📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Unseen Cost of Warehouse Pallet Failure

Let’s talk about a silent budget killer in your warehouse. It’s not the obvious stuff like labor or energy costs. It’s something more fundamental, something you walk on and stack your entire inventory upon: your pallets. Specifically, the cost of not using the right ones. If you’re managing a warehouse, you’re constantly battling two fronts: maximizing operational uptime and minimizing capital expenditure. T

he humble pallet sits squarely at the intersection of this battle. A failed pallet can halt an automated conveyor, damage a priceless product, cause a safety incident, or simply need to be replaced far too often, chipping away at your bottom line with frustrating regularity. This isn’t just about buying a platform for your goods; it’s about investing in the very foundation of your material handling system. In this comprehensive guide, we will delve deep into why galvanized steel pallets are not just an purchase, but a strategic investment that directly contributes to maximizing asset lifespan and dramatically reducing the total cost of ownership through lower replacement costs.

We’ll move beyond the sales pitch and provide the engineering and economic data you need to make an informed decision for your operation.

Why Pallet Choice is a Strategic Operational Decision, Not Just a Procurement Task

Most procurement departments are measured on upfront cost savings. A wooden pallet might cost $50, while a galvanized steel pallet might cost $300. On a spreadsheet, the choice seems simple. But this is a classic case of being “penny wise and pound foolish.” The true cost of a pallet is spread across its entire service life and encompasses far more than its purchase price. We need to consider:

Replacement Frequency: How often must you buy a new one?

Maintenance & Repair Costs: The labor and parts needed to keep it operational.

System Downtime: The cost of a production line stoppage because a pallet jammed or failed.

Product Damage: The value of goods damaged by a broken pallet or splintered wood.

Safety Risks: The potential cost of workplace accidents from nail protrusions or structural failure.

Hygiene & Contamination: Critical for food, Pharma, and electronics, where wood fibers and moisture can ruin products.

When you evaluate pallets through this holistic lens, the economics shift dramatically. Galvanized steel pallets consistently emerge as the superior long-term financial decision for demanding warehouse environments, especially those integrating automation.

The Galvanizing Process: A Deep Dive into Superior Protection

To understand why these pallets last so long, you need to understand the science behind galvanization. It’s more than just a coating; it’s a metallurgical bond.

What is Hot-Dip Galvanizing?

Hot-dip galvanizing is a process where fabricated steel is submerged in a bath of molten zinc at around 840°F (449°C). This creates a complex, multi-layered metallurgical structure that is integral to the steel itself, not just a surface film like paint.

The Layers of Defense

The zinc-steel alloy layers formed during galvanizing provide protection in two fundamental ways:

Barrier Protection: The zinc coating creates a physical barrier that prevents oxygen and moisture from reaching the underlying steel. Unlike paint, which can be scratched or chipped, the galvanized layer is uniformly thick and bonded to the steel.

Cathodic Protection (Sacrificial Anode): This is the magic. Zinc is more electrochemically active than steel. If the coating is scratched or damaged, exposing a small area of steel, the surrounding zinc will “sacrifice” itself by corroding first, protecting the steel. This unique self-healing property prevents rust from spreading.

This dual-action defense system is what gives galvanized steel pallets their legendary durability and incredibly long lifespan, even in the harshest warehouse environments.

Head-to-Head: Galvanized Steel Pallets vs. The Competition

Let’s break down the real-world performance of galvanized steel against other common pallet materials.

Galvanized Steel vs. Wood Pallets

Lifespan: Wood pallets typically last 1-3 years in a single-shift operation with careful handling. Galvanized steel pallets routinely last 10-15 years or more, even in 24/7 automated environments. That’s a 5x to 10x lifespan multiplier.

Strength & Consistency: Steel has a vastly higher strength-to-weight ratio. It won’t flex or sag under heavy loads, which is critical for Automated Storage and Retrieval Systems (AS/RS). Wood is inconsistent—knots, grain variations, and moisture content affect its strength.

Maintenance: Wood pallets require constant inspection for broken boards, protruding nails, and splinters. They often need repair or disposal. Steel pallets are virtually maintenance-free. A quick visual inspection is usually all that’s needed.

Hygiene: Wood is porous. It absorbs moisture, oils, and bacteria, making it unsuitable for clean environments. It can also harbor insects. A galvanized steel pallet is non-porous, impervious to moisture, and can be easily steam-cleaned or sterilized.

