📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Maximize Storage & Cut Costs with Fire-Safe Narrow Aisle Racks | ROI in 12 Months Guaranteed

In the competitive landscape of global logistics, operational leaders face a relentless dual mandate: achieve radical storage density while upholding absolute, defensible safety. The intricate interplay of space utilization and risk management finds its ultimate expression in the modern fire safety narrow aisle warehouse. This paradigm is not merely a storage configuration; it is a comprehensive operational philosophy that redefines efficiency.

This deep-dive analysis will demonstrate how a strategically engineered fire safety narrow aisle warehouse system serves as the cornerstone for dramatic cost reduction and capacity expansion. Beyond theory, it provides a concrete financial model, illustrating how a targeted capital investment in a certified fire safety narrow aisle warehouse solution can realize a full return on investment within a 12-month period. The transformation turns a static storage facility into a dynamic, high-throughput, and intrinsically safe profit center, directly addressing the core challenges faced by operations across Southeast Asia, the Middle East, Africa, and Latin America.

The Strategic Imperative: Density Meets Defense

The economic rationale for a narrow aisle warehouse configuration is compellingly straightforward. By systematically minimizing non-productive aisle space through the use of specialized handling equipment, facilities can increase pallet positions by 25% to 50% within the same building envelope. However, this pursuit of density introduces a critical variable: amplified fire risk.

A conventional narrow aisle warehouse, without integrated protective measures, can inadvertently create a high-risk environment where fuel load is concentrated and fire spread pathways are complex. Therefore, the singular focus must be on developing a fire safety narrow aisle warehouse. This term defines a holistic system where the racking structure, material handling processes, and active/passive fire protection measures are co-engineered from the outset.

The goal of any fire safety narrow aisle warehouse is to deliver unparalleled density without compromising the fundamental duty of care to personnel, inventory, and physical assets. It is this synthesis of aggressive efficiency and rigorous fire safety that forms the basis for both rapid ROI and long-term operational resilience.

Deconstructing the 12-Month ROI: A Tangible Financial Model

The claim of a 12-month ROI on a fire safety narrow aisle warehouse project is validated through a multi-faceted savings model that impacts both immediate cash flow and long-term capital avoidance. The financial justification extends far beyond the simple cost of steel.

Primary ROI Drivers: Capital Expenditure Avoidance.

The most significant financial impact of a fire safety narrow aisle warehouse is the deferral or complete cancellation of expansion-related capital expenditure. When a facility can store 40% more goods within its existing footprint, the need for a costly new building or leased space is eliminated. For a company facing a needed 10,000 sq.m. expansion, the annual lease or capital cost savings can easily reach seven figures, instantly offsetting the project cost. The fire safety narrow aisle warehouse directly converts future capital outlay into present-day operational investment.

Secondary ROI Drivers: Recurring Operational Efficiencies.

A well-executed fire safety narrow aisle warehouse generates continuous, year-over-year savings. Energy consumption plummets due to a smaller conditioned space footprint and high-efficiency, aisle-specific LED lighting. Labor productivity soars as travel distances for order pickers or turret trucks are drastically reduced; when integrated with a Warehouse Management System (WMS), pick rates can increase by 20-35%. Furthermore, insurance providers increasingly recognize the risk mitigation of a certified fire safety narrow aisle warehouse, often leading to materially reduced annual property insurance premiums. This combination of lower utility costs, higher labor throughput, and reduced insurance overhead creates a powerful recurring revenue effect that solidifies the ROI calculation.

Tertiary ROI Drivers: Risk Mitigation and Asset Protection.

The financial cost of a major warehouse fire is catastrophic, encompassing not only asset loss but also business interruption, customer attrition, and reputational damage. A fire safety narrow aisle warehouse with integrated suppression is an investment in business continuity. By containing a potential incident and supporting effective firefighting, the system protects the company’s revenue-generating capability. This aspect, while difficult to quantify on a balance sheet, represents perhaps the most strategic return of all, safeguarding the entire enterprise.

Core Engineering Principles of a Certified Fire Safety Narrow Aisle Warehouse

The integrity of a fire safety narrow aisle warehouse is rooted in its engineering specifications and component selection. It is a system built with intentionality, where every element contributes to both performance and protection.

