📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Unlocking Hidden Capacity Within Your Four Walls

For warehouse and operations managers, the constant pressure to do more with less is a relentless challenge. Inventory levels fluctuate, SKU counts explode, and the seemingly immutable four walls of the facility begin to feel like a straitjacket. The conventional playbook—costly physical expansion, disruptive relocation, or off-site leasing—presents a daunting financial and operational hurdle. This definitive guide presents a superior alternative: the strategic implementation of a mezzanine racking warehouse system. This solution represents the pinnacle of industrial ingenuity, a method to genuinely double your productive storage footprint without a single brick being laid for a new building.

The following sections will dissect every facet of these engineered systems, from the foundational principles of structural integrity and seamless racking systems integration to the advanced synergy with automation technologies like AGVs and AS/RS. This resource is designed to provide the comprehensive insight needed to make an informed decision, showcasing how a mezzanine racking warehouse is not merely an installation but a transformative strategic investment in your operation’s future efficiency and scalability.

Decoding the Mezzanine Racking Warehouse: An Engineered Ecosystem

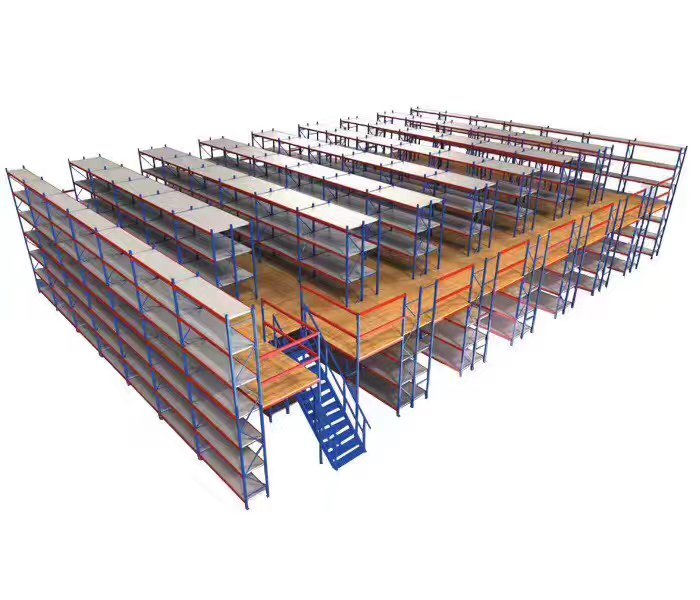

A mezzanine racking warehouse setup is fundamentally different from a simple storage platform. It is an engineered, free-standing structural ecosystem installed within an existing building, designed to create multiple tiers of highly functional space. The critical distinction lies in the integration; a true mezzanine racking warehouse solution sees the structural mezzanine and the storage racking systems designed as a single, cohesive unit. This synergy allows the system to handle immense dynamic and static loads, supporting everything from palletized goods and narrow aisle forklifts to sophisticated automated retrieval systems.

The transformative power of a mezzanine racking warehouse concept is its mastery of the cubic air space. Traditional warehouses often operate in two dimensions, overlooking the vast, unused volume that extends from the floor to the ceiling. A professionally designed mezzanine racking warehouse system capitalizes on this third dimension, converting empty air into a structured, accessible, and high-density storage asset. It is the ultimate expression of vertical optimization, effectively creating a new warehouse within the confines of the original structure. Every project undertaken is a custom-engineered endeavor, tailored to the specific dimensions, load requirements, and operational goals of the facility, ensuring the final mezzanine racking warehouse is a perfect fit for its environment.

The Compelling Financial Calculus: Mezzanine Racking Warehouse ROI

When capacity constraints begin to throttle growth, the financial analysis of potential solutions becomes paramount. The comparison between constructing a new building, relocating, and deploying a mezzanine racking warehouse system reveals a stark contrast in capital expenditure and return on investment. The economics of choosing a mezzanine racking warehouse are overwhelmingly persuasive, offering a path to rapid capacity expansion with minimal financial disruption.

