📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Unlock 80% More Storage Space Without Moving: The Definitive Guide to Multi-Tier Mezzanine Racking

For logistics managers, warehouse operators, and business owners across the booming industrial landscapes of Southeast Asia, the Middle East, Africa, and Latin America, a silent crisis is unfolding. It’s not a crisis of demand, but of space. Orders are pouring in, inventory is accumulating, but the four walls of the warehouse remain fixed. The traditional solution—leasing or building a new facility—is often a budget-busting, operationally disruptive nightmare.

However, a powerful and profoundly cost-effective multi-tier mezzanine racking strategy is enabling forward-thinking companies to shatter these spatial constraints. This comprehensive guide explores how leveraging this engineered storage solution is the most intelligent way to maximize storage in your existing warehouse, transforming underused vertical air into a dynamic, multi-level operational asset. This isn’t about cramming in more shelves; it’s about architecting a new dimension for workflow and growth.

The Untapped Potential: Your Warehouse’s Vertical Cube is a Goldmine

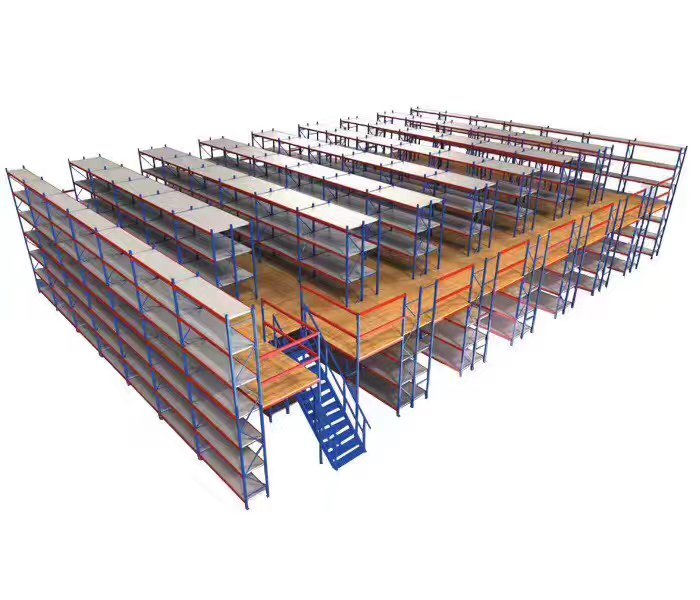

A walk through a typical warehouse reveals a common sight: crowded aisles, shelves bursting at the seams, and a frantic scramble to find a spare square meter. Yet, above this chaos, lies a vast, unused volume—often 8, 10, or even 12 meters of pure potential. This vertical cube represents the most overlooked asset on the balance sheet. A professionally engineered multi-tier mezzanine racking system is the key to unlocking this asset.

It is a structural platform that creates two, three, or even more fully functional levels within the existing building envelope. This approach effectively doubles or triples the usable floor area, converting a single-level, sprawling operation into a compact, multi-story storage and work facility. For companies in land-scarce markets like Vietnam or Chile, investing in a multi-tier mezzanine racking system is not just an option; it’s a strategic imperative for cost-effective expansion.

Deconstructing the Solution: What is Multi-Tier Mezzanine Racking?

It is critical to distinguish an industrial-grade multi-tier mezzanine racking system from simple retail shelving. This is a custom-engineered structural solution designed for heavy loads, constant use, and absolute safety. Understanding its components is the first step in appreciating its value.

The Anatomy of a Heavy-Duty Multi-Tier Mezzanine Racking System

Every robust multi-tier mezzanine racking installation is a symphony of integrated components:

Upright Frames: These are the vertical columns, the backbone of the system. Their steel gauge, depth, and bracing are calculated by structural engineers to transfer the entire load of the system, its contents, and operational forces safely to the warehouse floor.

Primary and Secondary Beams: Primary beams form the main support grid, locking into the upright frames. Secondary beams cross between them, creating the decking support structure. The connection between these beams is a critical point of engineering, often utilizing patented safety locks.