Structural Design and Material Specification:

The racking framework in a fire safety narrow aisle warehouse must be designed for the specific seismic, load, and environmental conditions of its location. In coastal regions of Southeast Asia or the Middle East, hot-dip galvanized steel is mandatory to combat corrosion, ensuring the long-term structural soundness essential for both safety and density. Beams and uprights are rated not only for static load but also for the dynamic forces imposed by high-speed, narrow-aisle equipment. The stability of the entire fire safety narrow aisle warehouse depends on this foundational robustness.

Integrated Passive Fire Protection Systems:

This is the defining characteristic that separates a standard narrow aisle warehouse from a true fire safety narrow aisle warehouse. Passive protection involves built-in features that compartmentalize fire spread without active intervention. Key elements include:

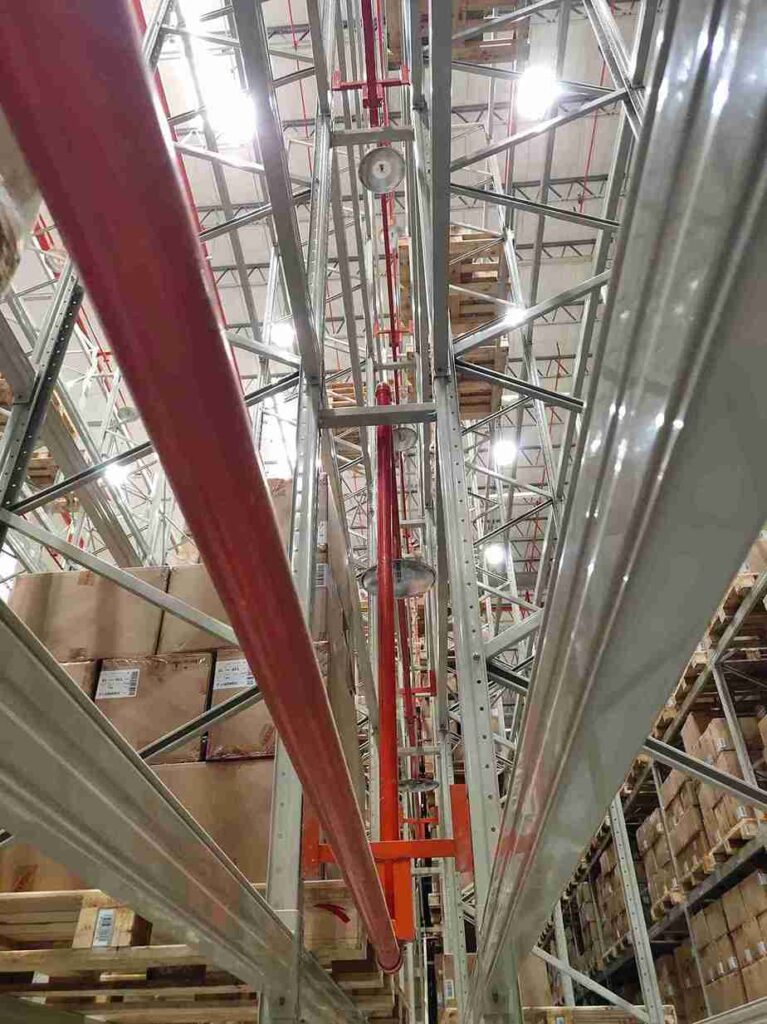

Horizontal Barrier Systems:

Solid or approved wire mesh decks installed at every storage level. In a fire safety narrow aisle warehouse, these barriers are critical for preventing the vertical “flue” or “chimney” effect, where fire races up the pallet faces. They compartmentalize the fire, limiting it to its bay of origin and buying crucial time.

In-Rack Sprinkler Systems:

Strategically placed sprinkler heads within the rack structure itself, connected to a dedicated water supply riser. In a dense fire safety narrow aisle warehouse, standard ceiling sprinklers may be obstructed by high storage, allowing fire to develop beneath them. In-rack sprinklers attack the fire at its source, directly within the fuel array. Their design and spacing follow strict NFPA 13 or FM Global guidelines for rack storage.

