📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Manufacturing Mezzanine Racking Guide: Maximize Space & ROI [Expert Strategy]

For manufacturing plant managers and operations directors, the equation is often a difficult one: production is scaling up, but the factory’s footprint is not. The constant battle between storing raw materials, housing work-in-progress, and managing finished goods relentlessly encroaches on the precious floor space reserved for the actual, value-adding manufacturing process.

The daunting capital expenditure and logistical nightmare of building a new facility or expanding an existing one is often off the table. This universal industrial challenge is precisely where the strategic implementation of industrial mezzanine racking for manufacturing transforms from a simple storage add-on into a critical, high-return operational advantage.

This definitive guide, drawing on decades of field engineering and design experience, delves deep into how a purpose-built mezzanine racking for manufacturing system is a powerful investment in operational density and profitability. It will provide plant decision-makers with a clear, actionable framework for evaluating, planning, and leveraging this transformative solution for their unique operational landscape. The journey to unlocking the potential of your vertical cube starts here.

Beyond Storage: The Strategic Role of Mezzanine Racking in Modern Manufacturing

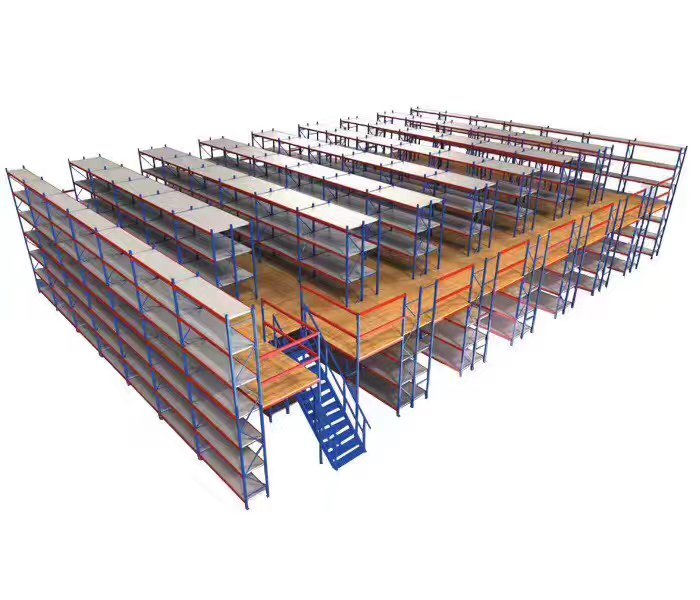

In the hyper-competitive global manufacturing landscape, spatial efficiency is a direct driver of margin and market share. Every square meter of a plant floor is prime real estate; when storage, kitting, or ancillary processes encroach upon primary production lines, the costs compound rapidly through delayed workflows, reduced throughput, and heightened safety risks. A manufacturing mezzanine racking system—an overhead structural platform that creates a second or third level within the existing facility—is the definitive answer to this spatial crunch. However, to perceive it merely as an elevated shelf is a profound underestimation of its strategic potential.

Leading providers of mezzanine racking for manufacturing approach the design process with a core, non-negotiable principle: integration over installation. The process begins not with measuring empty vertical space, but with a deep analysis of the entire material flow. How do raw components arrive? Where are they staged for assembly? What is the path of work-in-progress?

How quickly must finished products be dispatched to shipping? A properly engineered system for mezzanine racking for manufacturing becomes the central nervous system for internal logistics. It can be dedicated to high-density bulk pallet storage of raw materials, serve as a modular, well-lit assembly area for light production, house critical packaging and kitting operations, or even provide an enclosed, vibration-dampened office or quality control lab with direct visual oversight of the factory floor.

This strategic versatility is what separates a simple space-saver from a true, profit-generating asset. The decision to invest in mezzanine racking for manufacturing is, therefore, a decision to fundamentally re-architect a plant’s workflow for maximum efficiency.

Key Operational Challenges a Mezzanine Racking System Solves

The Cluttered Production Line: When components and sub-assemblies are stored haphazardly around high-value machinery, it slows down operators, increases search times, and creates significant tripping hazards. A dedicated mezzanine racking for manufacturing installation clears the floor, decisively dedicating ground-level space purely to value-adding production activities.

