📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Future-Proof Your Warehouse: The Definitive Guide to Achieving 100% ROI in 2 Years with AI-Driven Green Warehouse Automation

The global warehouse is at a crossroads. Pressures from every direction—skyrocketing consumer demand, a volatile labor market, escalating energy costs, and stringent new sustainability mandates—are converging to make traditional operational models obsolete. The enterprises that will thrive in the coming decade are those that recognize their logistics footprint not as a cost center, but as a strategic asset. The key to this transformation lies in the powerful, synergistic integration of Artificial Intelligence (AI) and Green warehouse automation. This is not a minor upgrade; it is a fundamental reinvention of material handling.

It represents a shift from reactive, labor-intensive processes to a proactive, intelligent, and self-optimizing ecosystem. This comprehensive guide delves into how forward-thinking companies are leveraging Green warehouse automation to build resilience, unlock unprecedented efficiency, and achieve a verifiable 100% return on investment within a 24-month horizon, all while establishing a new standard for corporate responsibility.

The New Logistics Paradigm: Where AI Meets Green Warehouse Automation

The conversation around warehouse efficiency has evolved. It is no longer sufficient to simply automate a single task. True competitiveness is now born from a system-wide, intelligent approach. Green warehouse automation is the embodiment of this approach. It is a holistic philosophy that combines advanced robotics and smart storage systems with a layer of predictive AI, all designed to minimize environmental impact while maximizing profitability.

This form of Green warehouse automation directly addresses the core pain points of modern logistics directors: the need to do more with less, faster, and cleaner. Implementing a strategic Green warehouse automation solution means building an adaptive operation that can withstand market fluctuations, comply with evolving regulations, and meet the ethical expectations of partners and consumers alike.

Deconstructing the 100% ROI Promise: The Tangible Economics of Green Warehouse Automation

A commitment to a two-year ROI is a bold claim, but in the realm of advanced Green warehouse automation, it is a realistic and calculated target. The financial model is built on a dual-engine of drastic cost avoidance and measurable revenue enhancement.

Capitalizing on Operational Cost Evasion

Traditional facilities leak capital through inefficiencies that are often accepted as “the cost of doing business.” A sophisticated Green warehouse automation system systematically identifies and eliminates these leaks.

Labor Redefinition and Empowerment: Unlike standalone automation, Green warehouse automation powered by an AI-driven Warehouse Execution System (WES) optimizes the entire ecosystem—human and machine. It dynamically assigns tasks based on real-time conditions, eliminating unproductive walking time and cognitive load. This allows a single operator to manage a fleet of AGVs (Automated Guided Vehicles) and AMRs (Autonomous Mobile Robots), dramatically increasing throughput per employee. The result is a significant reduction in labor costs as a percentage of revenue, a primary driver of the ROI for any Green warehouse automation project.

The Energy Efficiency Dividend: The “Green” in Green warehouse automation has a direct and powerful impact on the bottom line. Systems like Automated Storage and Retrieval Systems (AS/RS) utilize regenerative drives that capture energy during descent, feeding it back into the system. Smart, motion-activated LED lighting and AI-managed HVAC systems reduce a facility’s energy consumption by 40-50% or more. In regions like Southeast Asia and the Middle East, where cooling costs are prohibitive, this aspect of Green warehouse automation delivers massive and ongoing financial savings.

