📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Maximize Storage Efficiency with Custom Modular Platform Flooring Solutions

In the high-stakes world of logistics and warehousing, the battle for space is relentless. Managers and operations directors are perpetually tasked with squeezing more capacity, efficiency, and throughput from existing footprints. While many focus on high-density racking or sophisticated warehouse management systems, a more fundamental opportunity is often overlooked: the very foundation of the storage operation.

Traditional concrete floors are static, unyielding, and frequently inefficient. The future of industrial space optimization lies in dynamic, adaptable, and intelligent foundations. This is the domain of advanced modular platform flooring options, a transformative category of structural solutions that are redefining what’s possible within a warehouse’s cubic volume. These are not mere surfaces; they are engineered, multi-level platforms designed to unlock vertical air space, segregate workflows, and create a robust base for automation.

For any business serious about maximizing storage efficiency, a deep understanding of the capabilities and strategic applications of modern modular platform flooring options is no longer optional—it is essential. This comprehensive exploration delves into how these custom solutions serve as the cornerstone for building a more productive, safe, and scalable operation, directly addressing the pain points of warehouse managers across the globe.

The Inefficiency Epidemic: Wasted Cubic Space and Its Real-World Cost

The primary challenge in countless warehouses is the underutilization of cubic space. Most facilities are designed with generous clear heights, yet standard operations confine activity to a single, sprawling plane. The vast volume between the top of the racking and the roof represents a significant, untapped asset—a virtual floor of potential. This inefficiency carries a heavy and multifaceted cost:

Prohibitive Real Estate Expenses: Expanding a physical footprint through new construction or leasing additional space is a capital-intensive endeavor. Custom modular platform flooring options directly counter this by creating new, highly usable square footage within the existing building envelope, dramatically lowering the cost per stored unit.

Operational Drag: A single-level layout forces equipment and personnel to traverse greater distances, leading to increased cycle times, higher fuel or battery consumption, and elevated labor costs. The operational drag is a silent profit killer.

Strategic Rigidity: A static warehouse layout cannot pivot easily in response to market shifts, seasonal peaks, or the introduction of new product lines. This lack of agility can stifle growth and erode competitive advantage. Implementing flexible modular platform flooring options is a direct antidote to this rigidity, creating an environment that can evolve as the business does.

Deconstructing the Solution: What Are Modular Platform Flooring Options?

