📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Stop Wasting Space & Time: How Flexible Automated Storage Systems Deliver a 50%+ Efficiency Gain

In the high-stakes environment of modern supply chains, operational inefficiency is more than a minor inconvenience; it is an existential threat. Logistics managers and business leaders globally are grappling with the dual pressures of exploding storage needs and the imperative for rapid order fulfillment. The conventional playbook of adding manual labor or leasing more warehouse space is no longer a viable strategy. It is a reactive, costly, and ultimately limited approach. The paradigm has shifted.

The definitive solution lies in the strategic deployment of intelligent, adaptable Automated Storage Systems. This comprehensive analysis delves into how modern, flexible Automated Storage Systems are engineered to eradicate waste in space and time, systematically driving efficiency gains that reliably exceed 50% and fundamentally future-proofing warehouse operations against market volatility.

Deconstructing Inefficiency: The Multifaceted Cost of Outdated Warehousing

To appreciate the transformative power of advanced Automated Storage Systems, one must first fully understand the profound financial and operational drag of legacy methods. The cost extends far beyond monthly rent checks.

The Spatial Economics of Modern Warehousing

Underutilized warehouse space is a silent capital drain. Every square meter that is not optimized represents a direct loss on real estate investment, utilities, and taxes. However, the implications of poor space utilization are more systemic:

Prolonged Material Travel Paths: In a conventional warehouse layout, pickers can spend up to 60% of their shift simply walking. This non-value-added travel is a direct consequence of poor storage density and disorganized slotting.

Compromised Inventory Control: Without a system-driven approach, inventory visibility plummets. Items are lost in plain sight, leading to stock-outs, excessive safety stock, and frustrating order inaccuracies.

Failure to Leverage the Vertical Cube: Traditional static shelving and selective pallet racking often ignore the most valuable real estate—the air space above standard reach. This failure to build upwards is a primary contributor to spatial waste.

Inflexibility in the Face of Growth: A static storage layout creates a hard cap on scalability. Business growth becomes a logistical nightmare, forcing premature and expensive facility expansions or relocations.

The Compounding Tyranny of Wasted Time

In logistics, time is the ultimate competitive metric. Inefficient processes create a cascade of delays that impact the entire customer journey.

Legacy Picking Methodologies: Manual cart and paper-based picking are not only slow but are also prone to a high frequency of errors, requiring costly rework and damaging customer trust.

Cognitive Load and Process Friction: Workers relying on paper lists or outdated RF scanners experience constant mental stops and starts, breaking workflow rhythm and killing productivity.

Ineffective Inventory Slotting: When high-velocity SKUs are not positioned for optimal access, the entire picking process is slowed, creating a bottleneck that amplifies throughout the operation.

Congestion at Consolidation Points: The final stages of order fulfillment, where picked items are merged and packed, often become chaotic bottlenecks, erasing any efficiency gains made earlier in the process.

The Evolution of Automation: From Rigid Monoliths to Agile, Flexible Ecosystems

The term “automation” has historically evoked images of colossal, fixed-configuration systems requiring a wholesale dismantling of existing operations and a monumental capital outlay. These rigid, first-generation Automated Storage Systems were often characterized by their inflexibility; they were designed for a specific throughput volume and product profile, and any deviation or growth could render them obsolete. The modern answer is a fundamental paradigm shift towards flexibility. Today’s leading Automated Storage Systems are defined not by their rigidity, but by their inherent adaptability.

Defining the Flexible Automation Paradigm

A flexible Automated Storage System is an integrated, modular ecosystem. It is a symphony of hardware and software components that can be configured, scaled, and reconfigured in response to evolving business needs. This philosophy treats automation as a set of interoperable building blocks:

Modular Design: Implementation can be phased, targeting the most critical pain points first for a rapid ROI, then expanding systematically.

Inherent Scalability: The system grows with the business. Adding storage capacity, robotic units, or workstations is a planned, straightforward process.

Software-Defined Agility: The core intelligence resides in a sophisticated software layer that can be reprogrammed to optimize for seasonal peaks, new product lines, or changing order profiles.

Seamless Interoperability: Next-generation Automated Storage Systems are designed to integrate with and enhance existing infrastructure, such as legacy racking or forklifts, protecting prior capital investments.

The Architectural Components of a Modern Flexible Automated Storage System

A best-in-class flexible Automated Storage System is architected from a suite of complementary technologies, selected and integrated to address specific operational challenges.

