📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Strategic Integration: Uniting AGVs, Conveyors, and Custom Mezzanine Racking Design for Total Warehouse Automation

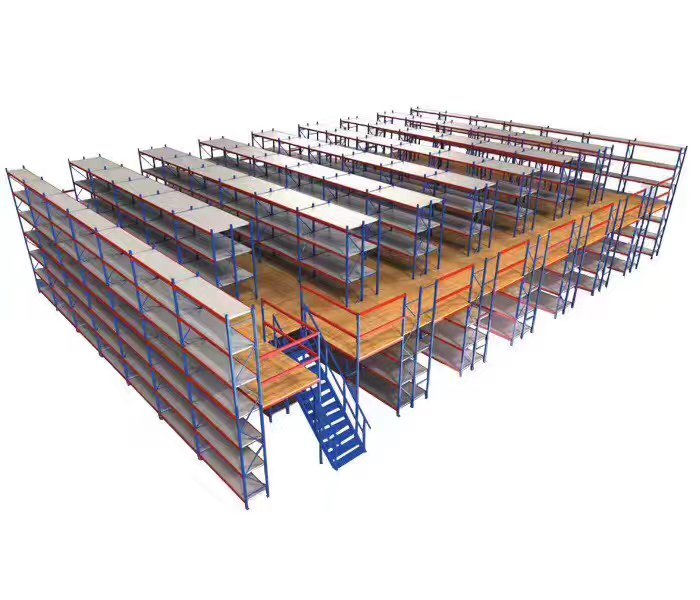

In the rapidly evolving landscape of global logistics, a revolutionary approach is setting new standards for efficiency and productivity. This in-depth analysis explores the powerful synergy achieved by integrating Automated Guided Vehicles (AGVs) and precision conveyor systems with a foundational custom mezzanine racking design. For businesses operating in the high-growth corridors of Southeast Asia, Latin America, the Middle East, and Africa, this holistic strategy transcends conventional storage solutions.

It represents a paradigm shift towards a fully automated, high-density storage and retrieval ecosystem. This article delves into the strategic imperatives, technical execution, and measurable ROI of creating a seamless operational flow, positioning the custom mezzanine racking design as the critical, non-negotiable starting point for any enterprise serious about achieving total warehouse automation and securing a dominant market position.

The Imperative for Integrated Automation: Moving Beyond Siloed Solutions

The traditional warehouse model, characterized by isolated equipment and manual processes, is hitting its breaking point. Companies often patch problems with point solutions—a standalone mezzanine here, a few forklifts there—resulting in a patchwork of inefficiencies. The modern supply chain demands a unified system where storage, horizontal transport, and vertical movement are intelligently connected. The core of this new paradigm is a custom mezzanine racking design that is conceived from the outset not as a standalone structure, but as the integrated backbone for the entire automated ecosystem.

True warehouse transformation occurs at the intersection of these systems. It’s the flawless handoff where an AGV, rather than idling at a staging area, delivers a pallet directly to a conveyor feed, which transports it to a vertical lift integrated into the custom mezzanine racking design, where it is automatically received and stored. This uninterrupted, “touchless” material flow is the ultimate competitive advantage, eliminating chronic bottlenecks and accelerating order cycles. The entire operational philosophy must be reimagined around this integration, with the custom mezzanine racking design serving as the central architectural element.

The Cornerstone of Automation: The Engineering Principles of a Custom Mezzanine Racking Design

To understand why a standard mezzanine is insufficient for automation, one must appreciate the engineering rigor behind a true custom mezzanine racking design. This is not a commodity product but a professionally engineered structure calculated to withstand the unique demands of a dynamic automated environment.

Structural Integrity for Dynamic Loads and Automated Traffic

A generic mezzanine is typically rated for static storage loads. In contrast, a custom mezzanine racking design for automation must account for a complex combination of forces. Engineers must calculate:

Live Load Dynamics: The constant weight of AGVs traversing the deck, the vibration and impact from conveyor systems, and the potential for concentrated loads from automated storage and retrieval systems (AS/RS). This often necessitates the use of high-tensile steel and reinforced decking solutions far exceeding standard specifications.

Precision Alignment: Automated systems are intolerant of even minor deviations. A superior custom mezzanine racking design is installed with exacting levelness tolerances to ensure AGV navigation systems and conveyor rails operate without fault. This precision is fundamental to achieving 99.9%+ system uptime.