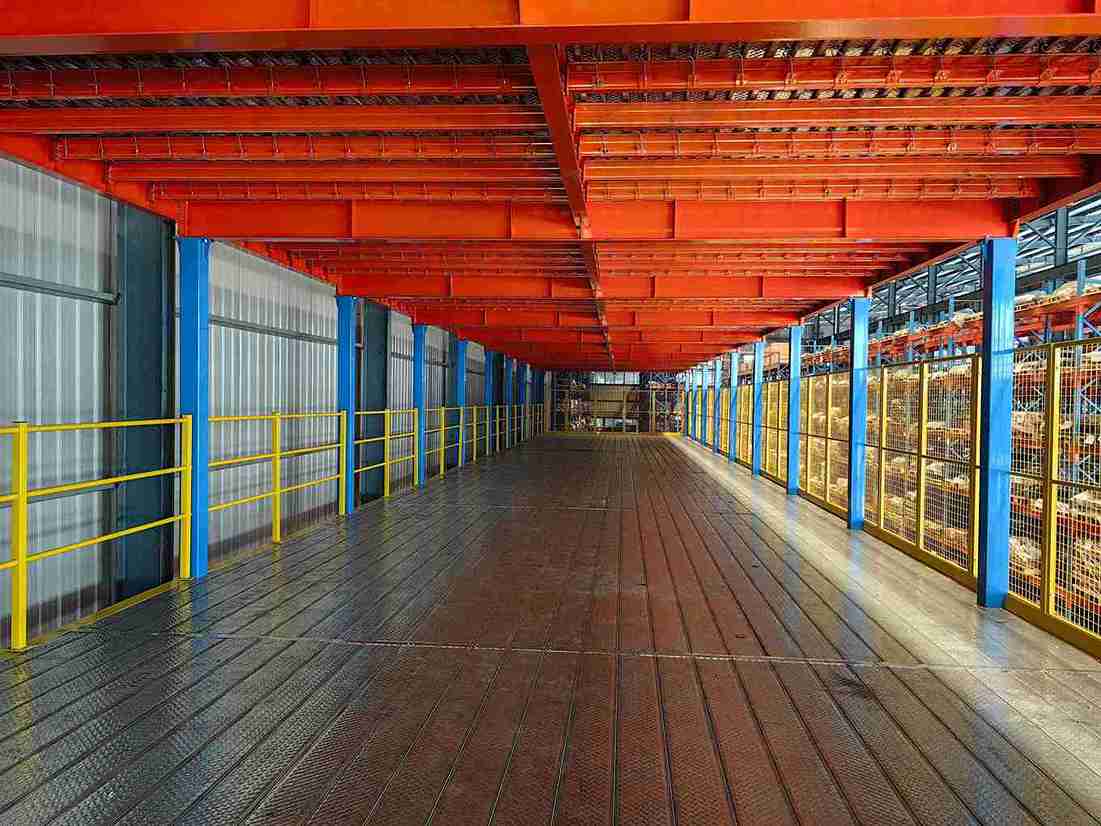

To appreciate their impact, one must understand what these systems are. The term modular platform flooring options encompasses a family of engineered structures, primarily industrial mezzanines, that create elevated working surfaces. A superior system is an integrated whole, composed of several critical components:

The Structural Framework: This is the skeleton, consisting of heavy-duty steel columns, primary beams, and secondary joists. The design is precisely calculated by structural engineers to meet specific load requirements and local building codes, ensuring integrity under the stress of pallet racking, machinery, and high-traffic workflows.

The Decking Surface—The Heart of the Options: This is where the variety of modular platform flooring options becomes apparent. The choice of decking is application-critical and includes:

Heavy-Duty Steel Grating: A premier choice for durability and permeability, allowing light, air, and sprinkler coverage to pass through. Ideal for general storage areas and environments where ventilation is key.

Solid Steel Plate or Laminated Duraplate: Provides a completely solid, seamless surface. This is the go-to option for supporting automated conveyor equipment, housing offices, or storing small items. It offers a perfectly flat, stable plane for precision-driven tasks.

Plywood Overstock: A cost-effective solution for light-duty applications or as a sub-base for a finished floor in office spaces.

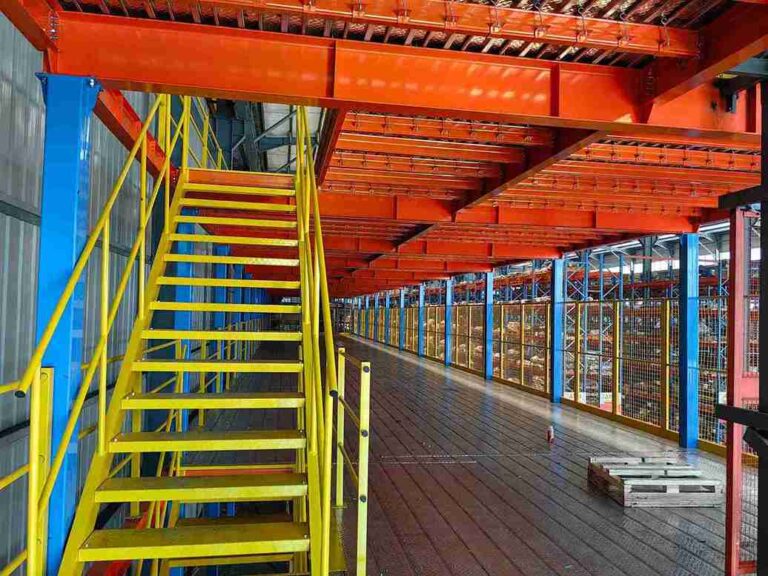

Access and Safety Integration: A platform is only as good as its access. Comprehensive systems include industrial staircases, safety gates, full-perimeter guardrails, and integration points for material lifts or conveyors, ensuring safe and efficient movement of both people and goods.