High-Density Dynamic Storage Solutions

The first principle of an efficient Automated Storage System is to store more in less space, intelligently.

Pallet Shuttle Systems: These semi-automated Automated Storage Systems utilize a battery-powered shuttle that operates within the racking structure, enabling deep-lane storage. This design dramatically increases storage density, improves safety by reducing forklift activity inside narrow aisles, and provides superior FIFO/LIFO control. It is a highly effective entry point into warehouse automation.

Vertical Lift Modules (VLMs) and Vertical Carousels: These space-centric Automated Storage Systems are essentially automated vertical cabinets. They store items in trays that are delivered on-demand to an ergonomic “goods-to-person” pick window. This eliminates walking and searching, catapulting pick rates and achieving near-perfect accuracy for small parts.

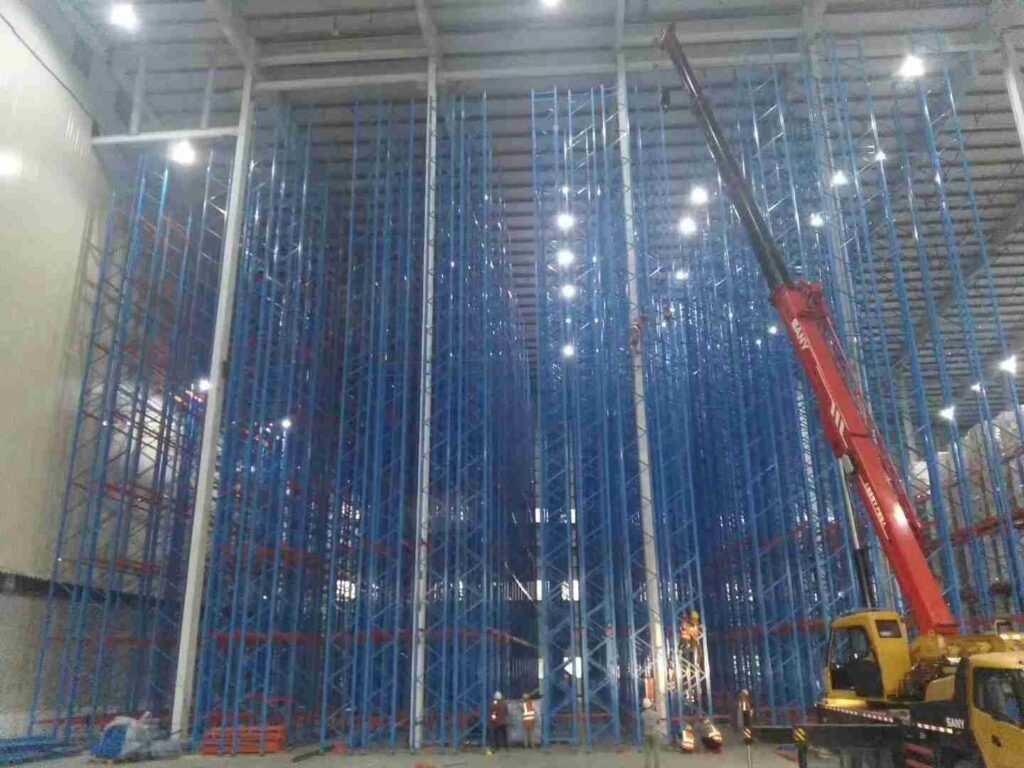

Modular ASRS (Automated Storage and Retrieval Systems): Representing the cutting edge of storage technology, these Automated Storage Systems employ independent, robotic shuttles that operate on a three-dimensional grid within a modular rack structure. This architecture allows for unparalleled scalability and density, making these Automated Storage Systems ideal for a wide range of item sizes, from small cases to full pallets.

Agile Robotic Material Handling

This category of Automated Storage Systems encompasses the mobile elements that transform static inventory into dynamic assets.

AGVs (Automated Guided Vehicles): As the foundational technology in mobile Automated Storage Systems, AGVs reliably follow pre-defined paths to transport loads. They excel in predictable, repetitive point-to-point moves, such as moving pallets from receiving to a storage aisle.

AMRs (Autonomous Mobile Robots): These represent a significant evolution in mobile Automated Storage Systems. AMRs use sophisticated sensors, cameras, and onboard computing to perceive their environment and navigate dynamically. This allows them to avoid obstacles, reroute in real-time, and work safely alongside human staff, offering a level of flexibility that fixed-path AGVs cannot match.

