📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Unlocking Your Warehouse’s Hidden Vertical Potential

For logistics directors, warehouse managers, and operations leaders, the constant pressure to store more within the same four walls is a relentless challenge. The traditional answer—physical expansion or relocation—is a path fraught with exorbitant costs, paralyzing downtime, and complex logistical nightmares. However, a superior, more strategic solution exists, one that leverages the most underutilized asset in any facility: the vertical cube. This comprehensive guide is the definitive resource on mezzanine racking, the engineered structural platform that creates a second or even third operational level within your existing warehouse. We will explore how a custom-designed mezzanine racking system effectively doubles or triples your usable floor area without a single brick laid, seamlessly integrates with AGVs, automated conveyor systems, and pallet racking to form a high-density, automated storage ecosystem, and delivers an unparalleled return on investment. This is not just about adding square footage; it’s about a fundamental re-engineering of your operational footprint for maximum efficiency, productivity, and scalable growth. Investing in a robust mezzanine racking solution is the hallmark of a forward-thinking operation.

The Prohibitive Reality of Conventional Warehouse Expansion

To fully appreciate the value proposition of mezzanine racking, one must first understand the profound drawbacks of the alternatives. When storage capacity hits its ceiling, the instinct to build anew or expand outward is a natural but often costly miscalculation.

Exorbitant and Unpredictable Financial Outlay: The construction costs per square foot for new industrial space represent a massive capital expenditure. This figure only scratches the surface, as it excludes the monumental associated costs: years of elevated property taxes, significantly higher insurance premiums, massive utility hookup fees, and the purchase or leasing of additional land. The budget for such projects is notoriously prone to overruns.

The Quagmire of Zoning and Permitting: Navigating the complex web of local municipal zoning laws, stringent building codes, and the arduous permit approval process is a time-consuming and uncertain endeavor. This bureaucratic labyrinth can delay critical expansion projects by months or even years, stalling growth and hampering competitiveness.

Operational Catastrophe and Crippling Downtime: The process of relocating an entire warehouse operation is a monumental task that brings productivity to a grinding halt. It inevitably leads to severe disruptions in order fulfillment, receiving, and shipping, directly impacting customer satisfaction, revenue streams, and brand reputation. The hidden costs of this downtime often far exceed the projected construction budgets.

The Strategic Inflexibility: Physically expanding your footprint in one location solves an immediate problem but creates a long-term strategic constraint. It anchors the business to a specific geographical location, which may not remain optimal for future logistics network designs, customer base shifts, or merger and acquisition activities.

It is within this context of high risk and even higher cost that mezzanine racking emerges not as a mere alternative, but as the superior strategic choice for intelligent capacity creation.

