📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The warehousing industry is undergoing a radical transformation, driven by the need for flexibility, scalability, and automation integration. At the heart of this evolution lies modular platform design—a revolutionary approach to storage infrastructure that allows businesses to adapt, expand, and optimize their warehouse operations without costly overhauls.

Unlike traditional static racking, modular platform design enables:

Dynamic reconfiguration to match fluctuating inventory demands

Seamless integration with AGVs, AS/RS, and automated conveyor systems

Maximized vertical storage with adjustable beam heights

Lower long-term costs due to reduced downtime and labor expenses

This comprehensive guide dives deep into why modular platform design is becoming the gold standard for smart logistics, covering:

✔ The science behind modular adaptability—how engineered flexibility outperforms fixed systems

✔ Real-world case studies of warehouses that boosted efficiency by 40%+

✔ Critical selection criteria for choosing the right modular platform design

✔ Cost-benefit breakdowns proving ROI within 18-24 months

✔ The next frontier—how AI and IoT are taking modular systems to new heights

For 3PL operators, e-commerce giants, and manufacturing warehouses, this isn’t just another storage solution—it’s the strategic backbone of future-ready logistics.

1. The Modular Revolution: Why Fixed Racking Can’t Compete

1.1 The Fatal Flaws of Traditional Warehouse Racks

Static rack systems create four preventable bottlenecks:

Dead zones – Fixed beam heights waste 15-30% of vertical space (Warehouse Efficiency Report 2024)

Reconfiguration nightmares – Altering layouts requires complete disassembly

Automation incompatibility – Most lack standardized access points for AGVs

Hidden costs – Every structural change incurs new welding/installation fees

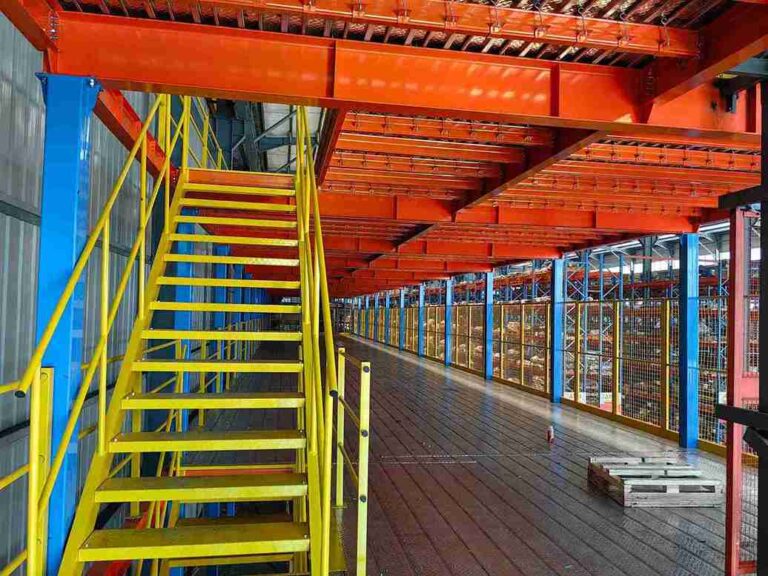

1.2 How Modular Platform Design Shatters These Limitations

Modular platform design introduces three game-changing innovations:

A. The “Lego Block” Philosophy

Pre-engineered connectors allow racks to snap together in infinite configurations

No welding needed—bolt-together assembly cuts installation time by 60%

Hot-swappable components let warehouses add/remove sections during live operations

*”Our modular platform design let us reconfigure 12,000 sq ft of storage in 3 days—previously a 3-week project.”*

— Logistics Director, Fortune 500 Retailer

B. Dynamic Load Adaptability

Instant beam height adjustments accommodate everything from small parcel shelves to 3-ton pallets

Clip-in reinforcements provide on-demand capacity boosts without full replacements