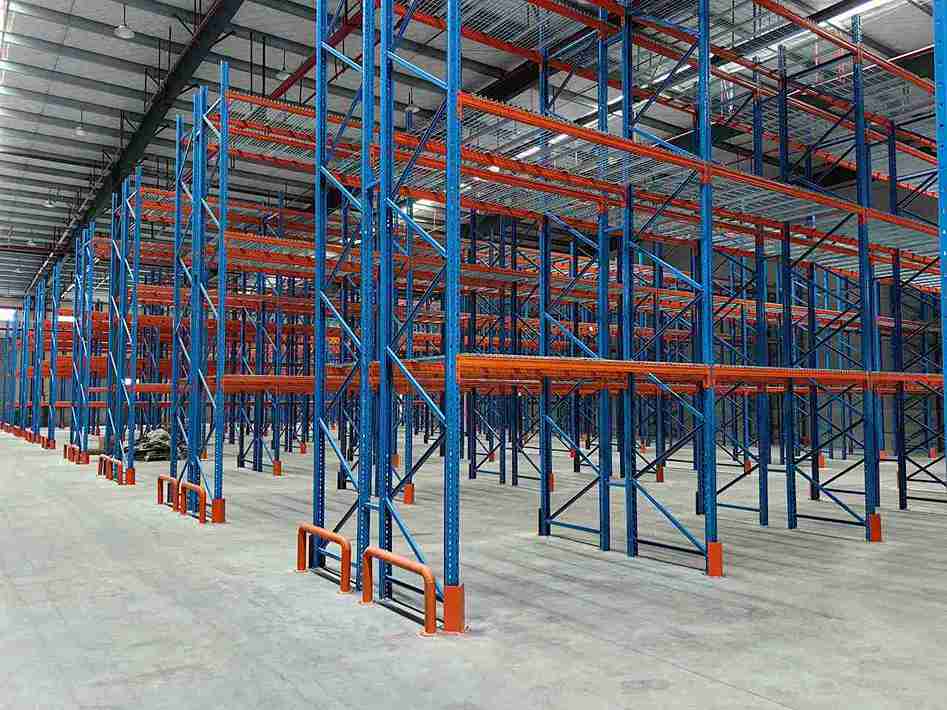

Real Estate Optimization: Vertical space is a dormant asset in most conventional warehouses. A core principle of Green warehouse automation is volumetric efficiency. High-density ASRS and pallet shuttle systems can double or triple storage capacity within the same footprint, deferring or eliminating the need for costly expansions or relocations. This capital expenditure avoidance is a critical, though often overlooked, component of the ROI calculation for Green warehouse automation.

Driving Tangible Revenue Enhancement

The financial upside of Green warehouse automation extends far beyond cost savings. A faster, more accurate, and more reliable operation directly boosts top-line performance.

Unprecedented Throughput Velocity: An AI-optimized Green warehouse automation system accelerates order fulfillment to a degree that reshapes business capabilities. Automated sortation systems, goods-to-person stations, and synchronized robotics work in concert to process orders at speeds that are unattainable manually. This allows businesses to handle peak-season volumes with ease, meet next-day or same-day delivery promises, and ultimately, process more revenue-generating orders every single day.

Perfect Order Accuracy: Human error in picking and packing is a silent profit-killer. Green warehouse automation introduces near-perfect accuracy through barcode scanning, computer vision, and robotic precision, achieving rates of 99.99%+. This virtually eliminates the costs of returns, reshipments, and inventory shrinkage, while simultaneously enhancing brand reputation and customer loyalty.

Uptime as a Revenue Stream: Predictive maintenance, an innate capability of AI-driven Green warehouse automation, analyzes sensor data from conveyors, automated forklifts, and robotics to forecast component failures. By performing maintenance proactively during planned downtime, it avoids catastrophic system halts during critical shipping periods. In a Green warehouse automation environment, every hour of preserved uptime is an hour of guaranteed revenue generation.

The Architectural Blueprint of an Intelligent Facility: Core Components of Green Warehouse Automation

A successful Green warehouse automation project is not a collection of disjointed machines; it is a seamlessly integrated symphony of hardware and software.

The Intelligent Core: AI and the Warehouse Execution System (WES)

The brain of any modern Green warehouse automation setup is a sophisticated WES that transcends the capabilities of a traditional WMS.

Real-Time Dynamic Optimization: A WES in a Green warehouse automation context doesn’t just track; it commands and optimizes in real-time. It calculates the most efficient path for every task, considering the location of all assets, energy consumption, and order priorities. It might direct an AMR to a picking station, task an automated forklift with replenishment, and command the sorter to prioritize an express order, all while minimizing total system energy use—a hallmark of true Green warehouse automation.

