📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

In the high-stakes, rapidly evolving world of food processing, the warehouse and distribution center have transcended their traditional roles. They are no longer static cost centers but the dynamic, beating heart of the entire supply chain. The ability to adapt to volatile consumer demand, stringent and ever-changing global safety regulations, and the relentless pressure for operational efficiency is what definitively separates market leaders from the rest. This comprehensive analysis delves into the transformative power of a sophisticated modular platform for food processing, a system designed to seamlessly integrate Automated Storage and Retrieval Systems (AS/RS) into a cohesive, adaptable, and intelligent operational backbone.

This concept moves far beyond simply installing new hardware; it is about architecting a future-proof backbone for the entire supply chain. This innovative approach masterfully combines the unparalleled storage density, speed, and accuracy of AS/RS with the inherent flexibility and scalability of a true modular platform for food processing, creating a living system that evolves alongside the business, rigorously safeguards product integrity, and drives sustainable profitability for decades to come. This article will explore the critical design principles, quantify the tangible ROI, and outline a strategic, low-risk implementation path that establishes this synergy as the ultimate competitive advantage in today’s demanding market.

(H2) The Modern Food Processor’s Dilemma: A Perfect Storm of Volatility, Regulation, and Physical Constraints

Operating a contemporary food processing facility involves navigating a perfect storm of complex challenges. The landscape is characterized by unprecedented volatility. Consumer preferences can shift overnight, fueled by social media trends and health reports, creating explosive demand for new product lines with entirely different packaging and storage requirements.

A sudden disruption in the supply chain, such as a crop failure or a logistical bottleneck, can force an immediate recipe change, necessitating rapid adjustments in raw material storage protocols. Simultaneously, regulatory bodies like the FDA, USDA, and global standards like SQF are in a constant state of refinement, updating hygiene, traceability, and labeling requirements with little room for error. Compounding these external pressures are the intense internal physical and operational constraints. Facility managers are perpetually battling:

SKU Proliferation: The explosion of product variants, flavors, and package sizes means storing a vastly greater number of items within the same, often insufficient, physical footprint.

Cold Chain Imperatives: Maintaining an unbroken, precisely monitored cold chain is paramount. A single temperature deviation in a freezer or chiller can result in a massive, costly write-off and devastating reputational damage.

Absolute FIFO Mandates: First-In, First-Out inventory rotation is not merely a best practice for inventory management; it is a fundamental pillar of food safety, critical for preventing spoilage and ensuring consumer safety.

Pervasive Labor Challenges: Finding, training, and retaining a reliable workforce willing to perform physically demanding tasks in harsh environments, such as freezing temperatures, is increasingly difficult and expensive.

The E-Commerce Tsunami: The dramatic rise of direct-to-consumer and online grocery channels requires efficient picking of individual items and mixed cases, a task that demolishes the efficiency models of traditional pallet-in, pallet-out warehousing.

Rigid, traditional storage systems—static shelving, fixed conveyor lines, and manual pallet racking—are fundamentally incapable of keeping pace with this new reality. Simply adding more static shelving or embarking on a capital-intensive new warehouse construction project are slow, expensive solutions that often create more long-term rigidity and operational bottlenecks. What is urgently needed is a system built on a radically different principle: intelligent, built-in adaptability, which is the core promise of a well-executed modular platform for food processing.

(H2) Deconstructing the Buzzword: The Core Components of a True Modular Platform for Food Processing

When industry leaders refer to a modular platform for food processing, they are describing a fundamental architectural philosophy for the entire material handling ecosystem, not just a marketing term for bolt-together shelving. It is a cohesive, integrated system where the physical structure, the automation technology, and the software intelligence are designed from the ground up to be expanded, reconfigured, and upgraded with minimal operational disruption and maximum long-term cost-effectiveness. This modular platform for food processing is the antithesis of a monolithic, one-size-fits-all installation.

