📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Introduction: Maximizing Warehouse Storage with Custom Heavy-Duty Beam Racking Solutions

In today’s fast-evolving logistics and warehousing sector, efficient storage solutions are not just a luxury—they’re a necessity. With space often at a premium, businesses must continuously innovate to optimize their warehouse layouts. Custom heavy-duty beam racking systems have emerged as a pioneering solution for maximizing storage space. These systems offer warehouses up to 30% more storage capacity, allowing businesses to store more goods without expanding their physical footprint.

This article will delve into the various aspects of custom heavy-duty beam racking, explaining its benefits, structure, and implementation in real-world warehouse environments. By the end of this guide, warehouse managers and business owners will gain a deep understanding of how custom heavy-duty beam racking can revolutionize their storage capabilities, improve operations, and ultimately lead to a more streamlined workflow.

Table of Contents

-

H1: Understanding Custom Heavy-Duty Beam Racking Systems

-

H2: Key Benefits of Custom Heavy-Duty Beam Racking in Warehouses

-

H3: Maximizing Storage Capacity with Customization

-

H3: Flexibility and Adaptability of Custom Beam Racking

-

H4: Meeting Specific Warehouse Needs with Custom Solutions

-

H2: How Custom Heavy-Duty Beam Racking Works

-

H3: Components of a Custom Beam Racking System

-

H3: Load Handling and Durability of Custom Beam Racking

-

H2: Why Custom Beam Racking is the Future of Warehouse Storage

-

H3: Tailoring the Racking System to Your Warehouse Layout

-

H3: Long-Term Cost Efficiency and Return on Investment

-

H2: Installation and Maintenance of Custom Beam Racking Systems

-

H3: Step-by-Step Guide to Installing Custom Beam Racking

-

H4: Optimizing Your Warehouse Layout with Custom Beam Racking

-

H2: Enhancing Safety with Custom Beam Racking

-

H3: Safety Protocols for Heavy-Duty Beam Racking

-

H3: Ensuring Compliance and Risk Mitigation

-

H2: Real-World Applications and Case Studies

-

H3: Success Stories from Leading Warehouses

-

H2: How to Choose the Right Custom Beam Racking for Your Warehouse

-

H3: Factors to Consider When Selecting Custom Beam Racking

-

H3: Evaluating Racking Needs Based on Product Types

-

H2: Conclusion

-

H2: Frequently Asked Questions

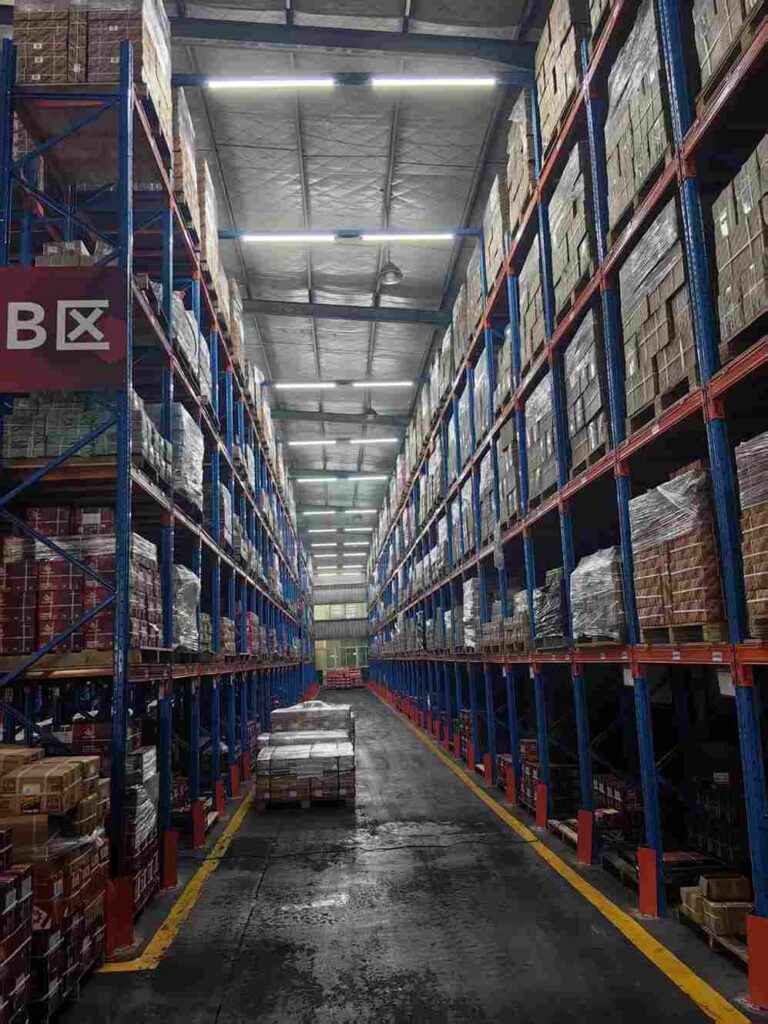

Custom Heavy-Duty Beam Racking maximizing warehouse storage capacity.

Understanding Custom Heavy-Duty Beam Racking Systems

At its core, custom heavy-duty beam racking refers to a robust storage solution designed to handle large quantities of goods, often weighing hundreds or thousands of pounds. Unlike standard racking systems, which offer fixed configurations, custom heavy-duty beam racking can be tailored to fit unique warehouse layouts and product types.

