📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Strategic Imperative: Mastering Modular Platform Handrail Design for a Safer, More Agile Warehouse

In the high-stakes world of modern logistics and manufacturing, the platform handrail is far more than a simple safety barrier. For executives and managers overseeing mezzanine projects and Automated Storage and Retrieval Systems (ASRS), it represents a critical intersection of personnel safety, operational efficiency, and financial prudence. The conventional approach—custom-fabricating and welding handrails on-site—has long been a source of project delays, budget overruns, and frustrating inflexibility. However, a profound shift is underway, driven by the principles of intelligent engineering and strategic foresight.

This shift is centered on the comprehensive adoption of an advanced modular platform handrail design. This philosophy transcends the product itself, advocating for a safety infrastructure that is inherently adaptable, economically superior, and seamlessly integrated with the dynamic nature of contemporary warehouse operations. This definitive guide delves into the multifaceted advantages of a sophisticated modular platform handrail design, illustrating how it serves as a cornerstone for building not just a compliant facility, but a resilient, efficient, and future-proof enterprise.

It demonstrates how the right modular platform handrail design directly catalyzes faster project completion, a lower total cost of ownership, and an unshakeable safety culture that can adapt to tomorrow’s challenges.

The Unsustainable Legacy: Why Traditional Handrail Systems Are a Bottleneck to Growth

To fully appreciate the revolution brought by a superior modular platform handrail design, one must first understand the profound limitations and hidden costs entrenched in traditional methods. The welded handrail, while once the standard, now acts as an anchor, holding back operational agility and inflating lifecycle expenses.

The Installation Quagmire: A Drain on Time and Resources

The process of installing traditional handrails is a study in operational inefficiency. It transforms a segment of the warehouse into a protracted construction site, characterized by a cascade of logistical and financial burdens. The requirement for certified welders, a specialized and often costly trade, introduces immediate scheduling dependencies and labor cost premiums.

The hot work process itself—with its mandatory permits, fire watch personnel, and containment of sparks and fumes—creates significant safety overhead and disrupts adjacent workflows for extended periods. This complex, multi-trade process ensures that the installation timeline for a simple safety component stretches into weeks, directly delaying the commissioning of critical assets like ASRS and mezzanine platforms. This delay represents a substantial opportunity cost, as revenue-generating operations are put on hold.

Operational Rigidity: The High Cost of Inflexibility

Perhaps the most significant drawback of a welded system is its permanence in an impermanent world. Warehouses are not static entities; they are dynamic ecosystems that constantly evolve. The introduction of new automated conveyor lines, the re-routing of AGVs, or a simple reorganization of processes can render a fixed handrail configuration obsolete. Adapting a welded system to these changes is a punishingly expensive and disruptive endeavor.

It necessitates the same costly trades, the same hot work protocols, and the same operational downtime as the initial installation. This inherent rigidity effectively penalizes continuous improvement and makes operational innovation a financially prohibitive undertaking. The safety system, meant to enable work, instead becomes a barrier to progress.

The Modular Paradigm: Re-engineering Safety for the Modern Warehouse

The modular platform handrail design emerges as the definitive solution to the shortcomings of its predecessor. It is a system-based approach, predicated on precision engineering, standardized components, and bolted assembly. This methodology redefines the safety perimeter from a fixed barrier into a dynamic, adaptable asset.

Deconstructing Excellence: The Anatomy of a Best-in-Class Modular System

A robust modular platform handrail design is characterized by the intelligent engineering of its core components, each playing a vital role in the system’s overall performance, ease of installation, and longevity.

Precision-Engineered Structural Posts: The foundation of any reliable modular platform handrail design lies in its posts. High-caliber systems feature posts manufactured with laser-cut or punched hole patterns, allowing for micro-adjustability in rail height to meet exact specifications. Some advanced designs incorporate an integrated T-slot or channel system, providing unparalleled flexibility for attaching accessories, signage, or wire management systems directly to the safety structure.