Think of it as building with high-precision, industrial-grade building blocks. The entire system’s integrity and flexibility depend on its core, interoperable components:

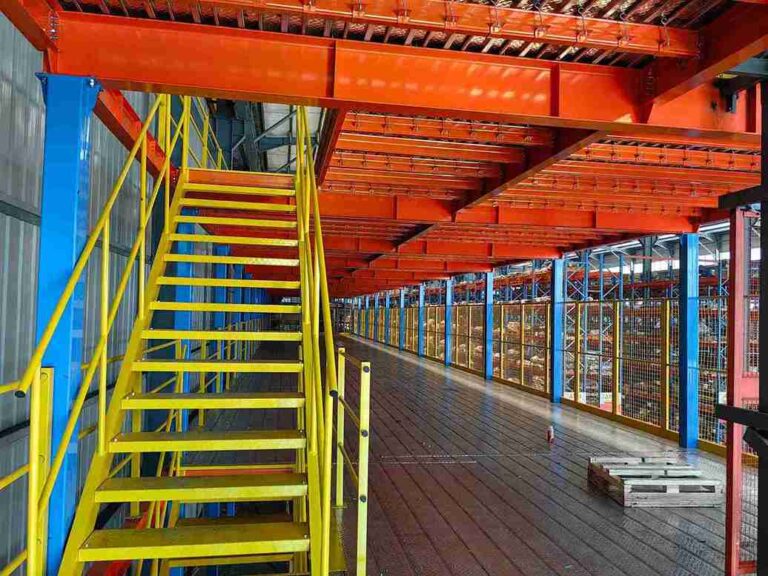

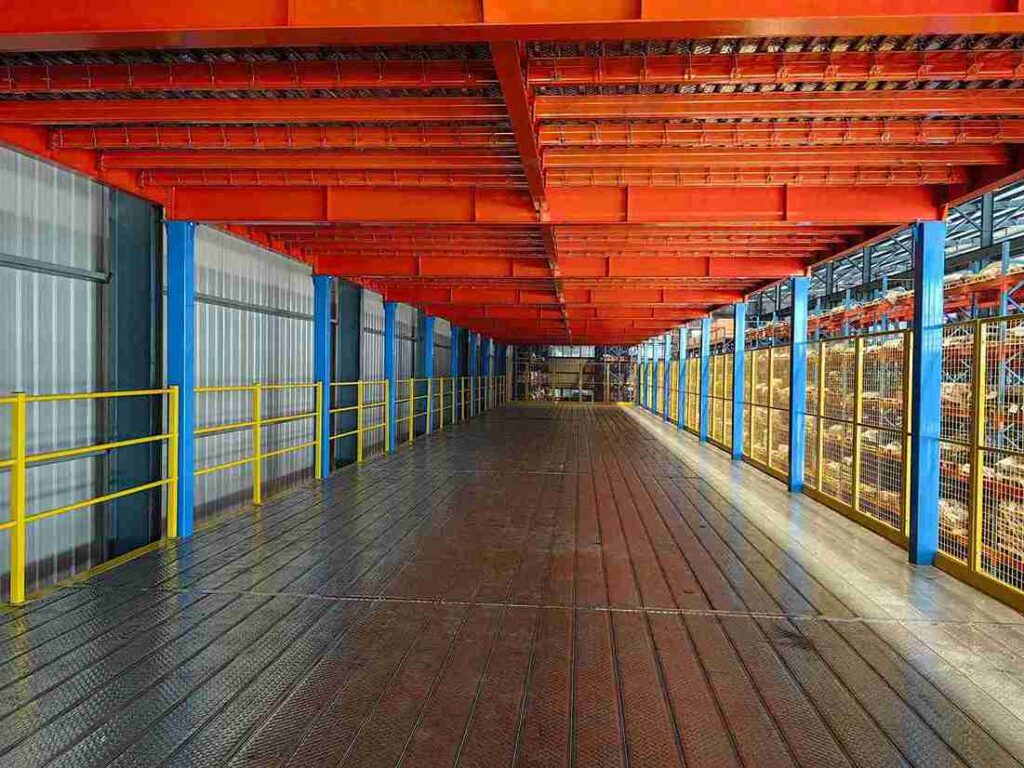

Modular Structural Framing: This is the skeleton of the operation. It consists of high-strength, stainless steel or specially coated carbon steel uprights, beams, and bracing that form the primary support for pallet racks, carton flow lanes, and mezzanine systems. These components are engineered to specific tolerances, allowing for safe, seamless, and predictable additions or reconfigurations without requiring custom fabrication or compromising structural integrity.