Fire Safety: Steel is non-combustible.

Galvanized Steel vs. Regular Painted or Powder-Coated Steel Pallets

This is a crucial distinction. A painted steel pallet might seem like a cheaper alternative, but it is fundamentally inferior.

Corrosion Resistance: Paint and powder coating provide only barrier protection. When scratched (which is inevitable in a warehouse), the exposed steel will rust, and that rust will creep underneath the coating, leading to rapid failure. The galvanized layer’s cathodic protection prevents this entirely.

Durability: The galvanized coating is harder and more abrasion-resistant than most paint systems. It can withstand the relentless impacts, scrapes, and friction of conveyor systems, forklift forks, and robotic arms without compromising its protection.

Galvanized Steel vs. Plastic Pallets

UV & Temperature Resistance: Plastic becomes brittle when exposed to ultraviolet light (from warehouse lighting) and extreme cold (e.g., cold storage). Galvanized steel is unaffected by temperature extremes or UV exposure.

Creep & Deformation: Plastic pallets are susceptible to “creep” – they permanently deform under constant heavy load, especially in racking. Steel does not creep, maintaining its structural integrity for decades.

Cost Stability: The price of plastic pallets is tied to petroleum prices, which are volatile. Steel prices are generally more stable.

Quantifying the ROI: How Galvanized Steel Pallets Save You Money

This is the core of the argument. Let’s translate durability into dollars and cents.

The Total Cost of Ownership (TCO) Model

The formula for TCO is:

TCO = Purchase Price + (Replacement Cost Frequency) + Maintenance & Repair Costs + Downtime & Damage Costs

Example Scenario:

A mid-sized warehouse uses 1,000 pallets in a high-throughput, automated environment.

Wood Pallet TCO (5-Year Period):

Purchase Price: $50/pallet * 1,000 = $50,000

Replacement: Assume replacement every 2 years. Over 5 years, you’ll buy 2.5 sets. 2.5 * $50,000 = $125,000

Maintenance/Repair: $5/pallet/year * 1,000 pallets * 5 years = $25,000

Downtime/Damage: Estimate 1 incident per week costing $500 in downtime/product loss. 52 weeks * 5 years * $500 = $130,000

Estimated 5-Year TCO: $125,000 + $25,000 + $130,000 = $280,000

Galvanized Steel Pallet TCO (5-Year Period):

Purchase Price: $300/pallet * 1,000 = $300,000

Replacement: None required in 5 years.

Maintenance/Repair: Negligible. $500 for occasional cleaning over 5 years.

Downtime/Damage: Virtually eliminated. Estimate $5,000 for 5 years (0.5% of wood cost).

Estimated 5-Year TCO: $300,000 + $500 + $5,000 = $305,500

Analysis: Over 5 years, the steel pallets are only slightly more expensive. However, the wood pallets will need to be fully replaced again in Year 6, while the galvanized steel pallets are just getting started. Over a 15-year lifespan, the steel pallet’s TCO is a fraction of the wood pallet’s. The ROI becomes overwhelmingly positive.

The Hidden Value of System Integrity

The TCO model often can’t fully capture the value of avoiding a catastrophic system halt. In an ASRS or AGV system, a single wooden pallet failure—a broken board jamming a conveyor or a nail snagging on a guide rail—can stop the entire operation. The cost of this downtime, especially in a high-value distribution center, can run into tens of thousands of dollars per hour. The reliability of galvanized steel pallets is a form of insurance against this massive risk.

Integration with Modern Warehouse Automation

The case for galvanized steel becomes irrefutable when you introduce automation. Precision and reliability are non-negotiable.

Perfect Harmony with AS/RS (Automated Storage and Retrieval Systems)

ASRS units are precision machines. They require pallets with exact, unchanging dimensions. Wood pallets warp and swell. A misshapen pallet can cause a mispick or, worse, a collision within the racking, resulting in devastating damage and downtime. Galvanized steel pallets maintain their dimensional integrity perfectly, ensuring flawless interaction with the storage and retrieval machines year after year.

Essential for AGV (Automated Guided Vehicle) and AMR (Autonomous Mobile Robot) Operations

AGVs and AMRs often use rollers or forks to pick up and move pallets. They rely on precise underclearance and a consistent, smooth bottom surface. A protruding nail or a splintered board on a wood pallet can disrupt the sensors or mechanics of an AGV, causing it to abort its mission. The smooth, consistent, and robust construction of a galvanized steel pallet ensures reliable handoffs and transportation every single time.

