📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

In the high-stakes world of durable goods logistics, where every square foot and every minute of labor directly impacts the bottom line, warehouse operators are constantly seeking a strategic advantage. The solution, increasingly, is not found in working harder but in working smarter with advanced storage technology.

This comprehensive guide delves deep into the engineering, application, and transformative benefits of heavy-duty case flow racking systems, the undisputed champions of high-density, high-throughput storage for non-perishable, high-weight items. For distributors of automotive parts, industrial supplies, building materials, and appliances, implementing a robust case flow racking system is the most effective way to enforce perfect FIFO inventory control, slash order picking times by over 50%, and dramatically increase storage capacity within an existing footprint.

Beyond the basics, we will explore the critical engineering nuances—from dynamic load capacities and roller pitch to integration with AS/RS and WMS—that separate a truly superior case flow racking installation from a mediocre one. This resource is designed to provide warehouse managers, operations directors, and logistics planners with the authoritative knowledge needed to specify, justify, and implement a case flow racking solution that delivers measurable, lasting ROI.

The Fundamental Warehousing Challenge for Durable Goods

Durable goods distributors operate in a uniquely demanding environment. Their products—think automotive components, industrial machinery parts, building supplies, and major appliances—are characterized by substantial weight, significant size, and often, a critical need for strict lot control. The traditional warehouse model, reliant on static selective pallet racking and manual order picking, is fraught with inefficiencies that erode profitability.

The most common pain points include catastrophic levels of wasted vertical and horizontal space, excessive labor costs as pickers traverse miles of aisles daily, the high risk of product obsolescence due to poor FIFO practices, and escalating safety concerns from handling heavy cases manually.

These operations require a storage solution that is not passive but active—a system that works continuously to move product to the picker, not the other way around. This is the precise operational problem that a well-designed case flow racking system is engineered to solve.