Inefficient, Linear Material Flow: A strategically positioned mezzanine racking for manufacturing platform enables a vertical “drop-through” or “feed-to-line” system. Bulk items are stored on the upper level, using gravity conveyors, vertical reciprocating conveyors (VRCs), or spiral chutes to deliver them precisely to the point of use on the production line below, slashing internal transport times.

The Prohibitive Cost of Physical Expansion: When weighed against the astronomical costs, lengthy timelines, and regulatory hurdles of physical building expansion, a project for mezzanine racking for manufacturing is demonstrably faster, more cost-effective, and typically requires no change to the building’s exterior footprint or complex planning permissions.

The Critical Need for Process Segregation: Certain high-value processes, like clean-room assembly, sensitive electronic testing, or pharmaceutical compounding, require isolation from the main factory environment. An enclosed mezzanine racking for manufacturing level provides this essential segregation without sacrificing the crucial proximity to the main operation, ensuring oversight and minimizing handling.

Engineering Your Success: A Deep Dive into Mezzanine Racking Design & Structure

The industrial environment is unforgiving, and not all mezzanine solutions are engineered to withstand its demands. The notion of an “off-the-shelf” mezzanine racking for manufacturing system is a dangerous misconception. The structural integrity, long-term performance, and ultimate safety of the installation hinge on a meticulous, peer-reviewed engineering process. Reputable specialists utilize advanced finite element analysis (FEA) software to model load capacities, seismic factors, and dynamic forces long before any steel is cut. This rigorous approach to designing mezzanine racking for manufacturing is what separates credible partners from mere suppliers.

Core Structural Components Explained

A foundational understanding of the anatomy of a mezzanine racking for manufacturing system is crucial for any plant manager to make an informed, confident decision.

Upright Columns:These are the vertical supports that bear the entire gravitational load of the structure, its decking, and the intended live load (inventory, equipment, personnel). High-grade mezzanine racking for manufacturing uses high-strength, cold-formed or structural steel columns, with robust, precisely engineered base plates that are securely anchored to a certified concrete floor using high-tensile bolts.

Primary and Secondary Beams:The primary beams form the main support framework, spanning between the upright columns. The secondary beams (or joists) then run perpendicular to the primaries, creating a rigid grid onto which the decking is installed. The spacing, depth, and steel gauge of these beams are calculated with precision based on the intended live load, a critical step in the engineering of reliable mezzanine racking for manufacturing.

Decking Options for Performance and Compliance:The choice of decking is a critical decision impacting safety, functionality, and compliance.

Heavy-Duty Steel Bar Grating: This is the preferred option for many applications of mezzanine racking for manufacturing where fire code compliance, ventilation, or light penetration is paramount. Its open design allows air, natural light, and sprinkler water to pass through unimpeded, maintaining the integrity of the building’s safety systems.

Solid Steel Plate or Checker Plate: This provides a completely solid, durable surface, ideal for storing small items, creating a clean, finished look for office or assembly spaces, and containing spills. It is a hallmark of heavy-duty mezzanine racking for manufacturing.

Plywood-over-Steel: A cost-effective option for very light-duty storage or archival purposes, but it lacks the durability and longevity of all-steel solutions in a demanding manufacturing setting and is seldom recommended for serious mezzanine racking for manufacturing projects.

Integrated Access & Safety Systems: A mezzanine racking for manufacturing structure is inert without safe, efficient access. Industrial-grade staircases with integrated landings, dedicated pedestrian stairwells, and for heavier loads, material lifts or even integrated conveyor systems are essential. Safety is non-negotiable; all reputable designs must include full perimeter guardrails meeting strict height standards, kick-plates (or toe-boards), and self-closing safety gates.