Automated Guided Carts (AGCs): A streamlined and cost-effective component of many Automated Storage Systems, AGCs are perfect for lighter loads and simpler material transport tasks, often deployed in supporting roles for assembly or kitting operations.

Intelligent Conveyance and Sortation

Acting as the high-speed circulatory system of the Automated Storage System, these components ensure seamless flow.

Modular Conveyor Systems: Modern belt, roller, and skatewheel conveyors are the workhorses of material transport within an Automated Storage System, designed to be easily reconfigured as operational needs change.

Automated Sortation Systems: These critical nodes within an Automated Storage System use a variety of technologies (e.g., pop-up wheels, cross-belts, sliding shoe sorters) to automatically identify and divert items to their correct destination. This is indispensable for high-volume e-commerce and distribution centers.

Put-to-Light and Pick-to-Light Systems: These operator-guided technologies integrate seamlessly with larger Automated Storage Systems to visually direct workers in sorting and order consolidation tasks, drastically reducing errors and speeding up the final stages of fulfillment.

The Command and Control Center: The Indispensable Software Layer

The hardware of an Automated Storage System is powerless without its digital brain. The sophistication of the software is what separates a basic mechanized solution from a truly intelligent, flexible Automated Storage System.

Seamless WMS/WCS Integration: A well-designed Automated Storage System is architected for seamless bidirectional data flow with the host Warehouse Management System (WMS) and Warehouse Control System (WCS), ensuring inventory and order data remain synchronized across the enterprise.

The Warehouse Execution System (WES): This is the strategic command center of a modern Automated Storage System. The WES goes beyond simple control; it executes and optimizes in real-time. It intelligently dispatches tasks to robots and machines, dynamically balances workloads across the entire facility, and prioritizes orders to meet critical SLAs. It is the source of the system’s adaptability and responsiveness.

Predictive Analytics and Performance Intelligence: A state-of-the-art Automated Storage System is a rich source of operational data. Advanced analytics platforms transform this data into predictive insights, allowing managers to forecast maintenance needs, identify emerging bottlenecks, and simulate the impact of process changes, enabling continuous, data-driven optimization.

The 50% Efficiency Blueprint: A Data-Backed Projection

The promise of a 50% or greater efficiency gain is not aspirational; it is a predictable outcome derived from the cumulative impact of specific, measurable improvements delivered by a well-implemented Automated Storage System.

Radical Optimization of Space Utilization

By fully leveraging the vertical cube and implementing high-density storage strategies, a flexible Automated Storage System routinely achieves a 100% to 400% increase in storage density within the same physical footprint. This effectively doubles or triples functional capacity, deferring or eliminating the need for costly facility expansion and delivering immense real estate savings.

The Transformation of Labor Productivity

Virtual Elimination of Travel Time: Goods-to-person technologies within an Automated Storage System, such as VLMs and AMRs, reduce worker walking time by over 90%, reallocating human effort to value-added tasks.

Exponential Gains in Picking Performance: By presenting the right item at the right time and place, an Automated Storage System can increase picking rates by 300-500% while simultaneously driving error rates down to a remarkable 0.01% or lower.

Workforce Upskilling and Enhanced Safety: Employees transition from manual, repetitive tasks to roles focused on system management, exception handling, and continuous improvement. This leads to higher job satisfaction, reduced turnover, and a safer work environment.

Unlocking Superior Throughput and Accuracy

Accelerated Order Cycle Times: An integrated Automated Storage System streamlines the entire workflow from receiving to shipping, enabling a shift from next-day to same-day or even instant shipping models.

Flawless Order Fulfillment: The precision of an Automated Storage System ensures that the right product, in the right quantity, is shipped to the right customer every time. This dramatic reduction in errors minimizes returns, boosts customer lifetime value, and solidifies brand reputation.

A Phased Implementation Roadmap for Sustainable Success

The flexibility of modern Automated Storage Systems allows for a strategic, low-risk implementation journey that aligns with business cycles and budget constraints.

Phase 1: Holistic Operational Assessment: Experts conduct a granular analysis of current workflows, inventory data, and growth forecasts to architect a solution with the highest potential for rapid, demonstrable ROI.