Optimizing Conveyor and Sortation System Throughput

Modern high-speed conveyor and sortation systems move packages at incredible speeds. A weak or failing pallet can collapse under load on a conveyor, creating a massive jam that takes hours to clear. The inherent strength and rigidity of galvanized steel pallets prevent this failure mode entirely, maximizing the uptime and efficiency of your entire material flow system.

Specialized Applications: Where Galvanized Steel is Non-Negotiable

In some environments, the choice is made for you by the operational requirements.

Cold Storage and Freezer Warehouses

These are the most punishing environments for pallets. The constant cycle of freezing and condensation accelerates the rot and warping of wood and the embrittlement of plastic. Galvanized steel pallets are completely immune to the cold and moisture. The zinc coating provides unparalleled protection against rust in these high-humidity conditions.

Food & Pharmaceutical Grade Facilities

Regulations like FDA CFR Title 21 and HACCP demand easily cleanable, non-porous, and non-shedding surfaces. Wood is a contamination nightmare. A galvanized steel pallet, especially with a smooth, electropolished finish, can be easily cleaned, sterilized with harsh chemicals, and will not harbor pathogens, making it the only choice for these regulated industries.

Heavy-Duty and High-Bay Storage

When you’re storing pallet loads exceeding 2,000 kg (4,400 lbs) at heights of 30 meters (100 feet) or more, there is zero room for error. The structural integrity of the pallet is a primary safety concern. The superior strength and stiffness of steel provide the confidence that the galvanized steel pallet will not fail under these extreme loads, protecting both your inventory and your personnel.

Design and Customization: Tailoring the Pallet to Your Operation

A key advantage of steel is its formability. We don’t just sell off-the-shelf pallets; we engineer solutions.

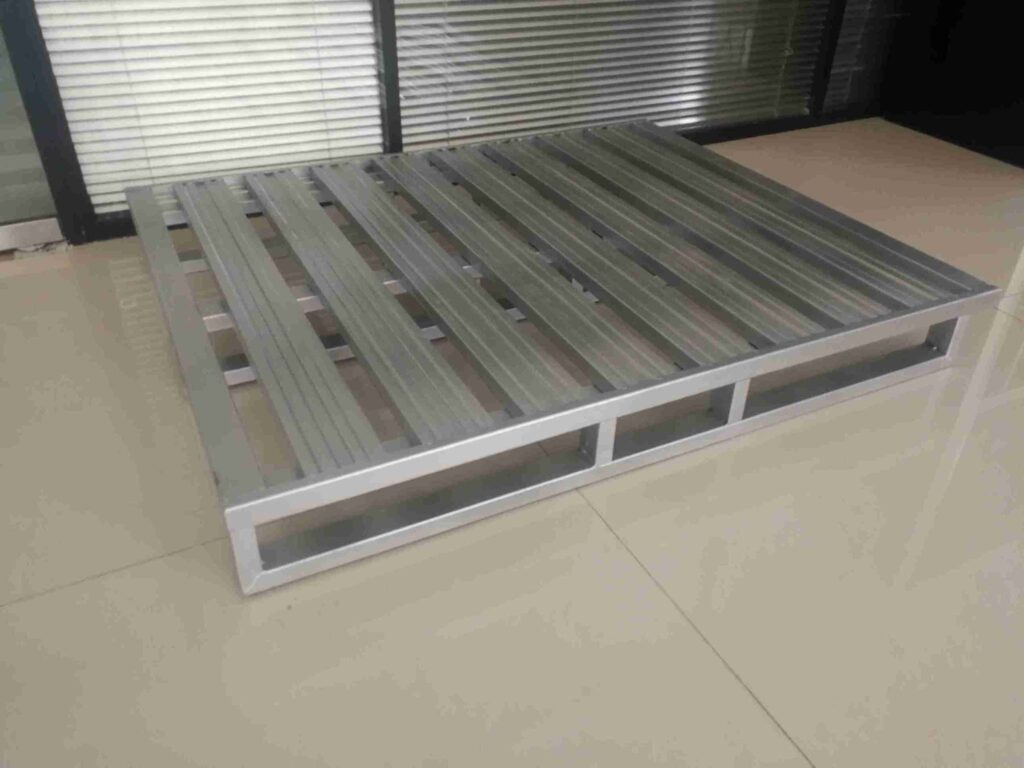

Deck Styles: Open mesh for reduced weight and maximum airflow, solid deck for containing small items, or a hybrid design.