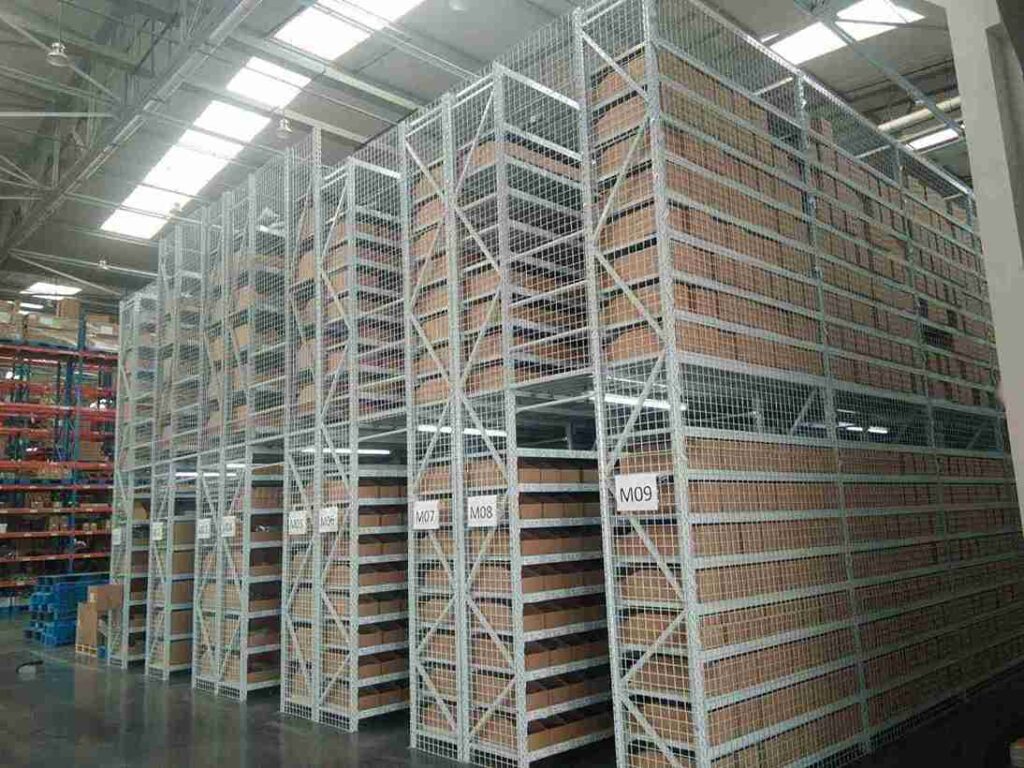

Decking: The Functional Surface: The choice of decking defines the application of the multi-tier mezzanine racking. Heavy-duty steel mesh allows for light penetration and air circulation, ideal for general storage. Solid steel plate is used for small parts or to contain spills, while pressure-treated plywood can be a cost-effective option for light-duty office spaces built on a mezzanine.

Access and Safety Systems: This is where operational safety is cemented. Industrial staircases with correct pitch and landings, safety gates that prevent falls from access openings, and perimeter guardrails are non-negotiable components of a professional multi-tier mezzanine racking installation.

Configuring for Your Workflow: Types of Multi-Tier Mezzanine Racking

There is no one-size-fits-all approach. The configuration of a multi-tier mezzanine racking system is dictated by its intended use:

Shelving-Supported Mezzanines: In this highly efficient design, the storage racking itself—be it selective, pallet flow, or drive-in—acts as the primary support for the multi-tier mezzanine racking deck above. This is the ultimate space-saving solution for maximizing pure storage density.

Free-Standing Structural Mezzanines: These are independent structural platforms built within the facility. They offer unparalleled flexibility, allowing companies to place offices, packaging lines, assembly stations, or even canteens on the upper levels of the multi-tier mezzanine racking, effectively separating functions without physical walls.

Rolling Mezzanine Systems: For facilities that require flexibility in aisle access, a rolling multi-tier mezzanine racking system sits on rails, allowing entire aisles to be opened or closed as needed, though this is a more specialized application.

The Compelling Economics: Why Multi-Tier Mezzanine Racking is the Most Cost-Effective Choice

When the conversation turns to expansion, the immediate thought is cost. A detailed financial analysis consistently reveals that a multi-tier mezzanine racking system offers a superior return on investment compared to physical relocation or building an extension.