The Digital Twin: A Sandbox for Perfection: A Digital Twin is a virtual, real-time replica of the physical warehouse. This powerful tool allows managers to simulate and optimize every aspect of their Green warehouse automation system without risk. Testing layout changes, process adjustments, or response to a 50% demand surge can be done in the digital realm, ensuring that the physical Green warehouse automation system operates at peak efficiency from day one.

The Automated Physical Layer: Robotics and Smart Storage

The intelligence of the WES is brought to life by a range of physical systems that form the body of the Green warehouse automation ecosystem.

Coordinated Robotic Fleets (AGVs & AMRs): In a mature Green warehouse automation environment, AGVs and AMRs operate as a coordinated swarm. The WES manages their traffic, assigns tasks to minimize empty travel, and ensures the entire fleet works in harmony. This coordination is essential for maximizing the efficiency gains promised by Green warehouse automation.

High-Density Automated Storage (AS/RS): The ASRS is often the centerpiece of a Green warehouse automation strategy. These systems store goods at extreme densities and deliver them with perfect accuracy. By enclosing the storage area, they drastically reduce the energy required for lighting and climate control, cementing the “Green” credentials of the Green warehouse automation installation.

Seamless Automated Conveyance: High-speed sorters, conveyors, and diverters act as the arteries of the Green warehouse automation system, ensuring a smooth, continuous flow of goods from receiving to shipping, connecting all the robotic and automated elements into a single, cohesive unit.

The Strategic Imperative: Why Green Warehouse Automation is a Non-Negotiable for Modern Business

Adopting Green warehouse automation is no longer a choice for industry leaders; it is a strategic necessity for survival and growth.

Market Access and Global Compliance: Major corporations and governments are now mandating sustainable supply chain practices. A facility powered by Green warehouse automation provides verifiable data on reduced emissions and energy use, making it the partner of choice for globally-minded brands. This compliance aspect makes Green warehouse automation a key to unlocking new, lucrative markets.

Attracting Capital and Top-Tier Talent: The investment community is heavily focused on ESG (Environmental, Social, and Governance) performance. A demonstrably sustainable operation, enabled by Green warehouse automation, makes a company more attractive to investors. Furthermore, a modern, safe, and technologically advanced Green warehouse automation environment is a powerful magnet for the skilled workforce needed to run the logistics centers of the future.

Building Resilience Against Volatility: By slashing dependence on the grid and insulating the business from labor market fluctuations, Green warehouse automation creates a more resilient and predictable operational model. This ability to control core costs is an invaluable form of risk management in an unpredictable global economy.

A Phased Implementation Blueprint for Guaranteed Success in Green Warehouse Automation

The path to a fully realized Green warehouse automation ecosystem is a journey, not a single event. A phased, managed approach ensures success at every step.

Phase 1: Discovery and Digital Twin Creation (Weeks 1-4): A deep-dive analysis of current operations fuels the creation of a baseline Digital Twin. This model is used to project a precise ROI and design the optimal Green warehouse automation roadmap.

Phase 2: Foundational Smart Infrastructure (Months 2-4): Installation of the physical backbone begins, which could include high-density selective pallet racking or the structural framework for the ASRS. The facility-wide IoT sensor network is also deployed.

Phase 3: Robotics Integration and WES Activation (Months 5-9): The first wave of AGVs and AMRs is deployed. The WES is activated, and staff training intensifies. Early efficiency gains from this phase of Green warehouse automation begin to fund subsequent investments.

Phase 4: System-Wide Optimization and Scaling (Months 10-12+): With the core Green warehouse automation system live, advanced AI modules for predictive maintenance and continuous optimization are fine-tuned. The scalable nature of the system allows for seamless expansion, adding more robotics or storage modules as business grows.

