📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Summary: In this detailed exploration of warehouse racking design, we examine how its strategic planning and optimization can substantially reduce safety hazards within warehouse operations. Through an in-depth analysis of storage systems, layout configurations, and the role of material handling equipment, we outline how warehouse racking design not only enhances efficiency but also improves overall safety for workers and inventory. The importance of incorporating the best practices in warehouse racking design cannot be overstated, as it serves as the foundation for a safe and productive warehouse environment.

Introduction: The Importance of Warehouse Racking Design in Safety

In today’s global supply chain, where warehouses are the backbone of logistics and distribution, the importance of warehouse racking design in ensuring safety cannot be underestimated. A poorly designed racking system can create significant safety hazards, leading to injuries, accidents, and damage to goods. Conversely, an optimized warehouse racking design helps mitigate these risks, creating a safe and efficient environment for workers and inventory. The foundation of any successful warehouse operation lies in warehouse racking design, which directly impacts operational safety.

Warehouse racking design is a multi-faceted concept that encompasses the structure, layout, material handling processes, and compliance with safety standards. Understanding these elements can lead to safer working conditions, enhanced productivity, and a reduction in operational costs.

The Role of Warehouse Racking Design in Reducing Safety Risks

Understanding the Direct Link Between Racking Design and Safety

When it comes to warehouse safety, warehouse racking design plays a pivotal role in reducing the risk of common hazards. These hazards may include fallen goods, collisions between workers and equipment, and slips and trips caused by inefficient layouts. Each aspect of warehouse racking design must be carefully considered to minimize these risks and create a smooth, safe operation. Proper racking design helps organize storage, ensures the stability of goods, and allows sufficient room for employees to maneuver safely.

-

Overloaded racks or poorly configured systems can lead to structural failures and the risk of falling objects.

-

Narrow aisles hinder the safe movement of forklifts, pallet jacks, and personnel, increasing the likelihood of accidents.

-

Improperly anchored racks or damaged structures can cause rack collapses, creating significant dangers in the workplace.

Optimizing warehouse racking design for safety involves careful planning, considering factors such as load capacity, aisle width, material durability, and the ongoing maintenance of racking systems.

Core Principles of Effective Warehouse Racking Design

1. Load Capacity and Weight Distribution in Warehouse Racking Design

A critical component of warehouse racking design is understanding the load capacity of the racking systems. Overloading shelves or incorrectly distributing the weight of stored goods can cause racks to fail, leading to product spills, equipment damage, and potential worker injuries. Therefore, the design should take into account the weight of each item and ensure that the racking system is capable of bearing the load.

-

Implementing load limits and clearly marked signage for safe weight distribution is essential for maintaining rack stability.

-

Rack inspections should be performed regularly to ensure that the racking system is not overburdened.

2. The Structural Integrity of Warehouse Racking Design

The structural integrity of the racking system is essential for warehouse safety. Warehouse racking design must prioritize the use of high-quality materials such as heavy-duty steel to support heavy loads and ensure the racks’ stability. The strength of the materials used in the design prevents bending, warping, and eventual collapse, which could pose serious safety risks.

-

Regular inspections and maintenance are necessary to detect any wear and tear, rust, or damage that could compromise the strength of the racking system.

-

Reinforcing racking systems with safety features like backstops or protective barriers can further enhance stability and protect workers from falling goods.

3. Optimizing Aisle Width and Accessibility in Warehouse Racking Design

One of the most important aspects of warehouse racking design is the effective management of aisle space. Adequate aisle width ensures safe movement for equipment such as forklifts, pallet jacks, and employees, reducing the chances of collisions or accidents. Warehouse racking design should consider the type of equipment used in the facility to determine the appropriate aisle width.

-

Standard aisle widths for manual handling should be wide enough for employees to navigate safely.

-

Wider aisles for automated systems or forklifts can help reduce congestion and prevent accidents.

Innovative Solutions in Warehouse Racking Design for Improved Safety

Automated Storage and Retrieval Systems (AS/RS)

One of the most effective ways to enhance safety in warehouse operations is through the integration of Automated Storage and Retrieval Systems (AS/RS). These systems reduce the need for human intervention in high-risk areas by using automated vehicles or robots to retrieve and store goods.

-

AS/RS significantly reduces the risk of accidents by automating the retrieval process, lowering the risk of human error.

-

These systems also reduce congestion in aisles, ensuring smoother and safer operations.

Selective Pallet Racking and Safety

Selective pallet racking is the most commonly used racking system in warehouses. It provides easy access to every individual pallet and is versatile enough to handle a wide range of goods. However, improper warehouse racking design with selective racking can lead to product instability or overloaded racks if not correctly planned.

-

In selective pallet racking, ensuring that the racks are properly balanced and securely anchored can mitigate safety hazards.

-

Installing guide rails or safety barriers at the edges of racks can prevent items from falling.

Cantilever Racking Systems for Irregular Items

Cantilever racking systems are designed to store long or bulky items such as pipes, timber, or steel. Due to the nature of these items, warehouse racking design must include safety features that prevent materials from slipping or falling from the racks.

