📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

A Strategic Guide to Automated Pallet Retrieval Systems for Modern Business Leaders

In the relentless pursuit of operational excellence, the warehouse has evolved from a static cost center into the dynamic, beating heart of the global supply chain. For CEOs and business leaders across the Middle East, Africa, Southeast Asia, and Latin America, the critical question has shifted from a tentative if to automate, to a decisive how and when. This comprehensive guide provides a strategic, C-suite perspective on Automated Pallet Retrieval Systems.

It moves beyond technical specifications to dissect how this transformative technology directly impacts corporate bottom lines, enhances operational scalability, and future-proofs logistics operations against the triple threats of rising costs, persistent labor shortages, and escalating customer demands. Adopting advanced Automated Pallet Retrieval Systems is not merely about storing pallets more efficiently; it is a strategic imperative for unlocking trapped capital, accelerating order throughput, and building an unassailable competitive advantage in the world’s most dynamic growth markets.

The CEO’s Strategic Dilemma: Is Your Current Warehouse Holding Your Business Hostage?

Progressive leaders are tasked with steering their organizations toward sustainable, profitable growth. Yet, frequently, the most significant and overlooked drag on profitability and agility lies hidden within the four walls of the distribution center. Traditional storage methodologies, heavily reliant on manual labor and inherently inefficient use of cubic space, create a cascade of hidden costs and strategic vulnerabilities that directly threaten core business objectives. These legacy systems are no longer merely inefficient; they are actively hazardous to corporate health in a fast-paced market.

Consider these critical, boardroom-level questions:

Are operational costs rising disproportionately to sales growth, with a significant and growing portion tied to manual labor, high error rates, and preventable safety incidents?

Is the organization’s ability to scale operations for peak seasons or new market entry consistently hampered by physical space constraints and the immense difficulty of recruiting, training, and retaining a large, skilled warehouse workforce?

Is the company experiencing persistent inventory inaccuracies that lead to costly stockouts, damaging overstocking, and steadily eroded customer trust?

Does the existing warehouse infrastructure fundamentally limit the ability to meet the accelerating market demands for same-day or next-day delivery, ceding ground to more agile competitors?

An affirmative answer to any of these questions indicates that the warehouse has transitioned from a passive asset to an active liability. Implementing a sophisticated Automated Pallet Retrieval System is the definitive strategic intervention that transforms this liability into a powerful, data-driven engine for growth. This technology represents a strategic capital investment that pays continuous, measurable dividends in efficiency, accuracy, and strategic flexibility for years to come.

Defining the Modern Automated Pallet Retrieval System: A Executive’s Perspective

Forget complex engineering diagrams. At its strategic core, an Automated Pallet Retrieval System is a high-density, software-controlled storage solution that utilizes robotic cranes, autonomous shuttles, or other automated mechanisms to store and retrieve pallets with precision and minimal human intervention. It is the physical manifestation of a digital supply chain.

Imagine a high-rise, ultra-efficient valet service for an organization’s entire inventory. Instead of relying on multiple forklift drivers navigating crowded, dangerous aisles, a sophisticated computer-controlled system receives an electronic order, dispatches a retrieval machine to the exact storage location, and delivers the required pallet to a designated pick-up point. This entire process occurs with unparalleled speed, precision, and consistency, 24 hours a day, 7 days a week. The robustness of modern Automated Pallet Retrieval Systems allows them to operate in environments ranging from deep-freeze cold storage to demanding manufacturing floors.

These intelligent systems are architected around three synergistic layers:

The Physical Hardware: This includes the high-rise storage structure itself, the robotic cranes or shuttles that move within the aisles, and the complementary conveyor or AGV systems that interface with the Automated Pallet Retrieval System.

The Control Software: This acts as the intelligent “traffic controller,” directing the real-time movements of the machines, optimizing travel paths for maximum throughput, and managing the dynamic queue of storage and retrieval tasks within the Automated Pallet Retrieval System.

