📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

In the high-stakes world of logistics and warehousing, stagnation is regression. Executives and operations managers face a relentless arithmetic problem: static square footage versus dynamic, often unpredictable, growth in inventory and throughput demands. The conventional playbook—adding more static shelving or leasing expensive additional space—offers diminishing returns and fails to address the core inefficiencies embedded within a disjointed storage system. The paradigm shift, the one that systematically unlocks a verified 30% or greater boost in storage efficiency, is rooted in a foundational engineering philosophy: the universal adoption of rigorous modular platform design standards.

This is not merely a discourse on bolting together prefabricated racking. This is an authoritative guide to conceiving, engineering, and deploying a storage ecosystem. A true modular platform functions as a dynamic, adaptable chassis for the entire material handling operation. It is the engineered backbone upon which everything from manual picking to fully automated retrieval systems reliably operates. This article will dissect the core principles, components, and implementation methodologies that define world-class modular platform design standards, providing a comprehensive blueprint for transforming warehouse infrastructure from a fixed cost center into a scalable, efficient, and future-proof competitive weapon. The focus is on the tangible engineering decisions that cumulatively deliver monumental gains in capacity, throughput, and return on investment.

Beyond Bolted Steel: The Core Philosophy of a Modular Platform

The term “modular” is frequently misapplied in the storage industry, often used as a synonym for “pre-fabricated” or “bolt-together.” This represents a profound misunderstanding of the term’s power. A genuine modular platform is not a product one simply purchases; it is an integrated, interoperable system governed by a comprehensive set of modular platform design standards. These standards form the genetic code of the storage ecosystem, dictating everything from dimensional tolerances and load dynamics to integration protocols for automation.

Imagine the difference between building a structure from standardized, precision-engineered LEGO® bricks versus carving it from a solid, unyielding block of granite. The granite structure, once carved, is permanent. Any alteration requires destructive, costly, and time-consuming re-carving. The LEGO structure, governed by its inherent modular platform design standards (the stud spacing and connection method), can be assembled, disassembled, reconfigured, and expanded upon infinitely without compromising the integrity of the individual components. This is the essence of a true storage modular platform. It is a living system designed for evolution.

The implementation of robust modular platform design standards is what enables this flexibility without sacrificing strength or safety. These standards ensure that every component, whether an upright frame from a 2022 production run or a beam fabricated in 2025, will connect seamlessly and perform predictably under load. This eliminates the compatibility nightmares, dangerous safety compromises, and operational bottlenecks that plague warehouses built with non-standard, piecemeal equipment. The philosophy is simple: standardize to optimize. By creating a predictable physical environment, these modular platform design standards become the bedrock upon which unprecedented levels of storage efficiency and operational agility are built.

<h3>Why “Standards” Are Your Secret Weapon Against Obsolescence</h3>

A recurring theme in underperforming warehouse projects is the ad-hoc approach to infrastructure. Companies frequently source racking from Vendor A, AGVs from Vendor B, and a Warehouse Management System (WMS) from Vendor C, operating on the precarious hope that these disparate systems can be forcibly integrated. This approach inevitably leads to costly custom engineering work, persistent operational glitches, and a storage environment that is effectively frozen in its initial configuration, incapable of adapting to future needs.

The rigorous application of modular platform design standards is the most potent defense against this technological obsolescence and operational rigidity. These documented modular platform design standards act as a constitutional document for the warehouse, governing critical aspects:

Dimensional Consistency and Grid-Based Layout: All system dimensions—bay widths, beam heights, and portal clearances—are derived from a base modular unit. This grid-based approach, enforced by the modular platform design standards, systematically eliminates the wasted “sliver” spaces and awkward gaps that are inherent in non-standard layouts, directly contributing to the 30% density improvement.

Unified Connection and Interface Protocols: The modular platform design standards predefine how different systems interact physically and digitally. This includes how an Autonomous Mobile Robot (AMR) aligns with a rack face, how a pallet is presented to an automated shuttle, or how a pick-to-light module is mounted. Standardized interfaces ensure that future technological upgrades can be integrated with a simple “plug-and-play” methodology, protecting the capital investment for a decade or more.