The power of these systems lies in their inherent customizability. They are not off-the-shelf products but are tailored solutions designed to fit the exact contours, load needs, and operational rhythms of a facility.

<h3>Strategic Design Considerations for Peak Performance</h3>

Selecting from the available modular platform flooring options is a strategic process. Expert providers don’t just sell a product; they engineer a solution based on a deep analysis of several factors:

Dynamic and Static Load Calculations: Determining the maximum weight the structure must hold, including the weight of stored goods, racking, and the dynamic impact of moving equipment like AGV carts and unmanned forklifts.

Column Grid Optimization: Strategically placing support columns to maximize clear, unobstructed space both on the platform and, crucially, on the ground level beneath it. This ensures smooth traffic flow for material handling equipment.

Seamless Infrastructure Integration: A professional design accounts for existing sprinkler systems, lighting, electrical conduits, and HVAC, redesigning them as necessary to serve the new multi-level environment without compromising safety or functionality.

Inherent Scalability: The best designs for modular platform flooring options are conceived with the future in mind, allowing for relatively straightforward expansion or reconfiguration as business needs change.

The Direct Correlation: How Modular Platforms Drive Storage Efficiency

The phrase “maximize storage efficiency” is the ultimate goal, and modular platform flooring options are one of the most direct tools to achieve it. The correlation is powerful and multi-layered.

<h3>Creating Vertical Storage Tiers</h3>

The most immediate impact is the creation of new, functional levels. This new space can be leveraged in several high-impact ways:

Bulk Storage Loft: Relocate slow-moving or overstock inventory to the platform level, freeing up prime ground-floor real estate for high-velocity SKUs and improving overall picking efficiency.

Multi-Level Order Picking Zones: Structure picking operations across different levels, dedicating each tier to specific product categories or order channels. This drastically cuts down travel time for pickers and reduces congestion.

High-Density Storage Support: The platform itself can be engineered to support the substantial weight of pallet racking systems or static shelving, effectively creating a multi-story storage cube within a single-story building.

<h3>Optimizing Workflow Through Vertical Segregation</h3>

True efficiency is as much about flow as it is about storage. The strategic use of modular platform flooring options allows for the intelligent vertical separation of distinct operational functions, leading to a more logical and productive workflow.

Dedicated Value-Added Services (VAS) Loft: House activities like kitting, custom packaging, labeling, and returns processing on the platform level. This contains these labor-intensive processes, preventing them from disrupting the primary inbound and outbound material flows.

Integrated Office and Control Rooms: Construct mezzanine offices, quality control labs, or supervisor stations above the warehouse floor. This provides visibility and proximity to the operation without sacrificing valuable storage or production space below.

Purpose-Built Automation Decks: Utilize the platform to create a dedicated, stable home for automated storage and retrieval systems (ASRS), a fleet of AGV carts, or their charging and maintenance stations.

<h4>Case in Point: A Southeast Asian Distribution Center Transformation</h4>

A tangible example illustrates this principle. A major distributor in Vietnam was constrained by a 12-meter clear height and an inefficient single-level layout. Their existing warehouse shelving and racking systems were failing to meet growing demand. By implementing a tailored modular platform flooring solution, a second operational tier was created. The chosen modular platform flooring options included a solid steel deck for conveyor integration and heavy-duty grating for storage areas.

This allowed for the installation of a high-density, narrow aisle pallet racking system on both levels. The result was a 135% increase in pallet storage capacity within the same footprint, a 30% reduction in order picking times, and a return on investment achieved in under two years. This case underscores how the right modular platform flooring options directly translate into quantifiable gains in storage efficiency and operational performance.

A Deep Dive into Modular Platform Flooring Options and Specifications

The decision regarding which specific modular platform flooring options to select is paramount. The choice of decking material dictates the system’s functionality, longevity, and suitability for specific tasks.

<h3>Heavy-Duty Steel Grating: The Workhorse Option</h3>

Primary Applications: Areas demanding maximum strength, slip resistance, and the free passage of air, light, and water (e.g., for sprinkler systems).

