📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Engineering Excellence in Component Design and System Integration

The superiority of a high bay pallet racking system is ultimately determined by the engineering of its individual components and how they coalesce into a singular, robust structure. For distributors in Africa and Latin America, where maintenance expertise and replacement parts may not be immediately accessible, the inherent reliability of every bolt, beam, and upright is paramount.

Upright Frames: The Backbone of Vertical Ambition

The upright frame, the vertical column of the system, carries the entire load. In premium high bay pallet racking systems, these are not simple roll-formed channels. They are fabricated from high-tensile, low-carbon steel, often formed into a closed tubular or box-section design. This design provides superior torsional rigidity, essential for maintaining alignment in systems exceeding 12 meters in height.

The punching pattern for beam connections is executed with laser precision, ensuring a perfect, play-free fit that eliminates the progressive loosening and sway that plagues poorly manufactured racks. For regions with seismic activity, such as parts of Latin America, upright frames feature additional reinforcement and specially designed connection points for seismic bracing, allowing the structure to absorb and dissipate energy dynamically.

Load Beams and Connectors: The Critical Interface

Load beams and their connectors form the shelving of the high bay pallet racking system. High-quality systems employ beams with a truss-like or step-beam design, offering an optimal strength-to-weight ratio. The connector—the device that locks the beam into the upright—is arguably the most critical safety component.

Premium systems use a patented, positive-locking connector, often with a double-safety feature such as a locking clip or bolt. This design prevents accidental dislodgement from forklift impact, a common occurrence in busy warehouses. The connector’s teeth engage deeply into the upright’s column, creating a moment-resistant connection that is fundamental to the structural integrity of the entire high bay storage system.

Bracing and Stabilization: The Invisible Network of Strength

While uprights and beams define the form, the bracing system provides the stability. Diagonal and horizontal braces, configured in specific patterns (e.g., X-bracing, saw-tooth bracing), transform individual frames into a unified, rigid structure capable of resisting lateral forces from seismic events, wind (in semi-open facilities), and the constant motion of material handling equipment.

In demanding environments, the bracing system’s design and its connection points are subjected to finite element analysis (FEA) to model stress distribution and identify potential failure points before fabrication begins. This level of analysis is what separates a commodity rack from an engineered high bay pallet racking system built for decades of service.

Strategic Configuration Selection: Matching the System to the Inventory Profile

Not all inventory is stored equally. The most cost-effective storage solution arises from meticulously matching the configuration of the high bay pallet racking system to the specific SKU profile, turnover rate (ABC analysis), and handling patterns of the distributor’s goods.

Selective Pallet Racking: The Gold Standard of Accessibility

The most common configuration for high bay pallet racking systems is selective racking. This design, with a series of accessible aisles, provides direct access to every single pallet location. It is ideal for warehouses with a high variety of SKUs and a need for fast, random-access picking. In a high bay context, this configuration is typically serviced by specialized Very Narrow Aisle (VNA) forklifts or man-aboard order pickers, which operate in aisles as narrow as 1.6 meters.

The efficiency gains in space utilization and picking speed make this a preferred choice for third-party logistics (3PL) providers and distributors of consumer electronics, pharmaceuticals, and packaged goods across major cities in Johannesburg, São Paulo, and Mexico City.

Drive-In/Drive-Through Racking: Maximizing Density for Low-Turnover Goods

For distributors dealing with bulk quantities of homogeneous products, such as beverages, canned goods, or seasonal agricultural products, density is paramount. Drive-in and drive-through high bay pallet racking systems sacrifice direct access for immense storage compression. In these systems, forklifts drive directly into the rack structure itself, placing pallets on rails in a last-in, first-out (LIFO) or first-in, first-out (FIFO) sequence.

This configuration can increase storage density by up to 75% compared to selective racking. For a beverage distributor in Angola or Colombia looking to store vast quantities of product in a limited urban footprint, this configuration of high bay pallet racking is often the most cost-effective storage strategy, despite requiring disciplined inventory management.