Predictable Load and Safety Engineering: Perhaps the most critical function of modular platform design standards is to guarantee structural integrity. Every component is engineered to exacting load ratings (Uniformly Distributed Load and Point Load) and safety factors, consistently across the entire platform. This eliminates the catastrophic risk of component mismatch and ensures the entire system performs as a unified, safe structure under all operational conditions, a non-negotiable requirement for any reputable provider adhering to international modular platform design standards.

Deconstructing the 30% Efficiency Gain: An Engineering Analysis

A 30% enhancement in storage efficiency is not a marketing fantasy; it is the arithmetic sum of multiple, targeted efficiency gains achieved by systematically eliminating waste through the application of modular platform design standards. Let’s deconstruct the primary engineering principles that deliver this result.

<h3>Principle 1: Maximizing Cubic Space Utilization</h3>

The most glaring inefficiency in many warehouses is the neglect of the Z-axis—the vertical space. Traditional selective racking often occupies only a fraction of the available clear building height. The implementation of modular platform design standards is inherently three-dimensional, demanding a full audit of the cubic volume.

Engineered Vertical Expansion: The first and most impactful step is to design the racking to safely exploit the full clear height of the facility, up to the structural limits and sprinkler head clearance. Moving from an 8-meter system to a 12-meter or 15-meter system, engineered according to precise modular platform design standards, can more than double the storage locations within the same footprint. This requires specific calculations for column thickness, bracing density, and baseplate specifications, all dictated by the modular platform design standards.

Seamless Integration of High-Density Modalities: The power of a unified modular platform is its ability to incorporate various high-density storage methods as modules within the same overarching system. The modular platform design standards ensure that these different modalities can coexist and interoperate. These include:

Push-Back Racking: Utilizing a series of nested carts on inclined rails, this LIFO system increases density over selective racking while maintaining good selectivity.

Pallet Shuttle Systems: Here, the modular platform becomes the track for battery-powered shuttles that run inside the rack structure, enabling incredibly dense, driverless storage and retrieval in deep-lane configurations. The tolerances for this are extreme and are strictly defined by the modular platform design standards.

The critical differentiator is integration. Instead of isolated blocks of different, incompatible racking, the warehouse operates as a continuous, optimized landscape, all governed by the same set of modular platform design standards.

<h3>Principle 2: Dynamic Slotting and Velocity-Based Profiling</h3>

Storage efficiency is not solely a measure of static capacity; it is profoundly influenced by the dynamics of material movement. A significant source of operational waste is inefficient picker travel, often accounting for over half of a picker’s shift. A warehouse built on modular platform design standards is inherently designed for dynamic slotting.

Because the system is standardized and adjustable, relocating a SKU from a slow-moving, upper-level location to a fast-moving, “golden-zone” position is a simple, predictable process. The beams adjust to the exact same height, the decking is interchangeable, and the new location is immediately operational. By profiling inventory using ABC analysis (categorizing by velocity) and slotting it within the modular platform accordingly, travel distances are dramatically reduced. This optimization of labor, a direct consequence of the flexibility afforded by modular platform design standards, is a major contributor to the overall 30% efficiency target, impacting both space utilization and labor costs.

<h3>Principle 3: The Strategic Elimination of Aisle Inefficiency</h3>

Aisles are non-revenue-generating space, but they are essential for access. The width of these aisles is dictated by the turning radius and operational requirements of the material handling equipment. A standard counterbalance forklift might require a 3.5-meter aisle. The adoption of a modular platform specifically engineered for narrow-aisle (NA) or very-narrow-aisle (VNA) equipment can radically reduce this footprint.

Narrow-Aisle Forklifts: Operate effectively in aisles ranging from 1.6 to 1.8 meters.

Turret Trucks and Order Pickers: Can function in aisles as narrow as 1.5 meters, with the turret truck rotating its forks within the rack bay.

The Engineering Imperative: This transition is not as simple as just buying new trucks. The rack structure itself must be engineered to a higher standard. The modular platform design standards for a VNA application must account for different load dynamics, including increased guidance forces and potential for more frequent minor impacts. This results in specifications for heavier-gauge steel, more robust baseplates, and often the mandatory inclusion of structural column guards. Reducing aisle width from 3.5m to 1.6m can instantly reclaim over 15% of the floor space for productive storage, a direct and massive gain facilitated by the specialized modular platform design standards.