-

Backstops or safety barriers should be used in cantilever racks to prevent items from shifting or falling off the shelves.

-

Ensuring that items are securely loaded and unloaded from cantilever racks can help maintain safety and operational efficiency.

Flow Racking Systems for Safe Inventory Management

Flow racking systems (FIFO) ensure that goods are stored and retrieved in the order they were received. This is particularly important for warehouses handling perishable goods or those with expiration dates. These systems help reduce the need for manual handling of inventory, which in turn reduces the risk of accidents.

-

Gravity flow racks reduce the need for manual intervention in the racking system, lowering the likelihood of accidents.

-

Proper system design can increase inventory turnover while maintaining a safe working environment for employees.

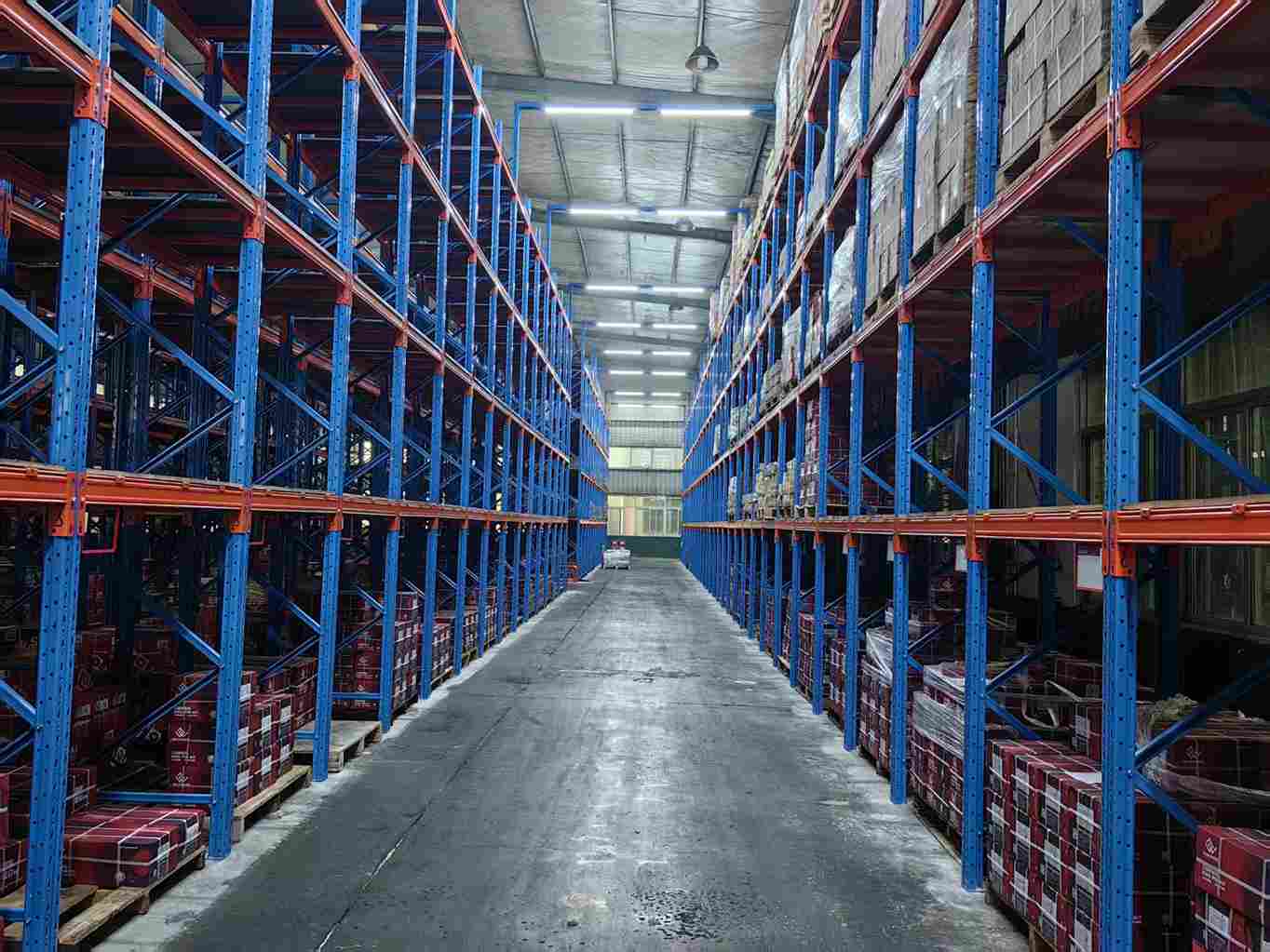

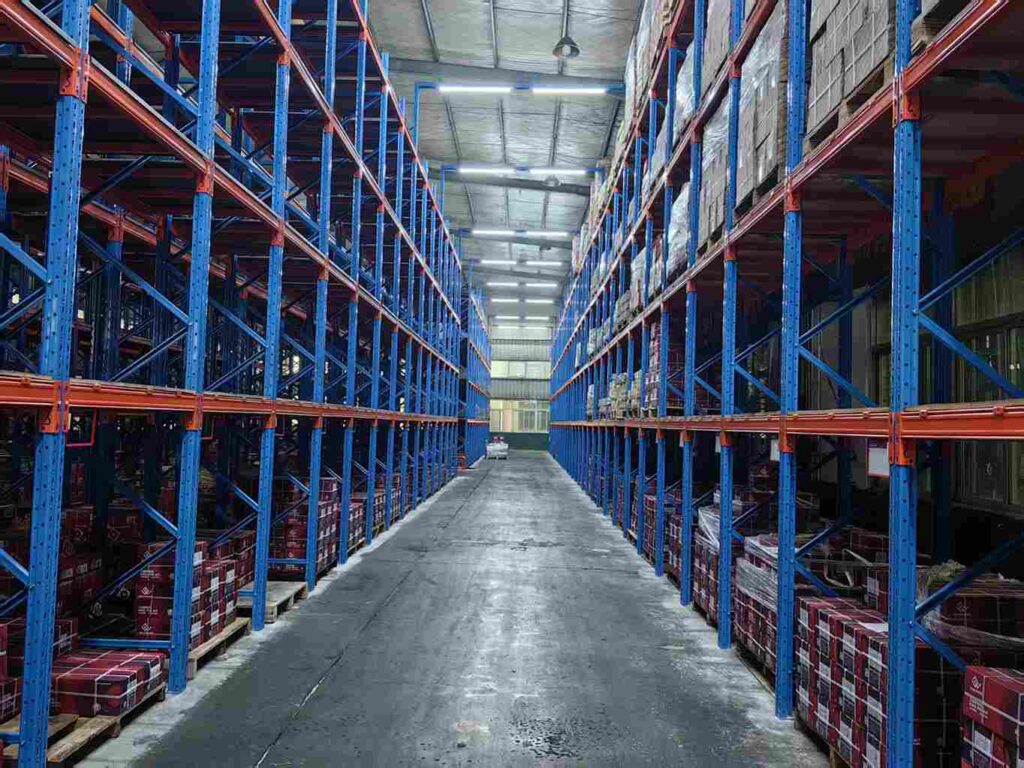

Wide aisle spacing around pallet beam racking systems for safer warehouse design

Best Practices for Enhancing Warehouse Safety Through Racking Design

Employee Training on Safe Warehouse Racking Design

Training warehouse staff to understand the risks associated with improper warehouse racking design is crucial for preventing accidents. Workers should be educated on load limits, aisle widths, and proper handling of materials to avoid injuries.

-

Forklift operators and material handlers should receive proper training to safely navigate around racking systems and avoid accidents.

Implementing Strict Maintenance Schedules for Warehouse Racking Design

Regular maintenance and inspections are essential to ensure that warehouse racking design remains safe and functional. Regularly checking for damage, corrosion, or wear on racks can prevent major safety issues and extend the lifespan of the system.

-

Scheduled inspections of racking components such as beams, uprights, and anchors should be a standard practice in any warehouse operation.

-

Immediate repairs should be made if any structural damage is found to avoid further risk.

Conclusion: The Future of Safe Warehouse Operations Through Warehouse Racking Design

