📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

In the world of industrial storage, few challenges are as persistent and costly as the efficient handling of long, bulky, and irregularly shaped items. Traditional shelving and pallet racking simply fall short, leading to wasted vertical space, compromised safety, and crippled operational workflow. At [Your Company Name], we have dedicated decades to solving this exact problem.

A custom cantilever racking system is not merely a product; it is a meticulously engineered storage solution designed to transform your warehouse’s capacity, safety, and efficiency. This comprehensive guide delves into the intricacies of how a tailored cantilever system can revolutionize the storage of items like timber, steel bars, plastic pipes, furniture, and automotive parts, ensuring you maximize every cubic foot of your available space.

H2: Understanding the Cantilever Racking System: A Primer

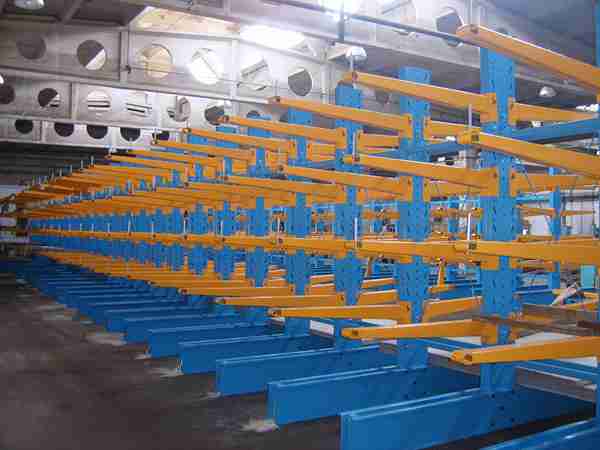

A cantilever racking system is uniquely designed for storage where vertical posts and front-facing beams would be obstructive. Its defining characteristic is the use of vertical columns (uprights) with arms that extend horizontally from one side. These arms are the loading surface, creating an open, column-free front that allows for easy side-loading and unloading of materials using forklifts or overhead cranes.

The basic components of the cantilever racking system include::

Baseplate: The foundation, anchored to the floor, providing critical stability.

Upright Column: The vertical mast, designed to handle significant downward and upward forces.

Arms: The horizontal beams that support the load. They are adjustable and can be single-sided or double-sided.

Arm Locks: Secure the arms to the column at various heights without the need for bolts or welding.

Bracing: Provides lateral stability, preventing sway and ensuring structural integrity.

The genius of the design lies in its simplicity and strength. By concentrating the load on a single side of the column, it creates unparalleled accessibility, making it the undisputed champion for long and bulky goods storage.

H2: The Critical Need for Customization in Storage Solutions-Cantilever Racking System

No two warehouses are identical. Factors like building dimensions, floor composition, ceiling height, and the specific weight and dimensions of your inventory make off-the-shelf solutions a compromise at best and a safety hazard at worst. Custom design is not a luxury; it is a necessity for achieving true operational excellence.

We approach every project with a blank slate. Our engineering team considers your unique data:

- The precise dimensions (length, diameter, weight) of your stored items.

The total volume of inventory and its turnover rate (FIFO, LIFO).

The type of material handling equipment (e.g., forklifts, stacker cranes, AGVs) you use.

Your facility’s specific layout, including clearances and obstructions.

Local building codes and seismic activity regulations.

This data-driven approach allows us to specify the exact column height and thickness, arm length and capacity, and overall configuration needed to create a system that doesn’t just fit your space but enhances your entire workflow. A one-size-fits-all approach can lead to underutilized space or, worse, catastrophic overloading. Our custom designs eliminate these risks entirely.

H3: Engineering for Unmatched Capacity and Load Stability-Cantilever Racking System

The core of our design process is a rigorous engineering analysis. We calculate the load capacity not just for the arms, but for the entire structure. This includes:

- Static Load Capacity: The weight the system can hold when stationary.

Dynamic Load Capacity: The additional forces introduced during loading and unloading operations.

Seismic Load Capacity: For regions prone to earthquakes, we design to specific seismic codes to ensure the racking remains stable under lateral forces.

We utilize high-tensile steel and often employ a stepped-column design, where the column thickness increases towards the base to handle the higher bending moments. Arm capacity is carefully matched to the stored items; for instance, storing dense metal bars requires a different capacity calculation than storing lightweight PVC pipes. This meticulous attention to engineering detail ensures that our cantilever racking system offer unparalleled load stability, preventing sagging arms and potential product damage or collapse.

H3: Maximizing Warehouse Space Utilization-Cantilever Racking System

The primary economic driver for investing in a cantilever system is space utilization. Traditional storage methods for long items often result in vast areas of wasted floor space. By leveraging the full vertical height of your facility, a cantilever system can dramatically increase your storage density.

Our designs focus on:

- Vertical Storage: Building upwards rather than outwards, freeing up valuable floor space for production, staging, or other uses.

Configurable Bay Sizes: Adjusting the distance between columns and the length of arms to perfectly match your inventory profile, eliminating dead space.•

Double-Sided Configurations: Where applicable, we design rows of back-to-back cantilever systems, effectively creating a highly dense storage zone for similar items.

The result is a transformative increase in storage capacity without the need for expensive facility expansion. This efficient use of warehouse space directly translates into lower real estate costs per stored item and improved operational flow.

H2: Seamless Integration with Automated Storage Systems-Cantilever Racking System

The modern warehouse is increasingly automated. A custom-designed cantilever system is not an isolated island but can be fully integrated into a broader automated storage ecosystem. This is where our expertise in holistic logistics solutions truly shines.

We design cantilever systems that are compatible with:

- Automated Guided Vehicles (AGVs): Our systems can be designed with clear pathways and precise heights for AGVs to automatically deposit and retrieve loads.

