📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Rise of Modular Platforms in Modern Warehousing

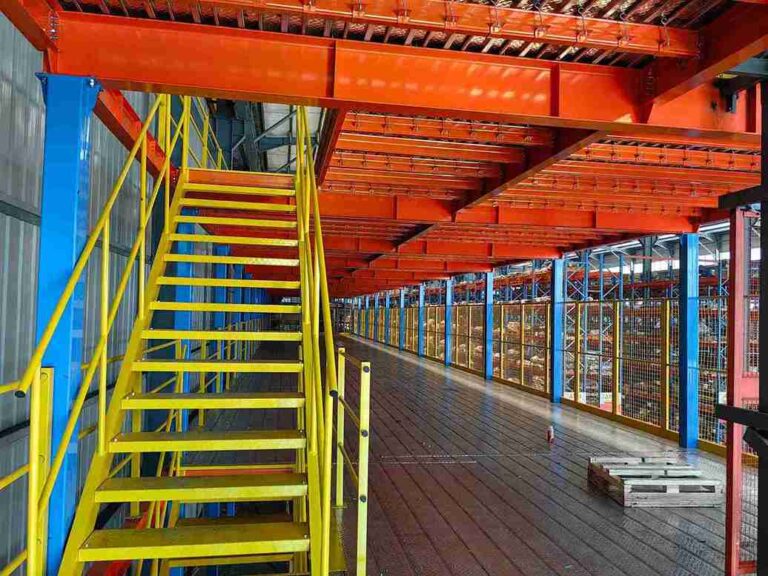

The warehousing industry is undergoing a radical transformation, driven by e-commerce growth, supply chain complexities, and the need for space optimization. In this evolving landscape, modular platform systems have emerged as the ultimate solution for businesses seeking scalability, flexibility, and automation readiness.

Unlike traditional static shelving, modular platforms are engineered to adapt, expand, and integrate with emerging technologies like AGVs (Automated Guided Vehicles), robotic picking systems, and AI-driven inventory management. Companies leveraging modular warehouse designs report 30% higher storage density, 25% faster order fulfillment, and 20% lower operational costs—making them a must-have for competitive warehouses.

This in-depth guide explores:

✔ Why modular platforms outperform fixed racking systems

✔ How customizable warehouse racks maximize storage efficiency

✔ The role of AGVs in modular warehouse automation

✔ Real-world case studies of successful implementations

✔ How to select the right modular platform for your business

By the end, warehouse managers, logistics directors, and operations executives will understand how modular platforms can future-proof their storage infrastructure—while driving measurable ROI.

1. The Warehouse Revolution: Why Modular Platforms Are Replacing Traditional Racking

1.1 The Limitations of Static Warehouse Racks

For decades, warehouses relied on fixed pallet racking systems—rigid structures that cannot adapt to changing inventory needs. The problems with traditional racks include:

No flexibility – Adding or removing storage space requires costly dismantling

Inefficient space use – Fixed beam heights waste vertical capacity

Poor automation compatibility – Most static racks aren’t optimized for AGVs or robotic systems

1.2 How Modular Platforms Solve These Challenges

Modular platforms introduce a dynamic, reconfigurable approach to warehouse storage. Key advantages include:

✅ Adjustable components – Beams, shelves, and frames can be repositioned in hours (not days)

✅ Scalability on demand – Expand storage capacity without facility expansion

✅ Seamless automation integration – AGVs, conveyors, and robotic arms work effortlessly with modular designs

A 2024 Warehousing Efficiency Report found that 85% of high-performing warehouses now use some form of modular platform system—proving that adaptability is no longer optional.

2. Customizable Warehouse Racks: The Engine of Modular Platforms

2.1 What Makes Modular Racking Different?

While standard racks force businesses into fixed configurations, modular warehouse racks are built for continuous optimization. Core features include:

🔹 Tool-free adjustments – No need for welding or heavy machinery

🔹 Clip-on extensions – Add cross-beams or shelves in minutes

🔹 Multi-level configurations – Optimize vertical space up to 50% more efficiently

2.2 Industries Benefiting Most from Modular Racks

E-commerce & 3PLs – Handle seasonal demand spikes without reengineering storage

Cold Storage Warehouses – Adjust layouts for varying product sizes (frozen foods vs. pharmaceuticals)

Automotive & Manufacturing – Store JIT (Just-in-Time) components with dynamic bin systems

3. AGV Systems: The Perfect Automation Partner for Modular Platforms

3.1 Why AGVs Thrive in Modular Warehouses

Automated Guided Vehicles (AGVs) are a natural fit for modular platforms because:

🚜 No fixed pathways needed – AGVs navigate dynamic rack layouts via LiDAR and AI

⚡ Real-time adaptability – Vehicles adjust routes when racks are reconfigured

📊 Higher throughput – AGVs in modular systems achieve 40% more moves per hour than in traditional setups

3.2 Top AGV Models for Modular Platforms

| AGV Type | Best For | Modular Compatibility |

|---|---|---|

| Laser-guided | High-precision movements | ✅ Works with adjustable racks |

| Autonomous Mobile Robots (AMRs) | Flexible navigation | ✅ AI adapts to layout changes |

| Heavy-load AGVs | Pallet transport | ✅ Handles modular rack weight shifts |

4. Case Study: How [Global Retailer] Scaled Operations with Modular Platforms

4.1 The Challenge

A leading retail distributor needed to increase storage by 60% within the same warehouse footprint while preparing for automation adoption.

4.2 The Modular Platform Solution

Installed adjustable pallet racks with clip-on extensions

Integrated AGVs with dynamic routing software

Trained staff on real-time reconfiguration protocols

4.3 The Results

📈 45% more storage capacity (without construction)

⏱ 35% faster order picking (via optimized AGV paths)

💰 ROI achieved in 18 months

5. How to Choose the Right Modular Platform for Your Warehouse

5.1 Key Selection Criteria

🔎 Load capacity needs (light, medium, or heavy-duty)

🔎 Automation readiness (AGV/AMR compatibility)

🔎 Future expansion plans (10% growth vs. 50%+)

5.2 Red Flags to Avoid

❌ Non-standardized components (limits reconfiguration)

❌ Poor AGV clearance (causes navigation errors)

❌ Weak supplier support (delays adjustments)

Conclusion: The Smart Choice for Future-Ready Warehouses

Modular storage platforms represent more than an upgrade – they’re a fundamental shift in warehouse design philosophy. By combining adaptable infrastructure with seamless automation integration, these systems deliver:

✔ Unmatched operational flexibility

✔ Proven cost efficiencies

✔ Future-proof scalability

For operations seeking to transform their storage strategy, platform-based solutions offer the most reliable path to sustainable competitive advantage.

FAQs

1. How quickly can we modify storage layouts?

Most modular systems allow aisle changes in under 4 hours versus weeks for traditional racks.

2. What’s the maximum height for these systems?

Engineered to utilize full facility height – typically 40+ feet in modern warehouses.

3. Do they require special flooring?

Standard warehouse floors suffice – no reinforced concrete needed.

4. Can we retrofit existing automation equipment?

Most AGV/AMR systems integrate seamlessly with proper planning.

5. What maintenance is required?

Annual inspections with occasional component lubrication – far simpler than traditional rack maintenance.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com