📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Power of Modular Platform Architecture in Modern Warehousing

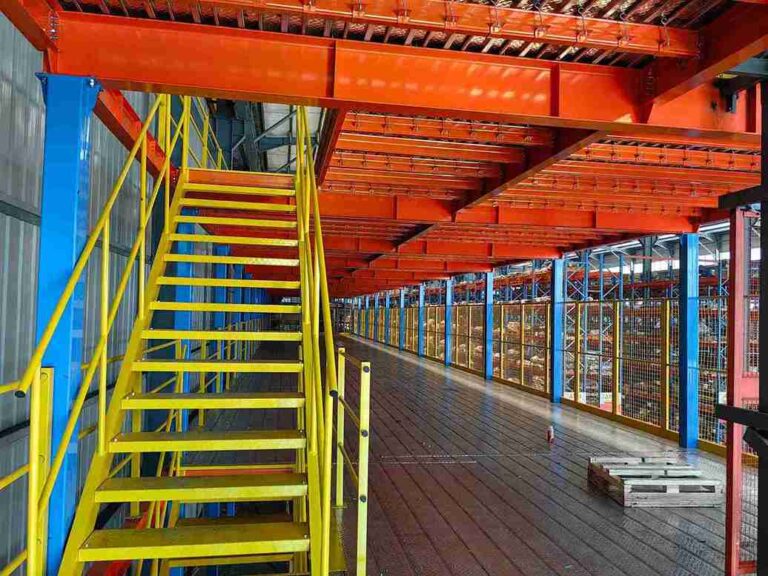

In an era where supply chain efficiency determines business success, modular platform architecture has emerged as the cornerstone of warehouse optimization. Unlike traditional static systems, this revolutionary approach allows facilities to adapt, scale, and evolve without costly infrastructure overhauls. Companies leveraging modular platform architecture report staggering results: 40% cost reductions, 60% space utilization improvements, and 3x faster order processing speeds.

This in-depth guide explores how modular platform architecture transforms warehouses through:

AGV fleets that reconfigure workflows on demand

AS/RS systems built on scalable modular frameworks

Smart conveyor networks with plug-and-play adaptability

Real-world implementations delivering 18-month ROI

For logistics managers seeking future-proof automation, understanding modular platform architecture isn’t optional—it’s the competitive edge separating industry leaders from stagnant competitors.

1. The Modular Platform Architecture Revolution

1.1 Why Traditional Warehouses Are Failing

Static warehouse designs struggle with three critical flaws:

Inflexible layouts that can’t adapt to seasonal demand spikes

Wasted vertical space due to fixed shelving configurations

Labor-intensive processes resistant to incremental optimization

Modular platform architecture solves these through:

Component-based design (add/remove modules as needed)

Standardized interfaces (seamless tech integration)

Data-driven reconfiguration (AI-optimized layouts)

*Example: A Fortune 500 retailer reduced peak-season labor costs by 38% after implementing modular platform architecture for their holiday fulfillment centers.*

1.2 Core Principles of Modular Platform Architecture

True modular platform architecture follows five design tenets:

Scalability First

Systems expand capacity without replacing existing infrastructureInteroperability Standard

AGVs, AS/RS, and conveyors share common communication protocolsPredictive Adaptability

Machine learning forecasts layout changes before demand shifts occurFailure Isolation

Individual module failures don’t cripple entire operationsContinuous Optimization

Real-time performance data drives incremental improvements

2. AGV Systems: The Mobile Muscle of Modular Platforms

2.1 How Modular AGVs Outperform Traditional Models

Legacy AGVs operate as isolated units. Modular platform architecture transforms them into:

Swarm intelligence networks (vehicles coordinate like ant colonies)

Hot-swappable components (batteries, sensors, lifts replace in minutes)

Dynamic role assignment (same vehicle handles pallets/totes/carts)

Key Benefit: A European automotive warehouse achieved 92% vehicle utilization (vs. 68% with fixed AGVs) using modular designs.