Standardized Automated Components: This is the muscular system that brings the platform to life. It includes AGVs (Automated Guided Vehicles) and AMRs (Autonomous Mobile Robots) designed with standardized coupling interfaces for attaching various load handlers. It encompasses conveyor segments, transfer cars, and lift modules that “snap together” mechanically and electronically. Crucially, it includes AS/RS cranes and shuttles whose control systems can be reprogrammed to adapt to new rack configurations and storage layouts, a key feature of a dynamic modular platform for food processing.

The Unified, Scalable Software Layer: This is the central nervous system and the brain of the entire operation. A scalable Warehouse Execution System (WES) or a tightly integrated Warehouse Management System (WMS) and Warehouse Control System (WCS) form this layer. This software must be capable of managing a mixed fleet of automation from different vendors, dynamically adapting to new facility layout maps, and incorporating new software modules—such as advanced lot tracking, recall management, or predictive analytics—as business needs evolve.

This powerful triad—an adaptable structure, interoperable automation, and intelligent, scalable software—working in perfect concert is what creates a genuinely resilient and future-proof backbone. For a deeper dive into how these modular structures form the foundational layer of this strategy, industry professionals can explore dedicated resources on modular warehouse design principles.

(H3) The AS/RS Revolution: Precision Automation Meets Food Processing Imperatives

For many years, Automated Storage and Retrieval Systems (AS/RS) were predominantly associated with massive, capital-rich industries like automotive manufacturing. They were often perceived as monolithic, inflexible “installations” that were prohibitively expensive for the food and beverage sector. That era has decisively ended. The latest generation of AS/RS solutions has undergone a quiet revolution, making them exceptionally well-suited for the unique and demanding challenges of food processing, especially when integrated as part of a broader modular platform for food processing.

An AS/RS typically consists of computer-controlled cranes, shuttles, or robotic carriers that automatically place and retrieve loads from defined storage locations with supreme precision. Within the context of a modern food facility, the benefits are profound and directly address core pain points:

Maximized Cube Utilization: By storing products from floor to ceiling with minimal aisle space—often just inches wider than the load itself—an AS/RS can frequently double or even triple storage density within the same existing building footprint. This enhanced density can defer or completely eliminate the need for astronomically expensive facility expansions.

Perfect and Guaranteed FIFO and Traceability: Every single pallet or tote is tracked by its exact location, batch number, and expiration date. The system’s software is programmed to automatically retrieve the oldest stock first, every single time, completely eliminating human error and ensuring the highest standards of food safety and quality control.

Unmanned Cold Chain Operations: There is no justifiable reason to subject human workers to the physiological strains and safety hazards of -25°C deep-freeze environments. AS/RS and complementary robotic palletizers can operate flawlessly 24/7 in these harsh conditions, ensuring both worker safety and unwavering product quality by minimizing door openings and temperature fluctuations.

Blistering Speed and Unerring Accuracy: Throughput rates can skyrocket while mis-picks and shipping errors plummet to near-zero levels. This directly translates into faster order fulfillment, higher customer satisfaction, and significant reductions in operational waste and rework costs.

However, the historical drawback of traditional AS/RS has been its perceived rigidity. Once the rails were grouted into the floor and the racking was installed, any significant change was a painful, disruptive, and expensive undertaking. This is precisely where the overarching concept of a modular platform for food processing fundamentally changes the game, transforming a static asset into a dynamic, adaptable tool.

(H2) The Powerful Synergy: Marrying Modular Flexibility with AS/RS Precision

This integration represents the very core of the future-proof backbone. Fusing a modular philosophy with an AS/RS does not merely combine their individual benefits; it creates a powerful symbiotic relationship where each component actively enhances the capabilities and value of the other. A modular platform for food processing provides the framework that liberates the AS/RS from its traditional constraints.

(H3) Scenario 1: Seamlessly Scaling for a Breakout Product Line

Imagine a company launching a new line of organic, plant-based frozen entrées. The product is a runaway success. Demand explodes beyond all forecasts, and the operation urgently needs to dedicate 300 new pallet locations specifically for this line, fully integrated into the existing automated frozen storage area.

In a Traditional, Fixed AS/RS System: This scenario would trigger a major, disruptive construction project. It would likely involve shutting down a significant section of the freezer, bringing in specialized contractors to install new fixed racking, potentially repouring floor concrete to extend the AS/RS rail network, and enduring weeks of costly downtime, lost sales, and logistical chaos.