Pallet Flow and Carton Flow Systems: Leveraging Gravity for Efficiency

Integrating dynamic storage elements into a high bay pallet racking system creates a powerful hybrid solution. Pallet flow systems use inclined rails with wheel or roller tracks, allowing pallets to glide from the loading (rear) to the picking (front) face by gravity. This enforces perfect FIFO inventory rotation, which is critical for perishable goods, chemicals, or items with strict expiry dates commonly found in the food and pharmaceutical distribution sectors in markets like Kenya and Chile. Similarly, carton flow systems integrated into the lower levels of a high bay pallet racking system enable high-speed, ergonomic picking of individual cases, streamlining the order fulfillment process for e-commerce and retail distribution centers.

The Synergy with Material Handling Equipment (MHE): A Co-Engineered Ecosystem

A high bay pallet racking system does not operate in isolation. Its performance is inextricably linked to the material handling equipment (MHE) that services it. The highest levels of efficiency and safety are achieved when the racking and the MHE are co-engineered as a single ecosystem.

Very Narrow Aisle (VNA) Equipment: Unlocking Vertical Potential

Conventional counterbalance forklifts require wide aisles (typically 3.5m+), which drastically reduces storage density in a high bay environment. VNA trucks, including turret trucks and order pickers, are the key to unlocking the system’s potential. These machines operate in aisles as narrow as 1.5 meters and can lift to heights exceeding 15 meters. Their operation, however, demands exceptional precision from the high bay pallet racking system.

The racking must be installed with near-perfect alignment and minimal tolerance to ensure the VNA truck’s guidance system (wire, rail, or optical) functions flawlessly. Furthermore, the rack structure must be designed to withstand the unique lateral thrust forces generated by these machines as they turn and position loads at height.

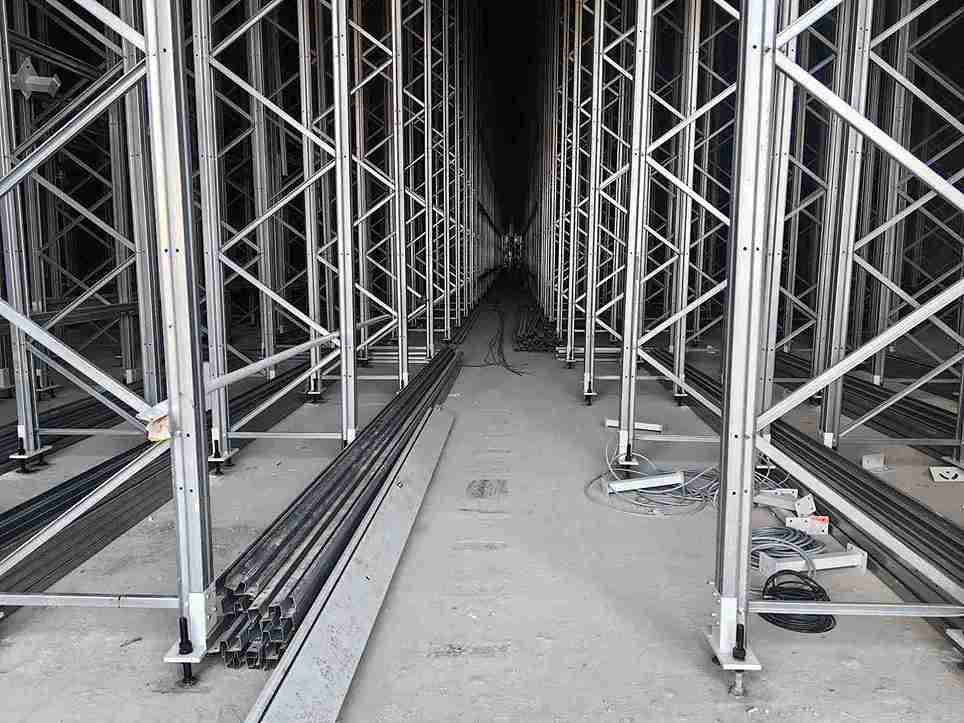

Automated Guided Vehicles (AGVs) and Stacker Cranes: The Automated Frontier

The ultimate expression of this synergy is with fully automated equipment. Automated Storage and Retrieval Systems (AS/RS) using aisle-dedicated stacker cranes or robotic shuttles represent the pinnacle of density and throughput. Here, the high bay pallet racking system becomes the precision guide rail and support structure for the automation.

