📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Custom Double-Flanged Beam Racking Systems: The Strategic Blueprint for Maximizing Warehouse Space

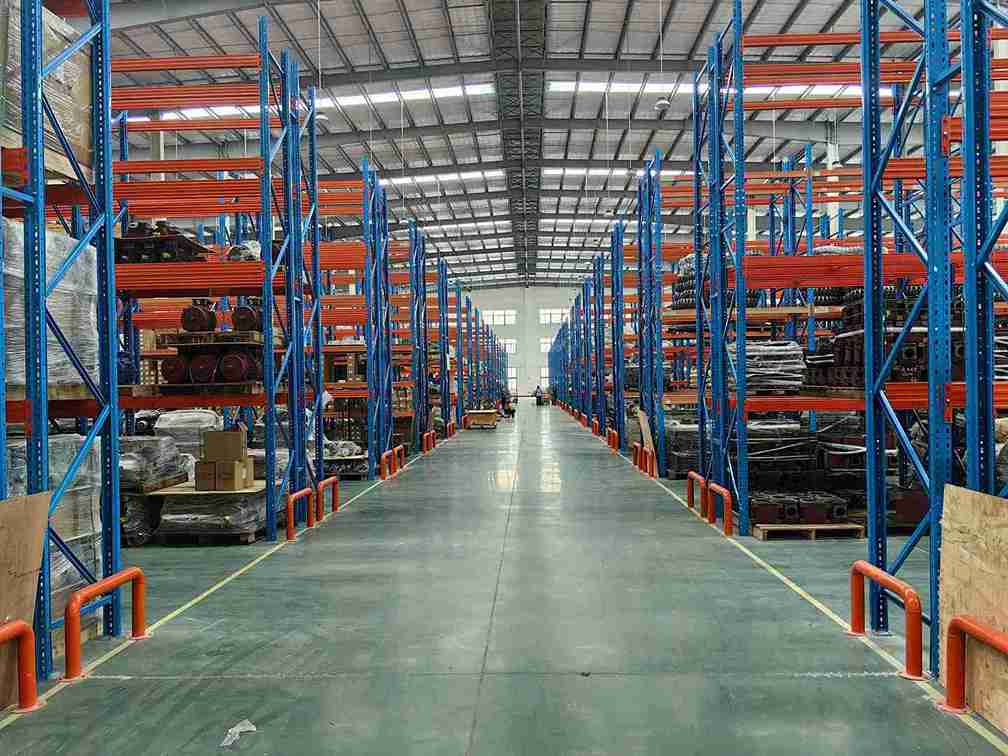

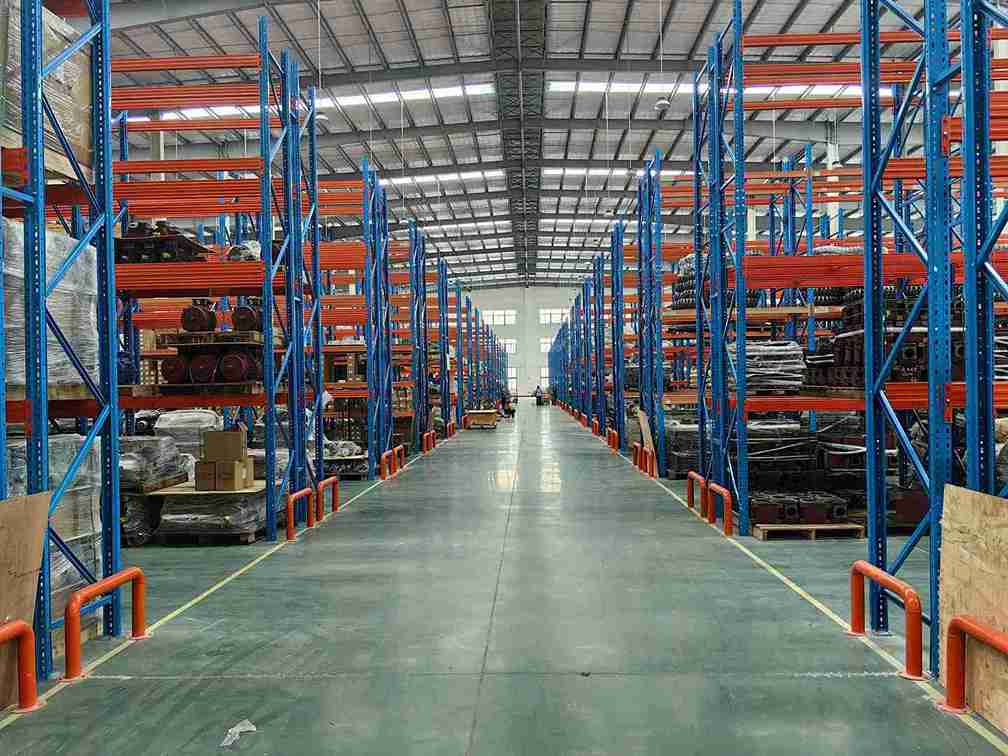

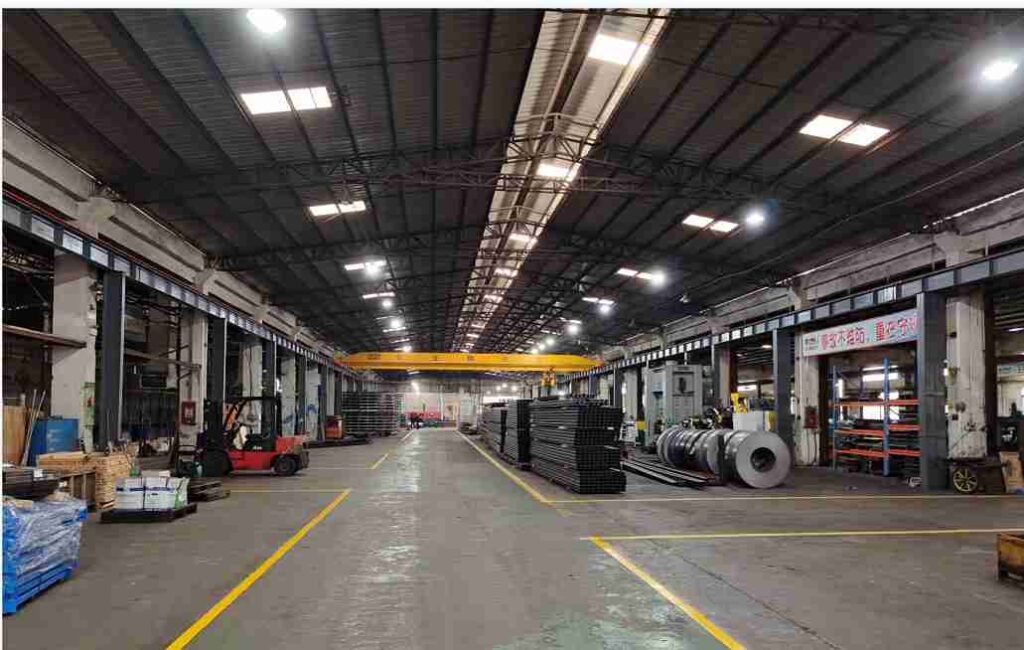

For logistics managers and warehouse operators across the globe, from the bustling ports of Southeast Asia to the industrial hubs of Latin America, the challenge is universal: achieving more within a finite footprint. The solution, however, is not universal. It requires a precision-engineered approach, beginning with the very skeleton of storage—the racking system. This comprehensive guide delves into the unparalleled advantages of investing in a custom double-flanged beam racking system. As industry veterans, the perspective offered here is rooted in decades of practical application, designing these robust systems for diverse environments, from arid deserts to humid coastal regions.

The core thesis is clear: a properly engineered double-flanged beam racking system is not a commodity purchase; it is a strategic capital investment that unlocks latent capacity, drives operational efficiency, and forms the critical foundation for any future automation. This deep dive will explore the engineering principles, economic justification, and integrative potential of these systems, providing a definitive resource for professionals seeking a tangible return on their storage investment.