Defining Mezzanine Racking: The Engineered Backbone of Vertical Storage

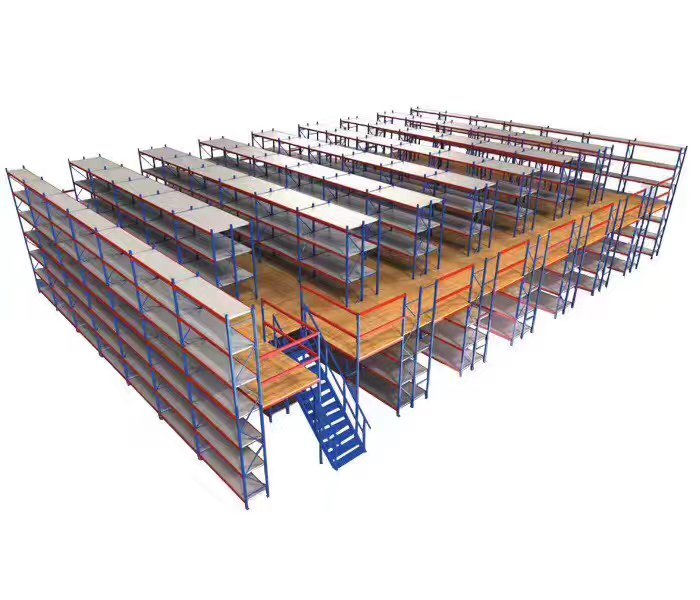

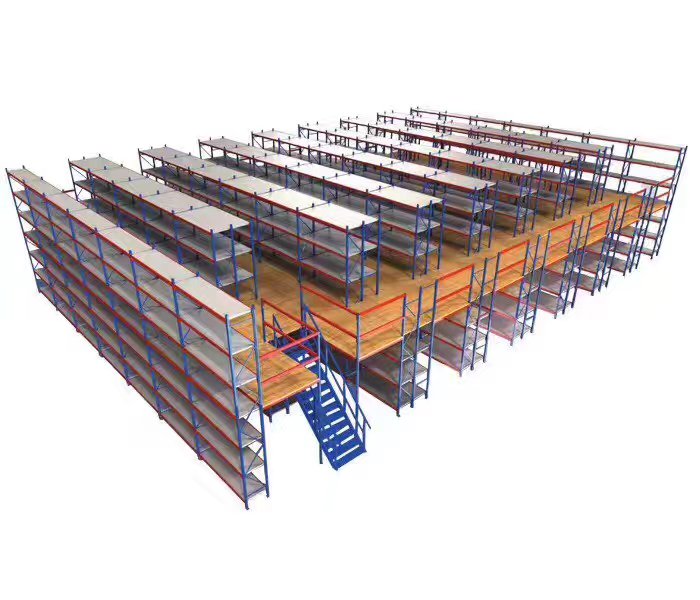

A industrial mezzanine racking system is fundamentally different from a simple storage loft or raised platform. It is a free-standing, custom-engineered intermediate floor system installed between the main floor and the ceiling of a facility. Constructed from high-strength, often hot-rolled steel components—upright columns, primary and secondary beams, decking (typically heavy-duty steel bar grating or particle board), and staircases—a properly designed mezzanine racking structure is engineered to support immense dynamic and static loads, from bulk storage to the constant vibration of fully automated distribution lines.

The transformative power of a modern mezzanine racking system lies in its inherent versatility and symbiotic relationship with other storage and handling equipment. It acts as the foundational platform upon which a multi-tiered storage universe is built. On the mezzanine racking deck, operations can install a complete storage ecosystem:

Selective Pallet Racking for high-density unit load storage.

Cantilever Racking for long, awkward goods like lumber, piping, or furniture.

Shelving and Bin Systems for small parts and piece picking.

Modular drawer systems for high-security tool or component storage.

Automated conveyor and sortation systems for continuous product flow.

Pick modules and workstations to create multi-level order fulfillment zones.

This inherent ability to host an entire storage system is the critical differentiator between a simple platform and a true mezzanine racking solution, and it is the key to unlocking genuine, operational capacity multiplication.

The Unbeatable Economics: Quantifying the ROI of a Mezzanine Racking Investment

The financial argument for choosing a mezzanine racking system over new construction is overwhelmingly persuasive. The cost per square foot of usable space gained with a mezzanine racking installation is typically a fraction of the cost of building new space, often ranging from one-third to one-half the price.

Superior Cost-Efficiency: With a mezzanine racking project, you are paying primarily for materials and expert installation, thereby avoiding the massive sunk costs of land acquisition, exterior walls, deep foundation work, and new roofing. The investment is almost entirely directed toward creating immediate, usable capacity.

Minimal Business Disruption and Downtime: A professional mezzanine racking installation can be scheduled during off-hours or phased in specific sections of the warehouse, keeping operational downtime to an absolute minimum. There is no need to halt receiving, shipping, or production, protecting your revenue stream throughout the installation process.

Immediate Capacity Gain and Scalability: From final project approval to completion, a typical mezzanine racking project can be executed in a matter of weeks, not the months or years required for new construction. This means businesses can almost immediately alleviate storage congestion, meet growing seasonal demand, and capitalize on new market opportunities without delay.

Favorable Tax Treatment: In many tax jurisdictions, mezzanine racking systems can qualify for highly advantageous treatment as equipment or machinery (e.g., under Section 179 of the IRS code in the U.S.), allowing for accelerated depreciation or even immediate expensing in the first year. This dramatically improves the already compelling return on investment and shortens the payback period.

Key Design and Engineering Considerations for a Flawless Mezzanine Racking Installation

A successful mezzanine racking project is not an off-the-shelf product; it is a custom-engineered solution tailored to the specific needs and constraints of a facility. Several critical factors must be meticulously analyzed to ensure absolute safety, optimal functionality, and full regulatory compliance.

Structural Load Capacity and Intended Use Case

The design live load is the paramount engineering consideration. The intended use dictates the required strength of the mezzanine racking structure. Will the system be used for:

Bulky Storage (Light-Duty): ~125 PSF (pounds per square foot) for items like empty containers or light fixtures.

Order Picking & Shelving (Medium-Duty): 150-250 PSF for active carton flow shelving or piece-picking operations.

Pallet Storage & Handling (Heavy-Duty): 250-500+ PSF for supporting fully laden pallets and the movement of material handling equipment.

Automated Equipment (Super Heavy-Duty): Requires sophisticated engineering for dynamic loads and vibrations generated by AGVs, unmanned forklifts, and conveyor systems.

