📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

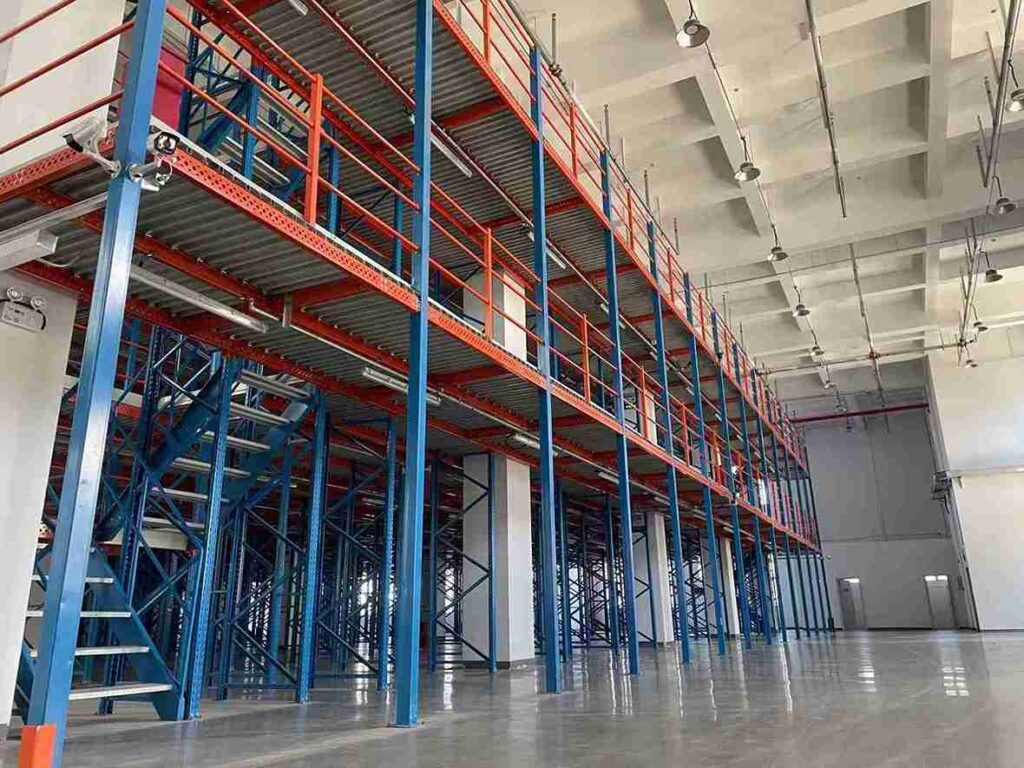

In the high-stakes world of industrial logistics and warehouse management, the pressure to optimize every cubic foot of space is immense. Modular platform design standards represent the critical bridge between ambitious storage solutions and structurally sound, safe, and efficient operational realities. These elevated structures, whether rack-supported or free-standing, offer a transformative potential for creating valuable mezzanine-level space. However, this potential is precisely proportional to the rigor applied in their planning and execution.

The industry is littered with stories of catastrophic failures—not due to a single egregious error, but from a cascade of minor oversights that collectively compromise structural integrity. A profound understanding and steadfast application of core modular platform design standards is the only reliable defense against these costly and dangerous outcomes.

This comprehensive analysis moves beyond basic checklists to explore the five foundational pillars of world-class modular platform design standards, providing facility managers, operations directors, and safety engineers with the knowledge required to specify, approve, and manage projects that not only meet code but set a new benchmark for performance and safety.The following sections will dissect the nuances of load dynamics, seismic resilience, foundational synergy, decking strategy, and integrated safety—each a non-negotiable component of superior modular platform design standards.

The Inherent Risks: Why Compromising on Modular Platform Design Standards is a Gamble You Can’t Afford

The decision to implement a mezzanine is often driven by an urgent need for space, a factor that can sometimes lead to rushed decisions and a dangerous prioritization of speed over substance. This is the genesis of the most common and costly rack system mistakes. A modular platform is a dynamic structural system, constantly interacting with its environment. It must resist the vibrational energy from material handling equipment, bear the immense point loads of concentrated storage, and withstand the test of time. Inferior modular platform design standards or a “good enough” approach fail to account for these real-world variables, treating the platform as a static entity.

