📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

In the rapidly evolving world of logistics and warehousing, businesses are constantly seeking smarter, more adaptable storage solutions that can keep up with automation. The modular platform system has emerged as the backbone of modern warehousing, offering unmatched flexibility, scalability, and durability—especially in facilities that rely on AGVs (Automated Guided Vehicles), robotic forklifts, and automated storage and retrieval systems (AS/RS).

This in-depth guide explores why modular platform systems are revolutionizing automated warehousing, how they outperform traditional racking, and what key factors businesses must consider when integrating them. Whether optimizing an existing warehouse or designing a new automated facility, this article delivers practical insights, technical benchmarks, and real-world case studies to help decision-makers choose the best modular platform system for their needs.

1. Why Modular Platform Systems Are the Future of Automated Warehousing

1.1 The Limitations of Traditional Static Racking

Fixed shelving and welded racking systems struggle with:

Inflexible layouts that can’t adapt to changing inventory profiles.

Limited AGV/AMR compatibility, forcing costly retrofits.

Lower weight capacities, restricting high-density storage.

A modular platform system solves these issues by offering:

Reconfigurable designs that evolve with business needs.

Optimized pathways for automated vehicles (AGVs, forklifts, conveyors).

Heavy-duty load ratings (up to 15,000 lbs per platform) for industrial demands.

1.2 How AGVs and Robotics Demand Modular Storage Solutions

Automation is reshaping warehousing, and modular platform systems are the ideal foundation because they:

Support dynamic slotting, allowing AI-driven inventory optimization.

Feature standardized docking points for seamless robotic integration.

Enable rapid reconfiguration when automation fleets expand.

2. Core Advantages of a High-Performance Modular Platform System

2.1 Unmatched Flexibility & Scalability

Unlike fixed racking, a modular platform system can be:

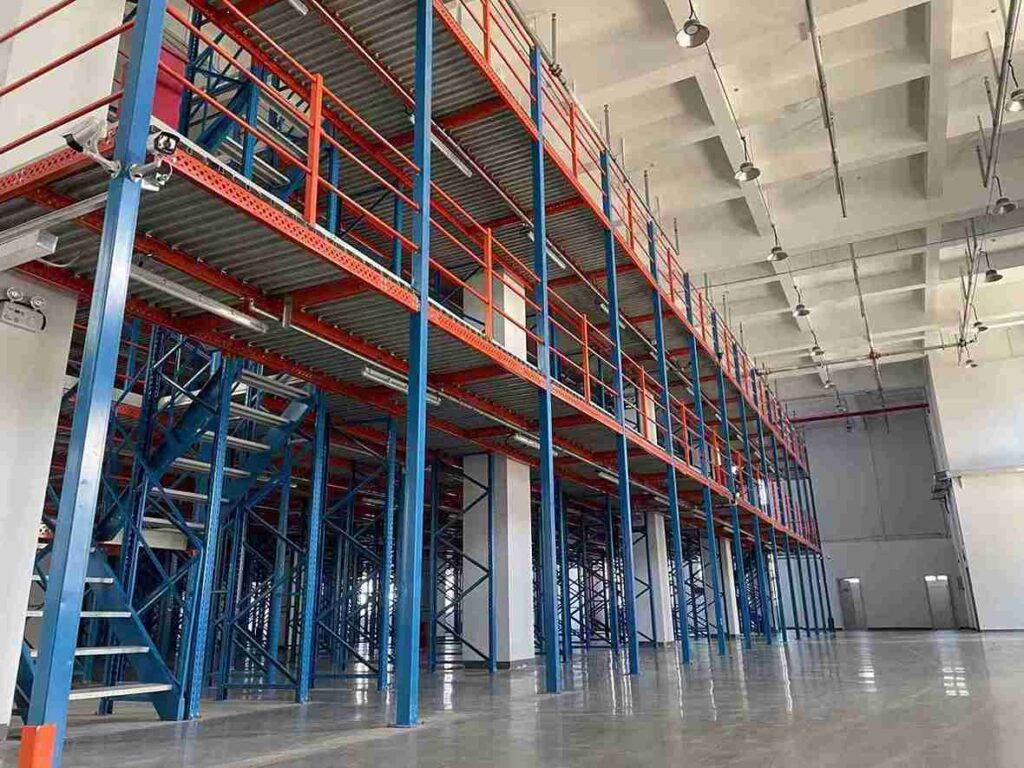

Expanded vertically or horizontally without structural modifications.

Reassembled in hours (vs. days for traditional systems).

Adapted for new automation tech (e.g., drone inventory scanning).