The Warehouse Management System (WMS) Integration: This is the “brain” of the entire operation. The enterprise’s WMS tells the Automated Pallet Retrieval System what to store and when to retrieve it, seamlessly connecting order fulfillment logic to the physical, automated movement of goods.

The Core Technologies Powering Modern Automated Pallet Retrieval Systems

While all Automated Pallet Retrieval Systems aim for automation, the underlying technologies are diverse, engineered to suit specific operational profiles, throughput requirements, and budgetary considerations. Selecting the right type of Automated Pallet Retrieval System is a critical strategic decision.

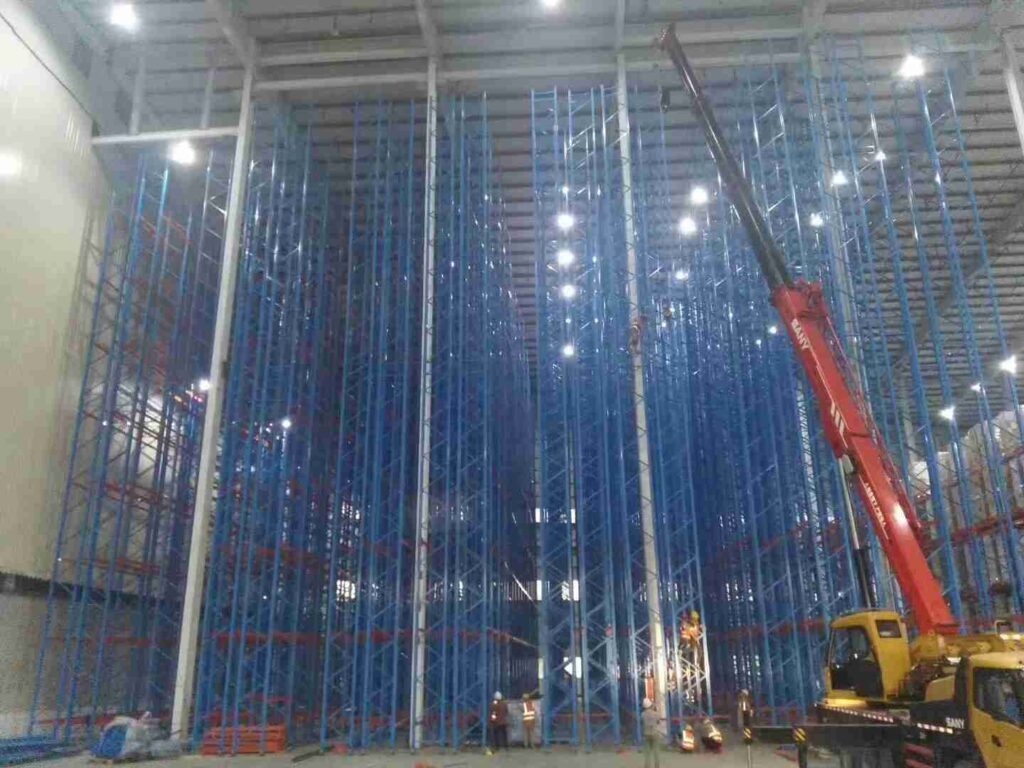

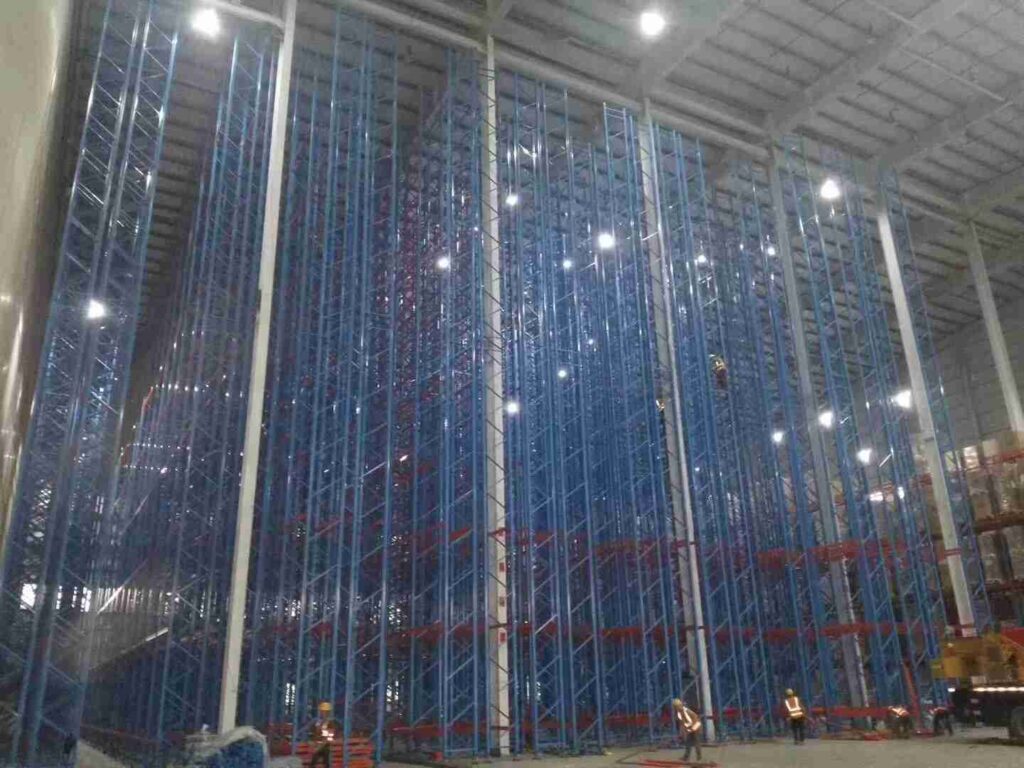

Unit-Load AS/RS: The High-Density Industrial Powerhouse

This is the classic, high-throughput image of industrial automation: towering aisles with single or multiple mast cranes storing and retrieving full pallets with immense precision. These Automated Pallet Retrieval Systems are engineered for maximum storage density, effectively doubling or tripling existing storage capacity within the same physical footprint.

They are the undisputed champion for cold storage applications, manufacturing raw material handling, and large-scale distribution centers with high-volume, full-pallet movements. The Return on Investment for this type of Automated Pallet Retrieval System is powerfully driven by immense space savings and significantly reduced energy costs, particularly in refrigerated environments.