Within a Modular AS/RS Platform for Food Processing: The expansion is a managed, streamlined process. The modular racking is explicitly designed with this kind of expansion in mind. The new uprights and beams are pre-engineered to connect directly and securely to the existing structure. The AS/RS shuttle or crane is simply reprogrammed with an updated digital map of the expanded storage grid. The standardized conveyor interfaces allow for a straightforward “plug-and-play” extension of the material flow path. The result? The expansion is completed in a matter of days, not weeks, with minimal operational disruption and a predictable, contained cost. The system’s software is updated seamlessly, and the facility continues to meet its demanding order schedules.

(H3) Scenario 2: Dynamically Adapting to Dramatic Seasonal Peaks

Consider a poultry processor that handles turkeys. For ten months of the year, the facility operates at a baseline capacity. However, in the two-month peak season leading up to Thanksgiving, storage and handling needs can easily triple or quadruple.

In a Traditional System: The company is forced to rent expensive, often distant, off-site storage. This incurs massive double-handling costs, creates a nightmare for logistics coordination, and introduces significant risks for traceability breakdowns and temperature excursions.

In a Modular AS/RS Platform for Food Processing: The system is inherently designed for dynamic reconfiguration. A specific section of the warehouse might utilize a modular, high-density storage system, such as mobile pallet racking, that remains condensed for most of the year. During the peak season, this system can be “unlocked,” with entire rows of racking shifted to create temporary aisles, instantly accessing a vast volume of backup storage capacity that was previously inaccessible. The AS/RS and a fleet of AGVs are then simply reprogrammed to understand and operate within this temporary layout, seamlessly absorbing the massive peak season load without any of the chaos and risk associated with off-site storage.

(H4) The Critical Enabler: Standardized Interfaces and Open-Architecture APIs

The powerful synergy described above is only technically and economically feasible through an obsessive focus on interoperability at every level. Leading providers design their modular platform for food processing using components with standardized mechanical and digital interfaces. This philosophy is analogous to the USB-C standard in consumer electronics; a user can plug in a new device, and it is recognized and functions immediately. In an industrial context, this translates to:

A new model of AMR from a different manufacturer can be integrated into the existing material handling fleet because it communicates using the same VDA 5050 or similar open communication protocol.

A new pick-to-light or put-to-light station can be added to a picking mezzanine because the power, data, and network connections are pre-planned, accessible, and standardized.

The central WES/WMS can seamlessly pull data from the corporate ERP system and send granular commands to the AS/RS without requiring months of complex, expensive, and proprietary custom software integration.

This unwavering commitment to an open architecture is a defining feature of a high-quality modular platform for food processing. It strategically prevents vendor lock-in and ensures that the operation can continually incorporate and benefit from the best new technologies as they emerge on the market. To understand the role of AGVs and AMRs as the flexible, horizontal transport companions to fixed AS/RS automation, readers are encouraged to review the insights in creating a hybrid automation warehouse.

(H2) Hygiene by Design: A Non-Negotiable Principle for Any Modular Platform for Food Processing

Any discussion of warehouse infrastructure within the food and beverage industry is rendered meaningless without a relentless, uncompromising focus on hygiene, cleanability, and contamination prevention. A truly future-proof backbone must, by definition, also be a cleanable, inspectable, and microbiologically secure backbone. A best-in-class modular platform for food processing is engineered with food safety as a primary design constraint, not as a retrofitted afterthought.

Materials and Finishes are Paramount: Specifiers select materials based on the specific zone requirements. 304 or 316 stainless steel is specified for all critical components in high-moisture areas, direct product contact zones, and high-risk environments. For other structural elements, advanced epoxy or nylon-based powder coatings that are resistant to chemical cleaners, corrosion, abrasion, and chipping are employed.

Cleanability Engineered from the Outset: All structural elements feature smooth, radiused corners with no sharp angles, crevices, or hollow sections where bacteria, mold, or pests could establish a foothold. Rack designs are open and avoid box sections where possible, preventing the accumulation of dust, debris, and moisture.

Seamless Integration with Plant-Wide Sanitation Protocols: The entire system, including the AS/RS machinery, conveyors, and guarding, is designed to withstand standard high-pressure, high-temperature wash-down procedures using industry-standard cleaning chemicals. Electrical components, motors, and sensors are housed in IP66, IP67, or higher-rated enclosures to provide complete protection against water and chemical ingress.