What is Heavy-Duty Case Flow Racking? The Anatomy of Efficiency

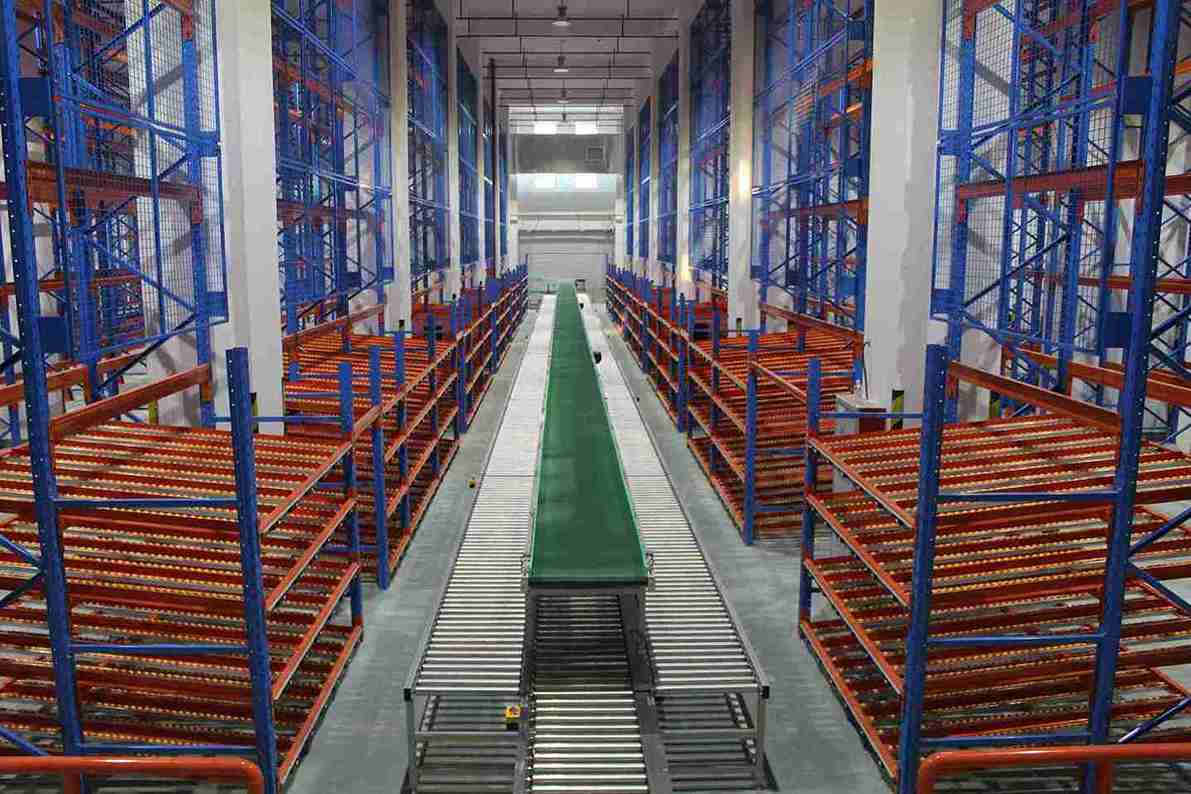

At its core, heavy-duty case flow racking is a dynamic storage system that harnesses gravity to create a continuous, automated flow of inventory. It is a masterpiece of material handling engineering, transforming static storage into a live, first-in-first-out pipeline. Products are loaded in pallet quantities onto the elevated rear of the system. From there, individual cases or cartons travel down a slightly inclined plane, riding on heavy-duty rollers or wheels, until they arrive at the forward pick face.

This simple yet brilliant principle ensures that the oldest stock is always presented first for picking, eliminating any possibility of out-of-sequence retrieval. The defining characteristic of a heavy-duty case flow racking system is its ability to handle substantial weight per lane, often exceeding 1,500 lbs, with exceptional durability and reliability, making it the ideal backbone for a durable goods warehouse.

Deconstructing the Components of a Superior Case Flow Racking System

Understanding the build quality of a case flow racking system is paramount to selecting a solution that will endure for decades. Not all systems are created equal.

Structural Upright Frames: The foundation of any industrial case flow racking installation is its steel framework. For heavy-duty applications, these frames are constructed from cold-rolled, high-tensile strength steel with a minimum thickness of 3mm. The uprights are designed to handle not only the immense vertical load but also the lateral forces imposed by the inclined flow lanes. The connection systems between beams and uprights are often bolted or utilize patented locks that provide superior seismic resilience and overall stability.

Flow Rails and Load Beams: These are the horizontal members that create the inclined channels for the rollers. In a high-capacity case flow racking system, these beams are reinforced and engineered to resist deflection under maximum load, ensuring a smooth and consistent product flow from the back to the front.

Roller Technology – The Heart of the System: This is the most critical differentiator. For a heavy-duty case flow racking application, manufacturers specify large-diameter (typically 50-75mm), high-gauge steel rollers with precision bearings.These are spaced closely together to provide continuous support for heavy, rigid containers. The rollers are often coated with polyurethane or a similar polymer to reduce noise, prevent marking of cartons, and provide a consistent coefficient of friction. The alternative to rollers is skatewheels, but for the immense weights common in durable goods, rollers are the unequivocal choice for reliability and smooth operation.

Speed Controllers and Flow Gates: Without control, gravity can be destructive. To prevent cases from gaining excessive speed and colliding at the pick face, a professional case flow racking system incorporates speed controllers. These can be simple mechanical friction brakes or more advanced electronic regulators that maintain a constant velocity. Flow gates and pick face laminates are also essential, acting as a final stop and presentation point, ensuring products are ergonomically accessible and secure for the operator.

The Compelling Advantages of Implementing Case Flow Racking

The decision to integrate case flow racking into a durable goods operation is a strategic investment that yields returns across multiple key performance indicators.

