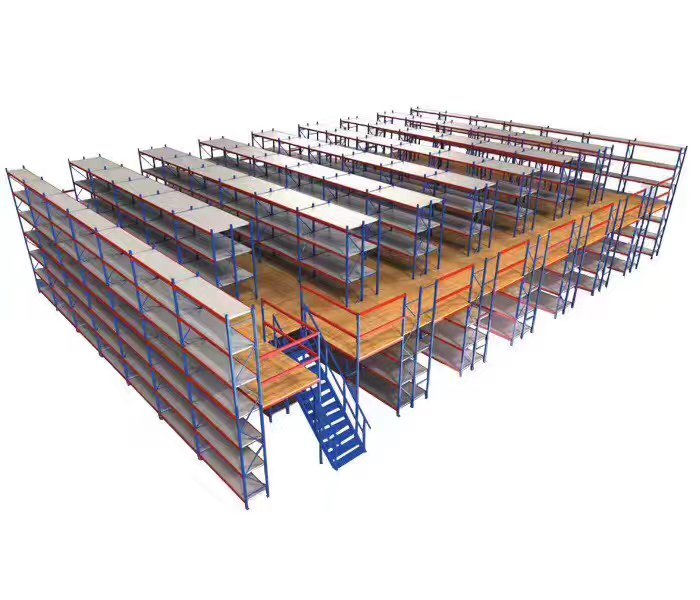

📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Mastering Mezzanine Racking Seismic Considerations: The Definitive Guide for Resilient Warehousing in Southeast Asia

For logistics directors, warehouse managers, and industrial facility operators across Southeast Asia, the Pacific Ring of Fire is not just a geographical term; it is a persistent operational reality. The decision to implement a mezzanine racking system is a strategic move to maximize cubic space and improve efficiency. However, in seismically active regions, this decision carries a profound responsibility. Standard mezzanine racking seismic considerations are often insufficient, bordering on negligent.

This comprehensive guide delves deeper than any other resource, moving from basic awareness to a master-class in applied engineering. It is designed for professionals who understand that true cost-saving is measured in risk mitigation and business continuity. The following sections will unpack the critical, non-negotiable mezzanine racking seismic considerations that form the bedrock of a truly resilient warehouse operation, protecting personnel, assets, and supply chain integrity.

<h2>The Seismic Imperative: Why Standard Mezzanine Racking is a Catastrophic Liability</h2>

The fundamental error many organizations make is treating mezzanine racking seismic considerations as a secondary check-box item. A mezzanine is a structure within a structure, and during an earthquake, it is subjected to complex, dynamic forces that standard static load calculations utterly fail to capture. The primary mezzanine racking seismic considerations in this context revolve around force and motion. Seismic events generate powerful horizontal ground accelerations that violently shake a warehouse’s primary structure.

A freestanding mezzanine racking system, if not integrally designed for these forces, will sway independently, leading to a phenomenon known as “racking.” This can cause column failure, connection shearing, and a progressive, pancake-style collapse. The resulting damage is not merely inventory loss; it is a total operational standstill, potential loss of life, and crippling legal liability. Therefore, the initial and most crucial of all mezzanine racking seismic considerations is acknowledging that in regions like Indonesia, the Philippines, and parts of Malaysia, a seismically rated design is not an optional upgrade—it is the minimum viable product for responsible operations.

<h2>Deconstructing the Dynamics: The Physics Behind Seismic Failure</h2>

To fully appreciate the engineering solutions, one must first understand the mechanisms of failure. The core mezzanine racking seismic considerations are rooted in physics.

<h3>Inertia and Overturning Moments</h3>

When the ground moves suddenly, the immense mass of stored inventory on the mezzanine deck resists that movement due to inertia. This resistance translates into powerful horizontal forces acting at the height of the load, creating what engineers call an “overturning moment.” This moment attempts to pry the racking away from its floor anchors and twist the entire structure. Standard designs, which prioritize vertical load capacity, lack the necessary resistance to counteract this pivotal force. Any comprehensive evaluation of mezzanine racking seismic considerations must begin with calculating these overturning moments based on the specific spectral accelerations expected at the site.