Integration-First Architecture: The design process proactively incorporates features for automation. This includes defining clear AGV pathways with appropriate turning radii, pre-designing openings for conveyor and lift integration, and ensuring structural support for future expansion. This forward-thinking approach is what separates a basic custom mezzanine racking design from one built for the future.

Maximizing the Cubic Footprint: The Strategic Vertical Expansion

The most compelling financial argument for a custom mezzanine racking design is its ability to exploit the often-wasted vertical airspace within a warehouse. By building upward, companies can effectively double or triple their operational footprint without the prohibitive cost and disruption of a physical building expansion. This vertical real estate becomes the platform for high-density storage, directly enabled by the custom mezzanine racking design. It facilitates the implementation of:

Multi-level pick modules for high-velocity order fulfillment.

Narrow aisle configurations serviced by automated guided carts.

Dedicated zones for automated item-to-person picking systems.

The strategic implementation of a custom mezzanine racking design is, therefore, the most effective first step in any warehouse automation project, creating the physical framework upon which all other technologies depend.

The Mobile Workforce: AGVs as the Flexible Logistics Partners

Automated Guided Vehicles (AGVs) represent the flexible, intelligent mobility layer within the automated warehouse. Their role evolves from simple transport to a critical link in a connected system, and their effectiveness is heavily dependent on the environment created by the custom mezzanine racking design.

Navigating the Multi-Level Landscape: AGV and Mezzanine Interaction

The interaction between AGVs and the custom mezzanine racking design is a critical engineering focus. Modern AGVs use advanced navigation, but their routing is defined by the physical structure.

The Vertical Lift Interface: The most robust integration method involves AGVs interfacing with Vertical Reciprocating Conveyors (VRCs) or lifts that are structurally tied to the custom mezzanine racking design. An AGV delivers its load to the lift, communicates its destination level via a control system, and the lift seamlessly transports the load, where it may be received by another AGV or a conveyor on the mezzanine level. This process is the circulatory system of the multi-level facility.

Ramp Integration for Continuous Flow: In specific scenarios, the custom mezzanine racking design can incorporate integrated ramps. This allows certain AGV models to drive directly between levels, eliminating transfer wait times and creating a truly continuous flow for non-palletized loads.

Selecting the Right AGV for the Integrated Mezzanine Environment

The choice of AGV is influenced by the specifics of the custom mezzanine racking design:

Forklift AGVs can directly access pallet locations within the racking system on the mezzanine level.

Unit Load Carriers are ideal for transporting standardized pallets or containers to and from lift stations.

Tugger AGVs can efficiently deliver batches of materials to multiple points on a mezzanine level, optimizing replenishment workflows.

The High-Velocity Corridors: Conveyor Systems in the Mezzanine Ecosystem

For moving high volumes of goods over fixed paths at maximum speed, conveyor systems are unparalleled. Their integration with a custom mezzanine racking design transforms the multi-level structure into a high-velocity sorting and transport engine.

Creating a Seamless Flow Between Levels

The custom mezzanine racking design must accommodate the vertical movement of conveyors:

Inclined Belt Conveyors efficiently move cartons and totes between the levels defined by the custom mezzanine racking design, ideal for connecting pick zones to packing areas.

Vertical Reciprocating Conveyors (VRCs) serve as the heavy-duty vertical link for palletized goods, seamlessly connecting the conveyor systems on different floors.

Spiral Conveyors offer a compact, continuous flow solution for items moving between the levels of the custom mezzanine racking design, perfect for space-constrained facilities.

Optimizing Mezzanine-Level Operations with Conveyors

On the deck of the custom mezzanine racking design, conveyors enable highly efficient processes like pick-to-belt and put-to-light operations. Workers pick items directly onto a take-away conveyor, which automatically routes them to sorting or packing, drastically increasing throughput and reducing non-value-added walking time.

The Central Nervous System: Warehouse Control Software

The physical integration of AGVs, conveyors, and a custom mezzanine racking design is orchestrated by a sophisticated Warehouse Control System (WCS). This software is the intelligence that transforms individual components into a cohesive, intelligent whole.