The Engineered Backbone: Components of a Robust Modular Platform

The theoretical advantages of a modular platform are realized through the precision engineering of its physical components. The modular platform design standards provide the exact specifications for each part, ensuring collective performance.

<h3>Upright Frames and Beams: The Primary Skeleton</h3>

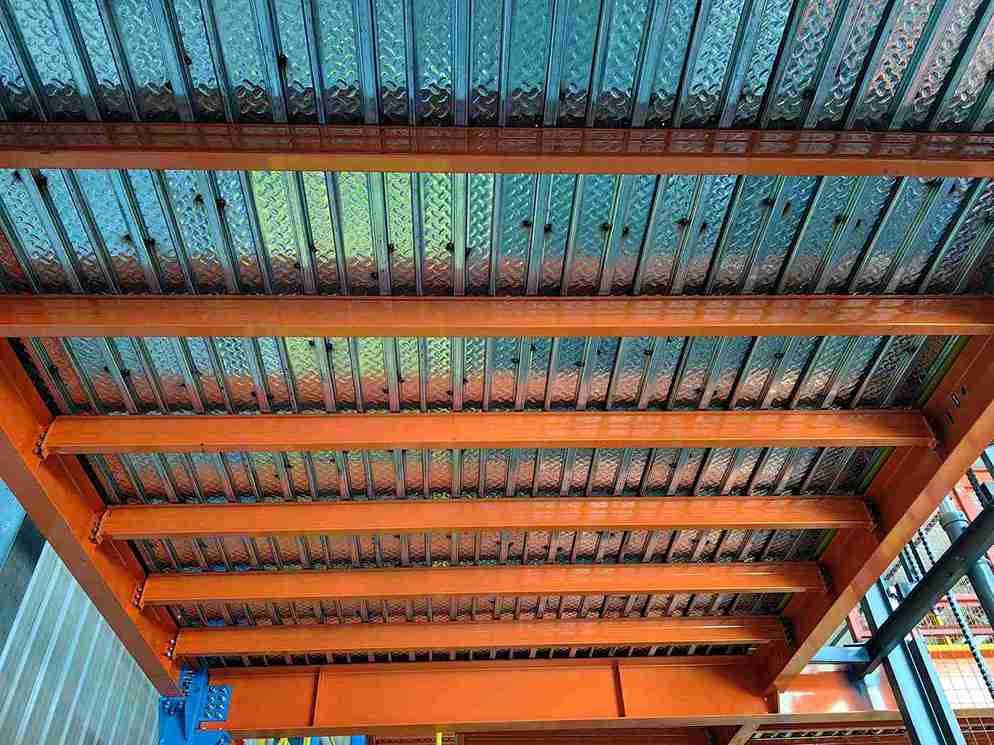

These are the main load-bearing elements, and their specifications are the cornerstone of the modular platform design standards.

Material Science in Practice: The standards specify high-tensile, cold-rolled steel with a precise yield strength (e.g., 350 MPa). The thickness of the column steel is not arbitrary; it is a calculated outcome based on the stored load weight, overall system height, and local seismic factors, all defined within the modular platform design standards.

The Critical Connection Point: The beam-to-upright connection is arguably the most engineered component in the entire system. Inferior designs use simple pins or clips that can fail under torsion or impact. Advanced modular platform design standards employ a positive-lock, torsion-resistant connector, often a patented hook-and-tee or cam-and-lever design. This ensures the beam cannot be accidentally dislodged and that the load is transferred efficiently and safely into the upright frame, a fundamental requirement of any credible modular platform design standards.

Load Beam Engineering: Beams are rated for specific Uniformly Distributed Loads (UDL) and are designed with a safety factor (typically 1.67:1) that exceeds the stated capacity. This means a beam rated for 2,500 kg UDL is engineered to withstand a significantly higher load before failure, a critical safety margin embedded in all professional modular platform design standards.

