📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Strategic Warehouse Expansion: Mastering Space and Cost with Custom Beam Racking

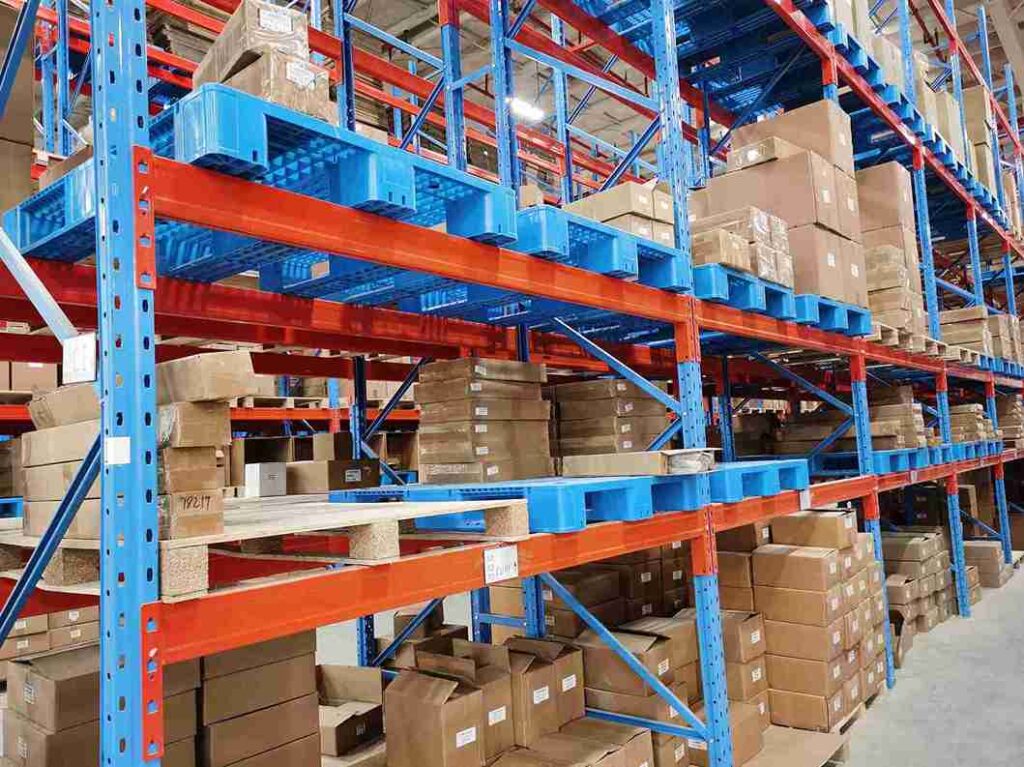

In the dynamic economic landscapes of Southeast Asia, the Middle East, Africa, and Latin America, businesses face a common, pressing challenge: exponential growth straining finite warehouse resources. The cost of new construction is prohibitive, and operational inefficiencies silently erode profit margins. The solution, increasingly adopted by industry-leading logistics managers and plant operators, is not to find more space, but to master the space they already own. This is achieved through the strategic implementation of Custom Beam Racking.

This comprehensive guide delves into why a professionally engineered Custom Beam Racking system is the most impactful investment a growing company can make. It explores how this foundational technology creates a high-density, highly organized, and utterly adaptable storage environment, transforming a warehouse from a cost center into a powerful engine for scalable growth. The focus is on achieving this transformation affordably, without compromising on the safety, durability, and future-readiness that modern supply chains demand.

The Critical Flaw of Standardized Solutions: A Data-Driven Case for Customization

The initial appeal of pre-configured, standard racking is understandable. However, industry data and operational post-mortems consistently reveal that this approach is a false economy. A warehouse is a three-dimensional chessboard, and every facility has unique characteristics—column placements, clear heights, floor load capacities, and traffic flow patterns. Standard racking ignores this reality, forcing a square peg into a round hole and resulting in permanent, structural inefficiency.

A true Custom Beam Racking system is conceived differently. It begins not with a catalog, but with a laser scan and a detailed audit of the client’s specific inventory profiles, handling equipment, and growth projections. This data-driven methodology ensures that the final Custom Beam Racking design is not just a storage system, but a material handling partner, perfectly synchronized with the client’s operational rhythm. The core value of Custom Beam Racking lies in its inherent flexibility; it is a solution built around the business, not the other way around.

Deconstructing the System: An Engineering Deep Dive into Custom Beam Racking Components

To appreciate the superior performance of a Custom Beam Racking installation, one must understand the engineering precision behind each component. This is where the promise of customization becomes a tangible, high-strength steel reality.

Engineered Upright Frames: The vertical backbone of any Custom Beam Racking system is its upright frames. Unlike standard offerings with limited size and gauge options, a true Custom Beam Racking solution employs uprights that are specified based on precise structural calculations. Factors such as total system height, cumulative load capacity, and even regional seismic activity codes dictate the steel gauge, the profile (e.g., closed-top vs. open-top), and the need for additional bracing. This level of specification in a Custom Beam Racking system ensures unwavering stability, even when fully loaded at significant heights.