A Quantum Leap in Storage Density and Cube Utilization

The most immediately visible benefit of a case flow racking system is the radical improvement in storage density. By eliminating the multiple aisles required for traditional selective rack access and utilizing the entire depth of the system for storage, facilities can often increase their pallet positions by 60% to 80% or more.

This high-density approach means more inventory can be stored within the same building envelope, effectively lowering the cost per stored pallet and delaying or eliminating the need for a costly facility expansion. The case flow racking design is a masterclass in maximizing the valuable air space, or “cube,” of the warehouse.

Revolutionizing Order Picking Productivity and Ergonomics

The productivity gains at the pick face are where case flow racking systems deliver their most dramatic financial payoff. By presenting products directly to the order picker in a consistent, predictable manner, the system eliminates all non-value-added travel time. Pickers no longer walk, search, or reach into deep shelves.

They stand at a single, ergonomically optimized station, and the inventory comes to them. This “goods-to-person” principle can reduce picking time per item by over 60%, directly translating to more order lines picked per hour and a significant reduction in labor costs. Furthermore, the reduction in walking drastically lowers physical fatigue, leading to higher accuracy rates, improved worker morale, and lower turnover.

Absolute and Guaranteed FIFO Inventory Control

For many durable goods, particularly in the automotive and industrial sectors, inventory rotation is not merely a best practice—it is a mandatory requirement. Parts may have lot numbers, engineering revisions, or manufacturer dates that must be tracked and consumed in sequence.

A case flow racking system is the physical embodiment of the FIFO (First-In, First-Out) principle. The inherent design makes it impossible to pick newer stock before older stock. This eliminates the financial loss associated with obsolete inventory, ensures perfect traceability for recalls, and provides warehouse managers with absolute confidence in their inventory integrity.

Enhanced Safety and Significant Reduction in Product Damage

Safety is a paramount concern in any warehouse, especially when handling heavy cases. A case flow racking system contributes to a safer work environment in several key ways. It minimizes the need for manual lifting and carrying of heavy items, reducing strain-related injuries.

The controlled descent of products via rollers prevents the sudden drops and impacts that cause damage in manual handling. Furthermore, a well-organized case flow racking bay, with clear lanes and defined pick zones, reduces clutter and forklift traffic in picking aisles, mitigating the risk of accidents.

Engineering for Excellence: Specifying a True Heavy-Duty System

The term “heavy-duty” must be rigorously defined and specified. For a case flow racking system in a demanding environment, several engineering factors are non-negotiable.

Dynamic vs. Static Load Capacity: Understanding the Critical Difference

This is the most important specification to grasp. Static capacity refers to the weight a shelf can hold when motionless. Dynamic or rolling capacity is the weight the roller system is designed to move smoothly and reliably. For a heavy-duty case flow racking system, the dynamic capacity per lane must be the primary focus. Top-tier systems are engineered to handle dynamic loads of 2,000 lbs, 3,000 lbs, or even higher. The structural frame must correspondingly be rated to support multiple fully loaded lanes across multiple levels.

The Science of Pitch Angle and Roller Gauge

The incline angle of the case flow racking lanes is not arbitrary; it is a precise calculation based on product weight, carton bottom type (e.g., corrugated, solid fiber, plastic), and the roller material. A pitch that is too steep will cause products to accelerate dangerously, while one that is too shallow will cause jams.

Engineers use complex formulas and real-world testing to determine the optimal angle, typically between 3 and 7 degrees. Similarly, the gauge (thickness) of the steel used in the rollers and the robustness of their axles and bearings are what allow a case flow racking system to withstand years of punishing use without failure.

Lane Divider Strength and System Configurability

The lane dividers in a case flow racking system are under constant stress from the lateral impact of heavy cases during loading. Flimsy dividers will bend and fail, causing lane cross-over and system failure. High-quality systems use thick, reinforced steel dividers that are integral to the load beam structure. Furthermore, the best case flow racking solutions are highly configurable, allowing lane widths to be easily adjusted on-site to accommodate changing product profiles, ensuring the system remains optimized for years to come.