Load Capacity: The Most Critical Engineering Metric

This is the cornerstone of a safe and effective mezzanine racking for manufacturing project, and it’s where inexperienced providers fail catastrophically. Load capacity is meticulously broken down into two distinct categories:

Uniform Live Load (ULL): This is the distributed weight the mezzanine deck is designed to support across its entire surface, typically measured in pounds per square foot (PSF) or kilonewtons per square meter (kN/m²). For storage applications in mezzanine racking for manufacturing, this can range from 125-150 PSF for light archive storage to over 300-500 PSF for dense palletized goods or light assembly.

Concentrated Load (CL): This refers to the maximum weight that can be applied to a small, specific area, such as the leg of a heavy piece of machinery, a pallet jack point, or a single pallet rack upright. A system might have a ULL of 150 PSF but a CL of 2,500 pounds, meaning it can safely support a very heavy item in one spot as long as the overall distributed load across the entire deck is not exceeded.

Professional engineers specializing in mezzanine racking for manufacturing calculate for both scenarios simultaneously, ensuring the structure can handle the complex, real-world loads of a dynamic manufacturing environment.

Tailored Solutions: Matching Mezzanine Types to Your Manufacturing Needs

The concept of a generic mezzanine racking for manufacturing solution is a myth. The optimal configuration for any plant is a direct function of its specific operational requirements, building constraints, and future growth trajectory. The choice of system type is the first and most critical design decision.

1. The Freestanding Structural Mezzanine

This is the most common and versatile type of mezzanine racking for manufacturing deployed. It is a self-supporting structure, entirely independent of the building’s primary walls and columns. Its paramount advantage is unparalleled flexibility in placement and design. It can be single or multi-tiered, cover a vast area, and is often designed to be reconfigured or even relocated in the future as needs change. This is the go-to solution for creating large-scale storage or production platforms in the center of an open plant floor and represents the workhorse of the mezzanine racking for manufacturing world.

2. The Shelving-Supported Mezzanine

In this highly space-efficient hybrid design, the storage racking system itself becomes the primary structural support for the mezzanine deck above. This approach to mezzanine racking for manufacturing is exceptionally effective for high-bay warehouses where the primary goal is to maximize cube utilization for storage. The lower level typically uses heavy-duty pallet racking, while the upper deck provides a second level for lighter bulk storage, slow-moving items, or manual picking operations. The integration between the racking and the mezzanine structure must be perfectly engineered for stability and load distribution, requiring a single-source provider with expertise in both disciplines.

3. The Catwalk & Equipment Access Mezzanine

Often a narrower, more targeted structure, this type of mezzanine racking for manufacturing is designed not for bulk storage but for providing safe, permanent overhead access to machinery, maintenance points, control panels, or overhead utilities. It effectively removes service personnel from the busy main production floor, allowing them to safely monitor, service, and adjust equipment from an elevated, dedicated walkway. These are almost always custom-fabricated to navigate around specific pieces of equipment, a specialized niche within the broader mezzanine racking for manufacturing domain.

4. The Multi-Tier & Rolling Mezzanine System

For facilities with very high ceilings (often 30 feet or more), a multi-tier mezzanine racking for manufacturing system can create three, four, or more levels of usable space. This is a complex engineering and logistical feat but multiplies storage or production capacity exponentially within the same ground-level footprint. For applications demanding maximum storage density for uniform goods, a rolling mezzanine racking for manufacturing system—essentially a giant, movable shelving system on tracks—can eliminate fixed aisles entirely, accessing different sections only when needed and achieving unparalleled density.

The Seamless Integration: Conveyors, AGVs, and Automation on Your Mezzanine

A state-of-the-art manufacturing mezzanine racking system is rarely an isolated island. Its true transformative power is unleashed when it is fully and intelligently integrated into the plant’s automated material handling ecosystem. The most advanced providers specialize in designing mezzanine racking for manufacturing that functions not as a static structure, but as a dynamic, active hub in an automated workflow.

