📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Introduction: Why High-Density Narrow Aisle Racking Is Revolutionizing Warehousing

In an era where every square foot of warehouse space translates to cost savings or revenue potential, high-density narrow aisle racking (HD-NA racking) has become a game-changer for logistics operations. This storage solution allows businesses to store more inventory in the same footprint, drastically improving space utilization while maintaining—or even enhancing—operational efficiency.

But is high-density narrow aisle racking the right choice for every warehouse? This comprehensive guide dives deep into its benefits, challenges, cost considerations, and best implementation strategies, helping businesses determine whether this system aligns with their operational needs.

What Is High-Density Narrow Aisle Racking?

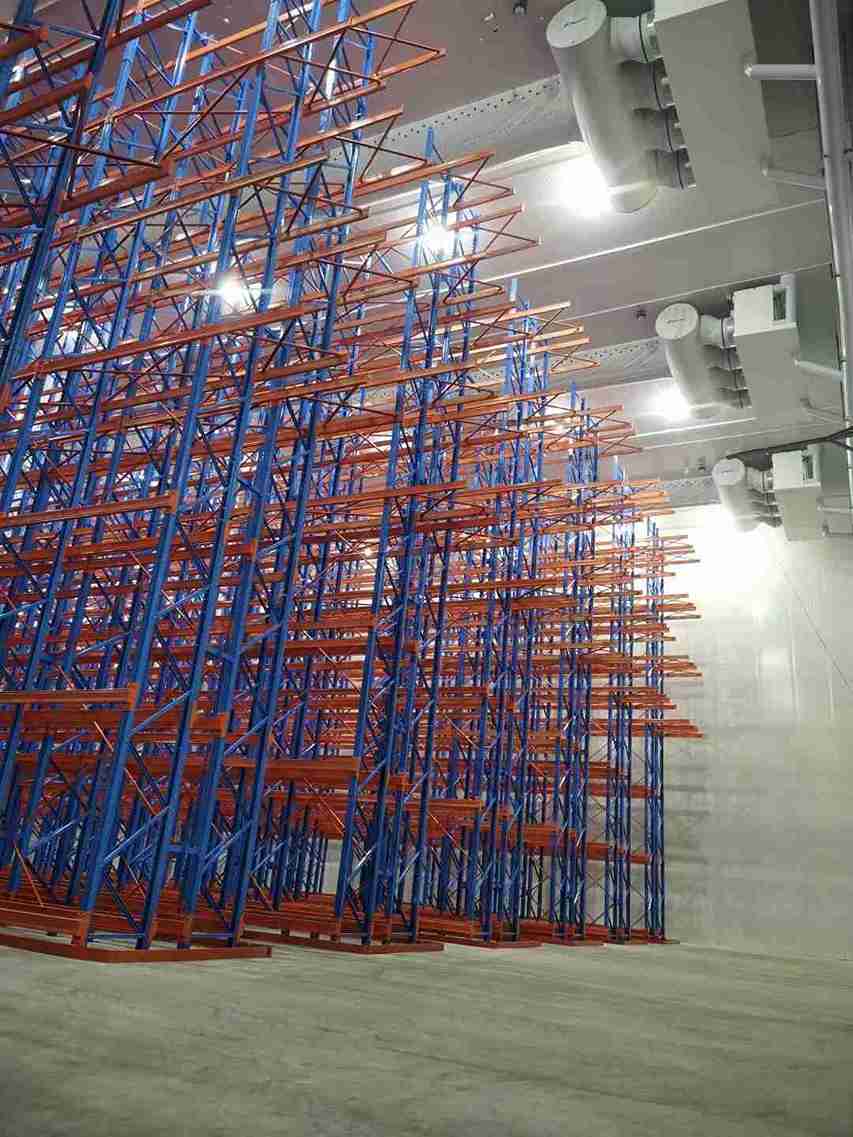

High-density narrow aisle racking (HD-NA racking) is a space-optimized pallet storage system designed to minimize aisle widths while maximizing vertical storage capacity. Unlike traditional wide-aisle setups, which require 10-12 feet of clearance for standard forklifts, narrow aisle racking reduces aisle widths to 5-7 feet, allowing for higher storage density without sacrificing accessibility.

