📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Maximize Storage Space & Efficiency: The Definitive Guide to Custom Cantilever Racking Systems

For distributors, manufacturers, and logistics managers grappling with the unique challenges of storing long, bulky, or irregularly shaped inventory, the limitations of conventional pallet racking are a constant source of operational friction and wasted capital. The search for a superior storage methodology leads to one inevitable, engineered solution: the custom cantilever racking system.

This comprehensive guide, presented by industry leaders with decades of experience in warehouse optimization, delves into the technical nuances, strategic advantages, and transformative potential of these specialized structures. It explores how a meticulously planned cantilever racking system transcends mere storage to become the backbone of an efficient, safe, and scalable material handling operation, particularly when integrated with modern automation like AGVs and unmanned forklifts.

The focus here is on actionable intelligence and deep industry insight, providing a roadmap for businesses to unlock unprecedented density and workflow efficiency in their bulk item warehousing activities.

The Inherent Limitations of Standard Storage: A Problem Only Cantilever Racking Systems Can Solve

In warehouses dedicated to construction materials, metal stock, furniture, or plastic piping, the deficiencies of standard shelving and pallet racks are glaringly apparent. Front-facing vertical columns create constant obstructions, forcing forklift operators into difficult maneuvers that increase the risk of costly product damage and equipment collisions. These fixed-bay systems lack the flexibility to accommodate items of vastly different dimensions, inevitably creating unusable dead space that represents a direct financial drain on the facility.

The structural design of standard shelving is simply inadequate for the concentrated point loads and extended lengths of bulky items, often leading to shelf deflection and potential failure. It is within this context of widespread inefficiency that the cantilever racking system emerges as the definitive corrective measure. Its column-free design is a direct response to these universal pain points, redefining storage from a passive activity into a dynamic, high-density asset.

The Engineering Excellence Behind Modern Cantilever Racking Systems

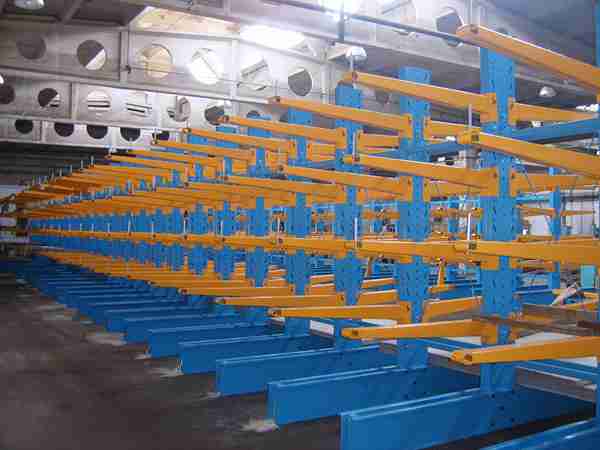

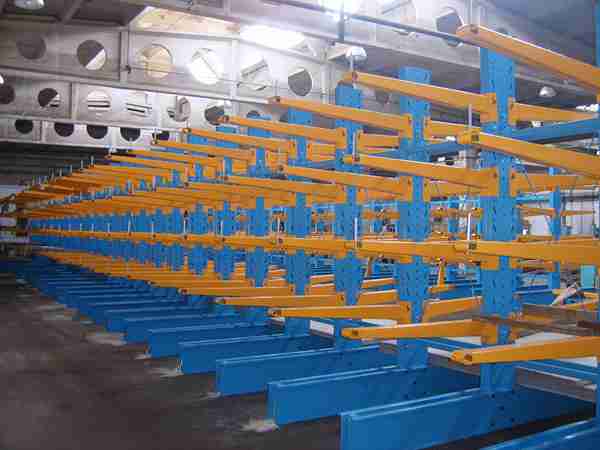

The remarkable strength and versatility of a cantilever racking system are not accidental; they are the result of precision engineering focused on optimal load distribution and structural integrity. The fundamental principle involves strong, upright columns that serve as the central spine, from which robust, cantilevered arms extend horizontally to support the stored load. The critical engineering feat is the connection between the arm and the column—a moment-resistant connection that transfers the bending forces from the loaded arm back into the vertical column and down to the anchored base.

High-grade structural steel, typically in the form of I-beams or heavy-duty tubular sections, is employed for the upright columns to provide immense vertical load-bearing capacity. The arms, which are often tapered to optimize strength-to-weight ratio, are attached using specially designed locking mechanisms that prevent accidental dislodgement. The vertical adjustability of these arms, often at one- or two-inch increments, is a cornerstone of the system’s flexibility.

This allows a single cantilever racking system to be perfectly tailored to an ever-changing inventory profile, ensuring that not a single cubic foot of valuable warehouse volume is wasted. This robust construction ensures that even the most demanding loads, such as several tons of steel bar or marble slabs, are supported with absolute stability and safety.