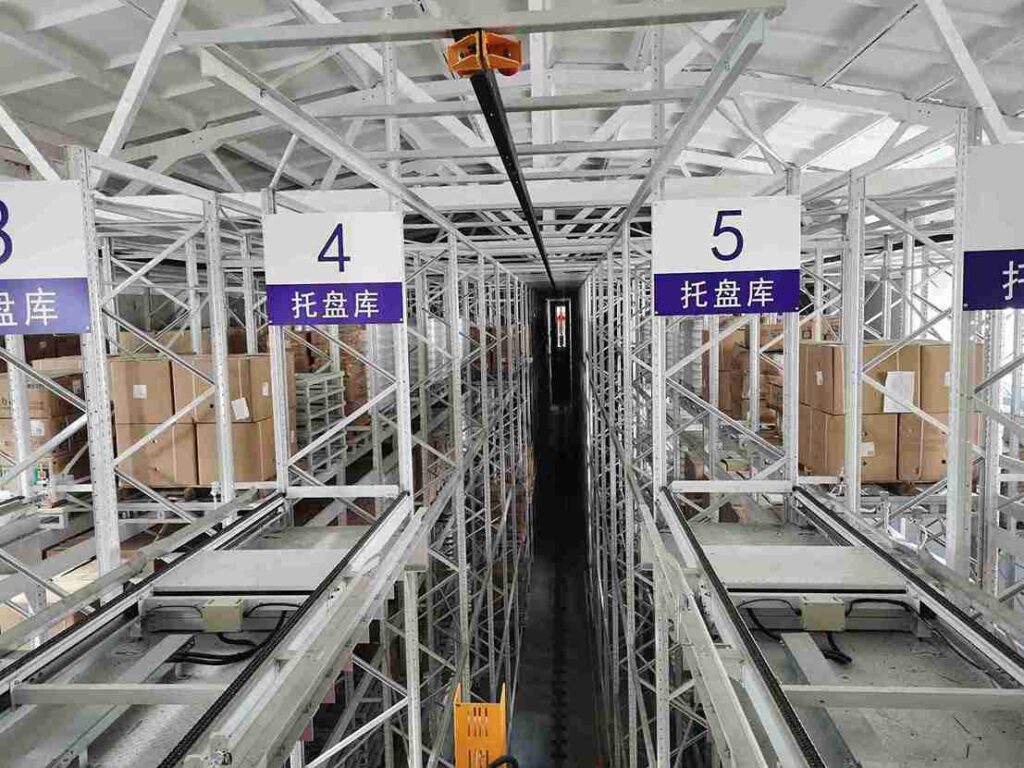

Shuttle-Based Systems: The Champions of Speed and Flexibility

Representing a more modern evolution, shuttle-based Automated Pallet Retrieval Systems utilize independent, battery-powered shuttles that run on rails at each level of the storage racking. These decentralized shuttles can move laterally to store and retrieve pallets, working in tandem with a vertical lift to move between levels.

This decoupled operation allows for simultaneous, multi-depth operations within a single aisle, a key differentiator. The paramount advantages of this design of Automated Pallet Retrieval System are incredible throughput speeds, superior scalability (as more shuttles can be added), and graceful degradation—if one shuttle fails, the others continue working uninterrupted, protecting operational integrity.

The Integrating Role of Robotics: AMRs and Forklifts

In the most advanced logistics ecosystems, the line between storage and movement is intentionally blurred. Autonomous Mobile Robots (AMRs) or Unmanned Forklifts are seamlessly integrated to perform the first and last mile of the retrieval process in conjunction with the core Automated Pallet Retrieval System. They autonomously transport pallets from the production line to the input point of the Automated Pallet Retrieval System and from the system’s output point to the dispatch area. This integration creates a truly end-to-end automated material flow, further reducing manual touchpoints and elevating the entire operation’s efficiency.

The Strategic Business Case: Quantifying the ROI of Automated Pallet Retrieval Systems

Investing in a comprehensive Automated Pallet Retrieval System is a significant capital expenditure, and its justification must be rooted in clear, quantifiable business outcomes that resonate powerfully in the boardroom. The financial rationale for deploying an Automated Pallet Retrieval System extends far beyond simple labor displacement.

Transforming Capital Expenditure into Sustained Operational Advantage

Radical Space Optimization and Virtual Real Estate: This is often the most immediate and dramatic saving. By building upwards and using narrow or even aisle-less configurations, advanced Automated Pallet Retrieval Systems can increase storage capacity by over 100% within the same building envelope. In regions like the Middle East and Southeast Asia, where prime industrial real estate costs are soaring, this translates into massive savings on land and construction costs or definitively defers the need for a costly new facility expansion. Companies are, in effect, creating highly valuable virtual real estate through the implementation of an Automated Pallet Retrieval System.

Drastic Labor Cost Reduction & Strategic Reallocation: Automation intelligently redefines workforce roles. A well-implemented Automated Pallet Retrieval System can reduce reliance on forklift operators by over 80%. This not only cuts direct labor costs but also mitigates the risks and costs associated with high labor turnover, continuous training, and workplace safety incidents. The existing skilled workforce can be upskilled to manage the high-tech system, oversee operations, and handle value-added tasks like custom kitting and quality control, making the human capital more strategic and valuable.