High-Strength Rails and Infill Panels: The rails in a superior modular platform handrail design are not simple tubes; they are engineered to interlock securely with the posts via robust, self-locking mechanical fasteners. Infill options—ranging from welded wire mesh for visibility and airflow to solid steel sheets for complete containment—are pre-fabricated to drop seamlessly into place, secured by integrated clips or bolts. This eliminates the need for on-site cutting, fitting, or welding of panels.

The Critical Role of Connection Technology: The heart of a modular platform handrail design is its connection system. High-tensile strength bolts, often with integrated serrated flanges or locking washers, create rigid, vibration-resistant joints. These connections are engineered to withstand the required loads without the brittleness and potential for stress corrosion cracking that can affect welds over time. The result is a joint that is, in many respects, mechanically superior to a weld.

Pre-Engineered Accessories and Gates: A comprehensive modular platform handrail design includes a full suite of compatible, bolt-together accessories. Safety gates, stair railings, and toe-boards are not custom fabrications but standard, off-the-shelf components designed for instantaneous integration with the main handrail run, ensuring a continuous, compliant safety barrier without a single weld.

Quantifying the Advantage: The Direct Link Between Modular Design and Operational KPIs

The transition to a modular platform handrail design is not merely an equipment upgrade; it is a strategic business decision with a direct, positive impact on key performance indicators. The promised benefits of “faster installation and lower cost” are not abstract claims but measurable outcomes.

Achieving Unprecedented Installation Velocity

The efficiency gains realized through a well-executed modular platform handrail design are nothing short of transformative, often reducing installation timelines by 50% to 70%.

The “Kit-of-Parts” Methodology: Every component for the modular platform handrail design arrives on-site pre-engineered, pre-cut, and pre-finished. This eliminates the most time-consuming aspects of the traditional process: manual measurement, cutting, deburring, and fit-up. The installation crew can begin assembly immediately upon unboxing.

Democratization of Labor: By removing the need for welding, the modular platform handrail design dismantles the labor bottleneck. A small team of general laborers, equipped with standard hand tools, can execute the assembly with minimal training. This reduces dependency on high-cost, specialized welders and provides immense scheduling flexibility.

Concurrent Assembly Workstreams: The nature of a modular platform handrail design allows for multiple sections to be assembled in parallel by different teams. There is no linear sequence waiting for a single welder. This parallel processing dramatically compresses the project’s critical path.

Minimized Operational Disruption: Without the hazards of hot work, the installation of a modular platform handrail design can proceed safely in close proximity to active warehouse operations. This means core activities like picking, packing, and shipping can continue unabated, preserving overall facility productivity.

The cumulative effect is a dramatic acceleration of the project timeline. A mezzanine or ASRS project protected by a modular platform handrail design becomes operational and begins generating a return on investment weeks ahead of schedule.

A Deeper Look at Total Cost of Ownership: Beyond the Initial Quote

While the unit cost of materials for a modular platform handrail design may be competitive, its true economic superiority is revealed through a comprehensive analysis of the total cost of ownership (TCO).

Direct Labor Cost Reduction: This is the most immediate and impactful saving. The combination of fewer installation hours and lower labor rates results in a direct and substantial reduction in the total installed cost.

Elimination of Ancillary Expenses: The modular platform handrail design process renders obsolete a host of ancillary costs: hot work permits, fire watch wages, welding gas and consumables, and the cost of renting welding equipment and fume extraction systems.

The Financial Value of Speed: The significantly reduced installation time translates into lower project management overhead and, most importantly, a drastically shortened time-to-value for the entire platform investment. The revenue or efficiency gains from the new space are realized much sooner.

The Transformative Power of Reusability: This is the single greatest financial differentiator of a modular platform handrail design. During a warehouse reorganization, retrofit, or expansion, the entire system can be disassembled and redeployed. Components are not scrapped; they are reused. This ability to adapt without capital reinvestment turns the modular platform handrail design from a consumable expense into a permanent, reconfigurable asset, delivering value through multiple project lifecycles.