The consequences are rarely immediate, which fosters a false sense of security. The first signs of failure are often subtle: a slight, permanent deflection in the decking, a hairline crack in a weld, or a bolt that never seems to stay tight. These are the warning signs of a system under duress, signals that the applied modular platform design standards were inadequate for the operational demands.

The ultimate failure modes—a rack-supported structure buckling under a load it was never calculated to hold, or a free-standing mezzanine experiencing a partial collapse due to lateral instability—are not mere equipment failures; they represent a fundamental breakdown in the duty of care. Therefore, investing in robust modular platform design standards from the outset is not an expense; it is the most critical insurance policy for protecting personnel, inventory, and operational continuity. Industry leaders now view these modular platform design standards not as a regulatory hurdle, but as a strategic framework for achieving scalable growth.

Standard #1: Mastering Load Dynamics – The Cornerstone of All Modular Platform Design Standards

At the very heart of all credible modular platform design standards lies the precise science of load analysis. This is the first and most critical line of defense against structural inadequacy. A superficial understanding of loads, often reduced to a simple pounds-per-square-foot (PSF) conversation, is the most prevalent origin point for catastrophic rack system mistakes. True, professional-grade modular platform design standards demand a multi-faceted, forensic-level examination of all potential forces that will act upon the structure throughout its lifecycle.

<h3>Deconstructing Load Types: Beyond the Basic PSF Figure</h3>

Advanced modular platform design standards categorize and calculate several distinct types of loads:

Uniform Live Loads: This is the distributed weight across the platform surface, encompassing personnel, movable equipment, and evenly stored materials. While important, it is often the least demanding factor.

Concentrated (Point) Loads: This is where rigorous modular platform design standards separate from amateur planning. It involves calculating the extreme force exerted on a very small area, such as:

The individual wheels of a fully laden pallet jack or forklift.

The leg posts of storage racking systems installed on top of the mezzanine.

The feet of heavy machinery like industrial printers or assembly robots.

Dynamic Impact Loads: Perhaps the most overlooked element in weak modular platform design standards is the multiplier effect of motion. The force of a 3,000-pound pallet jack hitting a deck expansion joint or braking suddenly is significantly greater than its static weight. Engineering-level modular platform design standards incorporate a dynamic impact factor (often between 1.25 and 2.0 times the static load) to ensure the structure can absorb these real-world shocks.

<h3>The Engineering Process: Translating Theory into Unshakeable Reality</h3>

To avoid the rack system mistakes stemming from load miscalculation, leading engineering firms employ a meticulous process. They begin with a detailed operational questionnaire and a site visit to observe workflow firsthand. This qualitative data informs the quantitative modeling performed using sophisticated Finite Element Analysis (FEA) software. This software simulates the complex interactions between different load types, identifying potential stress concentrations at beam connections, decking supports, and column bases long before fabrication begins.

The output of this process is a set of precise modular platform design standards that specify the exact gauge of steel for decking, the size and profile of secondary and primary beams, and the load capacity of every connection point. This exhaustive approach ensures that the final modular platform design standards are not just theoretical ideals but are bespoke prescriptions for a specific operational environment.

Standard #2: Designing for Seismic and Dynamic Forces – The Stability Imperative in Modular Platform Design Standards

A platform’s ability to hold weight is useless if it cannot remain stable under forces that attempt to displace it. The second pillar of uncompromising modular platform design standards addresses lateral stability and resilience against dynamic events. While seismic activity is the most dramatic example, a robust framework for modular platform design standards also accounts for the daily, low-grade seismic events generated within a busy warehouse.

<h3>Lateral Bracing Systems: The Backbone of Stability</h3>

The primary defense against lateral movement in any set of modular platform design standards is a well-engineered bracing system. The choice of system is a strategic decision based on the platform’s configuration and operational flow:

Diagonal Rod Bracing: This is the most efficient and common solution, using high-strength steel rods arranged in an “X” pattern between columns to create a rigid truss system that resists sway. These modular platform design standards are ideal for perimeter areas and back-of-house sections.