A Direct Cost Comparison: Mezzanine vs. Brick-and-Mortar

Consider a distribution center in Indonesia facing a 50% capacity shortfall. Leasing an additional warehouse of equal size seems like the logical step, but the true costs are staggering:

Recurring Rental Costs: Prime logistics real estate commands a premium, creating a permanent, escalating operational expense.

Duplicate Overheads: A second facility doubles the cost of utilities, security, insurance, and property taxes.

Operational Inefficiency: Running two separate locations inflates transportation costs between sites, increases administrative complexity, and often leads to higher labor costs.

Capital Outlay for Duplicate Equipment: The new facility requires its own racking, material handling equipment (MHE), and IT infrastructure.

In stark contrast, a multi-tier mezzanine racking system is a one-time capital investment that enhances the value of the property you already own. It consolidates operations, slashes duplicate overheads, and dramatically improves workflow efficiency. The Return on Investment (ROI) for a multi-tier mezzanine racking project is frequently measured in months, not years, precisely because it eliminates a vast array of recurring external costs.

Strategic Deployment: Where to Implement Multi-Tier Mezzanine Racking for Maximum Impact

The versatility of the multi-tier mezzanine racking system is a core part of its value proposition. Its applications extend far beyond simple bulk storage.

Revolutionizing Bulk and Slow-Moving Inventory Storage

Dedicate the upper levels of a multi-tier mezzanine racking system to slower-moving SKUs, raw materials, or seasonal items. This strategic move frees up the coveted, easily accessible ground-level space for high-velocity picking, streamlining the entire order fulfillment process.

Engineering High-Density Order Picking Modules

Transform an entire multi-tier mezzanine racking structure into a multi-level pick module. By consolidating thousands of SKUs into a compact vertical footprint, pickers can cover immense ground with minimal travel. This direct reduction in picker walk time is one of the most significant labor-saving benefits a multi-tier mezzanine racking system can deliver, a critical factor in tight labor markets.

Expanding Production and Value-Added Services

In manufacturing and assembly plants, the upper deck of a multi-tier mezzanine racking system provides ideal space for kitting, light assembly, quality control stations, or rework areas. This physically separates production from storage, reducing congestion on the main floor and creating a more organized, efficient, and safer workflow.

The Automation Nexus: Integrating Multi-Tier Mezzanine Racking with Smart Technology

The true potential of a multi-tier mezzanine racking system is fully realized when it becomes an integrated node in an automated ecosystem. This is where the solution evolves from a static storage structure into a dynamic logistics hub.

Seamless Synergy with AGVs and Autonomous Mobile Robots

A modern multi-tier mezzanine racking installation can be designed with integrated Vertical Reciprocating Conveyors (VRCs) or pallet lifts that serve as automated hand-off points for an AGV fleet. An AGV can autonomously deliver a pallet to the lift, which then transports it to a designated level on the multi-tier mezzanine racking. From there, another AGV or a manual picker can complete the storage or retrieval process. This creates a continuous, “lights-out” material handling loop that operates 24/7.

Leveraging Conveyor and Sortation Systems

For case and parcel handling, conveyors can be seamlessly integrated to connect different levels of a multi-tier mezzanine racking system. Cartons can be automatically inducted onto a conveyor, routed to the correct mezzanine level for order consolidation, and then sent to a sortation system for shipping. This level of integration is transformative for e-commerce and parcel distribution centers, where speed and accuracy are paramount.

Safety and Compliance: The Non-Negotiable Foundation of Every Project

The introduction of a multi-level structure into a busy industrial environment necessitates an uncompromising focus on safety. A reputable provider engineers safety into the DNA of the multi-tier mezzanine racking system.

Professional Structural Engineering: Every multi-tier mezzanine racking design must be stamped by a qualified structural engineer, ensuring it can handle the specified live (movable loads) and dead (permanent loads) weights, and is compliant with local building codes and seismic standards, which are particularly crucial in regions like the Philippines and Peru.

Clear Load Capacity Signage: Every bay and deck of the multi-tier mezzanine racking must be clearly and permanently marked with its maximum uniform and point load capacities to prevent dangerous overloading.