Performance Characteristics: Offers exceptional load-bearing capacity, making it suitable for supporting heavy pallet racking and withstanding the daily wear of material handling equipment.

Inherent Benefits: Creates a more open and less visually oppressive environment, ensures compliance with fire safety regulations by allowing sprinkler water to reach the ground floor, and is highly durable.

<h3>Solid Steel Decking: The Precision Automation Foundation</h3>

Primary Applications: Environments requiring a perfectly smooth and continuous surface. This is the ideal choice for pathways of AGV carts and unmanned forklifts, for supporting automated conveyor equipment and sortation systems, or for creating office and clean room spaces.

Performance Characteristics: Provides superior distributed load capacity and a vibration-dampened surface crucial for the accuracy of robotic systems.

Inherent Benefits: Delivers a “true floor” experience, is easy to clean and maintain, and provides an uninterrupted plane for precision-driven automation, making it a critical component among modular platform flooring options for the smart warehouse.

<h3>Hybrid and Composite Decking Strategies</h3>

In practice, the most efficient and cost-effective design often involves a hybrid approach. A facility might utilize a solid steel deck for its main conveyor line and office spaces while employing steel grating in the surrounding bulk storage areas. This strategic combination of modular platform flooring options allows for budget optimization while delivering maximum functional performance tailored to each zone’s specific requirements. Exploring these hybrid modular platform flooring options with an expert can yield the most intelligent and economical overall design.

The Synergy of Modular Platforms and Warehouse Automation

For operations moving toward a smart warehouse model, the selection of modular platform flooring options becomes a critically strategic decision. These platforms form the physical infrastructure upon which automation thrives.

Navigational Integrity for AGVs/AMRs: The flawless, consistent surface provided by solid deck modular platform flooring options is essential for the reliable operation of Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs). It eliminates the inconsistencies of traditional floors that can disrupt sensitive guidance systems.

Stable Foundations for Robotics: Robotic arms, automated shuttles, and palletizers require an absolutely stable and level base to operate with precision. Engineered modular platform flooring options provide this foundational stability, protecting the integrity and longevity of high-value automation investments.

Vertical Material Flow Integration: These platforms can be designed with precise openings and reinforced edges to seamlessly integrate automated conveyor belts and vertical lifts, creating a continuous, multi-level flow of goods that is both efficient and minimizes manual handling.

Navigating the Installation Process: A Blueprint for Minimal Disruption

A common concern for operations managers is the potential downtime and disruption associated with installation. A key advantage of professional modular platform flooring options is the methodology behind their implementation, which is designed to minimize operational impact.

Comprehensive Digital Site Survey: The process begins with advanced laser scanning to create a precise digital twin of the facility, ensuring a perfect fit.

Precision Off-Site Fabrication: All structural and decking components are manufactured to exact specifications in a controlled factory setting. This guarantees quality, reduces on-site waste, and accelerates the overall project timeline.

Phased and Managed On-Site Assembly: Certified installation teams assemble the pre-fabricated components on-site in a logical, phased manner. This bolted-together approach is significantly faster and cleaner than traditional construction, allowing work to often proceed alongside ongoing warehouse activities.

Final Certification and Handover: Upon completion, the system undergoes a rigorous inspection to ensure it complies with all design specifications and safety codes, resulting in a certified, ready-to-operate asset.

Calculating ROI: Viewing Modular Flooring as a Strategic Investment

Evaluating modular platform flooring options through a purely cost-based lens is a mistake. A more accurate perspective views them as a capital investment with a compelling and multi-faceted return.

Direct Cost Avoidance: The most significant financial benefit is avoiding the exorbitant costs of relocating or constructing a new building. The cost per square meter of added space via a mezzanine is typically a fraction of the cost of new industrial real estate.

Operational Efficiency Gains: The savings accrued from reduced travel times, lower energy consumption for equipment, and optimized labor directly improve the bottom line.

Enhanced Asset Utilization: This investment unlocks the value of an owned asset—the building’s air space—that was previously generating no return.

Long-Term Property Value: A well-designed and installed system of modular platform flooring options becomes a permanent, value-adding feature of the industrial property.