Unmatched Accuracy and Real-Time Inventory Visibility: Manual processes are inherently prone to error. An Automated Pallet Retrieval System, governed by its precise software, delivers near-perfect inventory accuracy (99.9%+). The system knows the exact location and status of every single pallet at all times. This eliminates costly shipping errors, drastically reduces inventory shrinkage, and provides the C-suite with real-time, accurate data for financial forecasting and strategic supply chain planning. The accuracy dividend of an Automated Pallet Retrieval System alone often delivers a compelling ROI.

Accelerated Order Fulfillment and Unconstrained Throughput: Speed is the new currency of modern logistics. High-performance Automated Pallet Retrieval Systems can retrieve pallets in minutes, not the hours it can take in a conventional warehouse. This dramatically compresses order cycle times, enabling businesses to meet tighter delivery windows for e-commerce and retail clients. The system doesn’t require breaks, enabling 24/7 operation and making the business capable of handling peak-season volumes without exponential increases in temporary labor or crippling overtime pay.

A Regional Strategic Perspective: Tailoring Automated Pallet Retrieval Systems for Global Growth Markets

The value proposition of automation is not monolithic. Its impact is magnified when perfectly aligned with the specific challenges and opportunities of distinct operating regions. A one-size-fits-all approach does not work, and the design of an Automated Pallet Retrieval System must be context-aware.

The Middle East: Building the Logistics Hubs of the Future

Nations like the UAE, Saudi Arabia, and Qatar are aggressively diversifying their economies and positioning themselves as preeminent global logistics hubs. In this high-ambition environment, an Automated Pallet Retrieval System is a prerequisite for competitiveness, not a luxury.

Climate Control Efficiency: The extreme heat makes climate-controlled warehouses a necessity. Automated Pallet Retrieval Systems are perfectly suited for these environments as the sealed, high-density design significantly reduces the energy required for cooling, offering a rapid payback.

Labor Dynamics and Stability: With a significant reliance on an ex-pat workforce, automation provides crucial operational stability and reduces vulnerability to policy changes and labor mobility.

E-commerce Boom: The explosive growth of e-commerce in regions like Saudi Arabia demands fulfillment centers capable of extreme speed and accuracy, which only a sophisticated Automated Pallet Retrieval System can provide at scale.

Southeast Asia: Meeting the Demands of a Manufacturing Powerhouse

In the manufacturing-centric economies of Vietnam, Thailand, and Indonesia, an Automated Pallet Retrieval System directly and robustly supports continuous production lines.

Just-in-Time (JIT) Manufacturing Reliability: An Automated Pallet Retrieval System ensures that raw materials and components are delivered to the production line with precise timing, minimizing line-side storage and preventing expensive production stoppages.

Solving the Space Premium: In bustling industrial parks, land is expensive and scarce. The high-density nature of an Automated Pallet Retrieval System allows manufacturers to expand capacity radically without acquiring new land.

The Rising Labor Cost Equation: As wages consistently rise, the ROI for an Automated Pallet Retrieval System improves significantly, making it an increasingly attractive and necessary alternative to large manual workforces.

Africa & Latin America: Leapfrogging to Modern Logistics

For the rapidly growing markets in Nigeria, Kenya, Mexico, and Brazil, automation offers a historic chance to leapfrog legacy infrastructure and establish a lasting competitive edge.

Building Unprecedented Reliability: An Automated Pallet Retrieval System brings a level of process reliability and predictability that can be a game-changer in regions where supply chains are often fragmented and unreliable.

Attracting Global Partnership: A state-of-the-art, automated warehouse signals to multinational corporations that a business is a reliable, modern logistics partner, opening doors to lucrative long-term contracts.

Solving the Skilled Labor Gap: It can be challenging to find a large, trained cohort of skilled forklift operators and warehouse managers. An Automated Pallet Retrieval System centralizes the skill requirement to a smaller, more manageable team of system operators and technicians.

The Implementation Blueprint: A Phased Approach for Automated Pallet Retrieval System Success

A successful Automated Pallet Retrieval System project is not just a purchase; it is a deep partnership and a carefully managed business transformation. Leading providers guide clients through a meticulous, phased process to de-risk the project and ensure it delivers on its strategic promises from day one.