A Detailed Cost-Benefit Analysis: Mezzanine vs. Brick-and-Mortar Expansion

The cost profile of a traditional expansion is burdensome. It encompasses land acquisition (if available), architectural services, foundation work, construction materials, labor, and new utility hookups, often culminating in a cost of hundreds of dollars per square foot. Conversely, a high-quality mezzanine racking warehouse system delivers new space at a fraction of that cost. The investment is directed solely into the materials, engineering, and installation of the structure itself, bypassing the exorbitant costs associated with exterior walls, roofing, and land. The return on investment for a mezzanine racking warehouse is frequently realized in a matter of months due to the immediate ability to house more inventory, accommodate new clients, or streamline operations, all without a corresponding increase in property taxes or base rent. The financial agility afforded by a mezzanine racking warehouse solution allows businesses to reallocate capital towards revenue-generating activities like sales and marketing, rather than sinking it into fixed assets.

Phased Implementation: Maintaining Productivity Through Installation

A common concern among operators is the potential for operational downtime during the installation of a mezzanine racking warehouse. This concern is mitigated through meticulous project management and a phased installation strategy. Experienced providers understand that warehouse operations cannot simply pause. Installation teams work in coordinated phases, often during off-peak hours or in designated sections of the facility, to ensure that receiving, shipping, and order picking activities continue with minimal interference. The modular nature of the mezzanine racking warehouse components allows for swift assembly, turning over new operational space in a remarkably condensed timeframe and ensuring that the pain of installation is far outweighed by the prolonged gain in capacity and efficiency.

The Bedrock of Safety: Engineering a Mezzanine Racking Warehouse

The paramount priority in any mezzanine racking warehouse project is structural integrity and safety. This is not an area for compromise or off-the-shelf solutions. Every aspect of the design and installation process is governed by rigorous engineering principles and a strict adherence to all relevant local building codes, OSHA regulations, and standards set forth by the Rack Manufacturers Institute (RMI). The creation of a safe mezzanine racking warehouse environment is a non-negotiable commitment.

Load Capacity Engineering: The Science of Dynamic and Static Forces

The safety and longevity of a mezzanine racking warehouse hinge on precise load calculations. Engineering must account for two primary types of loads:

Dead Load (Static Load): This refers to the inherent weight of the mezzanine racking warehouse structure itself—the steel columns, beams, decking, staircases, and guardrail systems.

Live Load (Dynamic Load): This is the additional weight the structure is designed to support during operation. This includes the weight of stored inventory, personnel, and critically, any material handling equipment such as pallet trucks, order picking carts, or even narrow aisle forklifts that will operate on the platform. Engineers design for maximum potential capacity, ensuring the mezzanine racking warehouse can handle these loads without unacceptable deflection or risk, often incorporating significant safety factors into all calculations.

Material Specifications: The Building Blocks of Durability

The choice of materials directly dictates the strength, durability, and lifespan of the mezzanine racking warehouse.

Structural Steel Framework: The skeleton of the system is typically constructed from high-grade, hot-rolled steel. The columns, main beams, and cross braces are meticulously specified for their gauge, yield strength, and structural properties to create a rigid and robust frame capable of spanning required distances and supporting design loads.

Decking Options for Varied Applications: The decking forms the operational floor of the mezzanine racking warehouse and is selected based on application needs.

Heavy-Duty Steel Bar Grating: Provides exceptional strength and durability while allowing light, air, and sprinkler water to pass through to the level below, making it ideal for general storage areas.

Stamped Steel Decking: Offers a solid, smooth surface that is excellent for wheeled traffic, order picking carts, and lighter-duty applications, often providing a more comfortable walking surface.

Plywood/Composite Decking over Stringers: A cost-effective solution for areas designated for very light storage or office space, though it requires protection from moisture and wear.