Comprehensive Fall Protection: Full perimeter guarding with robust handrails and toe-kicks, along with self-closing safety gates at all access points, are mandatory features of a safe multi-tier mezzanine racking installation.

Certified Installation: The best-engineered multi-tier mezzanine racking system can be compromised by poor installation. Professional, certified installers ensure that every component is assembled correctly and every bolt is torqued to specification.

The Implementation Roadmap: A Partnership from Concept to Operation

Acquiring a multi-tier mezzanine racking system is a collaborative process, not a simple transaction. A professional provider guides clients through a meticulous, multi-stage journey.

Comprehensive Consultation and Site Survey: Experts visit the facility to conduct laser scans, measure clearances, assess floor conditions, and, most importantly, understand the client’s unique operational workflow, pain points, and growth projections.

Customized 3D Design and Engineering: Using the data collected, engineers create a detailed 3D model of the proposed multi-tier mezzanine racking system. This model allows the client to take a virtual walkthrough of their future operation, ensuring the design meets all functional requirements before fabrication begins.

Precision Fabrication and Quality Control: The multi-tier mezzanine racking components are fabricated in a controlled factory environment using state-of-the-art machinery. Each element undergoes rigorous quality checks to ensure dimensional accuracy and structural integrity.

Professional Installation and Commissioning: An experienced installation team executes the project on-site with minimal disruption to ongoing operations. Upon completion, the system is fully inspected and certified, and client staff are trained on its safe use.

Ongoing Support and Maintenance: A true partner offers ongoing support, from providing spare parts to conducting periodic safety inspections of the multi-tier mezzanine racking system to ensure its long-term performance and reliability.

Conclusion: The Future of Warehouse Expansion is Vertical

The paradigm of solving storage crises through horizontal sprawl is obsolete. It is financially draining, operationally inefficient, and environmentally unsustainable. The strategic path forward for any logistics-dependent business in growth markets is to look upward. By investing in a custom-engineered, cost-effective multi-tier mezzanine racking system, companies are not merely purchasing steel; they are investing in a smarter, more resilient, and highly scalable operational model. This approach turns spatial constraints into a competitive advantage, paving the way for sustained growth without the prohibitive costs of physical expansion. The ceiling is no longer a limit; it is the foundation of your warehouse’s future.

Frequently Asked Questions About Multi-Tier Mezzanine Racking

1. How is the load capacity for a specific multi-tier mezzanine racking project determined?

The load capacity is a result of a detailed engineering analysis. Factors include the weight and distribution of stored goods, the presence of any heavy equipment like pallet jacks, the frequency of load movement, and the required safety factors as per local building codes. Engineers calculate both the uniform load (across the entire deck) and point loads (concentrated in a small area) to specify the exact capacity of the multi-tier mezzanine racking.

2. Can an existing multi-tier mezzanine racking system be expanded or reconfigured later?

Yes, one of the key advantages of a free-standing structural multi-tier mezzanine racking system is its inherent scalability and flexibility. With proper initial planning, systems can often be extended in length, width, or even height, or have their deck layouts reconfigured to accommodate changing business needs. This protects the long-term value of the investment.

3. What are the critical fire safety and building code considerations for a multi-tier mezzanine racking installation?

This is a paramount concern. A multi-tier mezzanine racking structure can interfere with a building’s existing sprinkler system and smoke detection coverage. A professional provider will always conduct a review that includes ensuring the new design meets all fire safety codes, which typically involves redesigning the sprinkler layout to provide adequate coverage on all newly created levels and ensuring clear paths for egress.

4. What is the typical lead time from project initiation to operational handover for a multi-tier mezzanine racking system?

A standard, moderately complex multi-tier mezzanine racking project typically has a timeline of 10 to 14 weeks. This encompasses 2-3 weeks for detailed design and engineering, 5-7 weeks for fabrication, and 2-4 weeks for on-site installation. Larger or highly customized projects may have longer lead times.

5. What documentation is provided upon completion of a multi-tier mezzanine racking installation?

A reputable supplier provides a comprehensive documentation package. This includes “as-built” CAD drawings, a full set of structural calculations stamped by a professional engineer, material certifications, a load capacity plaque for the structure, and a final project certification. This documentation is essential for insurance purposes, future audits, and any potential resale of the facility.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com