Moment-Resisting Frames: In main traffic aisles or picking zones where diagonal bracing would create an obstruction, the modular platform design standards call for moment frames. These utilize specially engineered, rigid connections between beams and columns to provide equivalent lateral stability without impeding workflow.

Building Tie-Ins: The most robust modular platform design standards often integrate the platform directly into the host building’s structure. By securely anchoring the mezzanine to the building’s columns and shear walls, engineers create a synergistic structural system that is exponentially more resistant to all forms of lateral force.

<h3>Accounting for Operational Dynamics: Vibration and Impact</h3>

Superior modular platform design standards anticipate the inevitable. They assume that a forklift will eventually make contact with a column and that the constant vibration from conveyor systems and heavy foot traffic will test the integrity of every bolted connection. To mitigate these risks, these modular platform design standards mandate the use of permanently installed column guards made from high-density polyethylene or steel. Furthermore, they specify the use of lock nuts, thread-locking adhesives, and precise torque specifications during installation to combat vibration-induced loosening. This proactive element of modular platform design standards is what ensures a structure remains tight, quiet, and safe for decades, not just on the day it’s installed.

Standard #3: Ensuring Foundation and Column Integrity – The Critical Groundwork of Modular Platform Design Standards

All the engineering in the world is futile if the structure lacks a solid foundation. The third set of critical modular platform design standards focuses on the interface between the platform’s columns and the facility’s concrete slab. This is the literal and figurative ground zero for many of the most expensive rack system mistakes, as slab failures are incredibly disruptive and costly to repair.

<h3>Concrete Slab Analysis: The Non-Negotiable First Step</h3>

No responsible set of modular platform design standards can be developed without first understanding the foundation. This requires a professional assessment to determine:

Compressive Strength: The PSI rating of the concrete, which indicates its ability to handle the concentrated load from a column base plate.

Slab Thickness: A critical factor, as a slab that is too thin will crack and spall under the point loads, even if the concrete’s PSI is adequate.

Subgrade and Condition: The quality of the substrate beneath the slab and the presence of any existing cracks, cuts, or chemical degradation that could compromise its performance.

These modular platform design standards for site assessment are fundamental. Attempting to apply a generic set of modular platform design standards without this site-specific data is a recipe for disaster.

<h3>Anchor Bolt Engineering: The Unsung Hero of the System</h3>

The connection between the steel column and the concrete slab is the linchpin of the entire structure. Professional modular platform design standards treat anchor bolt selection with extreme care, choosing from several technologies based on the calculated tensile and shear forces:

Undercut Anchors: These provide the highest and most reliable holding power by mechanically locking into the concrete in a way that is resistant to vibration and shock.

Adhesive (Epoxy) Anchors: Where drilled holes must be placed close to the slab edge or in cracked concrete, high-strength epoxy anchors are often specified within the modular platform design standards. They distribute the load beautifully but are highly dependent on correct installation, including hole cleaning and epoxy cure time.

Heavy-Duty Expansion Anchors: A robust solution for many applications, though generally considered to have lower performance in cracked concrete compared to the alternatives.

The installation procedures for these anchors are a core part of the modular platform design standards, requiring certified training for crews to ensure proper hole diameter, depth, and setting torque.

Standard #4: Strategic Decking and Surface Selection – The Operational Interface of Modular Platform Design Standards

The decking is the “work surface” of the platform, and its selection is a strategic decision that directly impacts safety, functionality, and compliance. The modular platform design standards governing decking choice are a balance of structural performance, operational need, and building code adherence.

<h3>A Comparative Analysis of Decking Types</h3>

Open-Grid Steel Grating: A staple in industrial modular platform design standards due to its high strength-to-weight ratio. It allows for the passage of light, air, and, most critically, sprinkler water, which is essential for maintaining the building’s fire protection integrity. The modular platform design standards will specify the bearing bar size and spacing based on the concentrated load analysis to prevent permanent deflection.