Orchestrating the Automated Workflow

The WCS breathes life into the structure. It manages the complex dance of automation, ensuring that every movement within the custom mezzanine racking design is synchronized. It directs AGV traffic, manages lift scheduling, and controls conveyor routing, all while providing a real-time dashboard of the entire operation. This centralized control is what makes the sophisticated custom mezzanine racking design truly intelligent and responsive.

A Phased Blueprint for Implementation

Deploying an integrated system requires a methodical, phased approach centered on the custom mezzanine racking design.

Discovery and Data-Driven Design: The process begins with a deep analysis of operational data to inform the custom mezzanine racking design, ensuring it is tailored to specific business needs.

Digital Twin Simulation: Before installation, a virtual model of the entire system—AGVs, conveyors, and the custom mezzanine racking design—is built and simulated to optimize performance and pre-empt bottlenecks.

Phased Construction and Integration: Installation is sequenced to minimize disruption, starting with the custom mezzanine racking design foundation, followed by conveyor and lift integration, and culminating with AGV deployment and software activation.

Commissioning and Knowledge Transfer: The system is rigorously tested, and client teams are comprehensively trained on managing and maintaining the new automated environment, with a focus on the custom mezzanine racking design and its integrated technologies.

Quantifying the Return on Investment

The investment in an integrated system with a robust custom mezzanine racking design delivers profound and measurable returns:

Space Utilization: A well-executed custom mezzanine racking design can increase storage capacity by over 200%, dramatically reducing the cost per stored item.

Labor Productivity: Automation of material movement can reduce associated labor costs by 50-70%, allowing staff to be redeployed to more value-added tasks.

Operational Accuracy: Automated systems guided by the WCS achieve near-perfect inventory and order accuracy, directly reducing losses from errors.

Scalability and Resilience: The foundational custom mezzanine racking design provides a scalable platform for future growth, ensuring the operation can adapt to increasing demand without major structural overhauls.

Conclusion: Building the Intelligent Warehouse of the Future

The journey to total warehouse automation is a strategic evolution, not a simple purchase. It requires a vision that sees the warehouse as a single, integrated machine. At the heart of this machine is the custom mezzanine racking design—the engineered backbone that makes high-density, automated storage possible.

By uniting this foundational structure with the mobility of AGVs and the speed of conveyors under a centralized intelligence, businesses can achieve a level of efficiency, accuracy, and scalability that defines market leadership. For companies in the world’s most dynamic regions, investing in a holistic custom mezzanine racking design and automation strategy is no longer an option but a critical imperative for long-term success and resilience.

Frequently Asked Questions (FAQs)

1. How does a custom mezzanine racking design for automation differ in cost from a standard storage mezzanine?

While the initial investment for a custom mezzanine racking design engineered for automation is higher due to the use of superior materials, more complex engineering, and integration features, it is a classic case of value over cost. The ROI is significantly greater because it enables the entire automated ecosystem, leading to massive gains in productivity and space utilization that a standard mezzanine could never support.

2. What are the critical site preparation requirements for installing a custom mezzanine racking design?

A professional site assessment is essential. Key requirements include verifying the floor load-bearing capacity to support the custom mezzanine racking design, ensuring adequate ceiling height for clearances, and providing a stable power supply for the automated equipment. The foundation must be suitable for the dynamic loads the integrated system will impose.

3. Can an existing warehouse management system (WMS) control an integrated system with a custom mezzanine racking design?

Typically, the existing WMS handles high-level inventory and order management, while a dedicated Warehouse Control System (WCS) acts as the real-time translator and orchestrator. The WCS takes commands from the WMS and executes them by directly controlling the AGVs, conveyors, and lifts within the custom mezzanine racking design environment.

4. How is fire safety and regulatory compliance addressed in a multi-level custom mezzanine racking design?

A professional custom mezzanine racking design for automation must incorporate comprehensive fire safety measures. This includes the integration of sprinkler systems on all levels, clearly marked and unobstructed egress routes, and often additional fire-rated materials. Compliance with local building codes and safety regulations is a non-negotiable part of the design and installation process.

5. What is the typical operational lifespan of a robust custom mezzanine racking design, and is it adaptable to future technologies?

A professionally engineered and installed custom mezzanine racking design can have an operational lifespan of 25+ years. Its inherent advantage is adaptability; the design can be reconfigured and the integrated technologies (AGVs, conveyors) can be upgraded or expanded as new technologies emerge, protecting the long-term value of the investment.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com