📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Unlocking Vertical Potential: The Definitive Guide to Custom Mezzanine Racking for Distribution Centers

In the relentless, fast-paced environment of a modern distribution center, the battle for space is a constant. Operational managers and logistics directors across Southeast Asia, the Middle East, Africa, and Latin America are facing unprecedented pressure to scale operations without the luxury of expanding their physical footprint. The solution, increasingly, is looking upward. The strategic implementation of custom mezzanine racking for distribution centers represents a paradigm shift in warehouse optimization.

This is not merely about adding a second level; it is about a fundamental re-engineering of the storage and workflow model. A properly designed system of mezzanine racking for distribution centers transforms underutilized vertical cube into a dynamic, high-density, multi-functional asset. For any business serious about competing in the age of e-commerce and rapid logistics, understanding the nuances of mezzanine racking for distribution centers is no longer optional—it is essential for survival and growth.

This comprehensive exploration delves into why a bespoke approach to mezzanine racking for distribution centers is the ultimate competitive advantage, offering a clear pathway to doubling capacity and streamlining operations, all backed by a professional, no-obligation design service.

The Imperative of Vertical Expansion: Why “Mezzanine Racking for Distribution Centers” is the Core Solution

The traditional model of sprawling, single-level warehouses is becoming economically and operationally unsustainable for many. The costs associated with land acquisition, construction, and property taxes in key industrial zones are prohibitive. Meanwhile, internal pressures mount: SKU proliferation, the demands of omnichannel retail, and the expectation of next-day delivery create a perfect storm of congestion and inefficiency. The search for a viable solution inevitably leads to the ceiling.

The implementation of mezzanine racking for distribution centers directly addresses this spatial crisis. It is a capital investment that creates new, usable floor space directly within the existing building envelope. The most effective systems of mezzanine racking for distribution centers are those conceived not as standalone storage but as fully integrated operational tiers. They create a multi-level ecosystem where specific functions—like bulk storage, pick-and-pack, value-added services, and returns processing—can be segregated and optimized.

This strategic segregation is what separates a simple storage platform from a transformative tool for mezzanine racking for distribution centers. The decision to invest in mezzanine racking for distribution centers is, therefore, a decision to fundamentally upgrade the entire logistics operation’s DNA.

Quantifying the ROI: The Tangible Benefits of Mezzanine Racking for Distribution Centers

The justification for investing in mezzanine racking for distribution centers is rooted in a compelling return on investment (ROI) that extends far beyond mere storage capacity.

Dramatic Increase in Storage Density: The most obvious benefit is the multiplicative effect on storage space. A single-tier system can effectively double the usable square footage. For operations constrained by their footprint, this is a game-changer, delaying or even eliminating the need for a costly facility relocation.

Radical Optimization of Workflow: By dedicating different levels of the mezzanine racking for distribution centers to specific tasks, companies can create a more logical and efficient material flow. For instance, slow-moving inventory can be stored on the upper level, while fast-moving goods are placed at ground level, or vice-versa, drastically reducing picker travel times.

Enhanced Operational Flexibility and Scalability: The modular nature of modern mezzanine racking for distribution centers allows for future reconfiguration. As business needs evolve, the system can be adapted, expanded, or even disassembled and relocated, protecting the long-term value of the investment.

Cost-Effectiveness Compared to Expansion: When compared to the astronomical costs of building a new warehouse or leasing additional space, the investment in mezzanine racking for distribution centers is remarkably efficient. The payback period is often measured in just a few years, after which the savings directly contribute to the bottom line.

Engineering for the Extreme: The “Custom” in Custom Mezzanine Racking for Distribution Centers

The term “custom” is the most critical differentiator when specifying mezzanine racking for distribution centers. Off-the-shelf, one-size-fits-all solutions are a profound liability in a high-traffic, high-stakes environment. The engineering philosophy behind robust mezzanine racking for distribution centers must be rooted in over-designing for safety, durability, and seamless integration.

Structural Analysis and Load Capacity Design

The foundation of any successful project involving mezzanine racking for distribution centers is a rigorous structural analysis. This goes far beyond a simple assessment of total weight.

Live Load Calculations: Engineers must account for the combined weight of the stored inventory, the weight of personnel, and the dynamic forces imposed by material handling equipment (MHE) like pallet jacks and order-picking carts. For mezzanine racking for distribution centers, live load requirements are typically much higher than for a standard office mezzanine.

Point Load Considerations: The placement of heavy machinery, such as pallet wrappers, automated guided vehicle (AGV) charging stations, or even sections of high-density shelving, creates concentrated point loads that the structure must be designed to support without deflection.

Seismic and Environmental Factors: In regions prone to seismic activity or with specific environmental challenges, the design of mezzanine racking for distribution centers must incorporate these forces. This often involves specialized bracing, connection details, and a more conservative overall design approach.

Material and Decking Selection: Matching the Component to the Task

The performance and safety of mezzanine racking for distribution centers are directly influenced by the materials used.