Checkered Plate (Durbar Plate): This solid steel sheet with a raised lug pattern offers a 100% standing surface, ideal for small parts handling or clean environments. However, its weight is significantly higher, and it blocks sprinkler coverage. Modular platform design standards for solid decking must, therefore, include the design and integration of a secondary, underwritten fire protection system to comply with NFPA and local building codes.

Heavy-Duty Wire Mesh or Perforated Plate: These options offer compromises, providing more surface than open grating while allowing some passage of air and light.

<h3>Designing for Safety and Compliance from the Ground Up</h3>

The best modular platform design standards integrate safety features directly into the decking system. This includes designing in a continuous toe-kick (a vertical lip at the floor edge) to prevent objects from being kicked off the side, as well as specifying integrated kick-plates of a mandated height to act as a barrier for pallets and equipment. The slip resistance of the chosen surface, whether inherent in the grating or provided by the raised pattern of checkered plate, is a non-negotiable element of these modular platform design standards.

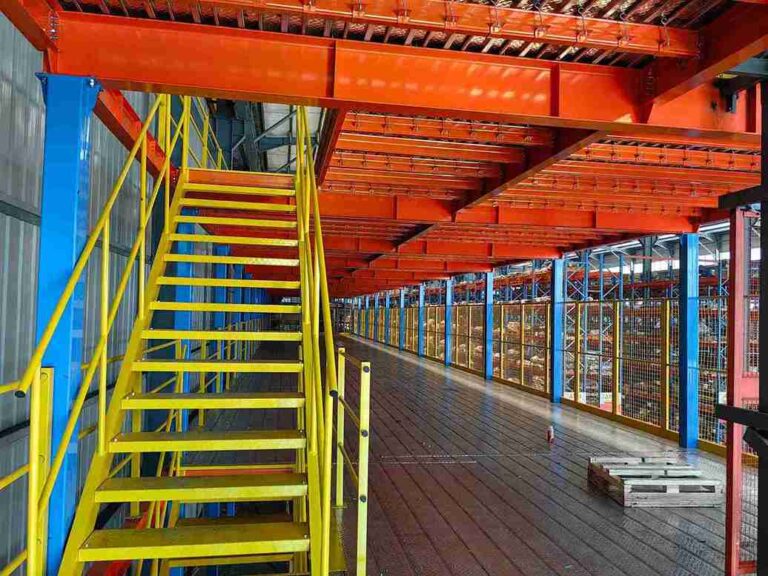

Standard #5: Integrating Access and Safety Systems – The Final Layer of Comprehensive Modular Platform Design Standards

A platform is inaccessible and unsafe without properly engineered means of access and perimeter protection. The fifth pillar of elite modular platform design standards governs the design of stairs, guardrails, and gates, viewing them not as add-ons but as integral, load-bearing components of the overall system.

<h3>Engineering Compliant and Efficient Access</h3>

The modular platform design standards for access are heavily influenced by OSHA 1910.23 and IBC regulations, but top-tier designs often exceed these minimums. This involves:

Stair Design: Calculating the optimal rise and run for safety and ergonomics, ensuring consistent pitch, and designing stringers and treads that can handle high-traffic flow. The modular platform design standards will specify non-slip surfaces on every tread.

Guardrail and Handrail Systems: These are engineered as structural components. The modular platform design standards require that guardrail posts and top rails can withstand a force of at least 200 pounds applied in any direction. Handrails must be continuous and at a consistent, graspable height.

<h3>The Critical Role of Gates in Traffic Management</h3>

At the top of stairwells and at the openings of picking aisles, the modular platform design standards must specify self-closing safety gates. These are not simple latches; they are heavy-duty, industrial-rated devices designed to prevent a catastrophic fall of a person or equipment. The choice between a horizontal-sliding gate and a vertical-lift gate, detailed within the modular platform design standards, is based on the specific traffic pattern and space constraints, ensuring that safety never impedes efficiency.

