📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Transformative Power of Engineered Flow Racking

In the high-stakes arena of modern logistics and warehousing, operational efficiency is the ultimate competitive advantage. For countless facilities, the single greatest impediment to this efficiency is the archaic, labor-intensive process of order picking. When operations rely on static shelving or conventional pallet racking, they inadvertently commit to a cycle of excessive walking, futile searching, and manual material handling that can consume over half of all labor hours. This isn’t just an inefficiency; it’s a direct and substantial drain on profitability. The strategic implementation of advanced flow racking systems presents a definitive solution to this endemic challenge.

This comprehensive guide serves as an authoritative deep dive into the world of flow racking, illustrating how these dynamic storage systems are meticulously engineered to eradicate waste from the picking process. The result is a demonstrable and dramatic reduction in picking time—often exceeding 50%—coupled with profound improvements in order accuracy, storage density, and workplace safety. This document moves beyond theoretical concepts to provide a practical, detailed roadmap for leveraging flow racking technology to achieve a tangible and rapid return on investment, solidifying a company’s position in a demanding market.

Why Order Picking is the Biggest Drain on Your Warehouse Efficiency (And Profit)

A thorough understanding of the problem is essential to fully appreciate the elegance of the flow racking solution. In a traditional warehouse setup, the picker-to-goods model dictates that employees spend the vast majority of their shift in motion. Industry studies consistently show that pickers can expend 60-70% of their productive time simply walking between disparate storage locations. This non-value-added travel is a monumental hidden cost, one that is compounded by several other critical inefficiencies:

Search and Retrieval Time: Even with a well-organized WMS, locating a specific SKU on a long shelf under time pressure leads to hesitation and mistakes.

Physical Fatigue and Ergonomics: Constant reaching, bending, stretching, and climbing ladders to access items leads to worker fatigue, decreased productivity, and a higher risk of workplace injuries and associated compensation claims.

Inventory Inaccuracy: Static systems are more prone to mis-picks and mis-placements, leading to shipping errors, costly returns, and diminished customer satisfaction.

Poor Space Utilization: Traditional static shelving often fails to leverage the available cubic volume of a facility, leading to inefficient use of expensive real estate.

These cumulative inefficiencies create significant bottlenecks that hamstring operations during critical peak periods, delay order fulfillment cycles, and contribute to high labor turnover due to the physically demanding and monotonous nature of the work. This operational model is unsustainable for businesses that aim to scale and meet the accelerating demands of modern e-commerce and just-in-time distribution.

What is Flow Racking? The Engine of Modern Order Fulfillment

Flow racking, also universally known in the industry as gravity flow racking or live storage systems, represents a paradigm shift in storage methodology. It is a dynamic, high-density storage solution that is fundamentally architected on the first-in, first-out (FIFO) inventory principle. This stands in stark contrast to static shelving where items remain passive until manually located and retrieved.

The core mechanism of any flow racking system is elegantly simple yet incredibly effective. It utilizes inclined rails or wheels housed within a robust bay structure. Pallets, cases, or totes are loaded onto the elevated “load” side of the system. The natural force of gravity then takes over, gently and consistently moving the stored units down the inclined tracks towards the lower “pick” face.

This continuous, self-replenishing line of inventory ensures that the next item to be picked is always positioned directly at the operator’s fingertips. This ingenious application of basic physics to a complex logistical challenge effectively transforms a passive storage area into a high-throughput order fulfillment engine. The strategic deployment of flow racking is a clear marker of a operation committed to peak performance.

The Unbeatable Benefits: More Than Just Faster Picking

While the dramatic reduction in picking time is the most immediately quantifiable benefit, a professionally engineered flow racking installation delivers a powerful cascade of operational advantages that compound the return on investment and transform overall warehouse performance.

Slash Order Picking Time by Over 50%: This is the primary and most impactful outcome. By virtually eliminating non-productive travel and search time, pick rates can increase exponentially. Pickers remain stationed in a compact, ergonomically optimized “golden zone,” performing a significantly higher number of picks per hour with markedly less physical and mental fatigue.