The tolerances are measured in millimeters. The rack’s uprights must be perfectly plumb, beam levels must be flawlessly horizontal, and the entire structure must have the dynamic stiffness to support the moving masses of the cranes without excessive deflection. For a major distributor in Lagos or Santiago planning a future automated facility, specifying a high bay pallet racking system that is “automation-ready” from day one is a critical strategic decision that prevents a total system overhaul later.

Forklift Impact Protection: A Non-Negotiable Safety Investment

In any busy warehouse, impacts are inevitable. Protecting the structural integrity of the high bay pallet racking system from forklift collisions is a vital safety and economic consideration. This goes beyond bolt-on post protectors. A comprehensive approach includes:

Structural Column Guards: Heavy-duty steel guards, sometimes concrete-filled, that encase the lower portion of upright columns.

Aisle End Protection: Robust barrier systems at the end of each aisle to prevent a truck from accidentally driving into the rack.

Integrated Wire Meshing or Pallet Backstops: Installed on the rear of selective racks to prevent pallets from being pushed through the opposite side, which is a significant risk in very narrow aisle configurations.

The Procurement Blueprint: Key Questions for Distributors

Navigating the procurement process for a high bay pallet racking system requires a disciplined, inquiry-based approach. Distributors should use the following questions as a blueprint to evaluate potential suppliers and ensure they are investing in a solution, not just purchasing commodity steel.

For the Supplier’s Engineering Credentials:

“Can you provide the specific FEM 10.2.02 or equivalent design calculations and load tables for our proposed high bay pallet racking system configuration?”

“Do you employ in-house, certified structural engineers who can perform site-specific seismic or dynamic load analysis for our location in [City, Country]?”

“What is your process for conducting a pre-installation site survey, and do you provide concrete floor specification requirements?”

Regarding Quality and Durability Assurance:

“What is the exact steel grade (e.g., S355JR) and yield strength used for upright frames and beams? Can this be verified with mill certificates?”

“Detail the step-by-step corrosion protection process. For our coastal environment, is Hot-Dip Galvanizing (HDG) recommended for uprights?”

“What are the manufacturing tolerances for your upright punch patterns and beam connectors, and how does this ensure a tight, safe fit?”

Concerning Long-Term Partnership and Support:

“What is included in your installation supervision and commissioning service? Do you provide ‘as-built’ drawings and a digital twin of the installed high bay pallet racking system?”

“Describe your spare parts strategy. Do you provide an initial spare parts kit, and what is the guaranteed lead time for future component orders?”

“What training do you provide for our warehouse staff on safe operation, daily inspection routines, and basic maintenance of the high bay storage system?”

By demanding clear, technical answers to these questions, a distributor separates experienced engineering partners from mere equipment vendors. The response will illuminate the supplier’s depth of knowledge, commitment to quality, and understanding of the long-term partnership required to maintain a mission-critical high bay pallet racking system over its full lifecycle in a challenging operational environment.

Conclusion: The Strategic Imperative of Engineered Storage Infrastructure

For industrial and distribution enterprises across the dynamic landscapes of Africa and Latin America, the warehouse is a strategic asset. Within it, the high bay pallet racking system forms the fundamental grid upon which supply chain velocity, operational resilience, and profitability are built. The choice between a generic, price-driven rack and a professionally engineered high bay pallet racking system represents a fundamental fork in the road.

The former offers a deceptively low entry cost but carries with it the hidden and substantial risks of premature corrosion, structural compromise, operational disruption, and ultimately, forced early replacement. It is a short-term expense that becomes a long-term liability.