Clear Span Capabilities and Strategic Column Placement

The distance between supporting columns is a fundamental design element that directly impacts material flow. Longer clear spans create more flexible, unobstructed floor space below and above the mezzanine racking deck but may require heavier gauge steel and different beam designs. Strategic column placement is crucial for maintaining smooth, efficient pathways for both man-operated equipment and automated guided vehicles.

Seamless Integration with Material Handling Equipment (MHE)

How will inventory, personnel, and robots move between levels? This is a core integration point that defines the system’s efficiency.

Personnel Access Points: Standard options include staircases, pedestrian gates, and safety cages. For larger systems, escalators or dedicated personnel lifts may be considered.

Vertical Transportation for Goods: For high-throughput operations, the integration of lifts, vertical reciprocating conveyors (VRCs), and even spiral conveyors is essential. The mezzanine racking structure must be specifically engineered to accommodate the point loads and dynamic forces of this equipment.

AGV and Robotics Integration: The pinnacle of modern mezzanine racking design features integrated automated lifts or gentle ramps that allow AGVs and autonomous mobile robots (AMRs) to travel to the mezzanine level unattended. This creates a truly hands-off, continuous-flow storage and retrieval process, maximizing productivity.

Navigating Building Codes, Permits, and Safety Standards

A reputable and expert mezzanine racking provider will manage this complex process, but it is vital for the client to understand its importance. All mezzanine racking installations must comply with local building codes (IBC, UBC), stringent fire safety regulations (which require integrated sprinkler systems on all levels), and OSHA standards for guardrails, toe kicks, and load signage. Professional engineering stamps are non-negotiable for ensuring the structure’s integrity and safety.

The Powerful Synergy of Mezzanine Racking and Warehouse Automation

This is where the modern mezzanine racking system transcends its role as a static storage platform and becomes the central nervous system of a high-performance automated storage and retrieval system (AS/RS). The marriage of a robust mezzanine racking structure with cutting-edge robotics is a definitive force multiplier for any distribution center.

Engineering a Multi-Tier AGV and Robotics Ecosystem

Why should automation be confined to the ground floor? With a properly designed and engineered mezzanine racking system, an entire fleet of AGVs or unmanned forklifts can access multiple levels. Via integrated ramps or automated lifts, these robots can autonomously store and retrieve pallets or goods-to-person bins from the racking on the mezzanine racking deck. This engineering feat effectively creates a dense, automated storage buffer that operates 24/7 without human intervention, dramatically increasing the facility’s throughput and slashing labor costs.

Hosting Overhead Automated Conveyor and Sortation Systems

Mezzanine racking provides the perfect structural framework for overhead conveyor systems. Goods can be received on the ground floor, elevated to the mezzanine racking level via an inclined conveyor, sorted, sequenced, and then transported to designated storage lanes or pick stations on the mezzanine before being sent back down for shipping. This continuous, multi-level flow optimizes the use of vertical space for the entire process, not just for storage, creating a highly efficient and compact operational layout.

Versatile Applications of Mezzanine Racking: Beyond Pure Storage

While high-density storage is the primary function, the incredible versatility of modern mezzanine racking systems allows them to solve a wide variety of space constraints and operational challenges.

High-Density Storage Systems: The classic and most common application, where the mezzanine racking structure supports selective pallet racking or cantilever racking overhead, effectively doubling the storage capacity within the same footprint.

Multi-Level Order Fulfillment and Pick Modules: Creating a highly condensed and efficient picking environment where pickers work on multiple levels within a small footprint, drastically reducing travel time and increasing picks per hour.

Manufacturing Platforms and Assembly Lines: Utilizing the mezzanine racking level for light assembly, kitting, sub-assembly, or manufacturing processes, freeing up the valuable ground-floor space for more heavy-duty operations like receiving, shipping, and bulk storage.

Office and Lounge Overlooks: Building enclosed, quiet office spaces, control rooms, or employee break rooms above the bustling warehouse floor. This provides supervisors with clear visibility of the operation while saving on expensive commercial office rental costs.

The Installation Process: A Step-by-Step Overview from Your Mezzanine Racking Provider

A smooth and successful mezzanine racking installation hinges entirely on choosing an expert provider with a proven track record. The process typically follows these key stages:

In-Depth Consultation & Site Survey: An expert consultant will visit your site to measure clear heights, assess floor conditions, understand your operational flow, and discuss future growth plans. This data is crucial for the design phase.

Precision Engineering & 3D Design: Using advanced CAD and BIM software, in-house engineers will create a custom 3D design and detailed schematics for your approval. This model will include all structural elements and integrated equipment.

Permitting Assistance and Management: A top-tier mezzanine racking provider will manage the entire process of drawing submissions and securing permits from local building authorities, alleviating a significant burden from your team.