Structural Steel Grade: High-strength, industrial-grade steel is the only acceptable material for the primary beams and columns of mezzanine racking for distribution centers. The steel is often treated with a powder-coat or other protective finish to resist corrosion from humidity or incidental chemical exposure.

Decking Options:

Heavy-Duty Pressed Steel Decking: This is the industry standard for most applications of mezzanine racking for distribution centers. It provides a solid, safe walking surface, facilitates easy cleaning, and offers excellent load-bearing properties.

Bar Grating: Ideal for areas where debris fall-through is a concern or where light penetration and ventilation between levels are desired.

Plywood or Concrete Fill: Used in specific scenarios where sound dampening, enhanced fire resistance, or an ultra-rigid floor feel is required.

Seamless Integration with Warehouse Automation and MHE

The most advanced applications of mezzanine racking for distribution centers are those that fully integrate with modern automation. This is where engineering foresight is paramount.

Vertical Conveyance Integration: The design must include dedicated, reinforced zones for vertical reciprocating conveyors (VRCs), spiral chutes, or continuous conveyor systems. This eliminates the need for forklift ramps for small-item transport, dramatically increasing speed and safety.

AGV and AMR Compatibility: For forward-thinking operations, the mezzanine racking for distribution centers can be designed with automated access points. This includes reinforced decks to handle the weight of robotic lifts and precise alignment for docking stations, enabling a fully automated multi-level workflow.

Forklift Access Solutions: Where ramp access is necessary, the design of mezzanine racking for distribution centers must include wide, gently sloped ramps with high-impact guardrail systems that comply with all international safety standards.

The Blueprint for Success: A Deep Dive into the Professional Design Process for Mezzanine Racking for Distribution Centers

A project of this magnitude cannot be based on assumptions or rudimentary sketches. A professional, methodical design process is what separates a successful installation from a costly failure. This process is the bedrock of achieving optimal mezzanine racking for distribution centers.

Phase 1: Comprehensive Site Assessment and 3D Laser Scanning

The first step involves an exhaustive site survey. Leading providers now utilize high-precision 3D laser scanning technology. This tool creates a perfect, “as-built” digital twin of the distribution center, capturing every structural column, overhead truss, fire sprinkler head, electrical conduit, and floor irregularity. This data eliminates costly errors and ensures the proposed design for the mezzanine racking for distribution centers fits the space perfectly from the outset.

Phase 2: Collaborative Workflow and Operational Analysis

Engineers and consultants must immerse themselves in the client’s unique operations. This involves mapping current and future workflow patterns, understanding peak season volumes, identifying specific load requirements for different product lines, and anticipating future growth. This collaborative phase ensures the final design for the mezzanine racking for distribution centers is not just a structure, but a tool that actively enhances productivity and adaptability.

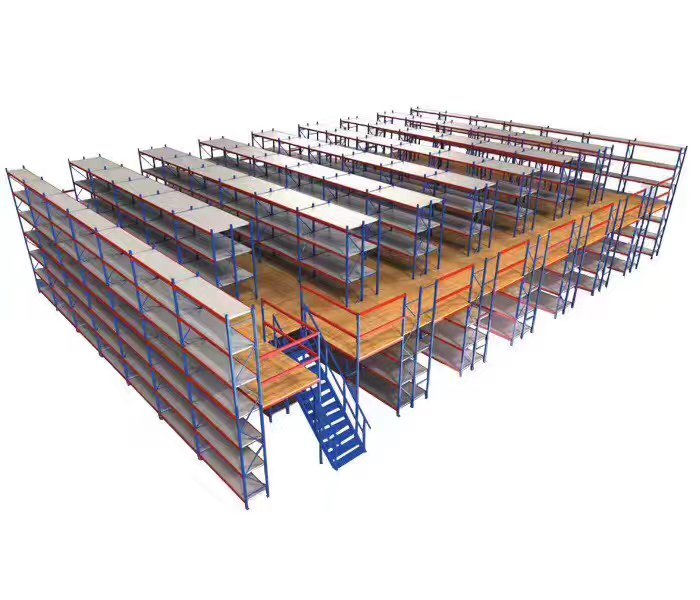

Phase 3: Detailed Engineering and Immersive 3D Visualization

Using the data collected, structural engineers create a complete set of fabrication-ready CAD drawings. More importantly, clients are provided with a photorealistic 3D visualization. This allows stakeholders to take a virtual walkthrough of the proposed mezzanine racking for distribution centers, experiencing the headroom, aisle widths, and operational flow before installation begins. This step is invaluable for confirming design intent and securing internal buy-in.

Phase 4: Final Proposal, Timeline, and Regulatory Compliance Assurance

The client receives a fixed-price proposal detailing every aspect, from material specifications to the installation schedule. Crucially, a professional provider will also manage the complexities of regulatory compliance, ensuring the design for the mezzanine racking for distribution centers meets all local building codes, fire safety regulations (including sprinkler head integration), and occupational health and safety standards.