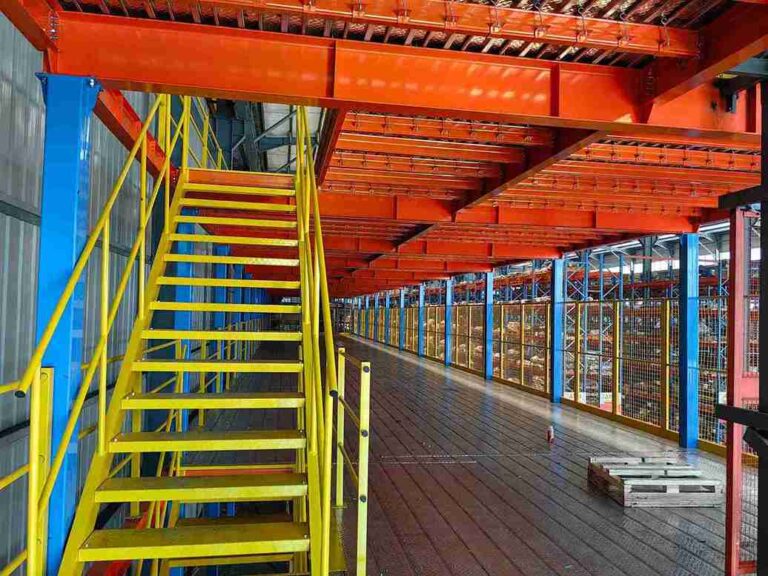

<h3>Decking and Integrated Surfaces: Creating a Stable Storage Plane</h3>

The choice of decking is a critical decision that impacts safety, functionality, and compatibility with automation, and is therefore strictly guided by the modular platform design standards.

Wire Mesh Decking: Provides ventilation, sprinkler water passage, and light penetration. Its open design is ideal for manual operations and is specified in the modular platform design standards for certain environmental and fire code requirements.

Solid Steel Decking: Offers a fully stable, continuous surface, essential for storing small items, supporting uneven pallets, and, most importantly, acting as the foundation for the guide rails of automated shuttle systems. The modular platform design standards will specify the gauge, pattern, and attachment method for this decking.

Structural Plywood: A cost-effective option, but its load capacity, fire resistance, and durability must be carefully evaluated against the long-term operational requirements outlined in the modular platform design standards.

<h4>The Critical Role of Bracing and Diagonal Ties</h4>

Horizontal and vertical bracing provide the racking system with its stability, resisting lateral forces and preventing sway. In high-bay warehouses or seismically active regions like parts of Southeast Asia and South America, the engineering of the bracing system is paramount. The modular platform design standards dictate the cross-sectional area, connection methods (e.g., bolt-through vs. riveted), and geometric pattern of this bracing to meet or exceed international codes like FEM 10.2.02 and RMI specifications. This is where the structural engineering behind the modular platform design standards becomes visibly apparent, ensuring the system remains rigid and safe under all anticipated loads, including seismic events.

The Conduit for Automation: How Modular Platforms Unlock AGV and AS/RS Integration

This is the apex of the modular platform philosophy, where the initial investment in standardization pays its highest dividends. Automation technologies—from AGVs and AMRs to unit-load AS/RS—are intolerant of physical inconsistency. They require a perfectly predictable and repeatable environment to function reliably and safely. The modular platform design standards provide this predictability.

<h3>Designing for AGV and Unmanned Forklift Interface</h3>

When an automated vehicle approaches a rack to deposit or retrieve a load, it relies on a symphony of precise physical and digital cues. The modular platform is the stage for this symphony.

Consistent Pallet Entry Height: Every single beam level across the entire warehouse must be at exactly the same height, with tolerances often held to within +/- 2 millimeters. This global consistency is impossible without enforced modular platform design standards governing manufacturing and installation.

Precise Portal Clearance: The opening of the rack bay is a calculated dimension, engineered to guide the pallet in smoothly without snagging, while being narrow enough to prevent tilting. This calculation, based on pallet standards and the fork mechanism of the AGV, is a key output of the modular platform design standards.

Integrated Navigation Infrastructure: The rack structure itself can be designed to host navigation aids. The modular platform design standards can include predefined mounting points for fiducial markers, retro-reflective tapes, or RFID tags that the vehicles use for precise triangulation, effectively turning the storage system itself into a giant, high-fidelity navigation map.

<h3>The Foundation for Automated Storage and Retrieval Systems (AS/RS)</h3>

For mini-load ASRS or unit-load shuttle systems, the modular platform is not merely support; it is the integral guideway and track. The tolerances here are surgical.