Guaranteed FIFO Inventory Rotation: For industries managing perishable goods, food products, pharmaceuticals, chemicals, or any product with strict expiration dates or lot codes, FIFO is not a suggestion—it is a mandatory operating procedure. Flow racking systems automatically and mechanically ensure the oldest stock is always picked first, dramatically minimizing the financial losses associated with product spoilage and waste.

Radical Space Savings and Increased Storage Density: Flow racking systems are engineered to be both taller and deeper than traditional storage solutions, actively utilizing the full cubic airspace of a facility. By design, they eliminate the need for multiple access aisles; only a single aisle on the pick face and a rear loading aisle are required. This design can achieve up to 60% greater storage density within the same existing footprint, delaying or eliminating the need for costly facility expansion.

Dramatically Improved Order Accuracy: With clearly labeled lanes dedicated to specific SKUs, the potential for mis-picks is drastically reduced. Pickers select from a single, unambiguous location rather than having to choose from multiple similar-looking items on a shelf or bin location. This leads to a direct reduction in shipping errors and customer returns.

Enhanced Worker Safety and Ergonomics: The entire picking process occurs at an optimal waist level, systematically eliminating dangerous reaching, bending, or climbing. This proactive approach to ergonomics reduces workplace musculoskeletal injuries, lowers insurance premiums, and significantly improves overall employee morale and retention.

Scalable and Adaptable Productivity: As order volumes grow and SKU profiles evolve, a well-designed flow racking system can be easily expanded, reconfigured, or modified to meet new demands, making it a supremely flexible and future-proof investment for growing businesses.

Pallet Flow Racking: The High-Volume Workhorse

How Pallet Flow Systems Operate

Pallet flow racking is a heavy-duty variant of flow racking specifically designed for the high-density storage of full pallet loads. It consists of deep storage lanes, often capable of holding 10 to 20 or more pallets in a single row. Each lane is equipped with heavy-duty flow rails or tracks. These tracks contain a series of high-capacity rollers or wheels that allow standard pallets to glide smoothly and consistently from the elevated loading end to the accessible unloading end.

A sophisticated mechanical system, including brakes, dividers, and speed controllers, is absolutely critical to manage the pallets’ momentum, ensure gentle handling throughout the descent, and maintain proper separation between loads to prevent damage.

Ideal Applications for Pallet Flow

This specific type of flow racking is the optimal solution for large-scale operations that require uncompromising FIFO compliance on a massive scale. It is the system of choice for large-scale distribution centers, cold storage and freezer facilities for frozen foods, major beverage distributors, and manufacturing plants with high-volume raw material or component storage. Essentially, pallet flow racking is the definitive answer for achieving maximum high-density storage of products that have a very high turnover rate and where inventory rotation is paramount.<h2> Carton Live Storage: The Heart of Piece-Pick and Case-Pick Efficiency