Consider this automated scenario: raw materials are received on the ground floor and automatically transported via a pallet conveyor system up an inclined belt to the mezzanine racking for manufacturing level for high-density, high-bay storage. When the production line’s Warehouse Management System (WMS) signals a need for more components, an automated retrieval system (such as a mini-load AS/RS) fetches the required tote or pallet and delivers it to a vertical reciprocating conveyor (VRC), which lowers it directly to a just-in-time kitting station on the production floor. From there, a fleet of AGVs (Automated Guided Vehicles) or AMRs (Autonomous Mobile Robots) can pick up the kits and deliver them autonomously to various assembly points.

Engineering a mezzanine racking for manufacturing platform for this level of integration requires foresight and expertise. It involves:

Reinforcing specific deck sections and creating large, clear, and protected openings for conveyor feed-throughs and VRCs.

Strategic column placement and clear-span designs to avoid interfering with the navigation pathways of automated vehicles operating below the structure.

Proactive provision for power, data, and communication infrastructure on the mezzanine level to support scanners, printers, and other automated equipment.

Direct integration with AS/RS (Automated Storage and Retrieval Systems) for the ultimate in storage density, accuracy, and retrieval speed.

This holistic, systems-level approach is what elevates a project of mezzanine racking for manufacturing from a simple space-creation exercise to a fundamental upgrade of the plant’s entire operational intelligence.

The Unbreakable Rule: Safety, Codes, and Compliance for Industrial Mezzanines

In the domain of industrial structures, there is no tolerance for compromise on safety. The installation of a mezzanine racking for manufacturing system is a significant structural modification to a building and is therefore subject to a stringent, non-negotiable web of local building codes, national standards, and industry-specific regulations. A provider’s commitment to compliance is the ultimate litmus test of their professionalism.

Reputable engineering teams design and certify their structures for mezzanine racking for manufacturing to comply with, and often rigorously exceed, the most demanding international standards, which typically include:

IBC (International Building Code) and relevant local adaptations.

OSHA (Occupational Safety and Health Administration) regulations, particularly concerning fall protection, load management, and access.

RMI (Rack Manufacturers Institute) ANSI MH16.1 standards for design, testing, and implementation.

Local seismic, wind, and snow load requirements, where applicable.

The professional process for implementing mezzanine racking for manufacturing must include a thorough review of the facility’s existing architectural and structural drawings, a professional on-site survey to verify conditions, and a detailed analysis of the concrete slab’s load-bearing capacity. The provider should manage the entire permitting process, providing all necessary sealed engineering drawings and documentation to ensure a smooth and fully compliant installation.

The final, critical step is a certified load test and the provision of a comprehensive safety, operations, and maintenance manual for the client’s team, closing the loop on a safe and compliant project of mezzanine racking for manufacturing.

Calculating Your True ROI: More Than Just Cost Per Square Foot

When the alternative—constructing a new facility—is used as a benchmark, the financial argument for a mezzanine racking for manufacturing system is often compellingly straightforward. However, the true Return on Investment (ROI) extends far beyond a simple calculation of created cost-per-square-foot. A sophisticated financial analysis reveals multiple layers of value creation.

The Tangible, Quantifiable Financial Benefits

Cost of Constructed Space vs. Created Space: The all-in cost of adding a mezzanine racking for manufacturing structure is typically a fraction of the cost of new construction. Where a greenfield building project can easily cost hundreds of dollars per square foot, a robust mezzanine racking for manufacturing project might range from $35 to $100 per square foot, depending on complexity, load requirements, and integrations. This direct cost avoidance is the most immediate financial benefit.

Operational Efficiency Gains: The value of a mezzanine racking for manufacturing system is also measured in time savings. Quantifying the reduction in walking and search time for operators, the acceleration of material flow from a central, elevated location, and the decrease in order processing times directly translates into higher output and a lower labor cost per unit produced.

Optimized Asset Utilization: A mezzanine racking for manufacturing system leverages an underutilized asset—the building’s vertical air rights—that was previously generating no return. It dramatically increases the productivity and revenue-generating potential of the real estate asset without triggering a proportional increase in property taxes or insurance.

Avoided Soft Costs: The project avoids the massive soft costs of a new build: architectural and civil engineering fees, land acquisition, extended construction timelines, and the profound business disruption of relocating operations.