The Rack as a Precision Guideway: The uprights must be perfectly plumb, and the rails upon which the shuttle travels must be perfectly straight, level, and parallel. Any deviation—a slight bow or a misaligned joint—can cause a high-speed shuttle to jam, derail, or drop its load, resulting in catastrophic downtime.

Tolerances an Order of Magnitude Tighter: The modular platform design standards for AS/RS integration are vastly more stringent than those for conventional racking. They specify requirements for rail flatness (e.g., ±1mm over 10m), column plumbness (e.g., ±3mm in 10m height), and bay-to-bay alignment that are essential for achieving the renowned reliability and throughput of these systems. This precision engineering, dictated by the modular platform design standards, is what separates a high-performance automation-ready facility from a basic storage shed.

The Implementation Blueprint: From Site Survey to Operational Handover

Translating the theory of modular platform design standards into a live, operational asset requires a meticulous, phase-gated process. This disciplined approach is what ensures the promised 30% efficiency gain is actually realized on the ground.

Phase 1: Comprehensive Site Audit and Data Interrogation: This phase goes far beyond measuring walls. It involves a deep analysis of the inventory profile (SKU cube, weight, turnover velocity), operational data (peak order volumes, picking and put-away rates, seasonality), and future growth projections. This data becomes the feedstock for the digital model, ensuring the modular platform design standards are applied to a realistic operational scenario.

Phase 2: Digital Twin Simulation and Layout Optimization: Before any steel is cut, a digital twin of the entire warehouse is constructed. This virtual model, built according to the proposed modular platform design standards, is used to run sophisticated simulations. Different layout scenarios, slotting strategies, and equipment workflows are stress-tested against forecasted peak demands. This digital prototyping identifies and eliminates bottlenecks, validates the 30% efficiency claim, and optimizes the design before committing to physical installation—a core benefit of a model-driven approach based on solid modular platform design standards.

Phase 3: Precision Installation and Rigorous Quality Assurance: The installation is not construction; it is precision assembly. Teams work from master drawings that are direct outputs of the modular platform design standards. Every step is verified against a rigorous QC checklist: anchor torque, column plumb, beam level, and connector engagement. This ensures the physical build perfectly matches the digital design, a non-negotiable requirement for system performance and safety.

Phase 4: System Integration and Commissioning: The modular platform is the physical layer upon which the software (WMS, WES) and automation operate. This phase involves meticulously mapping the physical assets to their digital twins in the management systems, ensuring that the location identified as “Aisle 4, Level 2, Position 5” in the WMS corresponds perfectly with the physical location built to the modular platform design standards.

Phase 5: Knowledge Transfer and Long-Term Strategic Support: The final deliverable is not just a racking system; it is the complete set of modular platform design standards documentation—the as-built drawings, load certificates, and component specifications. This package becomes the single source of truth for the client, empowering their team to manage future modifications, expansions, and integrations with full confidence and in compliance with the original engineered intent.

Case in Point: Transforming a 3PL’s Regional Hub with Modular Platform Design Standards

A leading third-party logistics (3PL) provider in Southeast Asia faced a critical capacity crunch. Their 15,000 sqm facility was at 95% utilization, and a key client was poised to increase volumes by 40%. Expansion was geographically impossible, and leasing additional space was financially prohibitive. Their existing infrastructure was a chaotic mix of outdated selective and drive-in racking, completely incompatible with the automation they needed to remain competitive.

The Engineered Solution: The provider engaged a team to redesign the entire facility around a unified set of modular platform design standards. The solution included:

A VNA racking zone, engineered to specific modular platform design standards for stability with turret trucks, for bulk pallet storage.

A dynamic carton-pick zone with fully adjustable pallet racking, allowing for continual re-slotting based on the modular platform design standards for flexibility.

A dedicated section built to the heightened modular platform design standards required for a future AS/RS shuttle system, with the necessary precision guides and reinforced structures.

Universal AGV interface points at all receiving and dispatch lanes, designed into the modular platform design standards from the outset.

The Quantifiable Result: Within six months of going live, the facility achieved a 34% increase in storage capacity within the exact same footprint. Picking efficiency rose by 22% due to the optimized, velocity-based slotting enabled by the flexible modular platform. Most importantly, the new high-volume client was onboarded without disruption. The client is now in the final stages of installing the AS/RS shuttles into the pre-engineered zone, a “plug-and-play” upgrade that would have been unimaginably complex and costly without the foundational modular platform design standards.