Precision Horizontal Beams: The beams carry the direct burden of palletized goods. In a high-quality Custom Beam Racking system, clients have a choice between roll-formed and structural step-beams. Roll-formed beams offer excellent strength-to-weight ratios and are ideal for dynamic environments where reconfiguration is common. Step-beams, with their positive locking ledge, are often specified for heavier loads or in high-traffic areas where forklift impact resistance is paramount. The choice is a critical part of the Custom Beam Racking design process, ensuring optimal performance for the specific application.

Integrated Safety and Connector Systems: The integrity of a Custom Beam Racking system hinges on its connection points. Professional systems move beyond basic teardrop designs to incorporate patented bolt-less connectors or reinforced bolt-together assemblies for extreme-duty applications. Crucially, every connection is secured with mechanical safety locks. These simple yet vital components prevent beams from being accidentally dislodged, making the entire Custom Beam Racking structure inherently safer for personnel and inventory.

The Art of Density: Advanced Space Optimization via Custom Beam Racking

The term “space optimization” is the central promise of Custom Beam Racking. For businesses in land-constrained or rapidly urbanizing markets, this is not an abstract concept but a financial imperative. A well-executed Custom Beam Racking strategy systematically attacks wasted space from multiple angles.

Vertical Utilization Mastery: The most immediate gain comes from exploiting the full vertical cube of the facility. A Custom Beam Racking system is designed to safely extend to within compliant distances of the ceiling structure and sprinkler systems. This single intervention can often increase storage capacity by over 100%, effectively creating a new mezzanine level without the construction cost. The Custom Beam Racking framework makes this vertical storage accessible and safe for material handling equipment.

Tailored Bay Configurations: This is where Custom Beam Racking demonstrates its surgical precision. Bay widths can be calibrated to the exact pallet size plus a minimal safety clearance, eliminating the wasted inches that, over hundreds of bays, amount to significant lost space. Furthermore, the depth of the Custom Beam Racking can be configured for single-row, double-row, or even deeper push-back configurations. This allows for strategic slotting of inventory based on turnover rates, aligning storage methodology with inventory management strategy.

The Affordability Paradigm: How Custom Beam Racking Delivers Superior ROI

The perception that Custom Beam Racking is a premium, costly option is one of the most persistent myths in the industry. In reality, a value-engineered Custom Beam Racking system offers the lowest Total Cost of Ownership (TCO), making it the most financially prudent choice.

Elimination of Wasted Capital: By perfectly fitting the facility and the inventory, a Custom Beam Racking system ensures that every dollar spent on steel is directly contributing to usable storage. There are no “wasted” bays or under-utilized components. This efficient use of materials is a cornerstone of an affordable Custom Beam Racking project.

Operational Cost Savings: The efficiency gains from a logically designed Custom Beam Racking layout translate into direct cost savings. Picking routes are shorter, reducing labor hours and forklift travel time. Fewer product damages occur due to a more organized and secure storage approach. The improved organization within the Custom Beam Racking system also drastically reduces inventory shrinkage and misplacement.

Scalability and Future-Proofing: As a business evolves, its storage needs change. The modular nature of Custom Beam Racking means it can be reconfigured, expanded, or even relocated. This protects the initial capital investment far better than a fixed, standard system that must be scrapped and replaced when requirements change. The long-term adaptability of Custom Beam Racking is a critical component of its affordability.

The Automated Foundation: Custom Beam Racking as the Backbone for Robotics and ASRS

For businesses eyeing the transition to Industry 4.0, the warehouse infrastructure must be precision-calibrated. A Custom Beam Racking system is not an obstacle to automation; it is its essential prerequisite.

Interface with AGVs and AMRs: Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) require a predictable, consistent physical environment to operate efficiently. A Custom Beam Racking system can be designed with exacting tolerances for aisle widths, beam heights, and pallet overhang, creating the perfect “roadway” and “destination points” for robotic fleets. The precision of the Custom Beam Racking directly influences the reliability and throughput of the automated system.

Enabling Shuttle and ASRS Technologies: More advanced technologies like pallet shuttles or mini-load ASRS are entirely dependent on the racking structure for their operation. These systems require perfectly aligned, high-tolerance Custom Beam Racking to guide the retrieval machines. Investing in a high-precision Custom Beam Racking system today lays the absolute groundwork for a seamless integration of these high-density technologies tomorrow, future-proofing the warehouse investment.

Safety as a Design Principle: Engineering Risk Out of the Custom Beam Racking Equation

In warehouse operations, safety is non-negotiable. A professionally designed Custom Beam Racking system has safety engineered into its very DNA, moving beyond compliance to create a inherently secure working environment.

Proactive Impact Protection: Recognizing that forklift impacts are a fact of life, a robust Custom Beam Racking design incorporates strategic protection. This includes column guards, post protectors, and reinforced end-of-aisle barriers. These features are not afterthoughts but are integral to the layout of the Custom Beam Racking system, designed to absorb energy and preserve the structural integrity of the uprights.