The system consists of adjustable beams and uprights that can be configured based on a warehouse’s specific needs. Whether you’re storing palletized goods, industrial equipment, or bulkier items, custom beam racking systems are designed to optimize vertical space and maximize storage density, offering up to 30% more storage than traditional racking solutions.

Key Benefits of Custom Heavy-Duty Beam Racking in Warehouses

Maximizing Storage Capacity with Customization

One of the most compelling reasons to opt for custom heavy-duty beam racking is its ability to increase storage capacity. With the flexibility to adjust the height, width, and depth of the racking, businesses can make full use of their warehouse’s available vertical space. Customization ensures that racks are perfectly suited to store goods of different sizes, reducing wasted space between shelves and improving storage density.

In warehouses where floor space is limited, custom heavy-duty beam racking allows for taller racking systems, utilizing the full height of the warehouse. This vertical storage capability enables businesses to store more products within the same footprint, driving up storage capacity by as much as 30%.

Flexibility and Adaptability of Custom Beam Racking

Another benefit of custom heavy-duty beam racking is its adaptability. These systems are designed to evolve with a business’s changing needs. Warehouse inventory often fluctuates, and the ability to reconfigure custom beam racking systems to fit new products is crucial. Adjustments can be made to beam height, depth, and load-bearing capacity without requiring significant investment in new systems.

The flexibility of custom heavy-duty beam racking also means that it can be optimized for various storage configurations, whether for selective racking, drive-in racking, or push-back racking. This adaptability ensures that businesses can continue to scale their operations efficiently.

Meeting Specific Warehouse Needs with Custom Solutions

Each warehouse has its unique storage requirements. Custom heavy-duty beam racking systems offer a tailored solution that aligns with a business’s specific operational needs. For example, warehouses storing bulky or irregularly shaped items can design racks with greater depth or specialized configurations to accommodate these goods.

By working with an experienced racking solutions provider, businesses can create a system that enhances operational flow, improving inventory access and product retrieval efficiency. A customized solution also allows for faster integration with existing warehouse technology, such as automated guided vehicles (AGVs) or automated sorting systems.

How Custom Heavy-Duty Beam Racking Works

Components of a Custom Beam Racking System

A custom heavy-duty beam racking system is made up of several key components:

-

Uprights: The vertical supports that form the frame of the racking system.

-

Beams: The horizontal supports that hold and distribute the weight of stored goods.

-

Pallet Supports: These are additional components that stabilize pallets and prevent them from shifting.

-

Braces and Connectors: Diagonal braces connect the uprights, providing stability and resistance against forces that could cause tipping.

