📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

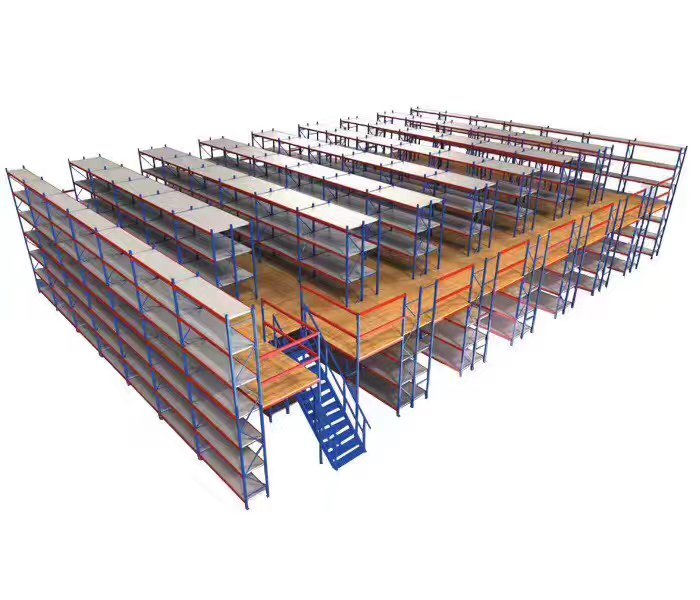

The Engineering Behind the Strength: Design Principles of Superior Modular Mezzanine Racking Systems

The reliability of any structure lies in its foundational engineering. When businesses invest in a modular mezzanine racking system, they are not just purchasing steel; they are investing in a engineered solution designed for safety and longevity. Leading manufacturers employ rigorous design protocols that adhere to international standards, ensuring every component works in harmony to support the intended load.

The design process for these modular mezzanine racking systems begins with a comprehensive analysis of the intended application. Engineers calculate the dead load (the weight of the structure itself), the live load (the weight of stored goods, personnel, and equipment), and dynamic loads (such as impact from machinery). For regions like Central Asia with seismic activity, seismic loads are a critical part of the equation. This data informs the selection of steel grade, the thickness of beams, and the configuration of the upright frames.

The result is a modular mezzanine racking system that is not just adequate, but possesses a significant safety factor, providing peace of mind for decades of operation. The very essence of a well-designed modular mezzanine racking system is its ability to perform predictably and safely under all anticipated conditions.

Material Science: The Steel That Builds Your Success

The choice of raw material is a primary differentiator between a mediocre platform and a top-tier modular mezzanine racking system. High-tensile, cold-rolled steel is the industry standard for high-quality modular mezzanine racking systems. This material offers an exceptional strength-to-weight ratio, meaning the structure can support immense loads without becoming unnecessarily bulky or heavy.

Furthermore, the finish applied to the steel components is crucial for durability, especially in varied climates. For instance, a modular mezzanine racking system installed in a humid coastal warehouse in Brazil requires a robust defense against corrosion. Manufacturers address this through advanced powder-coating processes or hot-dip galvanization. This protective layer ensures that the structural integrity of the modular mezzanine racking system remains uncompromised by rust or corrosion, significantly extending its service life and reducing long-term maintenance costs. The investment in premium materials for a modular mezzanine racking system is an investment in reduced total cost of ownership.

Operational Scenarios: Deploying Modular Mezzanine Racking Systems Across Industries

The versatility of modular mezzanine racking systems is one of their most compelling advantages. These systems are not confined to a single industry; they provide scalable solutions across a vast spectrum of sectors, each with unique requirements.

E-commerce and Retail Fulfillment Centers: In the fast-paced world of e-commerce, modular mezzanine racking systems are used to create multi-level pick zones. By storing fast-moving items on the mezzanine level with integrated shelving, companies can deploy a “goods-to-person” model, where pickers remain at stationary stations, and goods are brought to them via conveyors, dramatically increasing order accuracy and throughput. The flexibility of these modular mezzanine racking systems allows for easy reconfiguration as inventory profiles change seasonally.

Manufacturing and Assembly Plants: Manufacturing facilities utilize modular mezzanine racking systems for more than just storage. They are ideal for creating overhead offices, quality control stations, or light assembly areas. This frees up valuable production floor space for heavy machinery. A modular mezzanine racking system can also be designed to house raw materials or work-in-progress inventory directly above the production line, creating a highly efficient, vertical workflow.

Cold Storage and Food & Beverage: In cold storage environments, where every cubic meter is incredibly expensive to refrigerate, maximizing space is paramount. Insulated modular mezzanine racking systems can effectively double a freezer’s capacity. Special considerations, such as thermal breaks to prevent cold bridging, are incorporated into the design of a cold storage modular mezzanine racking system to maintain energy efficiency.

Automotive and Aerospace: These industries often deal with long, bulky, or heavy components. A heavy-duty modular mezzanine racking system with reinforced decks and high load capacities can be configured with cantilever arms or wide-span shelving to store everything from exhaust pipes to aircraft wings, keeping the main floor clear for assembly operations.

A Central Asian Case Study: Transforming a Textile Warehouse

A prominent textile distributor in Uzbekistan faced a critical space shortage that threatened to halt their growth. Their warehouse was filled to capacity with rolls of fabric, and ground-level expansion was impossible. By implementing a custom-designed modular mezzanine racking system, they were able to create a dedicated storage level for their bulk fabric rolls. The ground floor was reconfigured for cutting, packaging, and dispatch.

The new modular mezzanine racking system integrated a vertical reciprocating conveyor to move goods between levels efficiently. This transformation resulted in an 85% increase in storage capacity and a 30% improvement in order processing speed, all within their existing facility. This success story highlights the transformative impact a well-planned modular mezzanine racking system can have on a business’s operational ceiling.