Navigating the Real-World Challenges of Green Warehouse Automation Adoption

A transparent partnership acknowledges and plans for hurdles. The implementation of Green warehouse automation comes with specific challenges, each with a proven mitigation strategy.

Challenge: Significant Capital Investment.

The Solution: A detailed, bankable ROI model is crucial for securing financing. A modular approach to Green warehouse automation allows for phased investment, starting with a automated forklift fleet and WES, then adding the ASRS later, distributing costs while realizing early savings.

Challenge: Workforce Transformation.

The Solution: Effective Green warehouse automation implementation includes a robust change management and upskilling program. Employees are trained for higher-value roles in system management, data analysis, and exception handling, fostering a culture of innovation and retaining institutional knowledge.

Challenge: Integration with Legacy Systems.

The Solution: A modern Green warehouse automation platform is built with open APIs, ensuring seamless integration with existing ERPs and WMS. Experienced implementation partners manage this complexity to ensure a smooth transition.

Conclusion: The Future is an Adaptive, Efficient, and Green Warehouse

The trajectory of global commerce is clear. The warehouses that will define the future are those that embrace intelligence and sustainability not as separate projects, but as two sides of the same coin. Green warehouse automation is the practical application of this principle, offering a clear, financially robust, and future-proof path forward. It transforms the warehouse from a static liability into a dynamic, competitive weapon—a system that learns, adapts, and grows.

Achieving a 100% ROI in two years is an ambitious target, but for enterprises that partner with the right experts and commit to a strategic vision, it is an entirely achievable one. The journey toward a resilient and profitable future begins with a single, decisive step toward integrated Green warehouse automation.

Frequently Asked Questions (FAQs) on Green Warehouse Automation

1. How does the AI in a Green warehouse automation system continuously improve operations after the initial setup?

The AI utilizes machine learning algorithms that analyze operational data in real-time. It constantly tests and refines workflows within the Digital Twin, identifying patterns and inefficiencies invisible to the human eye. For instance, it might learn that rearranging certain SKU placements based on seasonal demand correlations can reduce robot travel distance by 15%, thereby self-optimizing the Green warehouse automation system for ever-greater efficiency and lower energy consumption.

2. Can Green warehouse automation handle complex value-added services like kitting, customization, or returns processing?

Absolutely. Modern Green warehouse automation is designed for flexibility. The WES can direct items to designated light-assembly or kitting stations where human workers, assisted by AMRs delivering components, perform the custom work. For returns, the system can automate the intake process, sort items based on disposition (restock, refurbish, recycle), and efficiently reintegrate sellable goods back into inventory, making the entire returns management process a part of the efficient Green warehouse automation cycle.

3. What are the cybersecurity implications of a fully connected Green warehouse automation system, and how are they addressed?

Cybersecurity is a paramount concern in any connected industrial environment. Reputable providers of Green warehouse automation solutions build security into the core of their architecture. This includes encrypted data transmission, regular security patches, strict network access controls, and segmenting the operational technology (OT) network from the corporate IT network. A comprehensive security audit is a standard part of the implementation process for a robust Green warehouse automation system.

4. How does Green warehouse automation scale with a business that is experiencing rapid growth or seasonal spikes?

Scalability is a fundamental advantage of a well-designed Green warehouse automation system. Because the architecture is modular, additional AMRs, ASRS shuttles, or picking workstations can be integrated into the existing WES with minimal disruption. The AI can immediately begin optimizing the use of these new assets. This allows the Green warehouse automation ecosystem to scale elastically alongside business demand, protecting the investment long-term.

5. Beyond energy and labor, what are some less obvious metrics where Green warehouse automation improves performance?

While energy and labor are the headline figures, a deep Green warehouse automation implementation drives improvement across a range of other Key Performance Indicators (KPIs). These include: a dramatic reduction in inventory carrying costs due to higher accuracy and faster turnover; a significant decrease in damage rates thanks to robotic handling; improved asset utilization (e.g., forklifts, space); and enhanced safety metrics, with automation removing personnel from high-risk areas.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com