2.2 Superior Durability for Heavy-Duty Operations

Top-tier modular platform systems use:

Hot-dip galvanized steel frames (50+ year corrosion resistance).

Bolt-together assembly (no welding, reducing long-term fatigue).

Engineered decking (slip-resistant, impact-resistant surfaces).

2.3 Seamless AGV & Robotic Integration

A well-designed modular platform system includes:

Low-profile decks (6-8″ height) for smooth AGV pallet access.

Precision alignment guides for automated forklifts.

Embedded RFID zones for real-time inventory tracking.

3. Key Applications of Modular Platform Systems in Modern Warehousing

3.1 High-Density Automated Pallet Storage

Narrow-aisle AGV-compatible layouts (as little as 5 ft clearance).

Automated pallet shuttles working within modular platform structures.

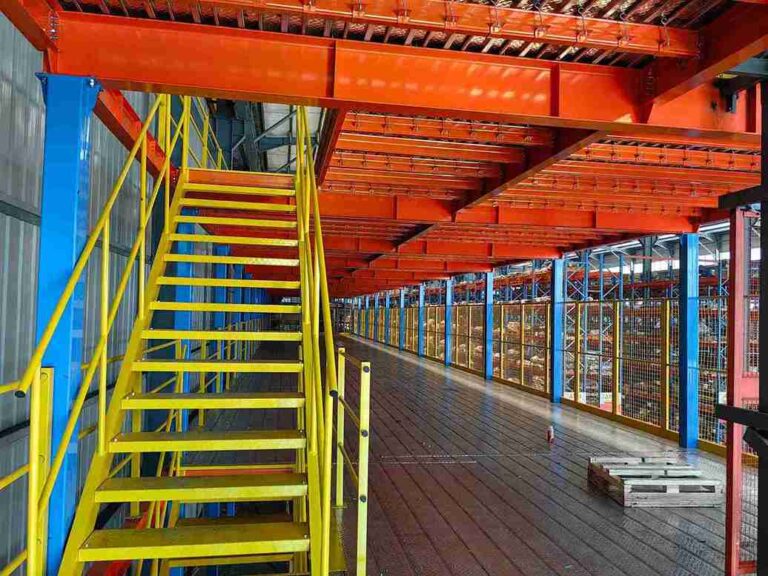

3.2 Multi-Level Automated Order Fulfillment

Robotic pick stations on elevated modular platforms.

Conveyor-integrated decks for high-speed sorting.

3.3 Specialized Environments (Cold Storage, Hazardous Materials)

Stainless steel modular platforms for pharmaceuticals.

Explosion-proof designs for battery/chemical storage.

4. How to Select the Right Modular Platform System

4.1 Critical Specifications to Evaluate

Static vs. dynamic load ratings (robotic vs. manual handling).

Floor load capacity (PSF requirements for automation).

4.2 Future-Proofing for Next-Gen Automation

IoT-enabled platforms (sensors for predictive maintenance).

Modular expansion slots for future AGV fleet growth.

4.3 Cost Analysis: Modular vs. Traditional Racking

ROI case study: A 3PL reduced labor costs by 60% after adopting modular platform systems.

5. Installation & Optimization Strategies

5.1 Pre-Installation Planning for Automation

3D simulation of AGV traffic flow.

Safety compliance (OSHA, FEM, RMI standards).

5.2 Long-Term Performance Maintenance

Self-lubricating joints for zero downtime.

AI-driven wear monitoring in smart warehouses.

6. The Future: Modular Platforms in Industry 4.0

Self-adjusting layouts via AI optimization.

Swarm robotics for autonomous reconfiguration.

Conclusion

A modular platform system isn’t just an upgrade—it’s a strategic investment in automated warehousing efficiency. By choosing the right system, businesses gain higher storage density, faster order processing, and seamless automation integration.

For operations leveraging AGVs, robotic forklifts, or AS/RS, modular platforms are the only long-term solution.

FAQs

Q1: Can modular platforms handle fully automated “lights-out” warehouses?

Yes, advanced modular platform systems support 100% robotic operations with AI-driven load balancing.

Q2: How quickly can a modular system be reconfigured?

Most modular platform systems allow same-day adjustments with simple tool-free modifications.

Q3: Are these systems suitable for outdoor automated logistics yards?

Yes, weather-resistant modular platforms with galvanized frames excel in outdoor automation hubs.

Q4: What’s the typical lifespan of a high-end modular platform system?

25+ years, far exceeding traditional racking.

Q5: Can I retrofit my current racks into a modular AGV-compatible system?

Partial retrofits work, but full automation optimization requires purpose-built modular platforms.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com