All of these components are designed to be modular, allowing for adjustments based on specific storage requirements. The strength and durability of custom heavy-duty beam racking come from the quality materials used in their construction, such as high-strength steel, which ensures they can handle heavy loads while maintaining structural integrity over time.

Load Handling and Durability of Custom Beam Racking

The durability of custom heavy-duty beam racking systems is one of their most valuable features. These racks are designed to bear heavy loads, often supporting several tons of goods. Custom designs allow businesses to choose beam types and upright sizes that match the weight and volume of their inventory, ensuring optimal load distribution and preventing strain on the system.

The durability of these systems is crucial for minimizing long-term maintenance costs. By investing in high-quality materials, businesses can rely on custom heavy-duty beam racking systems to last for many years without needing frequent repairs or replacements.

Why Custom Beam Racking is the Future of Warehouse Storage

Tailoring the Racking System to Your Warehouse Layout

Custom beam racking offers a unique advantage over traditional systems: tailored designs that maximize the potential of your warehouse’s space. The ability to adjust beam height and create custom shelf depths allows businesses to fit the racking system to the specific dimensions and workflows of their warehouse.

This customization also ensures that inventory management becomes more efficient. Whether you are using automated systems or manual processes, the tailored nature of custom heavy-duty beam racking helps facilitate smooth operations and better space utilization.

Long-Term Cost Efficiency and Return on Investment

While the initial investment in custom heavy-duty beam racking may be higher than standard systems, the long-term cost savings are significant. By utilizing space more efficiently, businesses can store more products without needing additional warehouse space. This reduces overall real estate costs, especially in regions where warehouse space is expensive.

Additionally, the enhanced durability of custom heavy-duty beam racking means fewer repairs and replacements, leading to lower maintenance costs over time. The return on investment (ROI) from custom racking solutions is clear, especially when factoring in increased storage capacity and optimized workflow.

Installation and Maintenance of Custom Beam Racking Systems

Step-by-Step Guide to Installing Custom Beam Racking

The installation of custom heavy-duty beam racking involves several steps, beginning with site evaluation and layout design. Experienced installers work with warehouse managers to ensure the racking system is properly aligned, secure, and compliant with safety standards. Installation includes assembling uprights, securing beams, and leveling the system to ensure it can handle heavy loads without shifting or becoming unstable.

Optimizing Your Warehouse Layout with Custom Beam Racking

Once installed, the racking system should be optimized for inventory management. Custom systems allow for better traffic flow, improved accessibility, and quicker retrieval of goods. This optimization leads to more efficient warehouse operations and faster order fulfillment.

Enhancing Safety with Custom Beam Racking

Safety Protocols for Heavy-Duty Beam Racking

When implementing custom heavy-duty beam racking, safety is a priority. Proper installation, weight distribution, and maintenance help ensure the system operates safely. Warehouse employees should be trained in safe loading and unloading procedures to prevent accidents.

Ensuring Compliance and Risk Mitigation

Adhering to industry safety standards and local regulations is crucial when implementing any racking system. Custom systems can be designed to comply with safety codes, ensuring that your warehouse meets all necessary guidelines and minimizes operational risks.

Real-World Applications and Case Studies

Success Stories from Leading Warehouses

Across industries, businesses have successfully leveraged custom heavy-duty beam racking to increase their storage capacity and streamline operations. From e-commerce giants to manufacturing warehouses, these systems have proven to be a valuable asset in optimizing warehouse layouts, improving efficiency, and lowering costs.

Conclusion

Custom heavy-duty beam racking systems represent a vital tool for businesses looking to improve their warehouse storage. By offering increased storage capacity, flexibility, and long-term cost savings, these systems can significantly enhance operational efficiency. Through customization, businesses can tailor their racking solutions to meet their specific needs, ultimately creating a safer, more efficient warehouse environment.

Frequently Asked Questions

-

What is the load capacity of custom heavy-duty beam racking systems?

-

How do I determine if my warehouse needs custom beam racking?

-

Can custom beam racking be adjusted as inventory changes?

-

What materials are used to build custom heavy-duty beam racking?

-

How do I maintain and inspect my custom beam racking system?