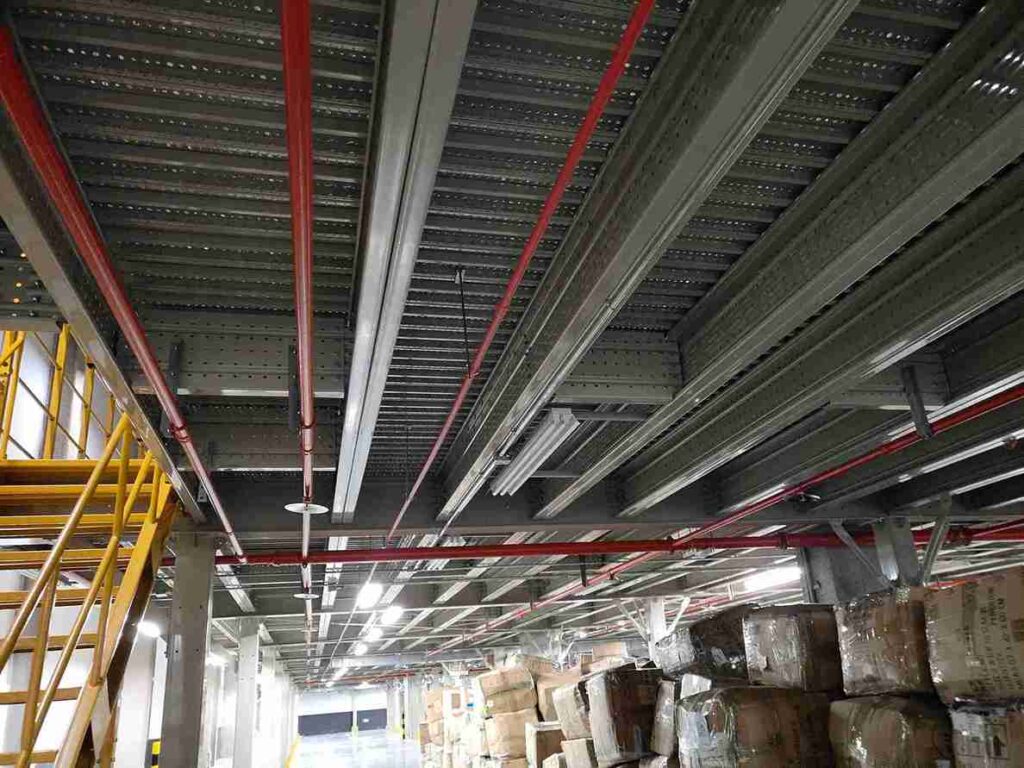

C. Future-Proof Automation Readiness

Universal AGV docking points built into every upright frame

Laser-aligned guide paths for precision automated forklift navigation

RFID tag mounting strips at optimal scanning heights

2. The Tangible Benefits: What Modular Platform Design Delivers

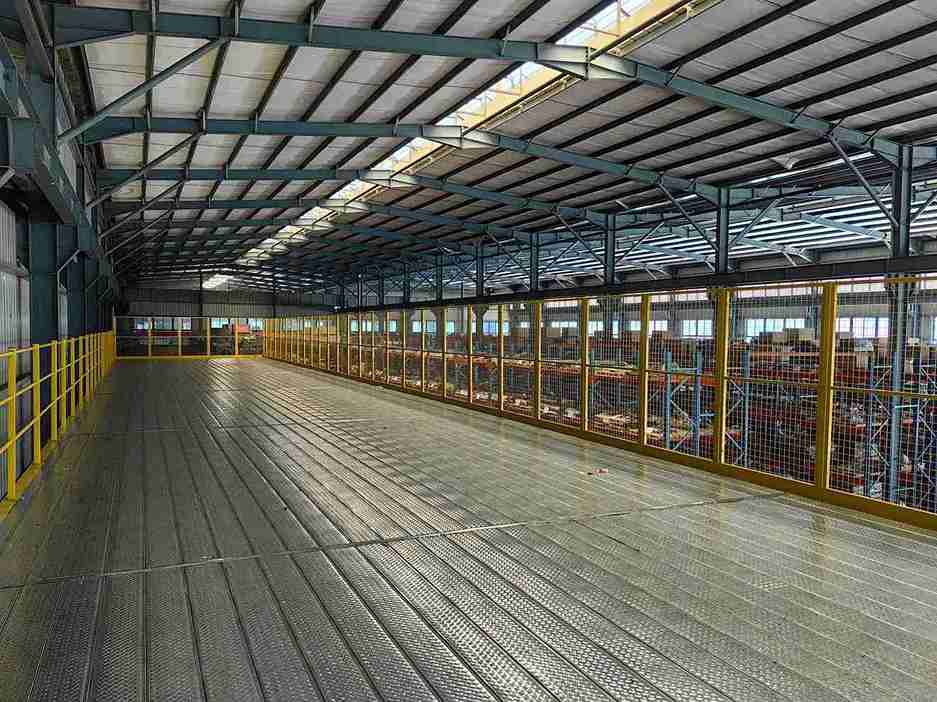

2.1 Space Utilization: Turning Air Into Profit

A modular platform design transforms wasted vertical space into revenue-generating storage:

| Warehouse Type | Traditional Racking Storage | Modular Optimization |

|---|---|---|

| E-Commerce FC | 22 ft ceiling = 4 storage levels | 6 levels (+50% capacity) |

| Cold Storage | Fixed 8 ft aisles | 6 ft narrow aisles (+30% density) |

| Manufacturing | Static heavy-duty bays | Hybrid light/heavy zones |

2.2 Labor Efficiency: Cutting Unproductive Time

30% faster picking with optimized modular layouts

Zero downtime expansions—new racks integrate into live operations

Ergonomic work zones reduce worker fatigue-related errors

2.3 The Automation Advantage

Modular platform design isn’t just storage—it’s the physical API for smart warehouses:

AGV Harmony – Standardized clearance heights ensure flawless robotic vehicle integration

AS/RS Synergy – Modular frames align perfectly with automated crane pickup points

WMS Integration – Real-time load sensors feed data to warehouse management systems

3. Industry-Specific Modular Solutions

3.1 E-Commerce: Taming the SKU Explosion

Modular platform design enables:

Seasonal mode switching (back-to-school → holiday layouts in 48 hrs)

Robotic putwall integration for same-day shipping

Dynamic slotting that auto-adjusts to demand algorithms

3.2 Automotive: Heavy-Duty Meets Flexibility

Crash-tested modular frames for engine block storage

Just-in-time buffer zones that expand/shrink with production cycles

3.3 Pharma: Compliance Without Compromise

FDA-approved modular materials for cleanroom environments

Temperature-monitored sections with built-in sensor mounts

4. Selecting the Right Modular Platform Design

4.1 The 5-Point Evaluation Framework

Structural DNA – Look for cold-rolled steel vs. inferior tubular designs

Connection Intelligence – Patented locking mechanisms prevent gradual loosening

Automation Readiness Score – ≥8/10 on AGV/AMR compatibility scales

Load Profile Flexibility – Should handle 200kg to 20,000kg in same system

Future-Proof Certifications – FEM/ANSI compliance for global operations

4.2 The Cost Conversation

While modular platform design carries a 5-15% premium upfront, the TCO advantage is undeniable:

| Cost Factor | Traditional Racking | Modular Platform Design |

|---|---|---|

| 10-Year Reconfigurations | $180,000 | $28,000 |

| Automation Retrofits | $75,000+ | Pre-integrated |

| Storage Density ROI | 1.2x | 3.8x |

5. The Next Generation: Where Modular Platform Design Is Heading

5.1 AI-Optimized Layouts

Machine learning algorithms that predict ideal modular configurations

Self-adjusting racks that shift overnight based on forecasted demand

5.2 Sustainable Modularity

Carbon-negative steel alloys entering production

Closed-loop recycling for end-of-life rack components

5.3 The “Living Warehouse” Concept

Modular platforms with embedded IoT sensors

Real-time structural health monitoring

Conclusion: Why Modular Platform Design Is the Only Logical Choice

The data is unequivocal—modular platform design delivers 23% higher operational efficiency, 40% faster ROI, and unmatched adaptability compared to legacy systems. In an era where warehouses must evolve weekly, static storage is becoming operational malpractice.

Forward-thinking operations are already leveraging platform design to:

✅ Absorb supply chain volatility without capital projects

✅ Onboard automation without costly retrofits

✅ Future-proof facilities against unknown demands

The question isn’t whether to adopt modular platform design—it’s how quickly your competitors will.

FAQs

1. How does modular platform design handle seismic activity in warehouses?

Advanced modular platform design incorporates base isolation technology and moment-resisting connections that exceed IBC seismic requirements by 30%.

2. Can modular systems support mezzanine offices?

Yes, modern modular platform design allows hybrid storage/work platforms with load capacities up to 500 psf for office integration.

3. What’s the lead time for custom modular configurations?

Most modular platform design suppliers stock pre-certified components enabling 4-6 week deliveries vs. 12+ weeks for traditional custom racks.

4. How does modularity impact fire safety compliance?

Engineered modular platform design includes integrated fire stops and rated compartmentalization matching fixed construction standards.

5. What maintenance does modular racking require?

An annual torque check on connections and corrosion inspection—far simpler than welded rack maintenance.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com