The Path to a Flawless Installation: Partnering with Experts on Modular Platform Design Standards

Understanding these five pillars of modular platform design standards is the first step for any informed facility manager. The second, and equally critical, step is selecting a partner whose entire workflow is built around these principles. The difference lies in the execution. Leading providers differentiate themselves through an unwavering commitment to these modular platform design standards at every phase:

The Comprehensive Site Audit: A deep-dive assessment that goes beyond measurements to understand workflow, future growth plans, and unique operational challenges.

Peer-Reviewed Engineering: The development of modular platform design standards is not a solitary task but a collaborative process, often involving internal review boards to challenge and validate every calculation.

Certified Fabrication and Installation: The physical realization of the modular platform design standards by crews trained to a certified standard, ensuring that the engineered vision is perfectly translated into steel and concrete.

This end-to-end ownership of the modular platform design standards is the ultimate guarantee of quality. It transforms the modular platform design standards from a document into a delivered reality, ensuring the final installation is a asset of unparalleled value and reliability.

Conclusion: Elevating Your Operations with Uncompromising Modular Platform Design Standards

In the final analysis, the implementation of a mezzanine is a significant strategic decision. The choice of which modular platform design standards to govern the project is the single most important factor in determining its long-term success. Cutting corners on these modular platform design standards is a high-risk gamble that jeopardizes personnel safety, asset security, and operational integrity. Conversely, a steadfast commitment to rigorous, comprehensive modular platform design standards—encompassing precise load analysis, dynamic force resistance, foundational integrity, strategic decking selection, and integrated safety—is an investment in certainty. It is the foundation upon which scalable, efficient, and safe operations are built.

By insisting on partners who demonstrably live and breathe these advanced modular platform design standards, decision-makers can proceed with confidence, secure in the knowledge that their facility is not just gaining space, but is building a platform for future growth on the most solid of foundations.

Frequently Asked Questions (FAQs)

1. How do your modular platform design standards account for future changes in our operational load requirements?

Our modular platform design standards are inherently forward-looking. During the initial engineering phase, we factor in a designated “future load capacity” based on your growth projections. This often involves specifying beams with a higher load rating or designing column bases and concrete foundations to support potential future increases. This proactive element of our modular platform design standards provides a built-in safety factor and can significantly reduce the cost and complexity of future modifications, ensuring your investment is protected for the long term.

2. We have a unique building feature, like a sprinkler main or conduit run, that passes through the intended mezzanine space. Can your modular platform design standards accommodate this?

Absolutely. Complex site conditions are the reason why tailored modular platform design standards are essential. Our engineering team regularly designs solutions for such challenges. This can involve creating custom clearance notches in beams, designing specialized bracing that works around the obstruction, or even integrating the building feature into the platform’s support structure in a way that maintains access and compliance. Our modular platform design standards are flexible enough to adapt to the real-world constraints of your facility.

3. What specific documentation do you provide to prove compliance with the stated modular platform design standards?

Upon project completion, we provide a comprehensive “Engineer’s Package.” This critical documentation includes sealed and signed structural drawings from a licensed Professional Engineer (P.E.), a summary of the load calculations confirming adherence to all relevant modular platform design standards, and a certificate of compliance. This package is often required for building permits and insurance purposes and serves as the ultimate verification that the installation meets the highest modular platform design standards.

4. Are there specific modular platform design standards that apply to environments with high humidity or exposure to corrosive chemicals?

Yes, environmental factors mandate specialized modular platform design standards. In these cases, our modular platform design standards specify materials and finishes suited to the challenge. This includes using galvanized steel or stainless steel for all components, selecting decking materials with high corrosion resistance, and specifying industrial-grade paint systems. These enhanced modular platform design standards are crucial for ensuring longevity and structural integrity in food processing, chemical storage, or marine applications.

5. How do your modular platform design standards interface with our existing racking system if we choose a rack-supported design?

For rack-supported platforms, the modular platform design standards become a unified document governing both the rack and the platform as a single, interdependent system. Our analysis calculates the combined stresses on the uprights and footplates. We often specify heavier-gauge rack components, reinforce upright frames with specialized bracing, and use engineered beam-to-upright connections that are significantly stronger than standard tab-and-slot designs. This holistic approach to modular platform design standards is what guarantees the entire system’s stability and safety.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com