<h3>Harmonic Resonance and Building Interaction</h3>

A frequently overlooked aspect of mezzanine racking seismic considerations is the dynamic interaction between the mezzanine and the host building. Every structure has a natural frequency at which it vibrates. If the seismic shaking frequency matches the natural frequency of the mezzanine, harmonic resonance occurs, dramatically amplifying the shaking and leading to certain structural failure. Expert mezzanine racking seismic considerations involve analyzing the building’s dynamic properties to ensure the mezzanine’s design de-tunes it from this resonance, a process requiring sophisticated Finite Element Analysis (FEA) software.

<h2>The Pillars of Seismic Resilience: A Multi-Tiered Design Philosophy</h2>

True protection is achieved through a holistic design philosophy where mezzanine racking seismic considerations are embedded in every component, from the foundation to the roof.

<h3>1. Advanced Dynamic Load Analysis and Site-Specific Zoning</h3>

Generic seismic maps are a starting point, but professional mezzanine racking seismic considerations demand a site-specific assessment. This involves:

Determining the Seismic Design Category (SDC): Based on local geological data and international codes (IBC, ASCE 7).

Calculating Spectral Response Accelerations: Modeling the specific ground motion forces the structure must withstand.

Incorporating Soil-Structure Interaction: Understanding how the local soil type can amplify or dampen seismic waves.

These detailed mezzanine racking seismic considerations allow engineers to create a digital twin of the racking and subject it to simulated earthquakes, identifying and reinforcing potential failure points long before fabrication.

<h3>2. Structural Configurations: Beyond Basic Bracing</h3>

The structural skeleton must be inherently robust. Key mezzanine racking seismic considerations for the frame include:

Moment-Resisting Frames (MRFs): These use rigid, specially engineered connections between beams and columns that resist bending and rotation under lateral loads, offering superior performance over simple braced frames.

Dedicated Seismic Bracing Systems: Implementing robust X-bracing or K-bracing with high-strength steel rods or cables creates a truss system that effectively dissipates seismic energy.

Increased Frame Robustness: This often involves using larger column sizes, heavier gauge beams, and reduced bay spacing to enhance overall rigidity and reduce deflection.

<h3>3. The Heart of the Matter: Seismic-Grade Connections and Anchorage</h3>

This is the single most critical area of mezzanine racking seismic considerations. A failure here renders the strongest frame useless.

Slip-Critical Bolted Connections: Unlike standard bolts that bear against the bolt hole, these high-strength bolts are torqued to a specific tension, creating friction between the connected steel members. This friction must be overcome by shear forces before slippage occurs, providing a ductile and predictable failure mode.

Seismic Base Plates and Epoxy Anchor Bolts: The connection to the concrete slab is paramount. Mezzanine racking seismic considerations mandate oversized, reinforced base plates paired with high-strength, deeply embedded epoxy anchor bolts. These systems are designed to resist the simultaneous uplift and shear forces that would instantly fail a standard expansion anchor.

<h4>Case Study: The Manila Retrofit</h4>

A distribution center in Manila operated a standard mezzanine. A moderate tremor caused several standard bolted connections to shear, leaving the structure permanently tilted. A retrofit focused on advanced mezzanine racking seismic considerations was implemented, replacing all connections with slip-critical bolts and adding seismic bracing. When a larger quake struck months later, the system performed as designed, swaying elastically but holding firm, saving an estimated $2M in inventory and avoiding a months-long operational shutdown.