The Financial Calculus: ROI of Investing in Modular Mezzanine Racking Systems

Justifying a capital expenditure requires a clear understanding of the return on investment (ROI). The financial benefits of a modular mezzanine racking system are tangible and multifaceted, making it one of the most sound investments a logistics or operations manager can propose.

The most direct financial benefit is the cost-per-square-meter savings. Compared to the cost of constructing a new building or leasing additional space, a modular mezzanine racking system typically offers new operational space at a fraction of the price. For example, if leasing new warehouse space costs $X per square meter, the one-time investment in a modular mezzanine racking system might equate to just a few years of lease payments, after which the space is effectively free.

Indirect financial gains are equally significant. An optimized layout, enabled by the modular mezzanine racking system, reduces labor travel time, leading to lower payroll costs for the same output. Improved inventory organization reduces stock loss and picking errors, saving money. Furthermore, the ability to handle increased business volume without moving prevents the massive one-time costs associated with relocation. When all these factors are modeled, the payback period for a high-quality modular mezzanine racking system is often surprisingly short, frequently under 24 months.

The Future-Proof Warehouse: Scalability and Adaptability

In today’s volatile market, a business’s storage system must be as dynamic as the business itself. The “modular” nature of modular mezzanine racking systems is their ultimate strategic advantage. Unlike a fixed building or a custom-built concrete mezzanine, a premier modular mezzanine racking system is designed for change.

These systems can be easily expanded, either vertically by adding a third level (where headroom permits) or horizontally by extending the deck area. They can also be reconfigured; a section can be modified to accommodate a new product line, or an entire level can be disassembled and reassembled in a new configuration or even a new location. This scalability ensures that a company’s initial investment in a modular mezzanine racking system is protected. The structure evolves alongside the business, preventing it from becoming an obsolete liability. This forward-thinking approach to storage, centered on adaptable modular mezzanine racking systems, is what separates growth-oriented companies from their competitors.

Navigating Regulations: Compliance and Safety for Modular Mezzanine Racking Systems

Safety is the non-negotiable cornerstone of any industrial structure. A reputable provider of modular mezzanine racking systems treats compliance not as a hurdle, but as a fundamental part of their service. This involves navigating a complex landscape of international and local regulations.

A best-practice modular mezzanine racking system installation will comply with a range of standards, which may include European (EN), American (ANSI/MH), or specific local building codes. Key safety features integral to a quality modular mezzanine racking system include:

Handrails and Toe-Kicks: Standard on all open sides to prevent falls.

Load Notices: Clearly displayed placards that state the maximum permissible load for the structure.

Professional Installation: Certified installers who follow precise procedures to ensure every bolt is torqued to specification.

Periodic Inspection Protocols: Providers often offer inspection services to ensure the modular mezzanine racking system continues to meet all safety standards throughout its lifecycle.

By partnering with an expert, businesses ensure their modular mezzanine racking system is not only efficient but also a safe and compliant working environment for their employees, mitigating risk and reinforcing corporate responsibility.

Conclusion: Building Your Competitive Advantage, One Module at a Time

In the relentless pursuit of operational excellence, the strategic utilization of space is a critical frontier. For businesses across Latin America, Central Asia, and beyond, the answer to space constraints is no longer a costly horizontal expansion. The modern solution is vertical, modular, and intelligent. A well-designed and professionally installed modular mezzanine racking system represents a paradigm shift in warehouse management, transforming underutilized vertical air into high-value, productive square footage.

The journey toward a more efficient and profitable operation begins with a single, informed step. The comprehensive, no-obligation warehouse audit offered by industry leaders is that first step. It is a data-driven conversation that moves beyond theoretical benefits to deliver a concrete, customized plan for growth. By choosing to explore the potential of a modular mezzanine racking system, businesses are not just installing a structure; they are installing a powerful engine for future growth, resilience, and market leadership.

Frequently Asked Questions (FAQs)

Can a modular mezzanine racking system be designed to accommodate specific, unusually shaped inventory?

Absolutely. The design flexibility of modular mezzanine racking systems is a key strength. Engineers can customize bay sizes, deck heights, and integrate specialized storage solutions like cantilever arms for long items or small-bin shelving for parts, ensuring every inch of the modular mezzanine racking system is optimized for your specific goods.What is the typical process for obtaining necessary permits for a modular mezzanine racking system installation?

A reputable provider will manage the entire permitting process on your behalf. Their engineering team prepares the required structural calculations and drawings, submits them to the local building authority, and liaises with officials until the permit for the modular mezzanine racking system is approved, ensuring a smooth and compliant project rollout.How does the maintenance requirement for a modular mezzanine racking system compare to traditional storage solutions?

High-quality modular mezzanine racking systems require minimal maintenance. An annual visual inspection for loose bolts or damage and ensuring load limits are respected is typically sufficient. This is often less burdensome than maintaining multiple, scattered standalone shelving units and is a key part of the long-term value proposition of a modular mezzanine racking system.Are there any limitations on the types of flooring a modular mezzanine racking system can be installed on?

While modular mezzanine racking systems are highly adaptable, the existing floor must be capable of supporting the additional point loads. This is a primary focus of the initial audit. In cases of weaker floors, the design of the modular mezzanine racking system can be adjusted to distribute the load over a larger area, often without the need for expensive floor reinforcement.Can lighting and electrical conduits be integrated directly into the modular mezzanine racking system?

Yes, integration is standard practice. To ensure a safe and well-lit working environment on the mezzanine level, lighting fixtures, power outlets, and data conduits can be seamlessly incorporated into the design of the modular mezzanine racking system, running along beams or uprights to provide power where it’s needed without cumbersome trailing cables.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com