to heavy loads, structural box beams are frequently recommended over standard step beams due to their superior resistance to twisting and bending under asymmetrical loads—a common occurrence during automated placement. The beam end connectors feature positive locking mechanisms (e.g., twin-tear drop locks with safety clips) that guarantee a rigid, unwavering connection to the upright. This prevents any beam movement that could alter the pallet’s position or create a hazard for passing vehicles.

Bracing and Reinforcement: Ensuring System Rigidity:

The bracing system within a high-performance narrow aisle pallet racking setup is designed for maximum rigidity. Cross-braces and horizontal struts are strategically placed to minimize any lateral sway or rack “breathing” that could occur from frequent AGV traffic or seismic activity in regions like parts of Latin America or the Philippines. The bracing design also considers the need for clear sightlines for AGV sensors and does not obstruct the free movement of pallets in and out of storage locations.

The Integration Blueprint: Synchronizing Racking with Robotics

The most perfectly engineered narrow aisle pallet racking setup is only half the solution. Its full potential is unlocked through meticulous integration with the automated material handling systems. This process requires a collaborative, phased approach from the initial design stage.

Phase 1: Co-Design and Digital Twin Simulation:

Successful integration begins long before installation. It requires a triad collaboration between the client, the racking provider, and the automation vendor. Key AGV specifications—including turning radius, mast lift height, fork dimensions, sensor array location, and navigation type (LiDAR, vision, wire-guidance)—directly inform the final parameters of the narrow aisle pallet racking setup. Aisles are not just made “narrow”; their exact width is calculated based on the AGV’s kinematics and required safety margins. A digital twin—a complete 3D virtual model of the proposed narrow aisle pallet racking setup within the warehouse—is created. This model allows for simulation of AGV workflows, identification of potential traffic bottlenecks, and verification of clearances before any physical work begins, de-risking the entire project.

Phase 2: The “Golden Aisle” Commissioning Methodology:

A best-practice installation protocol for an integrated narrow aisle pallet racking setup involves the creation of a “Golden Aisle.” This is a single, completed aisle that is built first to the exacting specifications. The automation team then uses this aisle for live testing with their AGVs. They verify navigation, pallet pickup/deposit accuracy, and system communication in this controlled, perfect environment. Only after this aisle is fully signed off by all parties does the full-scale installation of the remaining narrow aisle pallet racking setup proceed, using the Golden Aisle as the physical benchmark for quality and precision.

Phase 3: Software Integration and Workflow Governance:

The physical racking and the AGVs are orchestrated by the Warehouse Management System (WMS). The final, as-built drawings of the narrow aisle pallet racking setup, with precise coordinates for every pallet position (x, y, z), are imported into the WMS. This creates the “single source of truth” for inventory location. The WMS is then configured with rules that govern the automated workflow, dictating which SKUs are stored in which zones of the narrow aisle pallet racking setup, optimizing travel paths, and managing inventory rotation. The racking layout directly influences the efficiency algorithms within the software.

Regional Adaptation: Engineering for Local Environmental and Operational Realities

A one-size-fits-all approach is a recipe for failure in global logistics. An effective narrow aisle pallet racking setup for a warehouse in Germany may be wholly unsuitable for one in Indonesia or Saudi Arabia. Expert providers engineer adaptability into the core design.

For High-Humidity and Coastal Climates (Southeast Asia, Coastal Africa):

In these regions, corrosion is the primary adversary. An automation-ready narrow aisle pallet racking setup requires enhanced protective measures. This often involves specifying a higher-grade hot-dip galvanization (e.g., 120-150g/sqm) followed by a powder-coated finish for an additional barrier layer. Stainless steel components may be used for critical small parts. Design considerations also include promoting airflow within the dense narrow aisle pallet racking setup to mitigate moisture buildup that could affect both the steel and the stored goods.