Key Components of High-Density Narrow Aisle Racking Systems

- Ultra-Narrow Aisles (5-7 ft wide) – Enables tighter storage configurations

- Specialized Forklifts (VNA/Turret Trucks) – Designed for precision maneuvering

- Taller Storage Heights (Up to 40+ ft) – Maximizes vertical cube utilization

- Selective Pallet Access – Every SKU remains directly accessible

This system is particularly beneficial for high-SKU warehouses, cold storage facilities, and e-commerce fulfillment centers where space is at a premium.

Top 5 Benefits of High-Density Narrow Aisle Racking

1. Unmatched Storage Density & Space Savings

The primary advantage of high-density narrow aisle racking is its ability to increase storage capacity by 30-50% compared to conventional racking. By shrinking aisle widths, warehouses can store more pallets in the same square footage, delaying or even eliminating the need for costly facility expansions.

Case Study Example:

A 50,000 sq ft warehouse switching to HD-NA racking could potentially add 15,000+ additional pallet positions, translating to six-figure annual savings in avoided real estate costs.

2. Improved Operational Efficiency & Faster Order Fulfillment

- Reduced Travel Time – Narrower aisles mean forklifts spend less time moving between pick locations.

- Higher Throughput – Faster load retrieval speeds up order processing.

- Enhanced Picking Accuracy – Organized, high-density layouts reduce mispicks.

3. Long-Term Cost Efficiency Despite Higher Initial Investment

While high-density narrow aisle racking requires specialized forklifts and installation expertise, the long-term ROI often justifies the upfront costs. Businesses see savings in:

- Reduced warehouse expansion needs

- Lower labor costs due to faster operations

- Minimized product damage from optimized workflows

4. Scalability for Growing Businesses

Unlike drive-in or push-back racking, HD-NA systems allow for modular expansion. Warehouses can add vertical storage as inventory grows without needing additional floor space.

5. Ideal for High-Value or Temperature-Controlled Storage

- Cold storage facilities benefit from maximized refrigerated space.

- Pharmaceutical and high-value goods warehouses improve security with compact, controlled storage layouts.

Potential Challenges of High-Density Narrow Aisle Racking

1. Higher Upfront Costs

- VNA Forklifts (120,000 per unit)

- Racking Installation & Potential Floor Reinforcements

- Operator Training Expenses

2. Specialized Equipment & Training Requirements

- Not compatible with standard forklifts – Requires narrow aisle (NA) or turret trucks.

- Strict operator certification needed for safe maneuvering in tight spaces.

3. Reduced Flexibility for Changing Inventory Needs

- Less adaptable than selective racking for varying pallet sizes.

- Difficult to reconfigure without significant downtime.

4. Potential Congestion in High-Traffic Warehouses

If multiple forklifts operate in the same narrow aisles, bottlenecks can occur, requiring smart traffic management systems.

High-Density Narrow Aisle Racking vs. Alternative Storage Systems

Comparison with Selective Pallet Racking

| Feature | High-Density Narrow Aisle Racking | Selective Pallet Racking |

|---|---|---|

| Aisle Width | 5-7 ft | 10-12 ft |

| Storage Density | High (30-50% more pallets) | Medium |

| Forklift Compatibility | VNA/Turret Trucks Only | Standard Forklifts |

| Accessibility | Direct access to all pallets | Direct access to all pallets |

| Best For | High-SKU, space-constrained warehouses | General warehousing, flexibility |

Comparison with Drive-In Racking

- Drive-in racking offers higher density but operates on LIFO (Last-In-First-Out), making it less ideal for perishable goods.

- High-density narrow aisle racking provides selective access (FIFO or LIFO) without sacrificing density.

Comparison with Push-Back Racking

- Push-back racking is high-density but requires load sequencing.

- HD-NA racking allows immediate access to any pallet without unloading others first.

Is High-Density Narrow Aisle Racking Right for Your Business?

