📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Ultimate Guide to Mezzanine Racking Load Capacity: Maximizing Storage & Slashing Costs

In the high-stakes world of logistics and warehouse management, the pursuit of efficiency is relentless. As industry pioneers with decades of experience in warehouse storage and automation, the professionals at [Company Name] have identified a single, often overlooked metric as the linchpin of storage integrity and profitability: mezzanine racking load capacity.

This is not merely a number on a specification sheet; it is the definitive declaration of a structure’s capability, the cornerstone of operational safety, and the key to unlocking unprecedented volumetric efficiency. A profound understanding and strategic optimization of mezzanine racking load capacity can transform a static storage area into a dynamic, revenue-protecting asset.

This comprehensive guide delves deeper than any other resource, moving beyond basic definitions to explore the advanced engineering, strategic integration, and financial implications of mastering mezzanine racking load capacity. It is an essential read for any warehouse manager, logistics director, or business owner determined to build a safer, more productive, and future-proof storage operation.

<h2>Deconstructing the Engineering: The Multifaceted Nature of Mezzanine Racking Load Capacity</h2>

To truly master the application of a mezzanine floor, one must first deconstruct the engineering principles that define its strength. The term mezzanine racking load capacity is a blanket phrase for a series of precise calculations, each critical to the system’s overall integrity. Misunderstanding these nuances is the primary cause of underperformance and catastrophic failure in multi-level storage systems.

<h3>Uniformly Distributed Load (UDL) vs. Point Load: A Critical Operational Distinction</h3>

The distinction between Uniformly Distributed Load (UDL) and Point Load is the most fundamental concept, yet it remains a common source of dangerous miscalculation.

Uniformly Distributed Load (UDL): This is the maximum load capacity when weight is perfectly and evenly spread across the entire decking surface. It is the standard benchmark for general storage applications. For instance, a stated mezzanine racking load capacity of 150 kg/m² as a UDL means every single square meter of the deck can support 150 kilograms, provided the load is perfectly distributed. This is ideal for palletized goods stored with even weight distribution, or for rows of shelving units with a large footprint.

Point Load (Concentrated Load): This is arguably the more critical figure for modern, automated warehouses. It defines the maximum weight that can be applied to a single, concentrated point on the deck. The mezzanine racking load capacity for point loads is always a separate and distinct figure.

A system might boast a generous UDL of 200 kg/m² but have a point load capacity of only 600 kg. This becomes a critical failure point when heavy machinery, the compact legs of a pallet racking system placed on the mezzanine, or the small, heavy wheels of an Automated Guided Vehicle (AGV) are introduced. Exceeding the point load mezzanine racking load capacity can lead to localized decking failure, beam deflection, and a compromise of the entire structure’s integrity.

<h3>The Structural Trifecta: Decking, Beams, and Columns</h3>

The overall mezzanine racking load capacity is a symphony conducted by three primary components, where the weakest link dictates the final performance.

Decking Material – The Primary Load Interface: The choice of decking is a direct determinant of the system’s mezzanine racking load capacity.

Heavy-Duty Steel Mesh: This is the industry gold standard for most industrial applications. Its open-grid design provides exceptional strength-to-weight ratio, allows for fire sprinkler penetration, and improves air circulation and light distribution. The specific gauge of the steel wire and the integrity of its weld points are engineered to meet precise mezzanine racking load capacity requirements.

Solid Steel Plate: Utilized in environments requiring a perfectly smooth, sealed surface for liquid containment or the use of wheeled carts. While offering high strength, its significant self-weight must be factored into the overall structural calculation, often influencing the final achievable mezzanine racking load capacity for live loads.

Plywood or Particle Board: A purely economical option for exceptionally light-duty, manual storage. Its susceptibility to moisture, fire, and wear makes it a poor choice for any operation where a reliable, long-term mezzanine racking load capacity is a requirement.

Beam Configuration – The Skeleton of the System: Primary and secondary beams form the skeleton that transfers the load from the deck to the columns. The mezzanine racking load capacity is heavily dependent on their size, profile, and spacing.

Span and Section Modulus: Larger, deeper beams with a higher section modulus are essential for supporting greater loads over longer spans. Engineering calculations determine the optimal beam layout to achieve the target UDL and point load mezzanine racking load capacity without excessive deflection.

Column and Bracing Network – The Foundation of Stability: The columns are the legs of the operation, carrying the entire load to the building’s foundation. The design of the mezzanine racking load capacity must account for column thickness, material grade (e.g., S355 steel), and the critical role of bracing.