The importance of warehouse racking design in enhancing safety cannot be overstated. Through strategic planning, effective use of technology, and adherence to safety standards, warehouses can drastically reduce safety hazards while improving operational efficiency. As the demand for faster and more efficient warehouse operations continues to grow, focusing on innovative racking design will ensure safer working environments and better productivity in the long term.

Adopting modern warehouse racking design solutions such as AS/RS or flow racking systems can help mitigate risks while providing the flexibility needed to adapt to changing business needs. Ultimately, ensuring that your racking system is designed with safety in mind is a critical step toward building a more efficient, secure, and productive warehouse.

Frequently Asked Questions (FAQs)

1. What makes warehouse racking design crucial for safety?

Warehouse racking design is critical for safety because it determines how materials are stored, accessed, and handled. Poor racking design can lead to overloading, unstable storage, and restricted movement, all of which increase the risk of accidents.

2. How can proper warehouse racking design reduce employee injuries?

Proper warehouse racking design ensures that racks are stable, aisles are wide enough, and loads are evenly distributed, reducing the chances of falling goods, collisions, or strain-related injuries.

3. How does automated racking improve safety in warehouses?

Automated racking systems like AS/RS reduce human interaction with high-risk areas, lowering the chances of accidents and ensuring smoother, more efficient operations.

4. What is the role of aisle width in warehouse racking design?

Aisle width is essential in warehouse racking design because it determines how safely forklifts and employees can navigate through the warehouse. Insufficient aisle space can lead to collisions and increased risk of accidents.

5. What is the best type of racking system for improving warehouse safety?

The best type of warehouse racking design depends on the products being stored. Selective pallet racking offers accessibility, while flow racking systems reduce manual handling, and cantilever racking is ideal for long or bulky items.