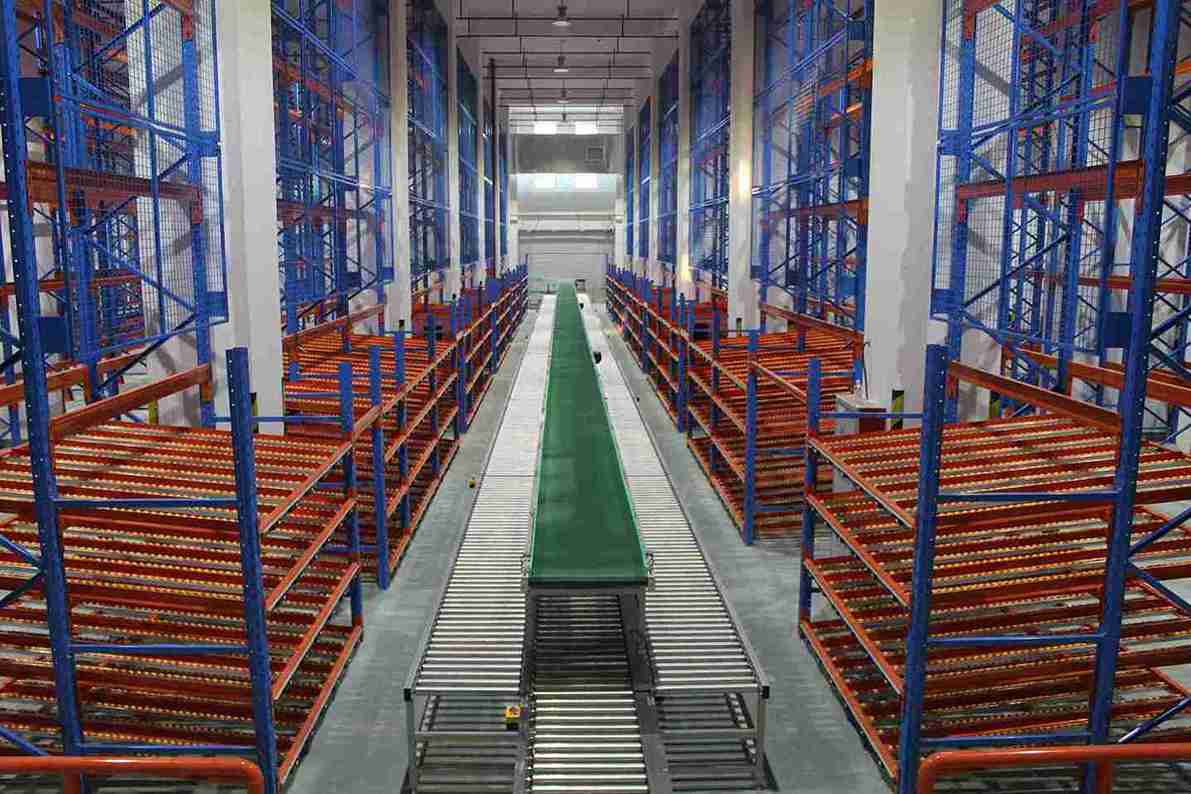

For the intense, high-speed piece-pick and case-pick operations that form the core of e-commerce fulfillment, retail distribution, and reverse logistics, carton live storage represents the pinnacle of efficiency. This form of flow racking typically utilizes narrower, lighter-duty flow tracks or wheels installed within shelving bay structures to handle individual cases, totes, or polybags.

Revolutionizing Carton Picking and Order Consolidation

In a carton live storage configuration, each flow channel is dedicated to a single SKU. As order pickers remove the front carton, the next one in line immediately and automatically rolls forward into the ready position. This is the “goods-to-person” principle operating at its most efficient. The applications for this technology are genuinely transformative for a business:

The Perfect Forward Pick Zone: It is ideally suited for creating highly efficient forward pick zones that hold fast-moving SKUs, enabling rapid single-order fulfillment.

Superior Order Consolidation: Different SKUs that comprise a single customer order can be picked simultaneously from multiple parallel flow racking lanes directly into a single tote or carton on a take-away conveyor belt below, drastically reducing order cycle times.

Exceptional for Reverse Logistics: Processing customer returns efficiently is streamlined by dedicating specific flow lanes to particular product categories or disposition types, speeding up the restocking or assessment process.

The integration of carton live storage with complementary technologies like pick-to-light or put-to-light systems can further multiply productivity and accuracy gains, creating a near-fail-proof picking environment that minimizes human error.

Choosing the Right Flow Racking System: A Strategic Guide

Selecting the optimal flow racking system is a complex decision that must be based on a rigorous and data-driven analysis of a company’s unique operational profile. It is never a one-size-fits-all proposition. The choice between different types of flow racking, including pallet flow and carton live storage, hinges on several critical factors:

Product Weight and Dimensions: This is the primary determining factor. Heavy, uniform pallet loads demand the robust construction of a pallet flow racking system equipped with high-capacity rollers. Lighter, smaller cases and totes are perfectly suited for the agility of a carton live storage system.