Conclusion: Efficiency is an Engineered Outcome, Not an Accident

Achieving a sustained 30% or greater boost in storage efficiency is not a hopeful aspiration; it is the direct and predictable outcome of applying disciplined engineering principles to warehouse infrastructure. The journey begins with a strategic commitment to the modular platform design standards philosophy—a decision to view the storage environment not as a collection of purchased assets, but as a single, integrated, and living system.

This approach, governed by rigorous modular platform design standards, systematically maximizes cubic space, optimizes material flow, and creates a future-proof foundation for the seamless integration of advanced automation. It transforms the warehouse from a static, depreciating liability into a scalable, adaptable, and supremely efficient engine of commerce and competitive advantage. The pivotal question for logistics leaders is no longer if such performance is attainable, but how swiftly they can initiate the engineering process to embed these transformative modular platform design standards into their operations.

Frequently Asked Questions (FAQs)

1. How do your modular platform design standards accommodate unique or non-standard pallet sizes common in certain markets?

The framework established by our modular platform design standards is designed for adaptability, not rigidity. While we strongly advocate for pallet standardization to maximize efficiency, our modular platform design standards are engineered to handle real-world diversity. We begin with a comprehensive pallet analysis, and our modular platform design standards use a base modular unit that allows for the customization of beam lengths and bay depths. This creates a “nested standard” within the overall system, efficiently accommodating oversized, non-EUR, or non-GMA pallets without compromising the overarching structural integrity or interoperability mandated by the core modular platform design standards.

2. What is the lead time for implementing a warehouse-wide modular platform compared to conventional racking?

The initial, front-end engineering phase for a true modular platform governed by comprehensive modular platform design standards is more intensive, typically adding 15-25% to the pre-installation timeline. However, this investment is recouped multifold during the installation phase. Because every component is manufactured to precise modular platform design standards, on-site assembly is dramatically faster, with fewer errors, fit-up issues, and delays. Consequently, the total project timeline from conception to operational handover for a modular platform is often comparable to, or even shorter than, that of a conventional, less engineered system, while delivering a far superior, more efficient, and future-proof outcome.

3. Can these standards be applied to retrofit or upgrade an existing warehouse without a complete teardown?

Yes, retrofitting is a common and highly effective application of the modular platform design standards philosophy. The process begins with a thorough structural and dimensional audit of the existing racking. Wherever feasible, we integrate the legacy system into the new modular platform design standards by using engineered adapter kits or strategically replacing only the non-compliant components (e.g., beams, decking, bracing). The objective is a phased, capital-efficient modernization that brings the entire facility into compliance with the new modular platform design standards, allowing for immediate efficiency gains in critical zones while planning for a complete transition over time.

4. How do you address the specific seismic and wind load requirements for regions like Southeast Asia or South America?

Designing for seismic and wind loads is a fundamental, non-negotiable component of our modular platform design standards, not a secondary consideration. Our engineering team utilizes location-specific data from international (IBC) and local building codes to perform dynamic structural analyses. The resulting modular platform design standards for these regions specify enhanced requirements: larger baseplates, specific anchor types (e.g., epoxy-set or mechanical), denser bracing configurations, and often the use of higher-grade steel. These modular platform design standards may also include specialized seismic beam connectors that allow for controlled movement without catastrophic failure, ensuring the system’s resilience in the face of environmental forces.

5. What kind of ongoing maintenance and inspection protocol does a modular platform require?

A system built to precise modular platform design standards is inherently easier and more predictable to maintain. We provide clients with a customized Planned Preventive Maintenance (PPM) schedule, a direct output of the specific modular platform design standards used in their facility. This protocol, derived from the modular platform design standards, includes regular, systematic checks for column plumbness, beam connector torque, anchor integrity, upright guard condition, and impact damage.

The standardization dictated by the modular platform design standards means any damaged component can be rapidly identified by its standardized part number and replaced with a guaranteed-compatible unit, minimizing operational downtime. We empower client teams to perform routine checks based on these modular platform design standards and offer annual professional audit services for long-term asset integrity.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com