Load Management and Visibility: A key safety feature of a well-executed Custom Beam Racking installation is clear, unambiguous load signage. Every bay is marked with its maximum permissible load, preventing dangerous overloading. Furthermore, the clean, organized sight lines afforded by a properly installed Custom Beam Racking system improve overall warehouse visibility, reducing the risk of accidents involving personnel and equipment.

The Implementation Journey: A Phased Approach to Custom Beam Racking Success

Deploying a large-scale Custom Beam Racking system is a significant project that benefits from a disciplined, phased approach managed by experienced professionals.

Phase 1: Discovery and Digital Twin Creation: The process begins with a comprehensive analysis, often using advanced tools like 3D laser scanning to create a “digital twin” of the empty warehouse. This model becomes the canvas for the Custom Beam Racking design.

Phase 2: Collaborative Design and Simulation: Engineers use the digital twin to design the Custom Beam Racking layout in sophisticated software, simulating load stresses and workflow efficiency. Clients can review the proposed Custom Beam Racking system in 3D, allowing for feedback and refinement before fabrication begins.

Phase 3: Quality-Centric Fabrication: The approved Custom Beam Racking design is sent to fabrication facilities where components are manufactured under strict quality control regimes, ensuring every upright and beam meets the specified engineering standards.

Phase 4: Professional Installation and Certification: Certified installation teams erect the Custom Beam Racking system according to the precise plans, ensuring all safety protocols are followed. The completed installation is then inspected and certified.

Phase 5: Lifecycle Support and Maintenance: The relationship continues long after installation with ongoing support, including periodic racking inspections and maintenance services to ensure the long-term performance and safety of the Custom Beam Racking investment.

Cross-Industry Applications: The Versatility of Custom Beam Racking

The adaptability of Custom Beam Racking makes it a universal solution across the diverse industrial sectors that drive growth in emerging markets.

Cold Storage and Perishables: In these high-cost environments, maximizing space is paramount. A Custom Beam Racking system for cold storage is designed to withstand corrosive, low-temperature conditions while achieving the highest possible storage density to minimize energy cost per pallet.

Heavy Manufacturing and Automotive: These sectors demand Custom Beam Racking solutions with exceptionally high load capacities, often configured with structural step-beams and reinforced connections to handle heavy machinery parts, steel coils, or automotive assemblies.

E-Commerce and Retail Fulfillment: The chaotic and fluctuating nature of e-commerce inventory requires a Custom Beam Racking system that is both high-density and highly flexible. The ability to easily adjust shelf levels and bay configurations is a critical feature for this sector.

Conclusion: Building a Foundation for Growth with Custom Beam Racking

For decision-makers in growth markets, the question is no longer if to upgrade storage infrastructure, but how to do it smartly and sustainably. The evidence is clear: a strategically planned Custom Beam Racking system represents the optimal confluence of affordability, density, safety, and future readiness. It is a tangible asset that pays continuous dividends through improved operational efficiency, reduced costs, and enhanced scalability. By choosing to invest in a professional Custom Beam Racking solution, businesses are not just installing steel; they are architecting a resilient, responsive, and competitive logistics operation capable of winning in the global marketplace.

Frequently Asked Questions (FAQs)

1. How does the seismic rating of a Custom Beam Racking system differ for a facility in Chile versus one in Thailand?

Seismic design codes are region-specific. A reputable provider designs its Custom Beam Racking systems to meet local seismic zone requirements. This often involves using heavier-gauge steel, specific bracing configurations, and specialized anchor bolts. The engineering for a Custom Beam Racking system in a high-seismic zone like Chile would be far more rigorous than for a lower-risk zone, directly impacting the system’s design and cost.

2. Can a Custom Beam Racking system be designed to accommodate a mix of pallet and carton picking from the same structure?

Absolutely. This is a key advantage of Custom Beam Racking. The system can be designed with multiple beam levels, creating pallet storage on the lower levels and carton-level picking shelves higher up. This integrated approach within a single Custom Beam Racking framework consolidates operations and improves picker productivity.

3. What is the environmental impact of using a Custom Beam Racking system, and are there sustainable options?

The primary material is steel, which is highly recyclable. The long lifespan and reconfigurable nature of Custom Beam Racking mean it generates very little waste over its lifecycle. Furthermore, by optimizing space and improving operational efficiency, a Custom Beam Racking system contributes to a lower carbon footprint for the overall logistics operation.

4. How does the procurement and project management process work for a multi-site international rollout of Custom Beam Racking?

Established providers have dedicated international project management teams. They manage a coordinated rollout, leveraging local fabrication partners where possible to control costs and lead times. This ensures consistency in the quality and specification of the Custom Beam Racking across all sites while providing a single point of accountability.

5. What specific maintenance routines are recommended to ensure the long-term integrity of a Custom Beam Racking system?

A proactive maintenance plan for Custom Beam Racking includes scheduled visual inspections by warehouse staff, coupled with annual professional inspections by a certified engineer. These inspections focus on checking for beam lock engagement, upright alignment, and any signs of impact damage. Keeping a damage log and replacing impacted components promptly is crucial for sustaining the safety and load capacity of the Custom Beam Racking system.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com