Structural Fire Protection:

For critical installations, components may be treated with intumescent coatings that expand under intense heat, providing additional minutes of structural integrity to support firefighting and evacuation efforts.

Synergy with Material Handling Equipment (MHE):

The design of a fire safety narrow aisle warehouse is inextricably linked to the equipment that operates within it. Aisles are precisely calculated for the specific turning radius of turret trucks, order pickers, or automated guided vehicles (AGVs). The layout must account for equipment clearances, guidance system installation (e.g., wire, rail, or laser), and the operational patterns that maximize flow while minimizing collision risk. The MHE is not an afterthought; it is a co-engineered component of the efficient and safe fire safety narrow aisle warehouse.

Implementation Blueprint: From Assessment to Operational Handover

The successful deployment of a fire safety narrow aisle warehouse requires a phased, meticulous approach that minimizes business disruption and ensures design intent is realized on the floor.

Phase 1: Comprehensive Discovery and 3D Modeling.

The process begins with a forensic analysis of current operations: SKU profiles, pallet specifications, inventory turnover (ABC analysis), peak throughput volumes, and growth projections. Simultaneously, a detailed survey captures every physical dimension and constraint of the existing facility. This data feeds into sophisticated 3D simulation software, creating a digital twin of the proposed fire safety narrow aisle warehouse. Engineers and planners use this model to optimize slotting, simulate pick paths, validate equipment maneuverability, and even model fire dynamics and egress routes, ensuring the fire safety narrow aisle warehouse design is optimized for both daily efficiency and emergency scenarios.

Phase 2: Phased Installation and Integration.

A hallmark of professional execution is the ability to install a fire safety narrow aisle warehouse within a live operational environment. A detailed phasing plan is developed, often sequencing the project to allow core operations to continue in adjacent areas. Installation teams work with military precision, coordinating with client logistics personnel to manage inventory shuffles. The integration of fire protection systems—pipe risers, in-rack sprinklers, and alarm ties—is conducted in parallel by certified technicians, ensuring the fire safety narrow aisle warehouse is activated as a complete, certified system.

Phase 3: Training, Commissioning, and Ongoing Support.

The most advanced fire safety narrow aisle warehouse underperforms if operators are not expertly trained. Training programs cover the safe operation of new narrow-aisle equipment, new WMS processes, and the unique safety protocols of the high-density environment. Upon commissioning, performance metrics are baselined. Furthermore, a proactive maintenance program is established for both the racking and the integrated fire systems, ensuring the fire safety narrow aisle warehouse maintains its safety certification and operational performance for its entire lifecycle. This long-term partnership is critical for sustaining the projected ROI.

Global Application: Tailoring the Fire Safety Narrow Aisle Warehouse to Regional Challenges

The core principles of a fire safety narrow aisle warehouse are universal, but their application must be adapted to regional market demands, regulatory climates, and environmental conditions.

For the Middle East & North Africa (MENA):

In regions characterized by high ambient temperatures and stringent civil defence codes, a fire safety narrow aisle warehouse must account for thermal expansion of steel and specify equipment with high-temperature operational ratings. Fire system design often requires close collaboration with local authorities for approval. The ROI model here heavily emphasizes the premium value of cooled storage space, making density gains exceptionally valuable.

For Southeast Asia:

In high-humidity climates and often in seismically active zones, a fire safety narrow aisle warehouse requires superior corrosion protection and seismic engineering. Facilities handling electronics or high-value goods for export prioritize the asset protection aspect of the fire safety narrow aisle warehouse. The solution often integrates closely with burgeoning automation trends to address labor cost inflation.

For Latin America:

Industries like automotive manufacturing and agriculture require a fire safety narrow aisle warehouse capable of handling heavy, non-standard loads. Engineering focuses on high-capacity beam designs and reinforced upright frames. The business case frequently centers on supporting export growth and protecting valuable commodities, with a strong emphasis on meeting international insurance standards to facilitate trade.

For Africa:

Solutions must be robust, often designed for ease of maintenance and with consideration for potential supply chain challenges for spare parts. A fire safety narrow aisle warehouse in this context provides a competitive edge by enabling import substitution industries or mineral exporters to manage buffer stocks more efficiently within secure, well-organized facilities.