Inventory Turnover (SKU Velocity): Conducting a thorough ABC analysis of inventory is crucial. The fastest-moving “A” items are the prime and most profitable candidates for investment in flow racking. Slower-moving “C” items may be more economically and sensibly stored in static shelving or selective pallet racking.

Product Characteristics: The physical characteristics of the product itself are paramount. Fragile items require specialized flow racking systems that incorporate extra cushioning rollers and precise speed controls. Irregularly shaped items that cannot roll or slide consistently may not be suitable for a gravity-flow environment and could cause jams.

Throughput Requirements: The number of picks required per hour and the number of operational shifts per day will directly influence the overall design of the flow racking system, including the number of lanes, the number of pick faces, and the required extraction rates.

Available Space and Ceiling Height: To maximize the high-density storage benefits that flow racking provides, a detailed assessment of the facility’s cube is necessary to design a system that leverages vertical space safely and in full compliance with all relevant building and safety codes.

The Critical Role of Professional Design and Installation

The ambitious promise of a 50%+ reduction in picking time is entirely contingent upon flawless engineering and execution. An improperly designed, specified, or installed flow racking system can lead to product damage, persistent jams, safety hazards, and ultimately, a failure to achieve the projected ROI. The implementation process must be meticulous and managed by experts:

In-Depth Consultation & Data Analysis: The process begins with a forensic-level analysis of WMS data, SKU profiles, order histories, and future growth projections to understand the exact flow of goods and pain points.

CAD Engineering & System Simulation: Using advanced computer-aided design (CAD) software, engineers create detailed plans and dynamic simulations to visualize the system’s operation in a virtual environment, optimizing lane depth, incline angles, and integration points before any metal is cut.

Precision Manufacturing and Installation: Certified technicians install the flow racking system with laser-level accuracy, ensuring every rail is perfectly aligned and leveled for smooth, reliable, and jam-free operation. This step is too critical to leave to uncertified crews.

Seamless Material Handling Integration: The flow racking system must not be an island. It needs to be seamlessly integrated with other material handling equipment (MHE) such as conveyor systems, AGVs (Automated Guided Vehicles), or forklifts for loading and unloading to create a cohesive ecosystem.

Beyond Flow Rack: Integrating with a Full Automation Ecosystem

To achieve truly transcendent efficiency gains and build a warehouse of the future, flow racking should function as the central nervous system within a fully integrated and automated warehouse automation ecosystem. Its value is multiplied when connected to other technologies:

AGVs and Autonomous Mobile Robots (AMRs): These robotic workhorses can be programmed to automatically transport full pallets to the load side of pallet flow racking or to retrieve picked orders from the carton live storage pick face, further reducing manual labor and creating a lights-out process for replenishment.

Conveyor Systems: Automated conveyor systems can be strategically placed along the pick face of a flow racking system to automatically transport picked items directly to packing, sortation, and shipping stations, creating a continuous, streamlined, and touchless material flow.

Warehouse Management System (WMS) Integration: A modern, tier-one Warehouse Management System acts as the brain that orchestrates the entire operation. It intelligently directs put-away to the correct lanes in the flow racking and orchestrates wave picking, ensuring the system’s innate intelligence is fully leveraged and synchronized with overall warehouse activity.

Calculating Your ROI: The Tangible Path to 50%+ Time Savings

Investing in a superior flow racking solution is a strategic capital expenditure with a clear and highly calculable financial return. A comprehensive ROI analysis will typically focus on several key areas where flow racking drives value:

Direct Labor Savings: This is the most significant factor. Quantify the current number of labor hours dedicated solely to picking activities. A 50% reduction in picking time translates directly into a 50% reduction in the labor cost for that function. These savings alone can often justify the capital investment, frequently with a payback period of less than 24 months.

Quantifiable Space Savings: The dramatically increased storage density achieved with flow racking can delay or completely eliminate the need for a costly facility expansion or relocation. The cost savings from avoided real estate expenses must be factored into the ROI model.