Proactive Pest Prevention Strategies: The design of the modular platform for food processing incorporates sealed floors, strategic bird-proofing netting or barriers, and integrated mounting points for rodent monitoring devices as part of a holistic Integrated Pest Management (IPM) plan.

(H2) Calculating the True, Holistic ROI: Looking Far Beyond Labor Savings

When evaluating a strategic capital investment of this scale and importance, it is absolutely critical to look beyond the simplistic and often overstated “we saved X number of forklift drivers” calculation. The return on investment for a sophisticated modular platform for food processing is multi-faceted, compounding, and delivers value across the entire organization.

Strategic Capital Expenditure (CapEx) Optimization: While the initial investment is significant, the modular approach fundamentally protects and future-proofs that investment. Companies no longer face a “rip and replace” scenario every 7-10 years as technology evolves or business needs change. Instead, they make smaller, incremental, and highly predictable capital investments that systematically extend the system’s functional life and capabilities almost indefinitely. This strategic approach effectively turns a portion of traditional CapEx into a more manageable and predictable operational expenditure (OpEx).

Comprehensive Operational Cost Reduction:

Labor: Significant reduction in direct labor (forklift operators, order pickers) and all associated costs (recruitment, training, benefits, turnover, and safety incident management).

Energy: In cold storage applications, the high density of an AS/RS drastically reduces the volume of air that requires refrigeration. Furthermore, the drastic reduction in the number of times freezer doors are opened for manned equipment traffic leads to massive, ongoing energy savings.

Product Loss: The near-total elimination of mis-picks, product damage from forklift impacts, and spoilage from missed FIFO deadlines directly and positively impacts the company’s bottom line.

Powerful Revenue-Enabling and Strategic Benefits:

Operational Agility to Capture Market Demand: The inherent ability to quickly scale up storage and throughput for a successful product launch means the company never misses a sales opportunity due to logistical constraints.

Enhanced Brand Reputation and Partner Status: A demonstrable capability for perfect order fulfillment and the ability to provide instant, granular traceability during a audit or potential recall incident makes a company a preferred, low-risk supplier for major retailers and food service distributors.

Proactive Risk Mitigation: The potential cost of a single, widespread product recall—including brand damage, litigation, and regulatory fines—can be catastrophic. The unparalleled traceability and operational control offered by an integrated modular platform for food processing serves as the most powerful and proactive insurance policy available.

(H2) A Blueprint for Success: The Phased, Low-Risk Implementation of a Modular Platform

The legitimate fear of a highly disruptive, all-or-nothing “big bang” implementation is a primary barrier to adoption for many companies. Leading providers systematically dismantle this barrier by advocating for a phased, pragmatic, and evidence-based implementation blueprint. This methodology de-risks the project, manages cash flow, and builds organizational confidence with each successful milestone.

Phase 1: Deep-Dive Discovery and Digital Twin Simulation. This initial phase goes far beyond simply collecting requirements. It involves experienced consultants spending time on the production and warehouse floor, conducting a granular analysis of existing workflows, identifying hidden pain points, and validating growth projections. The critical output of this phase is the creation of a dynamic “digital twin”—a highly accurate virtual model of the proposed operation. Within this simulation environment, engineers can test countless “what-if” scenarios, optimize layouts, and definitively prove system throughput and performance long before any physical installation begins.

Phase 2: Foundational Core Installation. This phase involves the installation of the core modular infrastructure—the primary racking systems, the key conveyor arteries, and the central software backbone. This installation is often strategically planned and executed in a manner that allows the existing legacy operation to continue running in parallel, minimizing disruption to live order fulfillment.

Phase 3: Phased Automation Integration and Validation. Automation is introduced in manageable, validated phases. This could begin with the commissioning of a single AS/RS machine in one designated aisle or the deployment of a pilot fleet of AGVs for a specific horizontal transport task. During this phase, the client’s operational team receives extensive hands-on training and becomes progressively more comfortable with the new technology in a controlled, low-risk environment.

Phase 4: Continuous Expansion and System Optimization. Once the core system is running smoothly and delivering the promised benefits, all future expansions become straightforward, predictable projects. Whether adding more AS/RS cranes, integrating an automated robotic palletizer, or expanding the storage grid to a new area of the facility, these projects follow the same “plug-and-play” philosophy established from the start.