Engineered for Certainty: How Modular Design Guarantees Safety and Compliance

A common misconception is that a bolted system is inherently less robust than a welded one. This is a fallacy. A properly engineered modular platform handrail design is subjected to rigorous structural analysis and testing to meet and exceed all relevant international standards, including OSHA 1910.23, ISO 14122, and other local regulations.

Structural Integrity: A Foundation of Engineering Precision

The strength of a world-class modular platform handrail design is derived from computer-aided engineering and quality manufacturing, not from the vagaries of a welder’s skill. Finite Element Analysis (FEA) is used to simulate loads and stresses, ensuring the system can withstand the mandated forces—typically 200 lbs. applied at the top rail in any direction.

The bolted connections are specifically designed with locking mechanisms that resist loosening under the constant vibration induced by AGVs, conveyors, and other machinery. The materials, whether hot-dip galvanized steel or structural-grade aluminum, are selected for their certified mechanical properties and durability.

Tailoring the Solution for Specific Hazard Mitigation

A superior modular platform handrail design is not a monolithic product but a flexible toolkit for addressing a wide spectrum of operational risks.

Heavy-Duty and Impact-Resistant Configurations: For zones with high forklift traffic or adjacent to automated conveyor transfer points, the modular platform handrail design can be specified with reinforced, heavier-gauge posts, double-railed configurations, and solid steel infill panels. These panels are engineered to absorb and dissipate impact energy, protecting both the structural integrity of the handrail and the material handling equipment.