Global Applications: Mezzanine Racking for Distribution Centers in Action

The versatility of mezzanine racking for distribution centers is demonstrated in its wide-ranging applications across different industries and regions.

E-Commerce Fulfillment in Southeast Asia: A major logistics provider in Thailand utilized a two-tier mezzanine racking for distribution centers to separate its high-velocity pick-and-pack operations from its bulk storage. The upper level became a dedicated picking zone with conveyors leading directly to a sortation and packing hub, reducing ground-level congestion and improving order accuracy.

Spare Parts Distribution in the Middle East: An automotive distributor in the UAE implemented mezzanine racking for distribution centers to create a multi-level system for small parts. The integration of vertical lifts and narrow aisle configurations on the mezzanine level allowed them to consolidate two warehouses into one, achieving massive operational and real estate savings.

Cold Storage Optimization in Latin America: A food distribution company in Brazil faced challenges in expanding its refrigerated space. By installing an insulated mezzanine racking for distribution centers within their existing cold storage facility, they gained significant additional pallet positions without the exorbitant cost of building a new cold room.

Safety and Compliance: The Non-Negotiable Pillars of Mezzanine Racking for Distribution Centers

In a high-traffic environment, safety is the highest priority. Any system of mezzanine racking for distribution centers must be designed and built to exceed the most stringent international safety standards.

Guardrail and Toe-Kick Systems: Full-perimeter guardrails must be of a specified height and strength to prevent falls. Toe-kicks at floor level prevent objects from being accidentally kicked off the edge.

Staircase and Gate Design: Staircases must be designed with the correct rise and run, featuring non-slip treads and continuous handrails. Self-closing safety gates at the top of all stairwells are mandatory.

Load Signage and Documentation: Clear and unambiguous load rating signs must be posted. The client receives a comprehensive package of engineering drawings and load calculations for their records and for any future regulatory inspections.

Fire Protection Integration: The design must include a plan for extending the facility’s fire sprinkler system to provide adequate coverage both above and below the mezzanine deck, as mandated by NFPA and local fire codes.

Conclusion: Elevating Your Distribution Center to the Next Level

The ceiling of a modern distribution center is not a boundary; it is the most immediate and untapped reservoir of potential. The journey to harnessing this potential begins with a strategic, data-driven, and professionally executed plan. The implementation of sophisticated mezzanine racking for distribution centers is a proven strategy for overcoming spatial constraints, boosting operational efficiency, and building a scalable foundation for future growth.

For logistics leaders looking to gain a decisive edge, the question is no longer if they should look up, but how to do it correctly. By partnering with experts who specialize in the custom engineering of mezzanine racking for distribution centers, businesses can transform their vertical cube into their greatest asset, ensuring they are equipped to meet the demands of tomorrow’s logistics challenges today.

Frequently Asked Questions (FAQs) on Mezzanine Racking for Distribution Centers

1. What is the typical lead time from design approval to full installation of mezzanine racking for distribution centers?

The timeline is project-dependent. For a standard system, the process from finalized design to completed installation typically ranges from 6 to 10 weeks. This includes the time for detailed engineering, fabrication of components off-site, and the on-site installation itself. Complex projects involving extensive automation integration may have longer lead times, but a professional provider will always provide a detailed, phased project schedule upfront.

2. Can a mezzanine racking for distribution centers system be installed without halting our 24/7 operations?

While a complete shutdown is often not required, some operational coordination is necessary. Professional installers are adept at working in live environments and will develop a phased installation plan to minimize disruption. This may involve working in specific sections of the warehouse during off-peak hours or on weekends. The key is early and transparent communication between the installation team and the distribution center’s management.

3. How do we determine if our existing concrete slab is strong enough for mezzanine racking for distribution centers?

This is a fundamental engineering question. As part of the initial site assessment, a professional engineer will review the existing slab specifications or may recommend core sampling to test the concrete’s compressive strength. The analysis will determine the point loads from the mezzanine columns and verify the slab’s adequacy. If reinforcement is needed, solutions such as spreader plates or localized underpinning of the slab will be proposed.

4. What kind of maintenance is required for a structural steel mezzanine racking for distribution centers system?

Maintenance requirements are generally minimal. A periodic visual inspection for any signs of impact damage, loose connections, or corrosion is recommended. The decking should be kept clear of debris. It is good practice to have a professional inspection every few years, or after any significant impact from material handling equipment, to ensure all structural connections remain secure and the system retains its integrity.

5. How does the procurement process for a large-scale mezzanine racking for distribution centers project typically work?

The process usually follows these stages: Initial Consultation & Site Visit -> Preliminary Design & Budgetary Proposal -> Detailed 3D Scanning & Engineering -> Finalized Design & Fixed-Price Quotation -> Contract Award & Manufacturing -> Phased Delivery & Installation -> Final Inspection & Handover. Reputable providers offer a turnkey service, managing the entire process from initial concept to final commissioning and regulatory sign-off.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com