Phase 2: Targeted Pilot Deployment: The project begins with automating a single, high-impact zone. This could involve deploying a VLM for high-value components or a fleet of AMRs for a specific transport loop. This phase delivers a quick win, validates the technology, and builds organizational buy-in.

Phase 3: Systematic Scaling and Integration: Following the pilot’s success, the Automated Storage System is expanded methodically. New modules and technologies are integrated, all orchestrated by the central WES, to create a unified, facility-wide automation strategy.

Phase 4: Continuous Performance Optimization: The partnership extends beyond implementation. Using the rich data generated by the Automated Storage System, specialists provide ongoing analysis and recommendations for fine-tuning and further enhancing operational performance.

The Strategic Ripple Effect: Impact Beyond the Warehouse Walls

The benefits of a sophisticated Automated Storage System propagate across the entire enterprise, delivering strategic advantages that transcend operational metrics.

Enhanced Supply Chain Resilience: A faster, more reliable, and predictable warehouse operation makes the entire supply chain more robust and capable of absorbing disruptions.

A Superior Customer Experience: The ability to consistently promise and deliver rapid, accurate orders is a powerful competitive differentiator that builds deep customer loyalty.

Empowerment through Data: The operational intelligence harvested from the Automated Storage System provides invaluable insights for strategic decision-making in sales, marketing, and procurement.

Advancement of Sustainability Goals: By maximizing the utility of existing space and optimizing energy consumption, these Automated Storage Systems contribute directly to corporate environmental, social, and governance (ESG) targets.

Conclusion: Building a Future-Proof Logistics Operation with Intelligent Automation

The landscape of global logistics has irrevocably changed. The companies that will thrive are those that recognize their warehouse not as a cost center, but as a strategic asset capable of driving market advantage. The journey toward this future is paved with flexible, intelligent Automated Storage Systems. These are not rigid installations but dynamic platforms for continuous efficiency gains. The commitment to implementing a modern Automated Storage System is a commitment to eliminating spatial and temporal waste, empowering the workforce, and building an operation that is not only efficient today but also inherently prepared for the challenges of tomorrow. The 50% efficiency gain is the starting point; the destination is market leadership.

Frequently Asked Questions (FAQs)

1. How does a flexible Automated Storage System handle our peak season volumes, like during the holidays?

Flexible Automated Storage Systems are specifically engineered for volatility. The Warehouse Execution System (WES) can be programmed with “peak mode” workflows that prioritize high-velocity orders and optimize material flow for maximum throughput. Furthermore, the modular nature of technologies like AMR-based picking allows for the temporary leasing of additional robotic units to scale labor capacity precisely for the peak season, a level of operational agility that rigid Automated Storage Systems cannot provide.

2. We have an older warehouse with uneven floors and tight spaces. Can an Automated Storage System still work for us?

Yes, absolutely. This scenario is a key differentiator for modern, flexible Automated Storage Systems. Technologies like Autonomous Mobile Robots (AMRs) are equipped with advanced navigation and suspension systems capable of handling minor floor imperfections. Their dynamic pathfinding and compact designs allow them to operate efficiently in confined or irregularly shaped spaces where traditional fixed-path automation would be impractical or prohibitively expensive to install.

3. What is the typical ROI period for an investment in this kind of Automated Storage System?

While the return on investment is project-specific, most organizations implementing a phased, flexible Automated Storage System achieve a full return on investment within 18 to 36 months. The ROI is driven by a combination of hard cost savings from reduced labor, lower real estate costs, and a dramatic reduction in error-related expenses. A detailed financial analysis is always provided during the initial consultation to model the specific payback period.

4. How do we manage maintenance and technical support for these complex Automated Storage Systems?

Providers of high-quality Automated Storage Systems offer comprehensive service level agreements (SLAs) that include proactive remote monitoring, scheduled preventative maintenance, and rapid on-demand technical support. Many modern systems are designed with modular, hot-swappable components, enabling on-site staff to perform quick replacements with remote guidance from support engineers, ensuring maximum system uptime and operational continuity.

5. Can your Automated Storage System integrate with the ERP and WMS we already use?

Seamless integration is a foundational principle of any professional Automated Storage System deployment. The system’s control software is built with a library of standard API connectors for all major ERP and WMS platforms. The implementation team works to ensure a robust, bidirectional data exchange, allowing the existing management systems to remain the system of record while the Automated Storage System executes the physical workflow with precision and intelligence.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com