Seamless Integration with Building Systems

A mezzanine racking warehouse must become a fully integrated component of the building’s infrastructure. This requires careful coordination with existing systems:

Fire Suppression Systems: Building codes mandate complete sprinkler coverage on all levels. The design of the mezzanine racking warehouse must include a new sprinkler riser and strategically placed heads on the mezzanine level itself, as well as ensure adequate coverage for the space created beneath the deck. This is a non-negotiable safety requirement.

Lighting and Electrical: Effective illumination is critical for safety and accuracy. New energy-efficient LED lighting is installed both beneath the mezzanine to maintain light levels on the ground floor and on the mezzanine level to create well-lit, safe work zones for order picking and inventory management. Electrical conduits for equipment and workstations are also integrated into the design.

HVAC and Ventilation: While not always fully climate-controlled, adequate ventilation is considered, especially if the mezzanine racking warehouse level will be occupied by personnel for extended periods.

The Fusion of Structure and Storage: Mezzanine Racking Integration

The ultimate performance of a mezzanine racking warehouse is realized when the structural platform and the storage racking systems are conceived as a single, unified system. This holistic design approach is what separates a true capacity-doubling solution from a mere raised platform.

Selective Pallet Racking: The Workhorse of the Mezzanine Level

The most prevalent and versatile integration is with selective pallet racking. In a well-designed mezzanine racking warehouse, the racking uprights are securely bolted directly to the mezzanine’s structural deck. This integration uses the inherent strength of the mezzanine frame to support the racking loads, allowing for the creation of tall, stable, high-bay storage on the upper level. This configuration can be designed to mirror the storage layout below or to serve a completely different function, such as housing slow-moving bulk inventory on the upper level while reserving the lower, more accessible areas for fast-moving goods. The engineering ensures all load paths are correctly calculated and transferred through the mezzanine racking warehouse structure directly to the building’s foundation.

Mastering the Ground Floor: Leveraging the Space Beneath the Mezzanine

The area beneath the mezzanine racking warehouse platform is invaluable real estate, often overlooked in initial planning. This space can be strategically repurposed for a multitude of high-impact functions:

High-Density Storage Solutions: The lower clearance often makes this zone perfect for installing drive-in racking, push back racking, or pallet flow systems, maximizing storage density for specific SKU types.

Staging and Logistics Hubs: Creating dedicated, protected zones for inbound receiving, outbound shipping staging, and cross-docking operations.

Value-Added Services (VAS) Zones: Housing light assembly, kitting, labeling, or customization workstations, centralizing these processes in a defined area.

Administrative and Support Spaces: Building enclosed offices, locker rooms, break areas, or maintenance shops, effectively freeing up prime floor-level space for revenue-generating inventory storage.

The Automated Mezzanine Racking Warehouse: The Pinnacle of Efficiency

For the modern distribution center, peak efficiency is achieved through automation. A mezzanine racking warehouse provides the perfect physical framework to host and integrate advanced automation technologies, transforming a storage solution into a high-throughput, intelligent fulfillment engine.

AGVs and Robotic Handling on Elevated Levels

Operating automated equipment on a raised platform within a mezzanine racking warehouse is a sophisticated but highly effective practice. Automated Guided Vehicles (AGVs) and unmanned forklifts can be seamlessly integrated into the workflow. These robots are programmed to navigate to freight elevators or conveyor lifts, transport themselves to the mezzanine level, and then execute precise put-away and retrieval missions within the racking systems. This automation within the mezzanine racking warehouse removes human operators from repetitive and potentially hazardous tasks, increases throughput, and enables continuous operation.

Conveyor and Vertical Transport System Integration

To create a truly continuous flow of goods between the different levels of a mezzanine racking warehouse, conveyor systems are indispensable. Spiral conveyors, vertical reciprocating conveyors (VRCs), and continuous vertical lifts can be seamlessly integrated into the structure. These systems automatically move totes, cartons, or full pallets from the ground-floor receiving area up to the mezzanine racking warehouse storage or order picking zones, and then back down to packing and shipping stations. This creates a fluid, high-volume material handling system where the mezzanine racking warehouse acts as the dynamic heart of the fulfillment process.