The Art of Customization: Engineering a Cantilever Racking System for Your Exact Needs

The term “custom” is often overused in industrial contexts, but for a truly high-performance cantilever racking system, it is the non-negotiable foundation. A generic, off-the-shelf solution will inevitably compromise on efficiency, safety, or both. A purpose-built custom cantilever racking system, however, is engineered as a perfect digital twin of a company’s specific operational reality before the first component is ever fabricated. This process involves a deep, analytical collaboration between the client and the storage solution provider to codify every variable into the final design.

Precision Tailoring: From Inventory Analysis to Spatial Optimization

The design process for a custom cantilever racking system begins with a forensic-level analysis of the client’s inventory. This goes far beyond a simple SKU list, delving into the physical characteristics, weight distribution, and turnover velocity of every stored item.

-

Dynamic Arm Length Specification: The length of the cantilever arms is critically engineered based on the longest items to be stored. An arm that is too short creates an unsafe overhang, while an arm that is excessively long wastes valuable aisle space and can reduce the system’s overall stability. A properly engineered cantilever racking system features arms that provide full support with optimal spatial economy.

-

Granular Vertical Adjustability: The fine-increment adjustability of the arms is what allows a cantilever racking system to achieve maximum storage density. It enables warehouse managers to create a storage profile where tall, bulky items occupy the lower levels while shorter, lighter items utilize the upper spaces, perfectly aligning with the warehouse’s vertical capacity and the principles of ergonomic picking.

-

Tiered Load Capacity Engineering: A one-size-fits-all load rating is a sign of an inferior design. A professionally engineered cantilever racking system will have a calculated load capacity for each level, with the strongest arms positioned at the bottom to handle the heaviest loads, such as solid metal or stone, and lighter-duty arms above for items like furniture or hollow-core piping.

Strategic Configurations: Designing for Density and Workflow

The physical arrangement of a cantilever racking system within the warehouse footprint is where theoretical gains are translated into tangible operational benefits. Expert providers use advanced simulation software to model various configurations.

-

Single-Sided vs. Double-Sided Applications: A single-sided cantilever racking system is ideal for lining perimeter walls, effectively utilizing space that is often underused. Conversely, a double-sided cantilever racking system, where arms project from both sides of a central row of columns, creates an incredibly high-density storage bank that can dramatically increase storage capacity within the same floor area.

-

Aisle Width Optimization and Equipment Synergy: The unobstructed access provided by a cantilever racking system is a key enabler for narrow-aisle operations. By eliminating the need for forklifts to navigate around front posts, aisle widths can be significantly reduced. This synergy is maximized when the cantilever racking system is paired with narrow-aisle forklifts or, even more effectively, with AGVs and unmanned forklifts that thrive in predictable, column-free environments.

-

High-Bay and Mezzanine Integration: For facilities with significant clear height, the cantilever racking system can be engineered to exceptional heights, often in conjunction with a structural mezzanine. This integration creates multiple tiers of storage, effectively multiplying the available storage surface area without the need for a costly physical expansion of the building itself.

The Automated Warehouse: Integrating Cantilever Racking Systems with Robotics and AS/RS

In the era of Industry 4.0, a storage system’s value is measured by its ability to integrate seamlessly into an automated workflow. A cantilever racking system is not merely compatible with automation; its fundamental design makes it a superior choice for robotic material handling, creating a symbiotic relationship that drives unparalleled efficiency.

AGVs and Unmanned Forklifts: The Ideal Companions for Cantilever Racking Systems

The clean, predictable access corridor presented by a cantilever racking system is perfectly suited for the operational patterns of Automated Guided Vehicles (AGVs) and unmanned forklifts. These automated systems excel in precision but can be vulnerable to complex physical obstructions.

-

Enhanced Operational Safety and Asset Protection: AGVs can be programmed to approach the cantilever racking system with consistent, repeatable accuracy. The absence of front columns removes a primary collision hazard, safeguarding both the integrity of the stored goods and the capital investment in the automated equipment. This makes the entire automated storage and retrieval process more reliable and less prone to costly interruptions.

-

Enabling 24/7 Unmanned Operations: The combination of a robust cantilever racking system and a fleet of AGVs facilitates a truly lights-out operation for storage and retrieval tasks. This provides a monumental advantage for manufacturing plants and distribution centers operating on extended or continuous production cycles, decoupling throughput from human labor constraints.

-

Data Harmony and WMS Integration: In a fully automated environment, the Warehouse Management System (WMS) is the brain, and the cantilever racking system provides the perfectly organized, accessible physical body. The logical, unobstructed layout of the cantilever racking system allows the WMS to direct AGVs with maximum efficiency, ensuring the fastest possible retrieval times and optimal inventory rotation.