Bracing for Lateral Stability: Diagonal bracing members are non-negotiable for resisting lateral forces. These forces can come from seismic activity, the dynamic impact of machinery, or even personnel movement. A robust bracing system ensures that the designed mezzanine racking load capacity remains stable and secure under real-world conditions, preventing sway and potential collapse.

<h2>The Strategic Imperative: How Optimized Load Capacity Drives Profitability</h2>

Viewing mezzanine racking load capacity through a purely technical lens misses its primary business value. A strategically specified mezzanine racking load capacity is not an expense; it is a direct investment in operational profitability and competitive advantage.

<h3>Maximizing Cubic Space: The Most Cost-Effective Real Estate Play</h3>

With industrial rental and purchase costs soaring in markets across Southeast Asia, the Middle East, and Latin America, the most intelligent growth strategy is often vertical. By building upwards with a mezzanine engineered for a high mezzanine racking load capacity, companies create new, highly functional floor space at a fraction of the cost of a physical expansion.

A system rated for 300 kg/m² mezzanine racking load capacity allows for the dense storage of high-turnover or heavy inventory overhead. This liberates precious ground-floor space for higher-value functions such as cross-docking, value-added services (kitting, labeling), or production lines, dramatically improving the revenue per square meter of the entire facility.

<h3>Enabling High-Density, High-Efficiency Workflow Design</h3>

A mezzanine is a functional tier in the operational workflow, not just a shelf in the sky. A correctly specified mezzanine racking load capacity enables the safe and efficient hosting of complex operations:

Multi-Level Pick Modules: By ensuring the mezzanine racking load capacity can support the weight of pickers, carts, and shelving, companies can create dedicated, high-density order-picking zones. These zones can be fed by gravity conveyors or chutes directly to packing stations below, slashing pick times and labor costs.

Integrated Office and Production Spaces: Specifying a lower, tailored mezzanine racking load capacity for administrative offices, quality control labs, or light assembly areas consolidates the entire supply chain under one roof, reducing overheads and improving communication.

The Foundation for Automation: This is the ultimate differentiator. A robust, correctly calculated mezzanine racking load capacity is the prerequisite for integrating automation. It must support the static and dynamic loads of Automated Storage and Retrieval Systems (AS/RS), conveyor systems, and serve as the operational pathway for AGVs and unmanned forklifts. The dynamic forces and concentrated point loads from this equipment require a forward-looking mezzanine racking load capacity specification that generic systems cannot provide.

<h3>The Immense Hidden Cost of Inadequate Load Capacity</h3>

The single greatest financial risk associated with a mezzanine project is not the initial investment; it is the catastrophic cost of failure due to an inadequate mezzanine racking load capacity. The repercussions extend far beyond the immediate damage:

Asset Destruction: The loss of inventory, racking, and equipment located on and under the collapsed structure.

Business Interruption: A halted operation cannot generate revenue. The cost of days or weeks of downtime can easily bankrupt a small or medium-sized business.

Regulatory and Liability Nightmares: Fines from building and safety authorities, coupled with skyrocketing insurance premiums and potential lawsuits from injured personnel, create a financial and reputational black hole.

The Human Factor: The unthinkable risk to human life is the ultimate reason why compromising on mezzanine racking load capacity is never an option.

**<h2>A Practical Framework for Calculating Your Mezzanine Racking Load Capacity Requirements</h2>

Determining the correct mezzanine racking load capacity is a systematic process that requires a detailed audit of current and future operations. This framework provides a roadmap for gathering the essential data needed for a precise engineering specification.

<h4>Step 1: Conduct a Comprehensive Inventory and Storage Media Audit</h4>

Palletized Goods: Record the maximum gross weight of your heaviest pallet (including the pallet itself). Determine the pallet footprint and how they will be stored—block stacked, or within racking placed on the mezzanine? The latter adds significant point loads that drastically influence the required mezzanine racking load capacity.

Shelving and Static Racking: Calculate the total loaded weight of each shelving unit and divide by its footprint to determine the load per square meter. This directly informs the UDL mezzanine racking load capacity needed in that zone.

Bulky and Irregular Items: For items stored without pallets or shelving, estimate their weight and contact area with the deck to understand both UDL and point load implications.

<h4>Step 2: Map All Dynamic and Concentrated Loads</h4>

This step is where most preliminary calculations fail. It requires foresight.

Material Handling Equipment (MHE): Will you use pallet jacks, order-picking carts, or forklifts on the mezzanine? Provide the manufacturer’s specifications for axle loads and wheel configurations. The point load from a pallet jack’s wheels is a critical data point for the mezzanine racking load capacity.