Best Use Cases for HD-NA Racking

✔ E-commerce & 3PL Warehouses – High SKU variety with rapid turnover

✔ Cold Storage & Food Distribution – Maximizes expensive refrigerated space

✔ Urban Warehouses with Limited Space – Delays facility expansion costs

✔ Automotive & Manufacturing Parts Storage – High-density organization for bulk components

When to Consider Alternative Systems

✖ Low-Budget Operations – High initial investment may not justify ROI

✖ Frequently Changing Pallet Sizes – Less flexible than selective racking

✖ Low-Volume Warehouses – Not enough storage demand to warrant the cost

Cost Breakdown & ROI Analysis of High-Density Narrow Aisle Racking

Initial Investment Estimates

| Cost Factor | Price Range |

|---|---|

| Racking System (per sq ft) | 50 |

| VNA Forklift (per unit) | 120,000 |

| Installation & Labor | 20,000+ |

| Floor Reinforcement (if needed) | 10 per sq ft |

Long-Term Savings & ROI

- Space Savings – Avoids costly warehouse expansions.

- Labor Efficiency – Faster operations reduce staffing needs.

- Reduced Product Damage – Fewer mishandling incidents.

Example ROI Calculation:

A 100,000 sq ft warehouse implementing high-density narrow aisle racking could save $200,000+ annually in avoided expansion and labor costs, paying back the investment in 2-3 years.

Best Practices for Implementing High-Density Narrow Aisle Racking

1. Conduct a Detailed Warehouse Space Analysis

- Use 3D modeling software to optimize layout before installation.

- Ensure proper clearances for forklifts and loading/unloading.

2. Invest in the Right Forklifts & Automation

- Turret trucks for very narrow aisles (under 6 ft).

- Semi-automated systems for even greater efficiency.

3. Prioritize Operator Training & Safety

- Certify all forklift drivers in narrow aisle operations.

- Implement traffic management systems to prevent collisions.

4. Optimize Inventory Placement for Speed

- Fast-moving SKUs near aisles for quick access.

- Use WMS (Warehouse Management Software) for real-time tracking.

5. Schedule Regular Maintenance & Inspections

- Check for racking damage to prevent collapses.

- Maintain forklifts to minimize downtime.

Future Trends in High-Density Narrow Aisle Racking

1. Integration with Robotics & Automation

- Autonomous forklifts for safer, more efficient narrow aisle navigation.

- AI-powered warehouse optimization for dynamic storage layouts.

2. Smart Warehousing & IoT Connectivity

- Real-time pallet tracking via RFID or Bluetooth sensors.

- Predictive analytics to optimize stock placement.

3. Sustainable Warehouse Design

- Energy-efficient LED aisle lighting to reduce costs.

- Eco-friendly racking materials for greener operations.

Final Verdict: Is High-Density Narrow Aisle Racking Worth It?

For warehouses struggling with space constraints, high SKU counts, or rapid inventory turnover, high-density narrow aisle racking is a highly effective solution. While the initial investment is significant, the long-term gains in storage capacity, efficiency, and cost savings make it a strategic choice for many modern operations.

Businesses considering HD-NA racking should:

✅ Evaluate current and future storage needs

✅ Compare costs vs. alternative systems

✅ Consult with a warehouse storage expert for a customized solution

Frequently Asked Questions (FAQs)

1. How much additional storage can high-density narrow aisle racking provide?

Depending on the existing layout, HD-NA racking can increase storage capacity by 30-50%, allowing warehouses to store significantly more inventory without expanding their footprint.

2. What forklift types are compatible with narrow aisle racking?

Only Very Narrow Aisle (VNA) forklifts or turret trucks can operate in aisles as narrow as 5-6 feet. Standard forklifts are not suitable.

3. Can existing warehouses be retrofitted with narrow aisle racking?

Yes, but it may require structural assessments, floor reinforcements, and forklift upgrades. A professional evaluation is recommended.

4. What’s the maximum height for high-density narrow aisle racking?

Some systems support heights exceeding 40 feet, but this depends on building codes, forklift reach, and racking stability.

5. Are there safety risks with narrow aisle operations?

Without proper protocols, collisions and racking damage can occur. Operator training, safety barriers, and routine inspections are essential.