The Pinnacle of Automation: Cantilever Racking in an AS/RS Framework

For the most advanced high-throughput applications, a cantilever racking system can be incorporated as the core storage component within a larger Automated Storage and Retrieval System (AS/RS). This involves custom-designed, computer-controlled retrieval machines—essentially robotic cranes—that travel on rails along the face of the racking. These machines automatically store and retrieve bulky items from the cantilever arms with breathtaking speed and precision. This represents the ultimate evolution of bulk item warehousing, merging the unparalleled density and accessibility of a cantilever racking system with the total hands-off efficiency of full automation.

Industry-Specific Deployments: Where Cantilever Racking Systems Deliver Dominant Value

The versatility of a well-designed cantilever racking system makes it the storage solution of choice across a diverse spectrum of industries. Its application is a common thread among market leaders who prioritize operational excellence.

Construction and Building Material Supply

In this sector, a heavy-duty cantilever racking system is indispensable for handling steel rebar, I-beams, structural lumber, PVC piping, and plasterboard. The system’s immense strength safely manages the extreme weights involved, while its open-access design allows for the swift selection of specific materials and lengths, directly contributing to keeping critical construction projects on schedule and within budget.

Metal Service Centers and Fabrication Shops

For businesses processing sheet metal, bar stock, and structural tubing, material organization is directly tied to profitability. A custom cantilever racking system allows for the meticulous segregation of different alloys, grades, shapes, and sizes. This drastically reduces handling time, minimizes the risk of surface scratches or cosmetic damage to high-value metals, and contributes to a safer, more organized shop floor environment.

Furniture, Appliance, and Glass Distribution

From flat-pack furniture components to large soils, mattresses, and major appliances, a cantilever racking system provides a safe and organized storage solution. It prevents the crushing and damage endemic to haphazard stacking and turns inventory management and order picking into a streamlined, predictable process. For glass and panel distributors, specialized cantilever racking systems with A-frame designs and padded arms provide secure, upright storage that is essential for preventing breakage.

The Financial Justification: Analyzing the ROI of a Custom Cantilever Racking System

Evaluating a custom cantilever racking system as a mere commodity purchase is a critical error in strategic judgment. A more accurate perspective is to view it as a capital investment with a clearly definable and compelling return, impacting both the balance sheet and the income statement.

-

Radical Increase in Storage Density: By fully exploiting vertical space and minimizing aisle widths, a properly configured cantilever racking system can often increase storage capacity by 40% to 60% within the same warehouse footprint. This directly defers or eliminates the massive capital outlay required for facility expansion or relocation.

-

Substantial Labor Efficiency Gains: The frictionless access provided by a cantilever racking system translates into faster storage and retrieval cycles. This lowers the labor cost per pallet or item handled, freeing up personnel for more value-added tasks and effectively increasing the throughput capacity of the existing workforce.

-

Significant Reduction in Product and Equipment Damage: The elimination of front-column obstacles is the single most effective way to reduce collisions. This preserves the value of inventory, reduces write-offs, and lowers maintenance costs for material handling equipment, all of which flow directly to the bottom line.

-

Inherent Operational Scalability and Adaptability: A custom cantilever racking system is designed with future growth in mind. The ability to add more bays, increase height, or reconfigure arm positions means the storage asset can evolve seamlessly with the business, protecting the initial investment for decades.

A Culture of Safety: Engineering and Operating Cantilever Racking Systems Correctly

The immense load-bearing capacity of a cantilever racking system demands an equally rigorous commitment to safety in both its engineering and its daily operation. Provider expertise and user training are the twin pillars supporting a safe working environment.

Inherent Safety Engineering in Cantilever Racking Systems

Reputable manufacturers build safety directly into the cantilever racking system. This includes structural column guards to absorb low-level impacts, positive-locking arm connectors that cannot vibrate loose, integrated walkways and safety gates for mezzanine levels, and seismic bracing for installations in active geological zones. Clear, unambiguous load rating plaques are affixed to every upright column.

Operational Protocols for Maximum Safety

Beyond engineering, safe operation requires disciplined protocols. Best practices dictated by experts include always loading from the bottom up, never exceeding the stated capacity per arm pair, ensuring loads are centered and balanced on both arms, and conducting regular visual inspections for any signs of damage or overload. Comprehensive training for all forklift operators who will interact with the cantilever racking system is not a recommendation; it is a necessity for risk mitigation.

Future-Proofing the Warehouse: The Unmatched Adaptability of Cantilever Racking Systems

In a volatile global market, the ability to pivot and adapt is a key competitive advantage. A storage system that is rigid and inflexible becomes an anchor, holding the business back. The foundational design of a custom cantilever racking system is one of inherent flexibility and scalability. The easily adjustable arms allow the entire storage profile to be reconfigured in a matter of hours to accommodate a completely new product line.