Fixed Equipment: Identify any heavy, fixed equipment like packing stations, printers, industrial scales, or robotic arms. Their exact weight and placement are non-negotiable inputs for the mezzanine racking load capacity calculation.

Personnel and Manual Carts: While a standard live load accounts for personnel, the movement of heavy manual carts or trolleys creates dynamic forces that must be considered within the overall safety factor of the mezzanine racking load capacity.

<h4>Step 3: Incorporate a Strategic Buffer for Future Growth</h4>

A mezzanine is a long-term capital investment. Specifying the mezzanine racking load capacity based solely on today’s needs is a short-sighted strategy. Industry best practice dictates incorporating a capacity buffer of 25-30% above the calculated maximum load. This buffer accommodates business growth, the introduction of heavier products, and the adoption of new technologies like automation, without requiring a costly and disruptive structural retrofit.

<h2>The Automation Nexus: Mezzanine Racking Load Capacity as the Enabler of Industry 4.0</h2>

The warehouse of the future is a seamlessly integrated, automated ecosystem. In this context, the mezzanine racking load capacity transitions from a static specification to a dynamic enabler of technological integration.

<h3>Engineering for AGVs and Robotic Fleet Operations</h3>

The introduction of AGVs and unmanned forklifts onto a mezzanine deck represents the pinnacle of dynamic loading. These vehicles do not apply static weight; they impose continuous, shifting forces through acceleration, deceleration, and precise positioning. A standard mezzanine racking load capacity calculation is insufficient. The structure must be engineered to absorb these vibrations and point pressures over millions of operational cycles.

This requires advanced finite element analysis (FEA) to model stresses and reinforce decking, beams, and connections accordingly. The resulting mezzanine racking load capacity specification is a specialized, high-performance benchmark designed for the age of automation.

<h3>Supporting Integrated Conveyor and AS/RS Systems</h3>

A mezzanine level can act as a high-density buffer or a dedicated picking level within an automated workflow. Automated conveyor systems and mini-load AS/RS that traverse the mezzanine add significant continuous loads. The mezzanine racking load capacity must support not only the static weight of the stored goods but also the combined weight of the automation hardware, the dynamic load of moving products, and the potential impact forces from sorting operations. Designing the mezzanine and the automation as a single, integrated system from the outset is the only way to ensure the mezzanine racking load capacity is perfectly matched to the operational demands, guaranteeing longevity and reliability.

<h2>Case Study: E-commerce Fulfillment Center Transformation via Strategic Load Capacity Planning</h2>

The Challenge: A major e-commerce logistics provider in Vietnam faced a 150% SKU growth, rendering its existing single-level fulfillment center a critical bottleneck. The cost of a new greenfield facility was prohibitive, and operational downtime was not an option. Their product mix was wildly diverse, from lightweight electronics to heavy power tools, demanding a highly flexible but supremely robust storage solution.

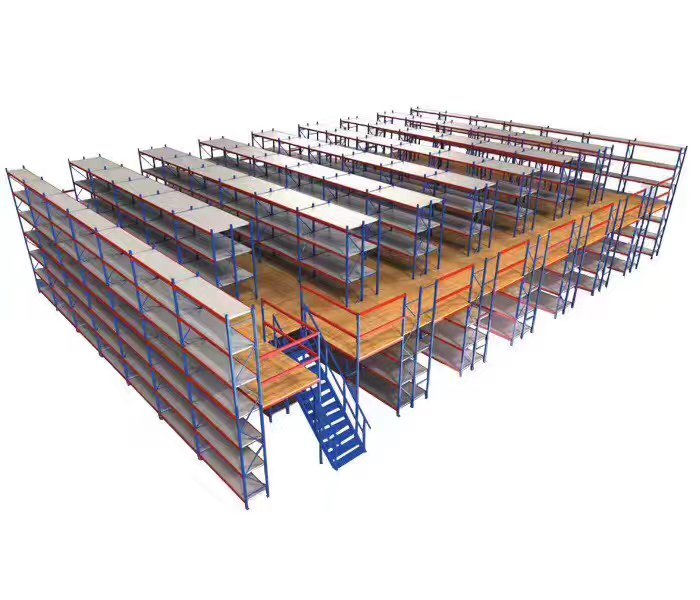

Our Engineering Solution: The team designed a multi-zone mezzanine system where the mezzanine racking load capacity was strategically tailored to specific operational functions, a concept known as zoned load capacity planning.