Conclusion: The Foundational Investment for Competitive Logistics

In final analysis, the transition to a professionally engineered fire safety narrow aisle warehouse represents one of the most impactful strategic decisions a logistics or operational leader can make. It is a direct response to the converging pressures of rising real estate costs, escalating supply chain complexity, and non-negotiable safety obligations. The fire safety narrow aisle warehouse is no longer a niche option but a mainstream imperative for businesses seeking to dominate their sector.

The promise of maximizing storage, radically cutting operational costs, and achieving a verifiable ROI within 12 months is the logical outcome of applying rigorous engineering and integrated systems thinking to the warehouse environment. Ultimately, investing in a fire safety narrow aisle warehouse is an investment in the future resilience, scalability, and profitability of the entire supply chain operation.

Frequently Asked Questions (FAQs)

1. How does the design of a fire safety narrow aisle warehouse accommodate different sprinkler protection standards, such as NFPA versus FM Global?

A professionally engineered fire safety narrow aisle warehouse begins with a clear understanding of the local jurisdiction and the client’s insurance requirements. Design engineers are fluent in both NFPA 13 and FM Global Data Sheet 8-9 standards for rack storage. The system is then modeled and specified accordingly, affecting variables like sprinkler head type, spacing, water demand, and the placement of horizontal barriers. The design documentation for the fire safety narrow aisle warehouse is prepared to clearly demonstrate compliance with the chosen standard, facilitating smoother approval from authorities and insurers.

2. Can an existing conventional warehouse be retrofitted into a true fire safety narrow aisle warehouse, or is a greenfield site required?

Retrofitting an existing facility into a fully compliant fire safety narrow aisle warehouse is common and often where the most rapid ROI is realized. The process involves a detailed structural appraisal of the building (column locations, ceiling height, floor load capacity), a review of the existing fire water supply, and a phased inventory transfer plan. The key is a comprehensive audit to identify constraints—such as inadequate water pressure for in-rack sprinklers or floor flatness tolerances—which are then engineered into the solution. A skilled provider can transform most existing warehouses into a high-performance fire safety narrow aisle warehouse.

3. What specific maintenance routines are critical for preserving the safety certification and performance of the fire safety systems within the racking?

Maintaining a fire safety narrow aisle warehouse requires a scheduled, documented regimen. Quarterly inspections should check for rack damage (impacts, alignment), ensuring integrity. The integrated fire system demands biannual inspections by a licensed technician to verify control valve status, inspect sprinkler heads for damage or corrosion, and ensure no obstructions to spray patterns. Annual full-flow tests may be required. Furthermore, any modification to storage layouts or rack configuration must be reviewed against the original fire safety narrow aisle warehouse design to ensure fire protection coverage is not compromised.

4. In markets with less predictable supply chains, how is the project timeline and equipment availability for a major fire safety narrow aisle warehouse installation managed?

Experienced providers mitigate this risk through proactive supply chain management and transparent communication. Long-lead items, especially specialized steel sections or fire protection components, are identified and ordered early in the design phase. Regional warehousing of critical components is increasingly common. Project management methodology builds in buffer times for customs clearance and logistics. A reputable partner will provide a realistic, risk-adjusted timeline for the fire safety narrow aisle warehouse project from the outset, with clear milestones and contingency plans, ensuring client expectations are managed even in volatile market conditions.

5. How does the fire safety narrow aisle warehouse concept integrate with broader automation trends like lights-out warehouses using AS/RS or AGVs?

The fire safety narrow aisle warehouse is the ideal physical infrastructure for automation. The precision and consistency of the rack structure provide the necessary datum for automated storage and retrieval systems (AS/RS) or for AGV navigation lanes. The fire protection strategy, however, must evolve. For a fully automated fire safety narrow aisle warehouse, fire detection systems may incorporate advanced air-sampling smoke detection for earlier warning, and suppression systems must be effective in an unmanned environment. The design integration between the automation controls, the building management system, and the fire alarm panel becomes paramount, ensuring a coordinated response in the event of an incident, even with no personnel on site.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com