Phase 1: Deep-Dive Consultation & Data Analysis: Reputable providers engineer a solution, not just sell a product. This begins with a forensic analysis of SKU data, order profiles, peak volumes, and growth projections. This data-driven approach ensures the Automated Pallet Retrieval System is designed for the specific business, not a generic blueprint.

Phase 2: Customized System Design & Digital Simulation: Expert engineers create a detailed 3D model of the proposed Automated Pallet Retrieval System. They then run advanced digital simulations using the client’s actual order data to model throughput, identify potential bottlenecks, and optimize the design before any metal is cut. This virtual commissioning is the ultimate insurance policy for performance.

Phase 3: Meticulous Project Management & Systems Integration: A dedicated project manager oversees every aspect: civil works, installation, electrical, and, most critically, the deep integration with existing WMS/ERP systems. The integration is treated as the non-negotiable backbone of the entire Automated Pallet Retrieval System project.

Phase 4: Commissioning, Comprehensive Training, and Go-Live: Elite providers do not just install and leave. Their teams are on-site to commission the Automated Pallet Retrieval System, rigorously test it under real-world conditions, and comprehensively train the client’s staff—from operators to maintenance technicians—on how to run and care for the system for its entire lifecycle.

Phase 5: Long-Term Strategic Support & Proactive Remote Monitoring: The partnership continues long after go-live. Leading firms offer proactive support packages and remote monitoring services for the Automated Pallet Retrieval System to ensure peak performance and minimize downtime throughout the system’s entire operational life.

Navigating the Investment: Total Cost of Ownership vs. Initial Price Tag

It is a critical strategic error to evaluate an Automated Pallet Retrieval System based solely on the initial purchase price. The true metric for a discerning CEO is the Total Cost of Ownership (TCO) over a 7 to 10-year period.

Initial Capital Outlay: This includes the cost of the hardware, software, and professional services (installation, integration). For a high-quality Automated Pallet Retrieval System, this is an investment in reliability.

Operational Cost Savings: This is where the overwhelming value is created. Companies must model the ongoing savings in labor, reduced energy consumption (especially for cold storage), lower pilferage, and a dramatically reduced cost per pallet position.

Maintenance and Support: A well-maintained Automated Pallet Retrieval System will operate reliably for decades. Factor in the cost of annual service contracts and spare parts. A high-quality system from a reputable provider often has a lower long-term maintenance cost.

Scalability and Flexibility Cost: What is the cost of future expansion? Modular Automated Pallet Retrieval Systems like shuttle-based configurations often allow for easier and more cost-effective scaling than monolithic crane-based systems.

When the comprehensive numbers are run, most organizations find that the payback period for a well-designed Automated Pallet Retrieval System falls between 2 to 4 years, after which the system becomes a significant and continuous profit center.

The Future is Now: AI, IoT, and the Self-Optimizing Automated Pallet Retrieval System

The evolution of Automated Pallet Retrieval Systems is accelerating, moving from simple automation to predictive, cognitive operations. The next frontier is already being integrated into leading systems, transforming them into intelligent supply chain nodes.

Artificial Intelligence (AI) for Predictive Analytics: AI algorithms can analyze vast operational data sets from the Automated Pallet Retrieval System to predict maintenance needs before a component fails, preventing unplanned downtime. They can also intelligently optimize storage put-away based on AI-driven demand forecasts, dynamically placing fast-moving SKUs in the most accessible locations.

Internet of Things (IoT) Sensor Integration: A network of sensors throughout the racking and on the cranes/shuttles of the Automated Pallet Retrieval System monitors performance, health, and environmental conditions in real-time, feeding a continuous stream of data for analysis and optimization.

Machine Learning for Dynamic Optimization: The software governing the Automated Pallet Retrieval System will no longer just follow static rules; it will learn. It will continuously optimize retrieval sequences, travel paths, and energy consumption based on real-time order patterns, becoming more efficient and intelligent over time.