The Intangible Strategic Advantages

Scalability and Flexibility: A well-designed mezzanine racking for manufacturing system can be expanded, reconfigured, or even relocated as business needs evolve, future-proofing the initial capital investment.

Improved Organizational Culture and Safety: A clean, organized, and logically structured work environment, enabled by a mezzanine racking for manufacturing installation, demonstrably boosts employee morale, reduces error rates, and lowers staff turnover.

Enhanced Market Responsiveness and Competitiveness: The ability to scale operations rapidly within an existing four walls allows a manufacturer to respond to market opportunities and volatile demand cycles faster than competitors who are constrained by physical space, creating a powerful competitive moat.

To empower plant managers with a clear financial picture, leading specialists have developed sophisticated ROI Calculators. These advanced tools go beyond simple square footage calculations, allowing executives to input specific variables like local rental costs, projected efficiency gains from workflow redesign, and costs associated with specific operational bottlenecks to generate a personalized, defensible financial analysis and business case for mezzanine racking for manufacturing.

From Vision to Reality: Our Proven Project Management & Installation Process

Introducing a major structural project into a live, high-tempo manufacturing environment is a delicate operation that demands military-grade precision and planning. The project management methodology for deploying mezzanine racking for manufacturing must be built on a foundation of experience, with an unwavering focus on minimizing disruption and maximizing predictability, safety, and quality.

A world-class, phased approach ensures clarity and control from the initial concept to the final handshake:

Phase 1: Discovery & In-Depth Consultation: This initial stage involves a deep-dive consultation to understand not just spatial pain points but the strategic goals of the operation. It is followed by a comprehensive, laser-based site survey that captures every pertinent dimension, obstruction, and structural detail.

Phase 2: Custom Engineering & Iterative Design: The in-house engineering team creates detailed 3D BIM (Building Information Modeling) models and performs all structural calculations, presenting the client with multiple, validated design options for mezzanine racking for manufacturing for review and collaborative refinement.

Phase 3: Controlled, Quality-Focused Fabrication: All structural components are precision-fabricated in controlled, ISO-certified facilities, ensuring the highest levels of quality, consistency, and finish before they ever arrive on site.

Phase 4: Staged Delivery & Precision Installation: All material deliveries are meticulously coordinated on a just-in-time basis to avoid cluttering the site and compromising safety. Certified, specialized installation crews work with exceptional efficiency, often during planned shutdowns or off-hours, to complete the project on schedule and within budget.

Phase 5: Commissioning, Certification & Training: The project culminates not with the last bolt being tightened, but with a full system commissioning, witnessed load testing, and the provision of thorough operational and safety training for the client’s staff, ensuring a seamless transition and long-term safe operation.

Case in Point: Mezzanine Racking Success Stories in Manufacturing

Case Study 1: Automotive Components Manufacturer

A Tier-1 automotive supplier was grappling with a severely congested final assembly line. Components were stored in off-site satellite warehouses, requiring frequent, disruptive forklift trips across the plant. The solution was a 5,000 sq. ft. structural mezzanine racking for manufacturing platform installed over the receiving bay. The lower level was re-purposed for efficient inbound raw material staging, while the new mezzanine level housed a dedicated, streamlined sub-assembly line for a critical component.

The result of this strategic mezzanine racking for manufacturing project was a 25% reduction in internal material handling time and a 15% increase in overall production line throughput, achieved by bringing the sub-assembly process into direct proximity with the main line.

Case Study 2: Food & Beverage Processing Plant

A rapidly growing food processor needed to expand their packaging and cold storage capacity but was physically landlocked. The innovative solution was a multi-tier, shelving-supported mezzanine racking for manufacturing system within their high-bay chilled warehouse. The system was seamlessly integrated with a case conveyor that transported products from the production level up to the mezzanine for automated labeling and manual boxing before being sent to dynamic pick modules.

This project of mezzanine racking for manufacturing effectively doubled their usable packaging area without a single brick being laid, enabling the successful launch of two new product lines that were previously logistically impossible.