(H2) Conclusion: The Strategic Imperative for the Next Decade and Beyond

The global food processing landscape will only continue to accelerate in its volatility, become more stringent in its regulations, and intensify in its competitive pressure. Clinging to static, labor-intensive, and inflexible warehouse and material handling models is a strategic risk that forward-thinking companies can no longer afford to carry. The strategic integration of a sophisticated modular platform for food processing with high-density, high-precision Automated Storage and Retrieval Systems (AS/RS) presents a clear, proven, and sustainable path forward.

This is not merely an incremental equipment upgrade; it is the deliberate construction of a resilient, intelligent, and inherently adaptable future-proof backbone for the entire enterprise. This backbone will empower companies to respond to market shifts with confidence, guarantee the safety and quality of their products with unwavering consistency, and unlock new, previously unattainable levels of operational efficiency and profitability. The critical question for industry leaders is no longer if they should move towards this transformative model, but how quickly and strategically they can begin building their own foundational modular platform for food processing to secure their position in the future of food manufacturing and distribution.

(H2) Frequently Asked Questions (FAQs)

(H3) 1. How does a modular AS/RS platform handle power outages or system failures in a critical environment like a freezer?

Robust systems are designed with redundancy and comprehensive fail-safe mechanisms. Critical components, such as the system’s central server and key controllers, are often supported by Uninterruptible Power Supplies (UPS) or even backup generators. In the event of a total power loss, the AS/RS machinery typically features manual retrieval modes (e.g., manual override controls) to allow for the safe recovery of stranded loads.

The modular racking itself is a passive, stable structure and remains completely secure. Furthermore, the software is designed to perform continuous health checks and can execute a “graceful pause” in operations during a power fluctuation, preventing data corruption, task duplication, or physical jams, thereby ensuring a swift and organized recovery once power is restored.

(H3) 2. We have an existing, older warehouse. Can a modular platform be retrofitted into our current facility, or is a new building required?

In the vast majority of cases, a retrofit is not only possible but is considered a core strength and a common application for a well-designed modular platform for food processing. The process begins with a detailed structural survey conducted by certified engineers to verify that the existing floor slab can handle the dynamic and static loads of the new system.

The modular components are then specifically designed and configured to work within the constraints of the current building’s dimensions, column spacing, clear height, and door locations. This approach maximizes the value of the existing capital asset and is often a more cost-effective and faster-to-implement solution than new construction.

(H3) 3. What is the typical lead time from design to full operational deployment for a system of this complexity?

Lead times understandably vary based on the project’s scale, scope, and level of customization. However, the phased approach inherently helps manage timelines. The initial design, engineering, and digital twin simulation phase might typically take 2 to 4 months.

The manufacturing and on-site installation of the core system typically range from 6 to 12 months for a medium-to-large scale project. The critical differentiator provided by a modular platform for food processing is that once the foundational backbone is installed and operational, subsequent expansion or reconfiguration phases can be executed and commissioned in a matter of just weeks or a few months, not years, providing unparalleled speed to market for new capabilities.

(H3) 4. How do you future-proof the software? What happens when a new, better WMS or automation technology emerges in 5 years?

This is where the strategic commitment to open APIs (Application Programming Interfaces) and standardized communication protocols delivers long-term value.

The software platform for a true modular platform for food processing is designed to be agnostic, acting as a central command center that can communicate with various “best-in-breed” subsystems through well-documented, open interfaces. Migrating to a new WMS or integrating a new, more advanced type of robot in the future becomes primarily a software integration project leveraging these APIs, not a physical rebuild or a complete system overhaul. This architecture strategically protects the client’s investment in both the physical infrastructure and the operational data.

(H3) 5. Beyond pallets, can this system handle smaller items like cases, totes, or individual pieces for e-commerce fulfillment?

Absolutely. The principle of a modular platform for food processing is universally applicable across all unit load types. Providers integrate a wide variety of scalable storage and retrieval technologies to handle this spectrum. This includes mini-load AS/RS for handling plastic totes, shuttle systems for managing cases and cartons, and goods-to-person (GTP) stations where AMRs deliver portable storage racks directly to ergonomic picking workstations.

This allows for a seamless, automated flow of materials from raw material (full pallets) through to finished goods (individual eaches for e-commerce) all within a single, unified, and intelligently managed modular platform for food processing. Discover the specific possibilities for automated small-item storage and order fulfillment in the detailed guide to automated order picking systems.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com