Bottom Configurations: Full four-way forklift entry, low-profile designs for AGVs, or specific runner configurations for conveyor integration.

Weight & Strength Optimization: Using high-strength steel grades, we can design galvanized steel pallets that are incredibly strong yet lightweight, reducing transportation costs and easing the load on automation.

Special Features: Adding features like RFID tag mounting points, unique identifying engravings, or custom paint colors for lane differentiation is simple with steel fabrication.

Sustainability and End-of-Life: The Green Choice

In the modern era, sustainability is a key operational metric. Galvanized steel pallets excel here too.

Long Life: The most sustainable product is the one you don’t have to replace. Their long service life means far less material waste entering landfills compared to wood or plastic.

Recyclability: At the end of its immense service life (often 20+ years), a steel pallet is 100% recyclable. It is not downcycled; it becomes new steel again with no loss of properties. This is a perfect closed-loop system. A wood pallet, if damaged, is often just thrown away.

Making the Switch: A Practical Guide for Warehouse Managers

Transitioning to a new pallet system is a project, but the payoff is immense.

Pilot Program: Start with a pilot batch of 50-100 galvanized steel pallets. Deploy them in your most demanding application (e.g., the freezer, or the highest-throughput automated line).

Monitor Performance: Track any changes in damage rates, system stoppages, and operator feedback.

Calculate the Savings: After 6-12 months, conduct a preliminary TCO analysis based on the pilot data.

Phased Rollout: Based on the positive results, create a capital plan for a phased replacement of your wood or plastic pallets, prioritizing areas with the highest ROI (automation, cold storage, heavy loads).

Conclusion: An Investment in Foundation

Choosing galvanized steel pallets is one of the most impactful decisions a warehouse or logistics manager can make to drive long-term efficiency and cost reduction. It is a decision that moves the pallet from a disposable commodity on the P&L sheet to a durable, strategic asset on the balance sheet.

The higher initial investment is quickly offset by the elimination of replacement costs, the drastic reduction in system downtime and product damage, and the seamless integration with the automated warehouses of today and tomorrow. In the relentless pursuit of operational excellence, galvanized steel pallets provide a solid, reliable, and intelligent foundation upon which to build.

Frequently Asked Questions (FAQs)

Q1: Are galvanized steel pallets too heavy for my operation?

While heavier than wood or plastic, modern design and high-strength steel alloys allow us to engineer galvanized steel pallets that are surprisingly lightweight, often only 1.5 to 2 times the weight of a comparable hardwood pallet. The trade-off in slightly higher shipping weight is overwhelmingly negated by the massive gains in durability and lifespan. Furthermore, their consistent weight is actually a benefit for automated systems that rely on precise weight sensing.

Q2: How do you prevent loads from slipping on a smooth steel surface?

This is a common concern. There are several effective solutions. We can fabricate the deck surface with an anti-slip pattern (like a diamond or raised button pattern). Alternatively, we can add friction-enhancing coatings or apply rubber pads to key contact points to dramatically increase the coefficient of friction and prevent load shifting.

Q3: Can galvanized steel pallets be repaired if they are somehow damaged?

Yes, absolutely. This is a key advantage over plastic pallets, which are often impossible to repair. A bent component on a steel pallet can often be straightened. If a section is severely damaged, it can be cut out and a new section welded in place. The repaired area can then be re-galvanized or coated with a zinc-rich paint to restore corrosion protection. This repairability further extends their already long service life.

Q4: Is the galvanized coating safe for food and pharmaceutical products?

Yes. Zinc is a naturally occurring mineral essential for human health. The galvanized coating is non-toxic and inert, making it completely safe for direct and indirect contact with food and pharmaceutical products. It is approved and recommended by regulatory bodies worldwide for such applications, especially when compared to the microbial risks of wood.

Q5: Do galvanized steel pallets work with all types of forklifts and pallet jacks?

Yes, they are designed to. Standard galvanized steel pallets are built with full four-way entry, meaning they can be accessed by forklifts and pallet jacks from all four sides. The critical design factor is ensuring the pallet’s bottom configuration provides sufficient clearance for the forklift forks or the pallet jack wheels. This is a fundamental part of our design process for any client.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com