The Intelligent Warehouse: Integrating Case Flow Racking with Automation and Software

A case flow racking system reaches its full potential when it ceases to be a standalone storage unit and becomes an integrated component of a smart warehouse ecosystem.

Synergy with Automated Storage and Retrieval Systems (AS/RS)

The marriage of case flow racking with AS/RS technology represents the pinnacle of warehouse automation. In this setup, the case flow racking bay acts as the dynamic forward-picking buffer. An automated mini-load crane or a robotic shuttle system (a type of AS/RS) is responsible for the replenishment function, taking full pallets from reserve storage and automatically depositing cases onto the load side of the case flow racking lanes. This creates a “lights-out” replenishment process that can operate 24/7, ensuring the pick face is never starved of inventory, all while minimizing labor costs.

Data-Driven Management with Warehouse Management Systems (WMS)

A Warehouse Management System (WMS) acts as the central brain, and the case flow racking system is a powerful limb executing its commands. The WMS can direct put-away to specific lanes based on velocity codes (A, B, C items), provide real-time visibility into inventory levels at the pick face, and automatically generate replenishment tasks for the AS/RS or forklift operators when lane levels drop below a predetermined threshold. This seamless data exchange maximizes the efficiency of both the physical case flow racking infrastructure and the digital management layer.

Creating a Cohesive System with AGVs and Pallet Shuttle Systems

The automation ecosystem can extend further. Autonomous Guided Vehicles (AGVs) or Autonomous Mobile Robots (AMRs) can be deployed to transport full pallets from receiving docks to the rear of the case flow racking system for manual or automated unloading. For very deep storage applications, a pallet shuttle system can be integrated within the rack structure to automate the placement and retrieval of pallets in the deepest lanes, further augmenting density and reducing manual labor. This holistic approach to integrating case flow racking with other technologies is what defines a world-class distribution center.

Industry-Specific Applications of Case Flow Racking

The versatility of case flow racking makes it suitable for a wide array of durable goods sectors. Each application leverages the core benefits of the system to solve industry-specific challenges.

Automotive Parts Distribution: This industry is a perfect use case for case flow racking. Distributors handling tires, batteries, oil filters, exhaust components, and collision repair parts benefit immensely from the enforced FIFO, which is critical for managing model-year changes and recall campaigns. The efficiency gains in picking complex dealership orders are monumental.

Building Materials and Hardware: Wholesalers of plumbing supplies (pipes, fittings), electrical components, fasteners, and tools use case flow racking to manage a vast number of SKUs in a compact footprint. The ability to handle heavy, often cumbersome boxes with ease makes the case flow racking system an indispensable tool.

Industrial Supply and MRO (Maintenance, Repair, and Operations): This sector manages everything from heavy-duty bearings and motor parts to safety equipment and janitorial supplies. A case flow racking system ensures critical maintenance items are always in rotation and readily available, minimizing downtime for client facilities.

Major Appliance and Electronics Distribution: For large-format boxes containing microwaves, vacuums, power tools, or audio equipment, a robust case flow racking system streamlines the order fulfillment process. The ergonomic pick face prevents worker injury from repeatedly handling heavy, bulky items.

The Implementation Blueprint: From Concept to Operation

Deploying a large-scale case flow racking system is a significant project that requires meticulous planning and execution. A professional provider will guide clients through a structured process.

In-Depth Consultation and Data-Driven Analysis: The process begins with a thorough analysis of the client’s entire product portfolio. This includes capturing precise dimensions and weights for every SKU, analyzing velocity data (ABC analysis), and understanding seasonal fluctuations and growth projections. This data is the foundation of all design decisions.

Customized CAD Design and Engineering Modeling: Using advanced computer-aided design (CAD) software, engineers create a detailed 3D model of the proposed case flow racking layout. This model optimizes the warehouse cube, determines the exact lane depths and configurations, and identifies the required structural specifications. Clients can virtually walk through the new design before a single piece of steel is fabricated.