Controlled Factory Pre-Fabrication: All steel components for the mezzanine racking system are precision-cut, punched, welded, and pre-finished (e.g., primed and painted) off-site in a controlled factory environment. This ensures最高 quality and accelerates on-site installation.

Professional and Certified Installation: A certified, experienced installation team will erect the structure methodically with minimal disruption to your ongoing operations. They ensure every bolt is torqued to specification, every weld is sound, and every safety standard is meticulously met before handing over the keys.

Selecting the Right Partner: Why Your Mezzanine Racking Provider is Critical to Success

The market is filled with suppliers, but not all possess the expertise for such a critical project. This is a significant investment in your operational infrastructure. The right mezzanine racking partner brings indispensable qualities:

In-House Engineering Expertise: Ensure the company has licensed Professional Engineers (PEs) on staff who understand regional seismic, wind, and safety loads. This is non-negotiable for structural integrity.

A Holistic, Full-System Approach: They must be experts not just in the mezzanine racking structure itself, but in the pallet racking, shelving, and automation that will be integrated onto it. They should act as a single-source solution provider.

A Proven and Robust Project Portfolio: Always ask for detailed case studies, videos, and references from projects of a similar scale and complexity to yours. A reputable provider will be proud to share their success stories.

Comprehensive End-to-End Service: From initial concept and feasibility study to final inspection, certification, and ongoing maintenance support, they should be a single point of responsibility, ensuring accountability and a seamless experience.

Conclusion: Building Up—The Smartest Strategic Direction for Modern Warehouse Growth

The constraint of limited warehouse space is not a dead end; it is a catalyst for innovation and optimization. Mezzanine racking stands as the most logical, financially astute, and operationally superior solution for businesses determined to scale their storage and handling capabilities in lockstep with market demands. By leveraging the vast, unused vertical cube of your existing building, you elegantly avoid the prohibitive costs and delays of outward expansion, future-proof your operation with a platform inherently ready for integration with robotics and automation, and achieve a dramatic, immediate increase in storage density and operational efficiency. The pressing question for today’s logistics leaders is no longer if they can afford to invest in a high-quality mezzanine racking system, but whether they can afford the staggering opportunity costs of not exploring this powerful and transformative solution. The path to genuinely maximizing your warehouse capacity begins not with a bulldozer, but with a strategic, upward look and a partnership with the right mezzanine racking expert.

Frequently Asked Questions (FAQs)

1. Can a mezzanine racking system be disassembled and relocated if we move our facility?

Yes, one of the most significant advantages of a structural mezzanine racking system is its relocatability. Unlike permanent construction, a quality bolted mezzanine racking system can typically be disassembled, transported, and reinstalled in a new location. This protects your capital investment and provides crucial flexibility for future business growth, consolidation, or changes. When discussing your mezzanine racking project, inform your provider of this potential future need.

2. How does fire protection and sprinkler system integration work on a mezzanine racking level?

This is a critical code requirement and a top priority for any mezzanine racking project. Any enclosed mezzanine or one used for storage must be equipped with a fire sprinkler system. Your mezzanine racking provider will work closely with your building’s sprinkler contractor to design the integration layout. The sprinkler lines are typically tied directly into the building’s main system and run along the structure of the mezzanine racking to provide full coverage on both the mezzanine deck and the area below, ensuring compliance with NFPA and local fire marshal regulations.

3. What is the typical lead time from design approval to complete installation of a mezzanine racking system?

Lead times can vary based on the project’s complexity, size, and current manufacturing schedules, but a general timeline is 8-14 weeks. This includes approximately 2-4 weeks for detailed engineering and permit drawing preparation, 4-6 weeks for manufacturing and fabrication of all mezzanine racking components, and 1-3 weeks for on-site installation by a professional, certified crew.

4. My warehouse has uneven floors. Is it still possible to install a mezzanine racking system?

Absolutely. Most warehouse floors are not perfectly level. Professional mezzanine racking installers are equipped to handle this very common issue. They use adjustable base plates and shims on the upright columns to compensate for floor irregularities and ensure the entire mezzanine racking structure is perfectly level and plumb. In cases of severe unevenness, a concrete topping pad or self-leveling epoxy might be recommended first to create a level and stable base.

5. Can a mezzanine racking system be expanded or modified after the initial installation?

Yes, the modular and bolted nature of steel mezzanine racking systems allows for future expansion or modification. This could include increasing the deck area, reinforcing the structure for heavier loads, or adding new access points. This flexibility is a key benefit, provided the original design had some foresight for future needs. It is far easier and more cost-effective to expand an existing mezzanine racking system than it is to build a new addition onto your warehouse. Discussing future plans with your design engineer during the initial consultation is highly advised.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com