Investing in a modern Automated Pallet Retrieval System today is the essential first step toward building the self-optimizing, “lights-out” warehouse of tomorrow.

Conclusion: Making the Strategic Decision to Lead with Automated Pallet Retrieval Systems

The question posed at the beginning—”Is Your Warehouse Future-Proof?”—is the defining strategic question for today’s business leaders in logistics and manufacturing. The performance gap between companies that embrace automation and those that cling to manual methods is widening into a decisive chasm. An Automated Pallet Retrieval System is more than a piece of machinery; it is a strategic, profit-generating asset.

It is the definitive key to unlocking trapped capital in real estate and labor, building a resilient and scalable supply chain, and delivering a level of service that cements customer loyalty for the long term. In the high-growth, fiercely competitive landscapes of the Middle East, Southeast Asia, Africa, and Latin America, an Automated Pallet Retrieval System is no longer a luxury for the few but an operational necessity for the many who intend to lead their industries. The journey begins with a strategic conversation, not a commitment.

It starts with a data-driven assessment of current operations and a visionary look at future ambitions. Partnering with an expert provider is the crucial step to guide that journey, providing the requisite expertise, proven technology, and unwavering partnership to transform a warehouse from a cost center into the organization’s most powerful competitive weapon.

Frequently Asked Questions (FAQs)

1. How does an Automated Pallet Retrieval System handle different pallet sizes and weights within the same system?

Modern Automated Pallet Retrieval Systems are highly adaptable and are custom-designed to accommodate a range of standard pallet sizes (e.g., EUR, UK, and industrial standards) and varying weights. The system’s software is configured with the dimensions and weight of each pallet type, and the handling equipment is engineered with the appropriate capacity and adaptable grip mechanisms to safely and efficiently manage the variety, ensuring seamless operation.

2. What happens during a power outage? Are our goods trapped inside the Automated Pallet Retrieval System?

Safety and operational redundancy are paramount in the design of any robust Automated Pallet Retrieval System. These systems are equipped with backup power systems, often UPS (Uninterruptible Power Supply) units, that provide enough power to complete an active cycle and safely bring all equipment to a parked position. Manual retrieval options are also a standard part of the design, ensuring that a company can always access its inventory, even in the unlikely event of a complete system failure.

3. Our business has strong seasonal peaks. Can an Automated Pallet Retrieval System handle such volatile throughput demands?

Absolutely. This is one of the key strategic strengths of automation, particularly shuttle-based Automated Pallet Retrieval Systems. Unlike a manual workforce, which requires lengthy hiring and training of temporary staff, an Automated Pallet Retrieval System can operate at its maximum designed throughput 24/7 during peak seasons. The system’s sophisticated software efficiently manages the queue of orders, ensuring the organization can extract the maximum possible throughput when it is needed most, without the associated labor headaches and costs.

4. How long does it typically take to see a return on investment (ROI) after implementing an Automated Pallet Retrieval System?

The ROI period is influenced by several factors, including the scale of the Automated Pallet Retrieval System, local labor and real estate costs, and the nature of the operations. However, based on extensive global project data, most clients achieve a full ROI on their Automated Pallet Retrieval System within 2 to 4 years. In regions with high labor costs or extremely expensive industrial land, this period can be even shorter. A detailed, client-specific financial model is always a core component of a professional initial feasibility study.

5. We already have a WMS. Will we need to replace it to implement an Automated Pallet Retrieval System?

In the vast majority of cases, no. A key part of a professional implementation process is achieving seamless integration. The control software for a modern Automated Pallet Retrieval System is designed with open APIs and standard protocols to integrate with all major WMS and ERP platforms (like SAP, Oracle, Microsoft Dynamics). The WMS remains the “brain” for inventory management and order processing, sending high-level commands to the Automated Pallet Retrieval System, which then executes the physical storage and retrieval tasks with precision.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com