Overhead Bridge Cranes and Gantries: We coordinate the racking design with the crane’s lift height and travel path to ensure smooth, efficient operations.•

Warehouse Management Systems (WMS): While not a physical integration, our racking can be part of a zone that is managed by your WMS, with locations being tracked for optimal inventory control.

This forward-thinking approach ensures your investment is future-proof. As you grow and evolve towards a fully automated warehouse, your cantilever storage will remain a core, integrated asset, not an obsolete relic.

H2: The Material Handling Equipment Partnership

The effectiveness of a cantilever system is wholly dependent on the equipment used to interface with it. The design must be a perfect marriage between the racking and the machinery.

We consider the specific capabilities of your equipment:

- Forklifts: We design aisle widths and first arm heights based on the forklift’s turning radius and mast lift height.

Side-Loaders: These are ideal for cantilever systems. We design the racking layout to maximize the efficiency of the side-loader’s unique capabilities.•

Overhead Cranes: The racking height and arm levels are calibrated to the crane’s hook height and travel, ensuring operators can place and retrieve loads effortlessly and safely.

This holistic view prevents a common pitfall: installing a perfect racking system that is awkward or inefficient to use with existing equipment. Our designs create a synergistic relationship between storage and handling.

H2: Safety and Compliance: The Non-Negotiable Priorities

In storage, safety is everything. A failure in a racking system can be devastating. Our custom design process embeds safety at every stage, ensuring compliance with all relevant standards (e.g., ANSI MH16.3, OSHA guidelines, SEMA standards in the UK).

Key safety features integral to our designs include:

- Overload Protection: Engineering the system with a clear and prominently displayed load capacity sign for each arm and column.

Column Guards: Installing protective bollards or reinforced concrete footings at the base of columns to prevent impact damage from forklifts, a primary cause of racking failure.•

Secure Locking Mechanisms: Using robust arm locks that cannot be accidentally dislodged.•

Professional Installation: Our certified installation teams ensure every component is perfectly leveled, plumbed, and anchored to the floor according to the engineering specifications.

We don’t just build to code; we build beyond it. A safe warehouse is a productive and profitable warehouse.

H2: Beyond Cantilever: Integrating with Broader Automated Systems

For the most advanced operations, a cantilever system is one node in a larger network. We specialize in designing it to work in concert with other automated storage and retrieval systems (AS/RS).

Imagine a facility where:

- An automated conveyor system transports long goods from production directly to the storage area.

A robotic arm or gantry crane offloads the items and places them onto the cantilever arms.

The entire process is managed by a WMS that tracks the location, quantity, and age of every single item.

This level of integration represents the pinnacle of warehouse efficiency. While not every business needs this immediately, our custom designs are always executed with this potential in mind, ensuring a clear upgrade path.

H2: The Investment Analysis: Cost vs. Value

A custom cantilever racking system is a significant capital investment. However, its value proposition is undeniable and typically realized through a rapid return on investment (ROI). The cost is not merely for metal and installation; it is for a engineered solution that delivers:

- Increased Storage Capacity: Delaying or eliminating the need for expensive facility expansion.

Reduced Labor Costs: Faster loading/unloading times and easier access lead to fewer man-hours spent on storage tasks.

Minimized Product Damage: Secure, dedicated storage locations prevent items from being stacked improperly or becoming damaged.

Enhanced Safety: Reducing the risk of accident-related costs and downtime.

We provide detailed ROI projections with our proposals, demonstrating how the system will pay for itself through hard and soft cost savings, making the case for investment clear and compelling.

Conclusion

In the demanding environment of industrial and warehousing, efficiently storing long, bulky, and heavy items is a constant challenge that directly impacts your bottom line. A standard, off-the-shelf storage solution will always be a compromise. The only way to achieve true operational superiority—maximizing space, ensuring safety, enabling automation, and boosting productivity—is through a custom cantilever racking system design. At [Your Company Name], we combine decades of engineering expertise with a deep understanding of material flow to create not just a storage product, but a transformative logistics solution. We invite you to contact our team for a comprehensive consultation and warehouse assessment. Let us design a system that turns your storage challenges into your most significant competitive advantage.

- 1.What is the maximum weight a single cantilever arm can typically hold?Capacities vary dramatically based on the design, steel grade, and arm length. While standard arms might hold 1,000 to 4,000 lbs per pair, our custom-engineered arms for heavy industries can handle 10,000 lbs or more per pair. The exact capacity for your application is determined during our engineering analysis.

- 2.Can a cantilever racking system be relocated or reconfigured if my inventory needs change?Absolutely. A key advantage of our bolted designs is their modularity. Arms can be easily unlocked and repositioned at different heights on the column. Entire bays can also be disassembled and moved to a new location within the facility or to a new site entirely, protecting your long-term investment.

- 3.How does the cost of a custom cantilever system compare to a standard option?While the initial unit cost of a custom system is higher, the total cost of ownership is almost always lower. A standard system often leads to wasted space, inefficient operations, and potential safety risks. The custom solution optimizes every dollar spent by perfectly matching your needs, eliminating waste, and driving operational savings that quickly outweigh the initial price difference.

- 4.What kind of foundation or flooring is required for installation?Cantilever systems require a solid, level concrete floor for proper anchoring. The thickness and compressive strength of the concrete are critical factors we analyze during the design phase. For exceptionally heavy loads or in new builds, we may recommend specific flooring specifications or the use of reinforced baseplates to properly distribute the load.

- 5.Do you provide ongoing inspection and maintenance services after installation?Yes, we offer comprehensive service packages. Regular professional inspections are crucial for maintaining safety and warranty compliance. Our teams can provide scheduled inspections, damage assessment, and any necessary repair or replacement parts, ensuring your system remains in optimal condition for its entire lifespan.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com