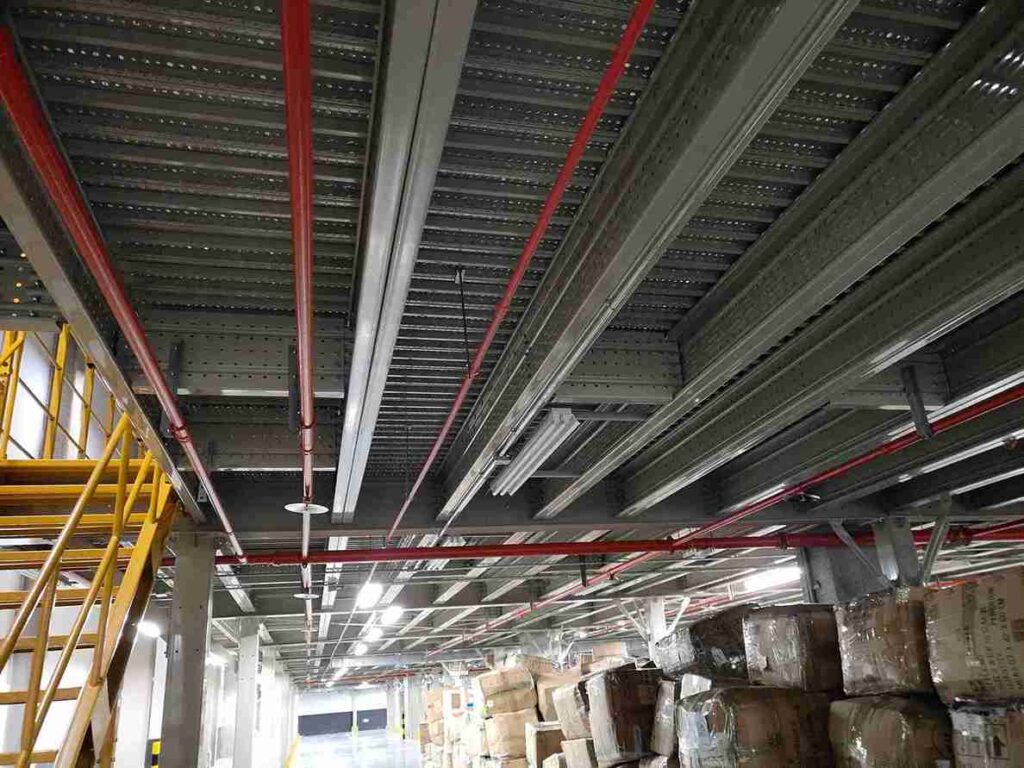

<h2>Integration and Isolation: The Mezzanine-Building Symbiosis</h2>

Sophisticated mezzanine racking seismic considerations extend beyond the rack itself to its relationship with the building.

<h3>Building Drift and Clearance Analysis</h3>

During an earthquake, a building will sway, and this lateral displacement is known as drift. A key mezzanine racking seismic considerations is ensuring adequate clearance between the mezzanine structure and the building’s columns, walls, and roof to prevent “pounding,” where the two structures impact each other, causing mutual damage.

<h3>Seismic Isolation for Mission-Critical Operations</h3>

For high-value, sensitive, or mission-critical storage, the pinnacle of mezzanine racking seismic considerations may involve seismic isolation. This advanced technique uses isolation bearings—components made of layered rubber and steel plates—placed between the mezzanine columns and the floor. These bearings decouple the mezzanine from the high-frequency shaking of the building, dramatically reducing the forces transferred to the structure and its contents.

<h2>Material Science: The Role of Ductility in Seismic Survival</h2>

The choice of material is a fundamental mezzanine racking seismic considerations. Steel must be strong, but in seismic zones, its ductility is more critical. Ductility is the ability of a material to undergo significant plastic deformation before fracture. A ductile steel member will bend and yield under extreme seismic load, providing a warning and absorbing massive amounts of energy. A brittle member will snap without notice. Therefore, specifying high-tensile, ductile steel is a non-negotiable mezzanine racking seismic considerations for ensuring a structure fails in a safe, controlled manner rather than catastrophically.

<h2>Load Security: The Often-Forgotten Final Frontier</h2>

Even the most perfectly engineered mezzanine will fail its purpose if the load it carries becomes unsecured. Comprehensive mezzanine racking seismic considerations must include the inventory itself.

Seismic Pallet Gates: Heavy-duty, lockable steel gates at deck edges prevent pallets from sliding off during shaking.

Containment Netting: High-strength steel or polymer netting can be installed vertically between rack levels or horizontally under decks to catch falling items.

Beam-Lock and Load Anchoring Systems: For high-value or hazardous materials, direct anchoring of pallets or containers to the racking beams provides the highest level of security.