Deconstructing the Standard: The Fundamental Engineering of Double-Flanged Beam Racking

To appreciate the value of a custom solution, one must first understand the inherent superiority of the standard component. The term double-flanged beam racking refers specifically to a pallet racking system where the horizontal beams are constructed with a distinctive I-beam profile, featuring a solid vertical web capped by a horizontal flange at both the top and bottom. This closed-section design is the cornerstone of its performance, offering a dramatic increase in load-bearing capacity and torsional rigidity compared to its single-flanged or roll-formed counterparts.

The Structural Superiority of the Double-Flanged Design

The engineering principle at work is the concept of the moment of inertia. The dual flanges on a double-flanged beam racking system create a geometry that resists bending forces far more effectively. When a load is applied, the top flange is subjected to compression and the bottom flange to tension; the closed section distributes these forces evenly, preventing the beam from buckling or sagging. This allows for:

Longer Spans: A double-flanged beam racking system can safely bridge wider distances between upright frames, reducing the number of columns needed and maximizing clear access space.

Heavier Loads: The inherent strength permits higher permissible load capacities per beam level, essential for storing dense products like automotive parts or canned goods.

Enhanced Safety Factor: The robust construction provides a built-in safety margin, crucial for withstanding the dynamic forces of forklift impacts or unevenly distributed pallet loads.

Component-Level Excellence: More Than Just Beams

A world-class double-flanged beam racking system is defined by the synergy of its components:

High-Grade Steel Uprights: The vertical frames are typically fabricated from high-strength, cold-rolled steel. The consistency of the column profile and the precision of the punch patterns are non-negotiable for ensuring a perfect, secure fit with the double-flanged beam racking connectors.

Precision Connectors and Locks: The connection point between the beam and upright is the system’s most vulnerable juncture. High-tensile steel connectors, coupled with positive locking mechanisms (such as a patented clip or bolt-less design), ensure the integrity of the double-flanged beam racking structure under daily operational stress.

The Economics of Space: Quantifying the ROI of Custom Double-Flanged Beam Racking

Justifying the investment in a custom double-flanged beam racking system requires a clear-eyed analysis of its return. The calculus extends beyond the simple cost-per-pallet-position to encompass gains in productivity, safety, and scalability.

Volumetric Optimization: The Art of Cubic Space Utilization

Most warehouses underutilize their air rights. A generic racking system might top out at a standard height, leaving a significant void below the ceiling. A custom double-flanged beam racking system is engineered to safely exploit every available centimeter of vertical space. By designing taller systems—often in excess of 15 meters—that are compliant with local seismic and wind load regulations, businesses can dramatically increase storage capacity without the exorbitant cost of physical expansion. The strength of the double-flanged beam racking components is what makes this vertical ambition structurally possible and safe.

Aisle Density: Converting Travel Lanes into Storage Assets

Aisle width is a primary determinant of storage density. A conventional Very Narrow Aisle (VNA) setup using a standard racking system might achieve good density, but a custom double-flanged beam racking system designed in tandem with the Material Handling Equipment (MHE) can achieve exceptional density. The system’s precision allows for aisles to be optimized to the millimeter for specific narrow aisle forklifts or AGVs. This level of customization, enabled by the reliable dimensions and strength of the double-flanged beam racking, can increase storage capacity by 40% or more by reclaiming floor space previously dedicated to maneuvering.

Operational Velocity and Damage Reduction

Efficiency gains are a direct contributor to ROI. A well-designed double-flapped beam racking system facilitates smoother workflow. Clear sightlines, wider bays (enabled by the strong beam spans), and logical compartmentalization reduce cycle times for put-away and picking. Furthermore, the secure and stable nature of the double-flanged beam racking structure minimizes pallet movement and the risk of load dislodgement, leading to a significant reduction in product damage—a hidden cost that often goes unaccounted for in storage planning.

The Automated Backbone: Integrating Double-Flanged Beam Racking with Modern Technology

In the contemporary warehouse, storage racking is no longer a passive entity. It is the foundational grid, the “city plan” for automated guided vehicles (AGVs), automated storage and retrieval systems (ASRS), and robotic pickers. The precision and rigidity of a custom double-flanged beam racking system are not just beneficial for automation; they are absolutely mandatory.