For Arid, Dusty, and High-Temperature Regions (Middle East, Inland Africa):

Dust infiltration can compromise AGV sensors and mechanical components. The design of the narrow aisle pallet racking setup in such environments may incorporate sealed bearing points and consider the rack structure’s role in managing dust accumulation. Furthermore, steel expands and contracts with temperature. In regions with extreme daily temperature swings, engineering calculations for the narrow aisle pallet racking setup must include thermal expansion joints in long runs of racking to prevent stress buildup and potential distortion that could misalign automated systems.

For Seismically Active Zones (Parts of Latin America, East Asia):

Safety is paramount. A narrow aisle pallet racking setup in these areas must be designed to relevant seismic codes. This involves using upright frames with higher ductility ratings, incorporating specialized seismic bracing that can absorb and dissipate energy, and designing secure load containment features. These enhancements are integrated without compromising the clear aisle widths required for automation, demanding sophisticated engineering expertise.

The Financial Rationale: Quantifying the Return on a Precision Investment

The initial capital outlay for a high-specification, automation-ready narrow aisle pallet racking setup is undeniably higher than for a basic storage system. However, the total cost of ownership (TCO) and the return on investment (ROI) tell a different story. Justifying this investment requires a holistic view of both tangible and intangible benefits.

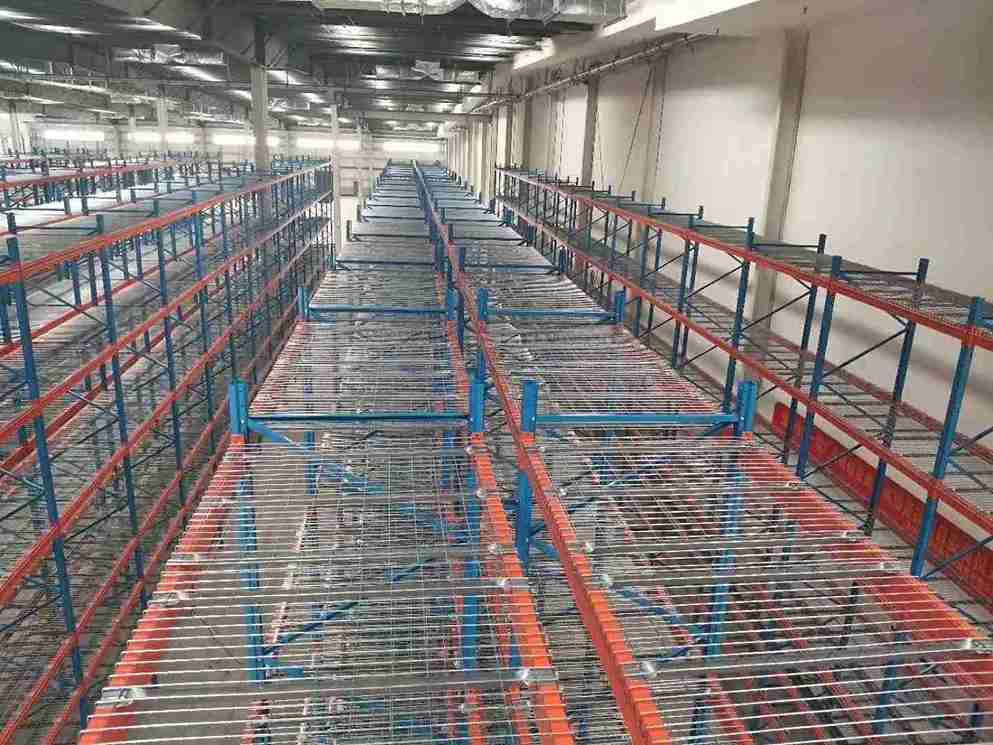

Density and Throughput Gains: The primary advantage of a well-executed narrow aisle pallet racking setup is dramatically increased storage density. By reducing aisle widths to the minimum required for machines (often 1.6m or less, compared to 3m+ for man-down forklifts), usable storage volume can increase by 25-40%. This directly defers or eliminates the need for costly warehouse expansion. Furthermore, automated systems operating within a precision narrow aisle pallet racking setup can achieve significantly higher, more consistent throughput rates than manual operations, especially over multiple shifts.