<h2>The Professional Design and Implementation Workflow</h2>

A systematic approach is what separates theoretical mezzanine racking seismic considerations from a field-proven solution.

Comprehensive Site Audit and Risk Assessment: An engineer-led evaluation of the facility, its usage, and local hazards.

Conceptual Design and FEA Modeling: Creating and digitally stress-testing multiple design options.

Detailed Engineering and Drafting: Producing shop drawings that specify every component, connection, and torque value.

Certified Fabrication and Quality Control: Manufacturing in an ISO-certified facility with rigorous material and welding checks.

Expert Installation by Specialized Teams: Installation crews trained specifically in the critical procedures for seismic systems.

Load Testing and Final Certification: Providing a structural engineer’s stamped certification, a vital document for insurance and regulatory compliance.

<h2>The Compelling Business Case: Quantifying the ROI of Seismic Investment</h2>

The advanced mezzanine racking seismic considerations outlined herein represent an investment, but one with a clear and compelling return.

Insurance Premium Reduction: Many insurers offer discounts of 15-25% for facilities with professionally engineered seismic mitigation systems.

Ensured Business Continuity: The ability to resume operations immediately after an event provides an unparalleled competitive advantage.

Asset and Inventory Protection: Safeguarding millions of dollars in assets against a predictable regional risk.

Regulatory Compliance and Liability Mitigation: Demonstrating due diligence protects the company from legal repercussions and aligns with corporate governance best practices.

<h2>Conclusion: From Consideration to Unshakeable Foundation</h2>

In the high-stakes environment of Southeast Asian logistics, superficial mezzanine racking seismic considerations are inadequate. The journey from a basic storage platform to a resilient, seismic-ready structure requires a deep, engineering-led commitment where mezzanine racking seismic considerations inform every decision. It is a specialized field that demands experience, sophisticated tools, and an unwavering focus on safety. By partnering with experts who live and breathe these mezzanine racking seismic considerations, organizations can transform their warehouse from a vulnerable asset into a strategic, unshakeable foundation for growth, no matter what the ground beneath it may do.

Frequently Asked Questions (FAQs)

1. We have a low-rise warehouse. Are detailed mezzanine racking seismic considerations still necessary?

Yes, absolutely. Seismic forces are a function of ground acceleration and mass, not just building height. A low-rise building can still experience severe shaking. The mezzanine racking seismic considerations related to overturning moments and connection integrity are equally critical, as a collapse would be just as devastating.

2. How do local building codes in, say, Thailand versus Indonesia, impact your mezzanine racking seismic considerations?

While international standards like IBC and ASCE 7 form our core engineering basis, our mezzanine racking seismic considerations process always includes a rigorous review of and compliance with all local national codes. These codes often specify unique seismic zone factors, design philosophies, and material requirements that must be integrated into the final design to secure permitting and ensure local compliance.

3. Can a seismically designed mezzanine be reconfigured or relocated in the future?

This is a sophisticated mezzanine racking seismic considerations question. While possible, reconfiguration is not as simple as with standard racking. Any modification—moving a brace, changing beam levels—alters the dynamic response of the structure and must be re-analyzed by a structural engineer. Relocation is even more complex, as the new site’s seismic conditions and floor slab must be evaluated. It is often more cost-effective to design for future flexibility from the outset.

4. What role does the concrete slab’s thickness and strength play in your mezzanine racking seismic considerations?

The slab is the foundation of the entire system. Our mezzanine racking seismic considerations include a mandatory review of the slab’s design drawings or, if unavailable, conducting core sample tests. We must verify the slab’s compressive strength and thickness to ensure it can handle the concentrated loads and pull-out forces from the seismic anchor bolts. A weak slab will fail before the racking does.

5. Beyond earthquakes, do these mezzanine racking seismic considerations offer any other benefits?

Indeed. A structure designed with rigorous mezzanine racking seismic considerations is inherently more robust. It is better equipped to handle other dynamic loads, such as the vibrations from heavy machinery, the impact from material handling equipment (e.g., forklifts), and even high-wind events. The result is a structure with greater overall longevity, reduced maintenance, and enhanced day-to-day safety.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com