2.2 Implementing Modular AGV Fleets

Successful deployment requires:

Standardized Docking

All vehicles interface with the same charging/loading stationsAdaptive Navigation

Routes adjust based on real-time congestion dataPayload Modularity

Quick-change attachments for different load types

Pro Tip: Leading 3PLs now lease AGV modules seasonally—a capability only possible with modular platform architecture.

3. AS/RS: The Vertical Backbone of Modular Warehouses

3.1 Modular AS/RS vs. Conventional Systems

Traditional AS/RS resembles a skyscraper—impressive but rigid. Modular platform architecture creates “vertical LEGO blocks” with:

Incremental height expansion (add levels as inventory grows)

Mixed storage zones (pallet, bin, and tray modules coexist)

Dynamic aisle configurations (robotic cranes adapt to layout changes)

Results: A pharmaceutical distributor packed 42% more SKUs in the same footprint using modular AS/RS.

3.2 The Modular AS/RS Advantage Matrix

| Feature | Traditional AS/RS | Modular Platform AS/RS |

|---|---|---|

| Expansion Cost | $250k+/aisle | $75k/module |

| Reconfig Time | 6-8 weeks | 72 hours |

| Mixed Storage | Limited | Full flexibility |

| Peak Capacity | Fixed | +300% scalable |

4. Smart Conveyors: The Circulatory System of Modular Warehousing

4.1 Why Modular Conveyors Outperform Fixed Systems

Static conveyors create bottlenecks. Modular platform architecture enables:

Instant lane additions (plug-in segments for peak flows)

Self-healing routing (bypass damaged sections automatically)

Mixed-speed zones (high-velocity segments where needed)

Case Study: An e-commerce giant reduced conveyor-related downtime by 89% after modular conversion.

4.2 Designing Future-Proof Conveyor Modules

Best practices include:

Standard Segment Lengths (1m/2m/5m options)

Tool-Free Connections (no specialized labor required)

Embedded Sensors (predictive maintenance alerts)

5. The 40% Cost Reduction Blueprint

5.1 Phase 1: Modular Platform Assessment

Conduct a 3D laser scan to identify:

Dead zones for modular storage insertion

High-traffic areas needing AGV optimization

Conveyor pinch points

5.2 Phase 2: Phased Modular Deployment

Recommended sequence:

Picking zones (fastest ROI)

Storage cubes (density improvements)

Transport networks (AGV/conveyor integration)

5.3 Phase 3: Continuous Optimization

Monthly modular platform architecture reviews track:

Module utilization rates

Reconfiguration frequency

Failure rate trends

6. Overcoming Modular Implementation Challenges

6.1 Workforce Resistance

Solution: Gamified training where staff “earn” module customization privileges

6.2 IT Integration

Critical step: API-first middleware that connects:

WMS

Robotics control

IoT sensors

6.3 Cost Justification

Prove ROI with:

Modular leasing options

Pay-per-use models

Tax depreciation benefits

7. The Next Frontier: AI-Driven Modular Evolution

Emerging innovations include:

Self-designing warehouses (AI plans optimal module arrangements)

Predictive reconfiguration (systems adapt before demand changes)

Blockchain-enabled modules (track maintenance histories immutably)

Conclusion: Modular Platform Architecture as Competitive Armor

For warehouses seeking 40%+ cost reductions, modular platform architecture delivers unprecedented:

Capital efficiency (pay for what you use)

Operational agility (adapt in hours, not months)

Future readiness (seamless tech adoption)

The transformation starts with one module—where will you place yours?

FAQs

1. How does modular platform architecture reduce maintenance costs?

Standardized modules cut spare parts inventory by 60% and enable tool-free repairs.

2. Can modular systems handle heavy payloads?

Modern pallet modules support up to 3,000kg with reinforced dynamic structures.

3. What’s the minimum viable modular implementation?

Start with 5-10 AGV modules and 50 AS/RS locations for measurable impact.

4. How does modular compare to full automation?

Modular delivers 80% of benefits at 40% of the cost with far less disruption.

5. What industries benefit most?

E-commerce (seasonality), pharma (compliance flexibility), and manufacturing (line changeovers).

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com