The latter—a high bay pallet racking system conceived through rigorous engineering, fabricated from certified materials, protected by advanced coatings, and installed to exacting tolerances—represents a strategic capital investment. Its true value is measured not in price per component, but in its remarkably low Total Cost of Ownership (TCO) over 25 years or more. This value is realized through relentless operational uptime, maximized storage density, inherent safety, and seamless readiness for the integration of automated systems. It is a platform for growth, engineered to scale alongside a business’s ambition.

In markets where every operational advantage counts, selecting the right high bay pallet racking system is a decision that echoes for decades. It is the decision to build a foundation of durability, efficiency, and intelligence—a foundation upon which a lasting legacy of supply chain excellence can confidently be constructed. The journey begins with a commitment to moving beyond commodity thinking and partnering with experts who view storage not as a product to be sold, but as a critical infrastructure to be engineered, delivered, and supported for the life of the facility.

Frequently Asked Questions (FAQs)

1: For a cold storage facility in a humid climate, are there special considerations for the high bay pallet racking system?

A: Absolutely. Cold storage presents a dual challenge: extreme condensation and constant thermal cycling. A standard epoxy-polyester powder coat can become brittle and fail. The high bay pallet racking system must be specified with a specialized, low-temperature plasticized coating designed for freezer applications. Furthermore, all steel should undergo a more rigorous pre-treatment to prevent sub-film corrosion. The design must also account for potential ice buildup on beams and consider the use of stainless steel components for critical connections in the most severe environments.

2: How does the design of a high bay pallet racking system differ for storing non-palletized, long loads like timber or rolled materials?

A: Storing long loads requires a specialized adaptation of the high bay pallet racking system. The standard configuration shifts to a cantilever racking design. This system uses heavy-duty vertical columns with arms that extend outwards to support the long loads. In a high bay context, these columns are engineered for significant cantilevered loads at height. The bracing pattern, base plate design, and anchoring are all intensified to resist the overturning moment created by the load. Beam levels may still be used for support and stability. The design must be precisely calculated based on the load length, weight, and distribution.

3: What is the process for extending or reconfiguring an existing high bay pallet racking system in the future?

A: A well-engineered high bay pallet racking system is designed with modularity in mind. The process should begin with a structural re-assessment by an engineer. Using the original digital layout and load calculations, they can model the extension or new configuration to ensure the overall structure’s integrity, especially the loading on existing upright frames and floor anchors. Provided the original system was from a quality supplier with available components, new bays can be added, and beams can be relocated. A critical step is sourcing components from the original manufacturer to guarantee dimensional and metallurgical compatibility, preventing unsafe mismatches.

4: Can a high bay pallet racking system be safely relocated to a new warehouse facility?

A: Relocation is possible but is a major engineering project, not a simple dismantling and reassembly. Every component must be meticulously inspected for damage, corrosion, or deformation, especially the critical beam connectors and the base of upright columns. Components showing any wear or damage must be replaced. The relocation design must re-validate the system for the new facility’s specific conditions, including floor slab specification, potential seismic zone changes, and new ceiling height/obstacle constraints. It is highly advised that this process be managed and certified by the original equipment manufacturer or a qualified racking engineer to ensure the relocated high bay pallet racking system meets all safety standards.

5: How are fire protection systems (sprinklers) integrated with a high bay pallet racking system, and are there specific design rules?

A: Integration with fire protection is mandatory and governed by local building codes and standards like NFPA. In a high bay pallet racking system, in-rack sprinklers are almost always required to prevent a fire shadow where storage height blocks ceiling sprinklers. The high bay pallet racking system design must incorporate dedicated horizontal branch lines and sprinkler heads at designated vertical intervals (often every 3-4 meters) within the rack structure itself. The rack’s design must accommodate the pipe runs and provide secure mounting points without compromising its structural members. This requires close coordination between the rack supplier, sprinkler contractor, and civil engineer from the earliest design phase.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com