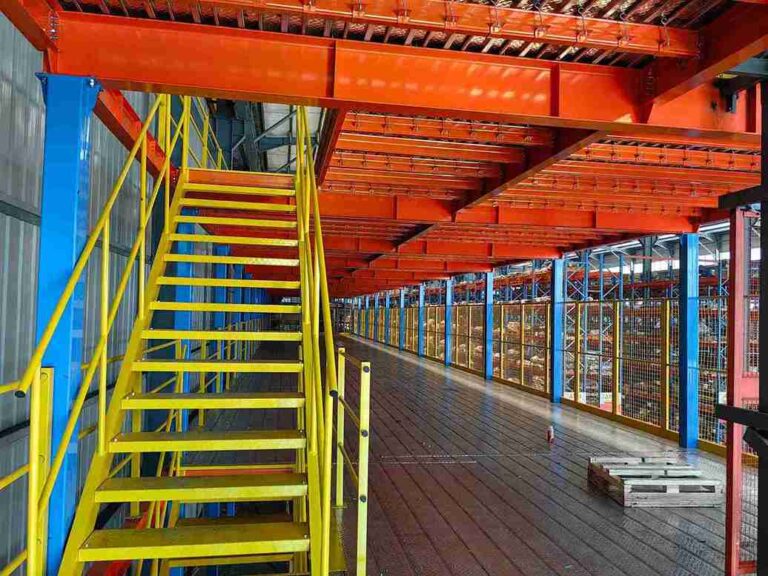

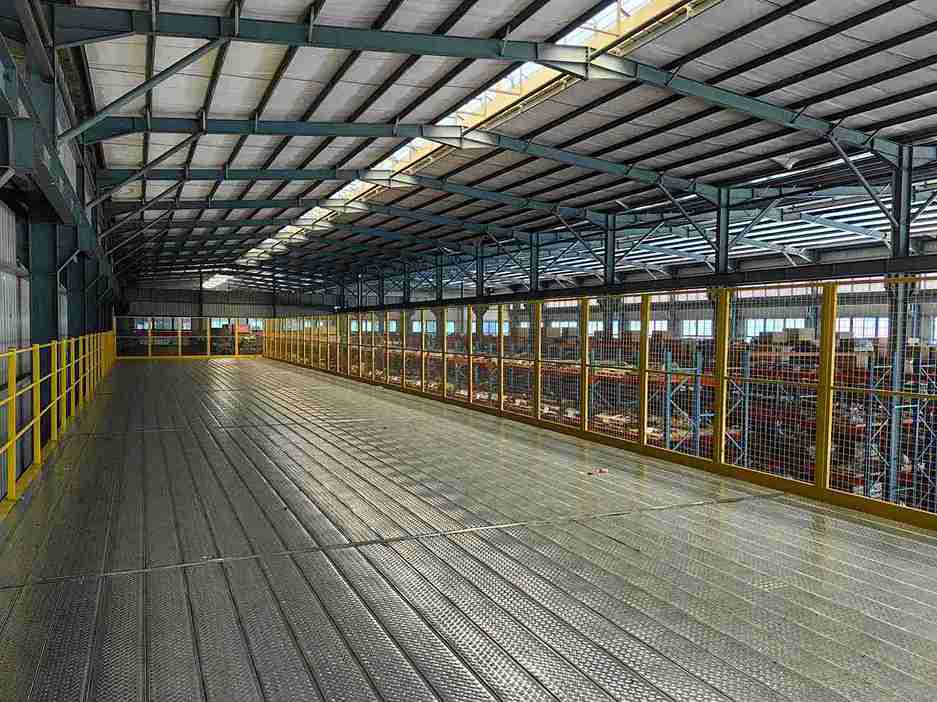

Containment-Focused Systems for Multi-Level ASRS: In high-bay warehouses and dense ASRS installations, the modular platform handrail design must address the critical risk of falling objects. Systems are configured with continuous, securely fastened toe-boards and fine-wire mesh infill that prevents any tool, component, or piece of debris from falling to the levels below, safeguarding both expensive inventory and personnel working underneath.

The Agile Enterprise: Leveraging Modular Handrails as a Strategic Enabler

In an era where supply chain agility is a primary competitive differentiator, the infrastructure must be capable of rapid change. A modular platform handrail design is a key enabler of this operational agility, allowing the physical environment to keep pace with strategic shifts.

Facilitating the Integration and Evolution of Automation

The rollout of AGVs or unmanned fork-lifts often requires reconfiguring traffic flows and protected work zones. A welded handrail system would make such changes prohibitively expensive and slow. In contrast, a modular platform handrail design can be quickly and economically disassembled and reassembled to create new pathways, adjust safety perimeters, or create dedicated maintenance bays for robotic systems. This allows the safety infrastructure to evolve in perfect synchrony with the automation strategy, a critical capability that welded systems cannot provide.

Streamlining Maintenance, Retrofits, and Future Expansion

The operational benefits of a modular platform handrail design extend far beyond initial installation. If a section is damaged in a collision, the repair process is swift and simple: the damaged components are unbolted and replaced with new ones from stock, minimizing facility downtime to mere hours or even minutes. Furthermore, the system itself can be used as a backbone for facility infrastructure. Conduits, sensors, lighting, and data cables can be neatly routed and mounted directly onto the handrail structure, adding a layer of functionality that welded systems cannot easily accommodate without further fabrication.

A Framework for Selection: Choosing a Partner, Not Just a Product

Selecting a provider for a modular platform handrail design is a critical decision. The goal is to identify a strategic partner whose expertise and product quality will ensure a successful, long-term investment.

Critical Due Diligence Criteria for Procurement

Demonstrable Engineering Capability: The supplier should provide certified load calculations, engineering drawings, and evidence of compliance with relevant standards. Their ability to offer custom base plates or special fittings for complex structural integrations is a key indicator of depth.

Uncompromising Material and Manufacturing Quality: Inspect samples for the quality of the finish (e.g., powder-coating thickness), the precision of the punched holes, and the robustness of the connection hardware. The components should be manufactured with tight tolerances to ensure a perfect fit.

Comprehensive Design and Support Services: A true partner will offer value-added services such as 2D layout drawings and 3D BIM models, ensuring the modular platform handrail design integrates flawlessly with the building structure and other equipment from the planning stage.

Proven Industry Expertise and References: Request case studies and client testimonials, particularly from projects involving complex ASRS or large-scale mezzanine installations. A proven track record in your specific sector is invaluable.