Designing for Peak Performance: Order Picking in a Mezzanine Racking Warehouse

Order picking is notoriously the most labor-intensive and time-consuming process in any warehouse. The design of a mezzanine racking warehouse offers a unique opportunity to re-engineer this process for maximum efficiency and ergonomics, dramatically improving pick rates and reducing travel time.

Ergonomic Aisle Design and Traffic Flow Management

The layout of a mezzanine racking warehouse pick level is meticulously planned for optimal human and material flow. Aisles are designed to be wide enough to accommodate order picking carts, portable data terminals, and potentially even narrow aisle equipment, all while ensuring clear pathways to prevent congestion. The strategic placement of stairs, gates, and material lifts is critical to minimize the distance pickers must travel between the mezzanine level and the downstream packing and shipping stations located on the ground floor. This thoughtful design of the mezzanine racking warehouse directly translates into fewer steps taken per order and faster cycle times.

Advanced Pick Technologies: Carton Flow and Put-to-Light Systems

For high-volume, multi-SKU fulfillment, the mezzanine racking warehouse can be transformed into a state-of-the-art pick module. This involves installing carton flow track or pallet flow racking on the mezzanine level. Products are replenished from the back (often from the bulk storage racks on the same mezzanine level), and gravity feeds them forward to the pick face. This creates an ergonomic, “golden-zone” picking environment where workers remain in one location and simply take the item that arrives in front of them. This design within a mezzanine racking warehouse can be further enhanced with put-to-light or pick-to-light systems, voice picking, or augmented reality glasses to guide pickers, ensuring accuracy and speed are maximized. This approach to designing a mezzanine racking warehouse for picking can often double or triple existing pick rates.

Case Study: From Capacity Crisis to Market Leadership with a Mezzanine Racking Warehouse

A compelling real-world example involves a mid-sized e-commerce fulfillment company operating from a 25,000 sq ft facility. Facing a 40% annual growth rate, they were bursting at the seams, with pallets clogging aisles and order fulfillment times slipping. Quotes for a new 50,000 sq ft building were financially prohibitive and would have forced a disruptive relocation.

The Engineered Solution: A comprehensive, two-tier mezzanine racking warehouse system was designed and installed, adding 18,000 square feet of highly functional space, effectively increasing their capacity by 72%.

Ground Floor Transformation: The space beneath the mezzanine racking warehouse was configured with push back racking for storing best-selling products in a high-density format, with dedicated zones for inbound inspection and outbound packaging.

Mezzanine Level 1: This level featured a versatile selective pallet racking configuration for medium-velocity SKUs and served as the primary replenishment source for the level above.

Mezzanine Level 2: The top level was engineered as a high-speed pick module with carton flow racking and put-to-light technology for the fastest-moving items. Two vertical belt conveyors efficiently transported picked orders down to the packing stations.

The Tangible Results: The facility was transformed into a 43,000 sq ft operational powerhouse without moving. The company achieved a 220% increase in daily order output, reduced picking errors by 65%, and onboarded two major new retail clients due to their demonstrated capacity and efficiency. The entire mezzanine racking warehouse project achieved a full return on investment in under 11 months through the new revenue and operational savings it generated, solidifying their position as a market leader.

The Blueprint for Success: The Mezzanine Racking Warehouse Installation Process

The journey to a fully operational mezzanine racking warehouse is a meticulously planned and executed process, requiring close collaboration between the provider and the client. Understanding this workflow demystifies the project and sets clear expectations.

Initial Consultation and Feasibility Assessment: A specialist conducts a detailed site visit to measure clear heights, assess floor conditions, evaluate column spacing, and understand unique operational workflows and challenges.

Detailed Engineering and Custom Design: Using data from the assessment, in-house engineers create detailed CAD drawings and structural calculations. These plans are presented for client approval and are used to secure any necessary local building permits.