Phased Installation with Precision and Minimal Disruption: Experienced installation teams understand that warehouses must remain operational. They work in carefully planned phases, often during off-hours, to install the case flow racking system with minimal impact on daily shipping and receiving activities. Precision during installation is critical to ensuring the system functions as designed.

System Commissioning, Training, and Ongoing Support: Once installed, the system is “commissioned.” This involves fine-tuning the pitch angles and speed controllers for the specific products that will flow through it. Comprehensive training is provided for warehouse operators, maintenance staff, and management. A reputable provider will also offer ongoing support and spare parts services to ensure the case flow racking system operates flawlessly for its entire lifespan.

Conclusion: Transforming Storage into a Strategic Advantage

For the modern durable goods warehouse, stagnation is not an option. The competitive pressures of e-commerce, rising labor costs, and the demand for faster, more accurate order fulfillment require a fundamental rethinking of storage methodology. A heavy-duty case flow racking system is far more than a collection of steel and rollers; it is a transformative material handling philosophy. It actively converts wasted space into high-density storage, converts laborious walking into productive picking, and converts inventory management guesswork into guaranteed FIFO control.

The return on investment is clear and compelling: radical gains in productivity, dramatic reductions in operational costs, and a significant enhancement in safety and accuracy. Investing in a properly engineered case flow racking system is not merely an equipment purchase—it is a decisive step toward building a faster, smarter, and more profitable distribution operation that is prepared for the challenges of the future.

Frequently Asked Questions (FAQs)

Q1: Our products vary greatly in weight and size. Can a single case flow racking system handle such a diverse SKU mix?

Absolutely. A key strength of a well-designed case flow racking system is its configurability and zoning capability. We can design a single system with different zones: one section with a steeper pitch and heavier rollers for dense, heavy products, and another zone with a shallower pitch for lighter items. Lane widths can be easily adjusted on-site to accommodate everything from small boxes to large cases. The system is engineered around your specific product mix.

Q2: How does the cost of a heavy-duty case flow racking system compare to traditional pallet racking, and what is the typical ROI?

The initial investment per pallet position in a case flow racking system is higher than standard pallet racking due to the added roller technology and engineering. However, the financial justification comes from the dramatic operational savings.

The ROI is calculated based on the value of the space saved (allowing you to avoid a facility move or expansion), the labor savings from drastically improved picking rates (often a 50%+ reduction in picking time), and the reduction in product loss from improved FIFO. Most operations see a full return on investment within 12 to 24 months through these hard savings.

Q3: We have existing pallet racking. Can we convert it to a case flow racking system?

In many cases, yes. Retrofit solutions are available where flow rails and roller kits can be installed into your existing upright frames. This can be a very cost-effective strategy. However, this requires a thorough structural analysis by an engineer to ensure your current racking can handle the different load dynamics and weight distribution of a live storage system. We always conduct this analysis before proposing a retrofit.

Q4: What happens if a roller jams or a lane gets blocked? How is maintenance handled?

Maintenance is straightforward. The rollers are designed for easy replacement from the pick face without tools in most high-quality systems. If a jam occurs, it is typically easily cleared by an operator. The system’s design includes access points to address any issues quickly. Furthermore, the robust construction of a true heavy-duty case flow racking system means mechanical failures are exceptionally rare. Preventative maintenance usually involves simply ensuring the lanes are kept clear of debris.

Q5: Are there any specific fire safety codes we need to consider with high-density flow rack systems?

Yes, this is a critical consideration. High-density storage, including case flow racking, can affect air flow and how traditional ceiling-mounted sprinkler systems operate. National Fire Protection Association (NFPA) codes often require in-rack sprinkler systems to be installed within the case flow racking structure itself to ensure adequate water coverage to all levels in the event of a fire. Any professional design will include a plan for integrating the necessary fire suppression equipment to meet all local building and safety codes.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com