The Symbiotic Relationship with AGVs and Autonomous Mobile Robots

AGVs operate on pre-programmed paths with minimal tolerance for error. Any inconsistency in the racking structure—a misaligned upright, a slightly sagging beam—can cause a mission failure or, worse, a collision. The manufacturing tolerances of a high-quality double-flanged beam racking system are tight enough to provide the consistent, predictable environment these robots require. The double-flanged beam racking structure becomes a fixed datum in the warehouse’s coordinate system, ensuring that every robot interaction with a storage location is executed with flawless accuracy.

Supporting Automated Storage and Retrieval Systems (ASRS)

For unit-load or mini-load ASRS, the racking is not just a support; it is the track and guide for the storage and retrieval machine. The performance of the entire multi-million-dollar automated system hinges on the dimensional stability and absolute vertical/horizontal alignment of the double-flanged beam racking. Even a millimeter of deviation over a 20-meter height can cause a system shutdown. The robust, non-deflecting nature of the double-flanged beam racking beams ensures that the S/R machines can travel and elevate at high speeds without encountering obstructions or misalignments, guaranteeing uptime and throughput.

Creating a Cohesive Ecosystem with Conveyors and Sortation

A fully integrated distribution center features a seamless flow of goods from racking to conveyance. A custom double-flanged beam racking design can incorporate structural supports for conveyor systems at various levels, creating a multi-tiered picking and replenishment system. The load-bearing capacity of the double-flanged beam racking allows it to support not only its stored inventory but also the weight and dynamic loads of the conveyor systems, eliminating the need for separate, space-consuming support structures and creating a truly unified material handling environment.

Beyond Specifications: The Critical Role of Professional Design and Analysis

Procuring a double-flanged beam racking system based on a catalog specification is a significant risk. The true value of a custom solution is unlocked through a comprehensive, data-driven design process conducted by qualified engineers.

The Imperative of a Site-Specific Structural Analysis

Every warehouse is unique. Factors such as floor flatness, seismic zone ratings (particularly relevant for markets in Central Asia and Latin America), and potential exposure to corrosive elements must be factored into the design. A professional analysis will determine:

The required base plate size and anchoring system to compensate for floor irregularities.

The necessary bracing and overall frame design to meet local seismic codes.

The appropriate steel grade and finish (e.g., powder coating, galvanization) for the operational environment.

This rigorous approach ensures that the installed double-flanged beam racking system is not only efficient but also inherently safe and compliant.

Load Capacity and Configuration Modeling

Sophisticated warehouse management systems (WMS) can provide detailed data on inventory profiles—pallet dimensions, weight distributions, and turnover velocity (ABC analysis). This data should directly inform the configuration of the double-flanged beam racking system. Advanced modeling software allows engineers to create a digital twin of the proposed layout, simulating load scenarios and optimizing beam spacing and capacity levels. This prevents the common pitfalls of over-engineering (wasting capital) or under-engineering (creating safety hazards), ensuring the double-flanged beam racking system is perfectly calibrated to the specific operational demands it will face.

Global Application: Tailoring Double-Flanged Beam Racking for Diverse Markets

The requirements for a storage system in a climate-controlled facility in the Middle East differ vastly from those in a high-throughput port warehouse in Vietnam. A global provider understands these nuances and tailors the double-flanged beam racking solution accordingly.

Addressing Environmental and Operational Challenges

High-Humidity Regions (Southeast Asia, Coastal Africa): For these markets, specifying a double-flanged beam racking system with a hot-dip galvanized finish is often essential. This provides a sacrificial layer of zinc that protects the underlying steel from rust and corrosion, dramatically extending the system’s service life.

Dusty and Abrasive Environments (Industrial Zones, Mining Support): In these settings, a robust paint system may be specified for the double-flanged beam racking, and special attention is paid to sealants and design details that prevent dust accumulation within the beam ends and upright columns, which can trap moisture and lead to corrosion from the inside out.

