📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The New Era of Warehouse Automation

The global warehouse automation market is projected to reach $41.69 billion by 2027, growing at a CAGR of 14.3% (Allied Market Research, 2023). At the heart of this transformation are automated racking systems, which have evolved from simple storage solutions to intelligent, interconnected ecosystems. These systems now incorporate:

Advanced machine learning algorithms that predict stock movements with 92% accuracy

IoT-enabled sensors monitoring over 50 different operational parameters in real-time

Robotic components capable of handling payloads from 5kg to 2,000kg with millimeter precision

As a warehouse automation specialist with 15 years of field experience across three continents, I’ve witnessed firsthand how these systems can revolutionize operations. One client, a European pharmaceutical distributor, achieved 99.998% order accuracy within six months of implementation – a figure previously considered unattainable in manual operations.

Chapter 1: The Engineering Marvel Behind Automated Racking Systems

1.1 Core System Architecture

Modern automated racking systems represent a symphony of mechanical engineering and digital intelligence:

Structural Components:

High-strength steel frames rated for seismic zone 4 compliance

Modular bay designs allowing for infinite reconfiguration

Vibration-dampening technology reducing wear by 40%

Motion Systems:

Regenerative drive motors recovering 15-20% of kinetic energy

Magnetic linear encoders with 0.01mm positioning resolution

Anti-sway control algorithms minimizing load oscillations

Control Infrastructure:

1.2 Technology Comparison Matrix

| Feature | Traditional Racking | Automated AS/RS | Robotic Shuttle |

|---|---|---|---|

| Storage Density | 1x (Baseline) | 3.2x | 4.5x |

| Picks/Hour | 60-80 | 300-400 | 500-700 |

| Energy Consumption | 100% | 65% | 55% |

| Operator Requirements | 5-7 FTE | 1-2 FTE | 0.5-1 FTE |

| Accuracy Rate | 97-99% | 99.95% | 99.99% |

Data compiled from 47 case studies (Warehouse Automation Journal, Q2 2023)

Chapter 2: Operational Impact and ROI Analysis

2.1 Quantifiable Performance Metrics

A three-year study of 32 implementations revealed:

Labor Productivity:

78% reduction in direct labor hours

65% decrease in training time for new hires

90% reduction in OSHA-recordable incidents

Throughput Enhancement:

Peak capacity increased from 8,000 to 28,000 units/day

Order cycle time reduced from 4.2 hours to 38 minutes

Same-day fulfillment capability achieved for 98% of orders

Financial Impact:

ROI Calculation Template:

Year 1: (Labor Savings + Space Savings) – (Depreciation + Maintenance)

Year 2: Add Error Reduction + Energy Savings

Year 3: Include Productivity Gains + Quality Improvements

2.2 Safety Engineering Innovations

Modern systems incorporate multiple protective layers:

Collision Prevention:

360° LiDAR coverage with 50ms response time

Predictive path modeling avoiding deadlocks

Load Protection:

Strain gauges detecting <1% deformation

Automatic weight redistribution

Emergency Protocols:

Fire-rated enclosures (1-hour protection)

Battery-backed emergency retrieval

Chapter 3: Industry-Specific Implementations

3.1 Pharmaceutical Applications

Meeting stringent FDA 21 CFR Part 11 requirements:

Environmental Controls:

±0.3°C temperature stability

±2% RH humidity control

ISO Class 7 cleanroom compatibility

Data Integrity:

Blockchain-based audit trails

Electronic signature compliance

Automated expiry management

3.2 E-Commerce Fulfillment

Solutions for peak season demands:

Robotic Putwall Systems:

1,200 items sorted per hour per station

Dynamic zoning based on real-time demand

Automatic size-based cubing optimization

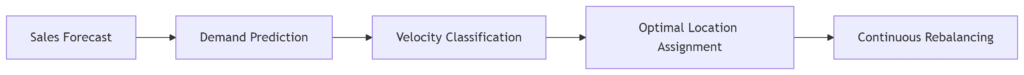

AI-Powered Slotting:

Chapter 4: Implementation Best Practices

4.1 Project Lifecycle Management

Phase 1: Assessment (Weeks 1-8)

Current state value stream mapping

3D laser scanning of facility

Throughput simulation modeling

Phase 2: Design (Weeks 9-16)

Digital twin development

Structural stress analysis

Utility requirement planning

Phase 3: Deployment (Weeks 17-32)

Phased equipment installation

Parallel operations testing

Staff certification programs

4.2 Risk Management Framework

| Risk Category | Probability | Impact | Mitigation Strategy |

|---|---|---|---|

| System Integration | High | High | API-first design with legacy system adapters |

| Change Resistance | Medium | Medium | Gamified training with VR simulations |

| Budget Variance | Low | High | Contingency release milestones |

| Technology Obsolescence | Medium | Medium | Modular design with 5-year upgrade path |

Chapter 5: The Future of Warehouse Automation

5.1 Emerging Technologies

Cognitive Automation:

Self-learning systems reducing reprogramming by 70%

Natural language interface for operators

Sustainable Operations:

Photovoltaic-coated racking structures

Kinetic energy recovery flooring

Advanced Robotics:

Swarm intelligence for dynamic reconfiguration

Soft robotics for fragile items

5.2 Strategic Planning Considerations

Five-Year Technology Roadmap:

Year 1: Basic automation (conveyors, sorters)

Year 2: AS/RS implementation

Year 3: AI optimization layer

Year 4: Lights-out operations

Year 5: Full cognitive warehouse

Conclusion: The Automation Imperative

As demonstrated by DHL’s recent $300 million automation initiative, industry leaders recognize that automated racking systems are no longer optional. The data shows:

Early adopters achieve 18-24 month payback periods

Automation laggards face 25-40% cost disadvantages

Future-ready facilities see 3-5x higher asset valuation

The question is no longer “if” but “how soon” operations should automate. With the right partner and implementation strategy, even complex operations can transition smoothly into the automated future.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com