Conclusion: Transforming the Safety Perimeter from a Cost Center to a Value Driver

The evidence is clear and compelling. The decision to implement a sophisticated modular platform handrail design is a definitive step toward building a safer, more efficient, and more resilient operation. It moves the conversation beyond mere compliance to one of strategic advantage. By embracing this engineered approach, organizations can immediately capitalize on faster project deployment and a lower total installed cost. More importantly, they invest in a long-term asset that provides perpetual value through its inherent flexibility, reusability, and adaptability.

In the relentless pursuit of warehouse optimization, the modular platform handrail design stands out as a rare opportunity to simultaneously elevate safety standards, enhance operational agility, and improve the bottom line. It is an investment that pays dividends from the first day of installation and continues to deliver value for the entire lifecycle of the facility.

Frequently Asked Questions (FAQs)

1. How does the material choice (e.g., steel vs. aluminum) impact the performance and cost of a modular handrail system?

The choice between steel and aluminum in a modular platform handrail design is a strategic one, balancing strength, weight, and corrosion resistance. Steel, typically finished with a durable powder-coat or hot-dip galvanization, offers maximum strength and impact resistance, making it the preferred choice for heavy-industrial settings, high-traffic forklift aisles, and cost-sensitive projects where ultimate durability is required. Aluminum, while generally having a higher initial material cost, provides an exceptional strength-to-weight ratio and inherent, maintenance-free corrosion resistance. This makes an aluminum-based modular platform handrail design ideal for environments like food and beverage processing, cold storage, and chemical plants, where its lighter weight also simplifies handling and installation, potentially offsetting some labor costs.

2. Can modular handrails be securely anchored to any type of mezzanine or platform decking?

A professional-grade modular platform handrail design is engineered with a variety of anchoring solutions to suit virtually any substrate. For steel decking or structural members, direct bolting with high-strength bolts is standard. For concrete floors, a range of concrete anchors, from chemical epoxies to mechanical drop-in anchors, are specified based on load requirements. The true mark of a comprehensive modular platform handrail design system is its availability of specialized base plates for challenging surfaces, such as proprietary open-grid flooring (e.g., DurAGRID, Grip Strut), where custom-fabricated clamps or base plates ensure a secure, code-compliant attachment without compromising the deck’s integrity.

3. We have a unique layout with multiple level changes and complex corners. Are modular systems capable of handling this complexity?

Absolutely. In fact, managing complexity is a fundamental strength of a well-conceived modular platform handrail design. These systems are not limited to straight runs. They are supported by a comprehensive catalog of pre-engineered, bolt-together components designed for complexity. This includes standard and custom angled connectors for navigating odd corners, dedicated stair stringer systems for safe access between levels, and offset base plates to handle parapet walls or irregular floor edges. A skilled provider will design the modular platform handrail design as a complete, cohesive system that elegantly and safely follows the unique contours of your facility’s layout.

4. What is the typical lead time for a custom-configured modular handrail system for a large-scale ASRS project?

Lead times are a key advantage of the modular platform handrail design methodology. While a fully custom-welded system can easily require 8 to 14 weeks for engineering, fabrication, and finishing, a modular system typically ships in 4 to 8 weeks. This acceleration is possible because manufacturers stock standard components in bulk and the “customization” lies in the engineering of the layout and the kitting of these standard parts for a specific project. For extremely large or complex ASRS projects, a phased delivery approach is often used, ensuring that critical installation paths are not delayed.

5. How does the long-term maintenance of a modular system compare to a welded one?

The long-term maintenance profile of a modular platform handrail design is significantly more favorable and cost-effective. Maintenance primarily consists of periodic visual inspections and torque checks on bolts, a simple task for in-house maintenance staff. Should damage occur, the affected section is modularly replaced without affecting adjacent sections, a process that takes a fraction of the time and cost of a welded repair. In contrast, maintaining a welded system often involves grinding, re-welding, and repainting, which requires specialized trades, creates more downtime, and results in a patchwork finish. The modular platform handrail design ensures the system’s appearance and integrity can be maintained consistently over decades of service.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com