High-Throughput, Multi-Shift Operations (E-commerce Fulfillment): Here, the focus for the double-flanged beam racking system is on durability and impact resistance. Heavier-gauge column guards, reinforced end-frames, and easily replaceable components are key design considerations to maintain operational uptime in a punishing 24/7 environment.

The Partnership Model: Selecting a Provider for Your Double-Flanged Beam Racking Project

Choosing a supplier for a custom double-flanged beam racking project is a strategic decision that extends far beyond initial price. It is about selecting a long-term partner capable of delivering a holistic solution.

Key Differentiators of a World-Class Provider

In-House Engineering Expertise: The provider should employ qualified structural engineers who specialize in storage systems, ensuring the double-flanged beam racking design is both optimal and compliant with international standards (e.g., FEM, RMI).

End-to-End Project Management: A true partner manages the entire process: initial survey, design, manufacturing, shipping, professional installation, and post-installation services like rack safety inspections and training.

Proven Integration Capability: The ideal provider does not view the double-flanged beam racking in isolation. They possess a deep understanding of how it interfaces with automation, MHE, and WMS, and can design the system as part of a cohesive whole.

Conclusion: Building the Foundation for a Smarter Warehouse

In the relentless pursuit of supply chain excellence, the storage infrastructure can no longer be an afterthought. It is the strategic enabler of density, speed, and intelligence. A custom double-flanged beam racking system, conceived through rigorous engineering and tailored to precise operational and environmental needs, represents the pinnacle of this infrastructure. It is the indispensable foundation upon which warehouses build resilience, unlock capacity, and seamlessly integrate the technologies of tomorrow.

For decision-makers looking to transcend the limitations of their current storage, the path forward is clear: engage with experts who can translate the theoretical benefits of double-flanged beam racking into a tangible, high-return operational asset.

Frequently Asked Questions (FAQs)

1. How does the procurement and installation process typically work for an international project?

The process is methodical. It begins with a detailed data collection phase, often involving a digital site survey. This is followed by the engineering and design stage, resulting in a comprehensive proposal including 3D layouts and load calculations. Upon approval, the double-flanged beam racking components are manufactured and prepared for shipment. The provider’s project management team then coordinates logistics, customs clearance, and dispatches a certified installation crew to ensure the double-flanged beam racking system is erected correctly and safely.

2. What are the primary safety standards that a double-flanged beam racking system should comply with?

Key international standards include the European FEM 10.2.02 and 10.2.03, and the American RMI (Rack Manufacturers Institute) ANSI MH16.1. Compliance with these standards ensures the double-flanged beam racking system is designed, tested, and manufactured to recognized benchmarks for structural integrity and safety. A reputable provider will design to these standards and often exceed them based on site-specific risk assessments.

3. Can an existing warehouse using a different type of racking be retrofitted or integrated with a new double-flanged beam racking system?

Integration is often complex but can be feasible with careful engineering. The primary challenge is ensuring compatibility between the old and new systems’ geometries and load capacities. A hybrid approach is sometimes used, where a new double-flanged beam racking zone is installed adjacent to an existing system. A full professional assessment is crucial to determine the viability and safety of any integration or retrofit strategy.

4. What is the typical operational lifespan of a professionally designed and installed double-flanged beam racking system?

With proper use and maintenance, a high-quality double-flanged beam racking system fabricated from protected steel can have an operational lifespan of 20 to 30 years or more. The longevity is directly tied to the quality of the initial installation, the absence of significant impact damage, and the environmental conditions. Regular professional inspections are recommended to monitor the condition and prolong the service life of the double-flanged beam racking investment.

5. How does the cost of a custom double-flanged beam racking system compare to a pre-engineered alternative over a 10-year period?

While the initial capital outlay for a custom double-flanged beam racking system may be higher, the Total Cost of Ownership (TCO) is almost always lower. The pre-engineered system often leads to inefficiencies in space utilization, higher product damage rates, and limited adaptability, incurring “soft costs” that accumulate over time. The custom double-flanged beam racking system, by maximizing capacity and enabling greater operational efficiency from day one, provides a superior return on investment, typically paying for itself within a few years through these saved costs and gained capabilities.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com

Newsletter Updates

Enter your email address below and subscribe to our newsletter