Zone A (Heavy Goods & Pallet Racking): This area was engineered for a superior mezzanine racking load capacity of 450 kg/m² UDL and a correspondingly high point load. This was necessary to support the weight of pallet racking itself and the dense storage of heavy automotive and hardware products.

Zone B (Medium-Duty Carton Flow & Shelving): Designed with a 250 kg/m² mezzanine racking load capacity, this zone accommodated multi-level shelving and carton-flow lanes for fast-moving consumer goods, optimizing the balance between strength and cost.

Zone C (Light-Duty Picking & Future AGV Integration): A dedicated area was pre-engineered with a 300 kg/m² mezzanine racking load capacity and enhanced point load specifications. This was done explicitly to future-proof the operation, allowing for the immediate installation of conveyor spurs and the seamless integration of an AGV-based goods-to-person system the following year.

The Quantifiable Result: The client effectively tripled their usable storage capacity without relocating. The zoned approach to mezzanine racking load capacity meant capital expenditure was optimized—they did not pay for a uniformly high mezzanine racking load capacity where it was not needed. More importantly, the pre-planned mezzanine racking load capacity for automation slashed the cost and time of the Phase II AGV integration by 40%. Overall picking efficiency soared by 75%, and the facility’s order throughput capacity increased by 200%, solidifying their competitive edge in the region’s booming e-commerce market.

<h2>Conclusion: The Foundation of Your Operational Integrity</h2>

In the final analysis, the specification of your mezzanine racking load capacity is the most critical decision in the planning of multi-level storage. It is the definitive factor that separates a safe, productive, and enduring asset from a potential liability. It is a complex calculation that balances immediate storage needs with long-term strategic goals, especially in an era defined by automation and supply chain volatility.

A deep, nuanced understanding of mezzanine racking load capacity—encompassing UDL, point loads, dynamic forces, and future-proofing—is what empowers logistics leaders to build warehouses that are not just larger, but smarter, safer, and significantly more profitable. When embarking on a mezzanine project, the paramount question is not simply about cost, but about the engineering rigor and strategic foresight behind the proposed mezzanine racking load capacity. The integrity of your entire operation depends on it.

Frequently Asked Questions (FAQs)

1. Can the load capacity of an existing mezzanine be increased or reinforced after installation?

Yes, structural reinforcement is possible but is a complex engineering undertaking that should never be assumed. It requires a certified structural engineer to assess the existing system. Methods may include adding new primary beams or columns to reduce spans, installing sister beams alongside existing ones, or upgrading the decking. However, the cost and disruption of retrofitting often far exceed the investment in specifying the correct mezzanine racking load capacity during the initial design phase.

2. How do seismic activity or high winds in certain regions affect mezzanine load capacity calculations?

In seismic zones (e.g., parts of Southeast Asia and Latin America) or regions prone to high winds, the structural design must account for significant lateral forces, not just vertical gravity loads. This often necessitates a denser and more robust bracing system, different connection details (e.g., moment-resisting connections), and can sometimes result in a de-rating of the advertised static mezzanine racking load capacity to ensure overall stability during a seismic event. Compliance with local building codes, which dictate these requirements, is non-negotiable.

3. What is the typical lifespan of a properly engineered and loaded mezzanine racking system?

A professionally engineered and installed mezzanine system that is consistently operated within its specified mezzanine racking load capacity can have a functional lifespan of 25 to 40 years. Its longevity is directly correlated to never exceeding its load limits, which prevents the onset of metal fatigue, creep, and permanent deformation in its structural members over time.

4. How do fire safety regulations and sprinkler systems impact the mezzanine design and its load?

International building codes, such as the IFC, typically require full sprinkler coverage on all occupied levels of a warehouse, including mezzanines. The additional dead load of the sprinkler system pipes (especially when filled with water), the sprinkler heads, and the potential need for fire-rated decking (like solid steel or concrete composite) must all be factored into the initial structural calculation for the mezzanine racking load capacity. Penetrations for sprinkler heads through beams also require specific engineering approval.

5. What is the difference between the “working load” and the “ultimate load” capacity specified by some manufacturers?

This is a critical distinction that speaks to the safety philosophy of the provider. The Working Load (or Safe Working Load) is the maximum load the structure is designed to support in daily operation. The Ultimate Load (or failure load) is the point at which the structure will collapse, and it is typically 1.5 to 3 times higher than the working load. This multiplier is the “factor of safety.” A reputable manufacturer will always clearly specify the safe working mezzanine racking load capacity; a focus on the ultimate load can be misleading and potentially dangerous if used for operational planning.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com