Additional bays can be added seamlessly to the end of an existing run, and the entire structure can be disassembled and relocated if operational needs change. This inherent adaptability future-proofs the warehouse investment, ensuring that the cantilever racking system remains a high-performing asset through multiple business cycles and strategic shifts.

The Provider Partnership: A Methodical Approach to Delivering Your Cantilever Racking Solution

Selecting the right partner for a custom cantilever racking system is as critical as the design itself. A proven, methodical process is the hallmark of a provider that delivers lasting value, not just products.

-

Comprehensive Discovery and Site Assessment: The process initiates with a deep-dive consultation to understand operational challenges, growth objectives, and workflow patterns. This is followed by a detailed site survey to capture precise spatial and structural data.

-

Advanced Engineering and 3D Visualization: Using state-of-the-art CAD and simulation software, engineers create a detailed 3D model of the proposed cantilever racking system. This virtual twin allows clients to conduct a digital walkthrough, validating the design and workflow before manufacturing begins.

-

Quality-Centric Manufacturing and Fabrication: The specified cantilever racking system is fabricated using high-tensile steel and controlled manufacturing processes, with rigorous quality checks at every stage to ensure every component meets exacting standards.

-

Professional, Certified Installation and Training: A crew of certified technicians executes the installation with precision and efficiency, ensuring the system is perfectly level, plumb, and securely anchored. This is followed by thorough operational and safety training for the client’s staff.

-

Ongoing Support, Maintenance, and Optimization: A true partnership extends beyond installation. Leading providers offer ongoing support, readily available spare parts, and periodic inspection services to ensure the cantilever racking system continues to perform safely and efficiently for its entire operational lifespan.

Conclusion: Elevating Bulk Storage from an Operational Burden to a Strategic Advantage

In the modern logistics and supply chain landscape, where efficiency and adaptability are the primary currencies of competition, settling for inadequate storage is a strategic misstep. For businesses that manage long, bulky, or heavy inventory, the implementation of a professionally engineered custom cantilever racking system is one of the most impactful investments they can make.

It is the key to converting wasted space into profitable density, transforming workflow bottlenecks into streamlined processes, and building a storage operation that is not only efficient but intelligently resilient. The journey toward a superior cantilever racking system begins with a conversation with experts who can translate operational challenges into engineered solutions.

Frequently Asked Questions (FAQs)

1. What specific foundation or floor requirements are necessary for installing a high-bay cantilever racking system?

A high-bay cantilever racking system imposes significant point loads on the warehouse floor. A professional structural analysis is mandatory to verify that the existing concrete slab has the requisite thickness and compressive strength. In many cases, the cantilever racking system will be designed with base plates that distribute the load effectively, but for extreme heights or weights, foundation upgrades or specialized anchoring may be required.

2. How does the lead time for a fully custom cantilever racking system compare to a standard system?

A truly custom cantilever racking system that involves non-standard arm lengths, specialized load capacities, or complex configurations will naturally have a longer lead time than a standard model. This is due to the engineering design phase, potential for custom fabrication of components, and more detailed project planning. The lead time is an investment in ensuring the final cantilever racking system is a perfect fit for the application, delivering superior long-term value over a rushed, generic alternative.

3. Can a cantilever racking system be designed to handle both very long items (e.g., 20-foot pipes) and very short items simultaneously?

Absolutely. This is a prime example of the flexibility of a custom cantilever racking system. The design would utilize long arms on certain levels for the pipes, while other levels would be configured with shorter arms for smaller items. The fine vertical adjustability allows this mixed configuration to be optimized for density, ensuring that the space around shorter items is not wasted.

4. What are the key differences between a clip-in style arm connection and a bolted connection for a cantilever racking system?

Clip-in (or snap-in) connections offer faster adjustability and are excellent for applications where reconfiguration is frequent and loads are within standard ranges. Bolted connections provide the highest level of structural rigidity and are typically specified for the most heavy-duty applications, such as storing immense weights of metal or stone, where absolute connection integrity is paramount. The choice depends entirely on the operational requirements and load specifications.

5. We have a mixed fleet of traditional, narrow-aisle, and AGV forklifts. Can a cantilever racking system be designed to work efficiently with all of them?

Yes, a proficient provider can design a cantilever racking system that accommodates a mixed fleet. This involves strategic planning of aisle widths—wider aisles for traditional forklifts transitioning into narrower aisles serviced by narrow-aisle equipment and AGVs. The consistent, obstruction-free face of the cantilever racking system is the common denominator that makes this multi-mode operation feasible and efficient.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com