Elimination of Future Retrofit Costs: Perhaps the most powerful financial argument is the avoidance of future obsolescence. Retrofitting a standard racking system to accommodate automation is a prohibitively expensive and disruptive endeavor. It often requires a complete warehouse shutdown, disassembly of existing racking, and potentially costly reinforcements to the building structure. The cost of such a retrofit can easily exceed 50-100% of the original racking investment. Choosing an automation-ready narrow aisle pallet racking setup from the outset is a capital-preserving strategy.

Operational Efficiency and Damage Reduction: Precision begets efficiency. An AGV operating in a perfectly aligned narrow aisle pallet racking setup experiences fewer navigation errors, stops, and product misplacements. This maximizes uptime and throughput. Additionally, machine-precise handling drastically reduces product damage caused by forklift impacts. It also minimizes damage to the racking system itself, lowering long-term maintenance costs and extending the asset’s lifecycle. The reduction in product loss and racking repair alone can justify a portion of the initial premium.

A Phased Implementation Roadmap: From Vision to Operational Reality

Deploying a complex, integrated system requires a disciplined, phased approach. The following roadmap outlines the journey from initial concept to a fully operational, automated storage environment centered on a superior narrow aisle pallet racking setup.

Stage 1: In-Depth Discovery and Feasibility Analysis (Weeks 1-4)

This foundational stage involves a deep analysis of the client’s operational data: SKU profiles, pallet dimensions, inventory turnover (ABC analysis), and peak throughput requirements. A comprehensive site survey is conducted, including laser scanning of the building and precise floor flatness measurement (to FF/FL standards). This data fuels preliminary capacity modeling and ROI projections for the proposed narrow aisle pallet racking setup, ensuring the project’s strategic and financial viability.

Stage 2: Collaborative Design and Technical Specification (Weeks 5-10)

Here, the conceptual plan is transformed into detailed engineering. Joint workshops with the automation partner finalize all interface specifications. The complete technical package for the narrow aisle pallet racking setup is defined: steel grades, connection types, safety factors, and all critical tolerances. The digital twin is refined, and the master integration blueprint, governing how the racking, AGVs, and WMS will interact, is signed off.

Stage 3: Precision Fabrication and Quality Assurance (Weeks 11-16)

Components for the narrow aisle pallet racking setup are manufactured in a controlled factory environment. Rigorous quality control checks are performed at multiple stages, verifying dimensions, weld integrity, and coating thickness. Critical sub-assemblies may be pre-built and checked before shipment. This off-site precision work is crucial for ensuring the quality that will be required during the efficient on-site installation.

Stage 4: Staged Installation and Live Integration (Weeks 17-22)

On-site work follows the “Golden Aisle” protocol. After the benchmark aisle is built and tested with live AGVs, the full installation proceeds in a staged manner. This phased build-out often allows sections of the warehouse to remain operational, minimizing business disruption. Installation teams work with laser guidance tools to ensure the narrow aisle pallet racking setup is erected to the specified tolerances. Concurrently, the automation team begins deploying and calibrating the AGV fleet in completed zones.

Stage 5: System-Wide Calibration, Training, and Handover (Weeks 23-24)

The final stage involves system-wide performance testing and fine-tuning. AGVs execute full workflow cycles across the entire narrow aisle pallet racking setup. The client’s operations and maintenance teams undergo comprehensive training on both the physical racking system and the integrated control software. The project concludes with the formal handover of all documentation, digital models, and system management protocols, empowering the client to operate and maintain their new, future-proof asset effectively.