Looking Ahead: The Future of Mezzanine Racking in the Smart Factory

The next generation of mezzanine racking for manufacturing is evolving from a passive structure into a smart, connected, and fully integrated component of the Industry 4.0 ecosystem. The frontier of innovation for mezzanine racking for manufacturing already includes several transformative technologies:

Integrated IoT (Internet of Things) Sensors: Load cells embedded within the mezzanine structure itself can monitor real-time weight distribution, providing data for predictive maintenance and real-time inventory visibility. Vibration sensors can monitor structural health over time.

Fully Automated, Lights-Out Operations: Mezzanine levels are increasingly being designed as dedicated zones for fully automated, goods-to-person picking systems, where autonomous mobile robots (AMRs) or robotic shuttles work in tandem with the structure, operating 24/7 without human intervention.

Modular and Reconfigurable Designs: Advanced connection systems and component standardization are paving the way for mezzanine racking for manufacturing systems that can be robotically assembled, disassembled, and reconfigured with minimal downtime, offering unparalleled adaptability to changing product lines and market demands.

Investing in a system for mezzanine racking for manufacturing today is, therefore, not just about solving an immediate spatial constraint; it is about building the agile, scalable, and data-driven infrastructure that will power a manufacturer’s growth and resilience for the next decade and beyond.

Conclusion: Your Next Step Towards a More Profitable Operation

The vertical cube in a manufacturing plant is, consistently, its most dormant and undervalued asset. A professionally engineered, precision-built mezzanine racking for manufacturing system is the master key to unlocking this latent potential, systematically transforming operational bottlenecks into streamlined, efficient workflows and storage headaches into tangible, measurable profits.

It is a strategic capital investment that pays continuous dividends in the form of increased capacity, enhanced operational efficiency, and fortified long-term competitiveness. The journey from concept to operational reality requires a partner endowed not just with engineering prowess, but with a deep, intuitive understanding of manufacturing logistics and material flow dynamics. The blueprint for a plant’s spatial and operational transformation is ready to be drawn.

Frequently Asked Questions (FAQs)

1. How long does a typical manufacturing mezzanine project take from concept to completion?

The timeline for a project involving mezzanine racking for manufacturing varies based on size, complexity, and customization. A standard project typically follows this timeline: 2-3 weeks for detailed design and engineering, 4-8 weeks for fabrication, and 1-3 weeks for on-site installation. Reputable providers always work to align the installation phase with the client’s production schedule to absolutely minimize disruption to core operations.

2. Can a mezzanine be installed in a facility with limited ceiling clearance?

While higher ceilings are ideal for maximizing the ROI of mezzanine racking for manufacturing, expert providers can engineer effective solutions for facilities with clearances as low as 12-14 feet. The key is a highly optimized design that uses shallow beam profiles, minimized decking depth, and a focus on headroom to maximize the usable height both under the mezzanine and on the deck itself for the intended application.

3. What is the lead time for the materials once the design is finalized?

For standard structural systems of mezzanine racking for manufacturing, the current industry lead time for fabrication typically falls between 4 to 8 weeks from the receipt of order and final approved drawings. For more complex, highly customized projects or those involving integrated automation, the lead time may be extended. A professional provider will always provide a firm, reliable timeline during the project quotation and commitment phase.

4. Do you provide ongoing maintenance and inspection services after installation?

Absolutely. Leading specialists in mezzanine racking for manufacturing offer comprehensive, scheduled annual inspection and maintenance contracts. These services are crucial to ensure the mezzanine remains in peak structural condition and continues to comply with all safety standards over its entire lifecycle. This typically includes checking bolt torques, inspecting for wear or corrosion, and verifying the integrity of guardrails and safety gates.

5. How does the process work if we need to relocate or expand the mezzanine in the future?

One of the fundamental design advantages of a structural mezzanine racking for manufacturing system is its inherent flexibility and reconfigurability. Professional systems are specifically engineered with future relocation or expansion in mind. While some specific components may need to be modified or replaced, the vast majority of the primary structure can be disassembled, moved, and reassembled at a new location or integrated into a larger system, thereby protecting and extending the client’s long-term capital investment.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com