Error Reduction and Associated Cost Savings: Calculate the fully loaded cost of a single mis-pick, including return shipping, processing, lost product, and the immeasurable cost of diminished customer loyalty. Reducing these errors by 80-90% adds straight to the bottom line.

Increased Throughput and Revenue Capacity: The ability to process more orders per shift with the same or fewer staff members directly increases the revenue capacity of the operation without proportional increases in overhead, providing a clear path to scaling the business.

Conclusion: Transform Your Warehouse, Not Just Your Storage

The strategic adoption of a best-in-class flow racking system is far more than a simple equipment purchase; it is a decisive move from a reactive, inefficient storage model to a proactive, high-velocity fulfillment engine. It represents a fundamental re-engineering of warehouse operations to systematically eliminate waste in motion, waste in time, and waste in valuable space. The goal of slashing order picking time by 50% or more is not an aspirational marketing claim; it is an achievable, measurable, and repeatable outcome for businesses that are ready to leverage intelligent storage technology.

By choosing to partner with an experienced provider who can design, engineer, and integrate a flow racking system tailored to unique product and order profiles, companies unlock unprecedented levels of operational efficiency, accuracy, and scalability. The future of high-performance warehousing is dynamic, and it flows. The critical question for decision-makers is whether they will be pushed aside by its current or will they strategically harness its power to propel their business forward into a new era of productivity and profit.

Frequently Asked Questions (FAQs)

1. How does the weight of the load affect the design of a flow rack system?

The weight per pallet or carton is the most critical engineering factor. Heavier loads require larger diameter rollers, stronger gauge steel in the frame structures, and more sophisticated braking and speed control systems to safely manage the descent speed and prevent impact damage that can occur at the end of the lane. Our engineers perform precise calculations of the kinetic energy of the load to specify the exact roller type, pitch, and braking mechanism required for safe, smooth, and reliable operation under your specific load conditions.

2. Can flow racking be used for slow-moving items (low SKU velocity)?

While technically possible, deploying flow racking for slow-moving items is often not economically justified. The primary value proposition of any flow racking investment is realized with high-velocity SKUs where the labor savings quickly offset the capital cost. For slow-moving “C” items, the cost per lane is typically not offset by sufficient labor savings. We almost universally recommend traditional selective racking or shelving for these items and reserve the powerful advantages of flow racking for your “A” and “B” movers to maximize ROI.

3. What kind of maintenance do flow rack systems require?

Maintenance for a well-installed flow racking system is generally minimal but crucially important for long-term performance. It involves a schedule of periodic visual inspections to check rollers for debris buildup or damage, ensuring that all brakes are functioning correctly, and verifying the structural integrity and plumb of the frame. A significant advantage of gravity flow racking is the absence of complex motors, drives, or electrical components, which greatly enhances system reliability and reduces long-term maintenance costs compared to fully automated systems.

4. Are there any products that are NOT suitable for flow racking?

Yes, certain product types are poor candidates for a standard flow racking system. Products that are extremely fragile and could be damaged by any movement (unless special dampening rollers or track are used) are a concern. Irregularly shaped products that cannot roll or slide consistently will cause jams. Products with packaging that can easily become entangled or caught between rollers (e.g., loose plastic bags, shrink wrap) are also not suitable. Furthermore, liquids in non-rigid containers are generally not recommended for a gravity flow environment due to potential leakage and instability.

5. How do you prevent jams in a carton live storage system?

Preventing jams in a carton live storage system is achieved through a combination of proper design, appropriate product selection, and trained operators. Key strategies include using the correct wheel or roller spacing for the specific carton size to provide consistent support, ensuring each lane is dedicated to a single SKU with uniform and stable packaging, and installing full-length lane dividers to prevent cartons from crossing over into adjacent lanes. Perhaps most importantly, comprehensive training for staff loading the lanes is essential to ensure items are placed correctly and oriented properly to prevent tipping or snagging during their descent.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com