Safety and Regulatory Compliance: The Non-Negotiable Foundation

In any industrial setting, safety is paramount. Reputable providers of modular platform flooring options design and build with safety as a core principle, adhering to international standards like OSHA and ISO. Integral safety features are not add-ons but are built into the design:

Full-Perimeter Guardrail Systems: Robust handrails and toe-kicks to prevent falls from height.

Industrial-Grade Staircases: Designed with correct rise/run ratios, anti-slip treads, and continuous handrails.

Self-Closing Safety Gates: Installed at the top of all stairway openings.

Load Rating Certification: Clearly displayed placards that specify the maximum allowable load, preventing dangerous overloading.

Conclusion: Elevating Your Operational Potential

In an era where logistics capability is a primary determinant of business success, settling for an inefficient storage footprint is a significant strategic liability. The sophisticated modular platform flooring options available today represent a fundamental evolution in industrial space utilization. They are the key to genuinely maximizing storage efficiency, building a resilient and adaptable operation, and laying a foundation that is prepared for the demands of tomorrow’s supply chains.

This is about more than adding a second floor; it is about multiplying productivity, agility, and profitability. For operations managers, distribution center directors, and business owners, the message is clear: to compete and win, looking up and unlocking the potential overhead is no longer an innovative idea—it is an operational imperative. The right modular platform flooring options provide the key.

Frequently Asked Questions (FAQs)

1. How do the load capacities of different modular platform flooring options compare, and what is suitable for supporting pallet racking?

Load capacity is a defining characteristic of different modular platform flooring options. Heavy-duty steel grating and solid steel decking are both capable of supporting significant loads, often exceeding 150 kg per square meter or more when part of a properly engineered structure. For supporting loaded pallet racking systems, a specific engineering analysis is mandatory. The entire structure—columns, beams, and decking—is calculated to handle the concentrated and dynamic loads, making certain modular platform flooring options perfectly suitable for this demanding application.

2. Can these platforms be designed to accommodate future expansion or reconfiguration of our warehouse layout?

Yes, inherent flexibility is a core benefit of quality modular platform flooring options. Unlike permanent concrete structures, these bolted steel systems can often be disassembled, expanded, or reconfigured. When discussing a project with a provider, it is crucial to articulate future growth plans. A skilled engineer can design the initial layout with potential expansion in mind, for instance, by specifying a column grid that can be easily extended, making the investment in modular platform flooring options a long-term, adaptable asset.

3. What is the typical process for ensuring fire safety compliance, particularly with sprinkler systems, under a solid deck platform?

Fire safety is a critical part of the design process for modular platform flooring options. When a solid deck is used, it creates a separate compartment that requires its own fire suppression. The solution involves a collaborative redesign of the building’s sprinkler system. This typically entails installing a new dedicated sprinkler loop on the platform level itself, while also ensuring that the system beneath the platform is adjusted for proper coverage. Reputable providers of modular platform flooring options have experience coordinating this with sprinkler contractors to ensure full compliance with all local building and fire codes.

4. For a facility with a high volume of AGV traffic, what specific features should we look for in the platform decking?

For AGV cart operations, the choice among modular platform flooring options is critical. The paramount requirement is a perfectly smooth and stable surface. A solid steel plate deck is the unequivocal best choice. It provides the consistent, vibration-free plane that AGV navigation systems—whether based on lasers, magnets, or vision—require for precise and uninterrupted operation. Furthermore, the seams between decking panels must be designed and installed to be flush, creating a seamless “roadway” that prevents any wheel jostling or navigation errors that can occur with grated modular platform flooring options.

5. We have a busy operational warehouse. How can installation proceed without bringing our entire logistics flow to a halt?

Professional installers of modular platform flooring options are accustomed to working in live environments. The key is meticulous phasing and planning. The installation can be sequenced to occur in specific sections of the warehouse, allowing other areas to continue normal operations. Pre-fabrication is also a major advantage; since components are manufactured off-site, the on-site assembly is primarily a bolting-together process, which is far quicker and less disruptive than traditional construction. A detailed project plan will outline the phased approach, working hours, and any necessary temporary safety barriers to ensure minimal impact on your ongoing business.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com