Precision Manufacturing: All structural steel components, decking, and integrated racking systems are precision-manufactured to specification in a controlled factory environment, ensuring the highest quality and fit.

Phased and Coordinated Installation: A certified installation team executes the project in planned phases to minimize operational disruption. This includes coordinating with other trades, such as electricians and sprinkler fitters, to ensure all systems are integrated on schedule.

Final Load Testing and Client Handover: The completed mezzanine racking warehouse undergoes a rigorous final inspection and load testing protocol. The provider then conducts a comprehensive walk-through with the client’s operations team, ensuring they are fully trained and comfortable with the new system before final handover.

Conclusion: Architecting the Future of Your Warehouse Today

The constraint of physical space is a solvable problem. The evidence is clear: a mezzanine racking warehouse system presents the most strategic, financially astute, and operationally brilliant answer to the capacity puzzle. It transcends the definition of a simple storage add-on; it is a comprehensive re-imagining of your facility’s potential, a masterclass in vertical integration that doubles your usable square footage without the monumental cost and disruption of expansion. By leveraging the unused cubic volume of your building, you invest in a multi-level, automated, and hyper-efficient mezzanine racking warehouse operation that is purpose-built for scalability and growth. In the final analysis, the most critical question for a growing business is no longer whether they can afford to install a mezzanine racking warehouse, but whether they can afford the staggering opportunity cost of not doing so.

Frequently Asked Questions (FAQs)

Q1: What is the typical lead time from signing a contract to completing the installation of a mezzanine racking warehouse?

The total project timeline for a mezzanine racking warehouse is influenced by its scale and complexity. Generally, manufacturing of custom components takes 4-6 weeks. The on-site installation phase for a standard system typically requires 3-5 weeks, with more complex automated integrations taking longer. A detailed and phased project schedule with clear milestones is always provided upfront, ensuring full transparency throughout the process of building your mezzanine racking warehouse.

Q2: If our company relocates in the future, can the mezzanine racking warehouse be disassembled and moved to our new facility?

Absolutely. A significant advantage of a structural mezzanine racking warehouse is its inherent modularity and reconfigurability. The system can be carefully disassembled, transported, and reinstalled in a new location. While there are costs associated with the labor of disassembly/reassembly and potential modifications for the new space, this process protects your capital investment and typically costs a fraction of purchasing a completely new mezzanine racking warehouse system.

Q3: Are there specific building types or conditions that are not suitable for a mezzanine racking warehouse?

While versatile, a mezzanine racking warehouse does require certain conditions. The most critical factor is sufficient clear height—typically at least 15-16 feet—to accommodate the structure itself and provide practical headroom on both levels. The existing building floor must also be in good condition and able to support the concentrated point loads from the mezzanine columns. Buildings with significant roof obstructions or very weak flooring may require remedial work prior to installation, which can be assessed during the initial feasibility study for your mezzanine racking warehouse.

Q4: How does the permitting process work for a mezzanine racking warehouse installation?

The permitting process is a crucial step handled by the provider. Because a mezzanine racking warehouse is a permanent structural addition, it typically requires a building permit from the local authority having jurisdiction (AHJ). The provider’s engineering team prepares all necessary structural calculations and architectural drawings required for the permit application. They often manage the entire submission process on the client’s behalf, leveraging their experience to ensure all code requirements are met and the permit is obtained smoothly and efficiently.

Q5: Can a mezzanine racking warehouse be designed to support specific heavy machinery or specialized industrial processes?

Yes, without a doubt. This is where custom engineering shines. A mezzanine racking warehouse can be specifically designed to support exceptional loads, whether from heavy industrial machinery, large-scale assembly operations, or massive archival storage. Engineers would calculate the required live load capacity (e.g., 250 psf, 500 psf, or more) and design the structural framework, decking, and connections accordingly. This makes a mezzanine racking warehouse a viable solution not just for storage, but for a vast range of industrial and manufacturing applications.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com