Conclusion: Building the Unshakeable Foundation for Logistics Growth

In the competitive landscape of global and regional supply chains, warehouse infrastructure is a strategic determinant of success. For businesses in high-growth emerging markets, the decision to invest in a precision-engineered, automation-ready narrow aisle pallet racking setup is a decisive step toward securing long-term operational superiority. This approach moves beyond simple commodity purchasing into the realm of strategic capital investment. It is an investment in a flexible, high-density, and intelligent storage spine that not only solves today’s capacity challenges but also seamlessly absorbs tomorrow’s technological advancements.

The journey to implementing such a system demands expertise, collaboration, and a commitment to precision at every stage—from initial design and component fabrication to integration and calibration. The result, however, is a transformative asset: a warehouse that operates with higher efficiency, greater reliability, and inherent scalability. By prioritizing a foundational narrow aisle pallet racking setup built for the future, companies do not just store inventory; they activate a powerful engine for growth, resilience, and enduring market competitiveness.

Frequently Asked Questions (FAQs)

1. How does the design of a narrow aisle pallet racking setup differ for a fully automated system versus one that will use manned narrow-aisle reach trucks?

While both systems aim for space density, the design priorities diverge significantly. A setup for manned reach trucks includes considerations for operator visibility, slightly wider aisles for human error margins, and may use different overhead guidance systems. An automation-ready narrow aisle pallet racking setup prioritizes machine precision: tighter tolerances on every dimension, stricter floor flatness requirements, integrated location markers for AGV scanners, and structural rigidity to handle consistent, precise contact from automated vehicles. The aisle width is calculated down to the millimeter based on the AGV’s kinematic profile, not a human operator’s comfort zone.

2. What are the most common pitfalls or oversights when companies attempt to plan a narrow aisle pallet racking setup for future automation without expert guidance?

Common pitfalls include: underestimating the importance of floor flatness, leading to costly corrections later; specifying racking with insufficient load beam rigidity, causing deflection that confuses AGV fork sensors; failing to coordinate the racking layout with the AGV’s navigation system type (e.g., not planning for reflector placement); overlooking the need for consistent, machine-readable location identification on every pallet position; and not building in adequate service access lanes for maintaining both the racking and the AGVs without shutting down entire aisles.

3. For a brownfield site (existing warehouse), what are the key feasibility checks before committing to an automation-ready narrow aisle pallet racking setup retrofit?

The critical feasibility checks involve: a detailed laser scan and floor flatness survey to determine if the slab can meet FF/FL 50/40+ standards without prohibitive corrective work; a structural analysis of the building itself to ensure it can handle the potential increased point loads and overall weight of a denser storage system; a thorough review of clear heights and obstructions (sprinklers, lighting, HVAC) to ensure compatibility with the desired racking height; and an analysis of existing workflows to plan a phased installation that minimizes operational disruption during the transition.

4. How does the choice of pallet type (wooden, plastic, metal, slip sheets) influence the design specifications of a narrow aisle pallet racking setup intended for automation?

Pallet type directly impacts the narrow aisle pallet racking setup design. Non-standard or damaged wooden pallets can vary in dimensions and bottom board configuration, potentially jamming in an automated system. Automation thrives on consistency. The racking design, particularly beam openings and pallet support rails, must be optimized for the specific pallet dimensions and bottom structure that will be used 100% of the time in the automated zone. Plastic and metal pallets offer more consistency. Slip sheets require entirely different handling attachments on the AGV and corresponding support systems within the racking, which must be designed in from the outset.

5. Can different zones within the same warehouse have different types of narrow aisle pallet racking setups (e.g., one zone for fast-moving SKUs with AGVs, another for slow-moving with manned access)? How is this managed?

Absolutely, this hybrid approach is common and practical. It is managed through clear physical and digital zoning. Physically, the two narrow aisle pallet racking setups may have different aisle widths and may be separated by a cross-aisle. Digitally, the WMS is configured to direct automated vehicles only to racks in the AGU zone and to assign storage locations accordingly. The racking in the manual zone is designed to the (slightly less stringent) specifications for manned equipment, potentially offering cost savings where full automation is not justified. The key is seamless boundary management within the WMS to ensure efficient material flow between zones.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com