📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Strategic Convergence for Unbeatable Warehouse Performance

In the dynamic and rapidly evolving industrial landscapes of Africa and Latin America, logistics and warehouse managers face a daunting trifecta of challenges: explosive demand growth, severe spatial constraints, and intensifying pressure on operational margins. The traditional warehouse model, reliant on wide aisles and manual forklift operations, is fundamentally ill-equipped to meet these demands. It represents a significant bottleneck, consuming excessive real estate, capping throughput, and introducing costly errors and variability.

The solution is not merely to automate, but to automate with strategic intelligence. This is where the powerful, synergistic integration of Automated Storage and Retrieval Systems (ASRS) with Narrow Aisle Racking emerges as the definitive operational paradigm. This comprehensive guide, crafted from decades of field implementation, serves as a master blueprint for logistics leaders in Lagos, São Paulo, Johannesburg, and Mexico City. It delves beyond superficial specifications to reveal how the fusion of ASRS with narrow aisle racking creates a resilient, high-throughput, and supremely space-efficient storage cell.

We will explore the nuanced engineering behind this pairing, its unparalleled adaptability to local infrastructure realities, the compelling economic calculus for return on investment, and the critical implementation pathway from vision to reality. For any organization serious about transforming its warehouse from a cost center into a scalable, precise, and dominant competitive asset, mastering the application of ASRS with narrow aisle racking is the most critical decision on the horizon.

Part 1: The Unyielding Logistics Landscape of Growth Economies

Anatomy of a Pressure Cooker: Why Legacy Systems Are Failing

The warehouse operations across emerging markets are not merely busy; they are operating under transformative stress. In major distribution hubs from Accra to Bogotá, several irreversible macro-trends are converging. The digital revolution has permanently altered consumer behavior, creating an expectation for rapid, flawless delivery that strains manual picking and storage systems. Simultaneously, urban industrial land values have skyrocketed, making horizontal expansion a prohibitively expensive or simply impossible option. Compounding this, the labor market for skilled, reliable forklift operators—especially for challenging narrow aisle environments—is tight, leading to rising wages, high turnover, and operational inconsistency.

Furthermore, global supply chain volatility has underscored the non-negotiable need for perfect inventory visibility and accuracy. A single mis-shipment or stock-out can unravel customer relationships painstakingly built over years. In this context, the conventional warehouse, with its sprawling aisles and human-dependent processes, is a liability. It actively wastes the most valuable asset—space—while its productivity is capped by human endurance and skill.

The mandate for forward-thinking operations directors is unequivocal: achieve radical gains in storage density, slash order cycle times, and attain near-perfect inventory integrity, all while stabilizing and optimizing operational expenditure. Addressing this mandate requires moving beyond incremental improvements to a foundational re-engineering of the storage core, a task for which ASRS with narrow aisle racking is uniquely architected.

Defining “Smarter” Automation in Context

For markets in Africa and Latin America, “smarter” automation is a principle, not just a product label. It signifies solutions that are context-aware, robust, and scalable. It rejects the notion of importing overly complex, fragile systems designed for ideal conditions. Instead, smarter automation focuses on deploying resilient technology that delivers the highest impact on core metrics—specifically space utilization, throughput velocity, and operational accuracy—while being engineered to withstand local realities such as power fluctuations, varying technical expertise, and demanding duty cycles.

It is about augmenting human potential, displacing repetitive and strenuous physical labor with higher-value tasks in supervision, analytics, and exception management. This philosophy finds its ultimate expression in the combined deployment of ASRS with narrow aisle racking. While each technology is potent alone, their integration creates a cohesive, high-performance storage organism perfectly aligned with the growth trajectories and practical constraints of these vibrant regions.

Part 2: Core Synergy: The Technical Mastery of ASRS with Narrow Aisle Racking

The Density Engine: Re-engineering Space with Narrow Aisle Racking

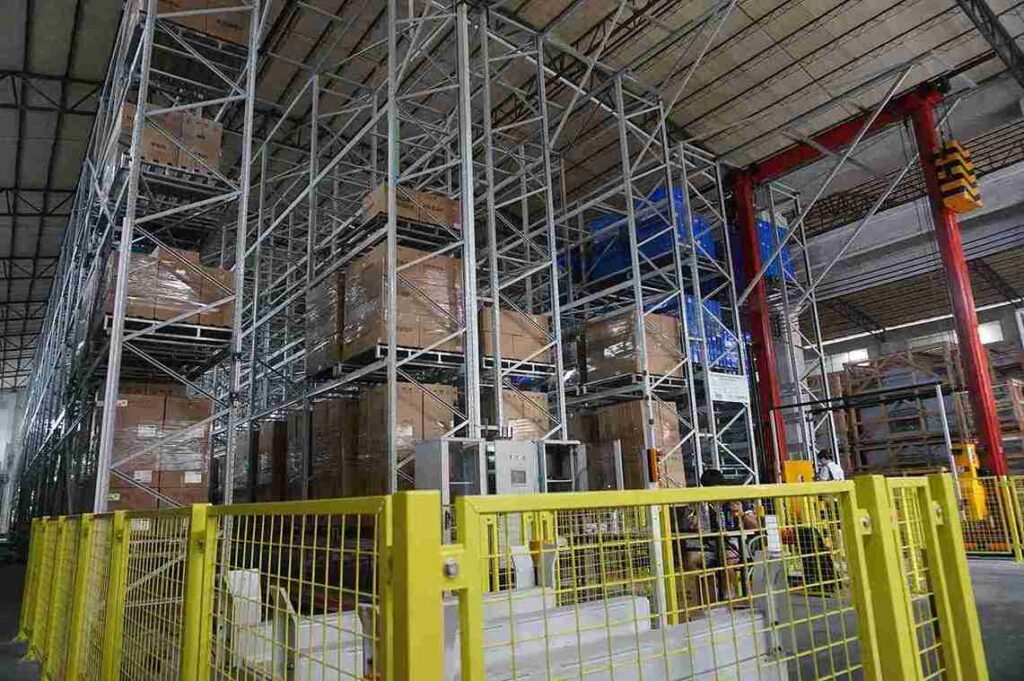

The foundation of this powerful synergy is the narrow aisle racking system. It is crucial to understand that this is not standard pallet racking installed with marginally less space between rows. It is a purpose-built, structural ecosystem engineered for precision. Aisles are typically reduced to 1.5 to 1.8 meters, compared to the 3.5+ meters required for a counterbalance forklift’s turning radius. This single change can yield a 40-50% increase in storage positions within the same building footprint—a transformative figure for a facility in a premium zone in Lima or Nairobi, effectively deferring massive capital outlays for expansion.

The integrity of a narrow aisle racking structure is paramount. It demands installation with exceptional precision, as tolerances are tight. The racking itself often features robust, closed profiles for superior stability at greater heights, safely supporting loads in aisles where traditional forklifts cannot maneuver. Historically, exploiting this density required specialized manned equipment like turret trucks or reach trucks, which introduced their own challenges: high operator skill requirements, ongoing training costs, and persistent safety risks in confined spaces. The logical, and smarter, evolution is to remove the human operator from the vehicle entirely and integrate the storage structure directly with an automated machine designed for this singular purpose. This evolution is the cornerstone of implementing ASRS with narrow aisle racking.

The Robotic Workhorse: The ASRS as the Unmanned Operator

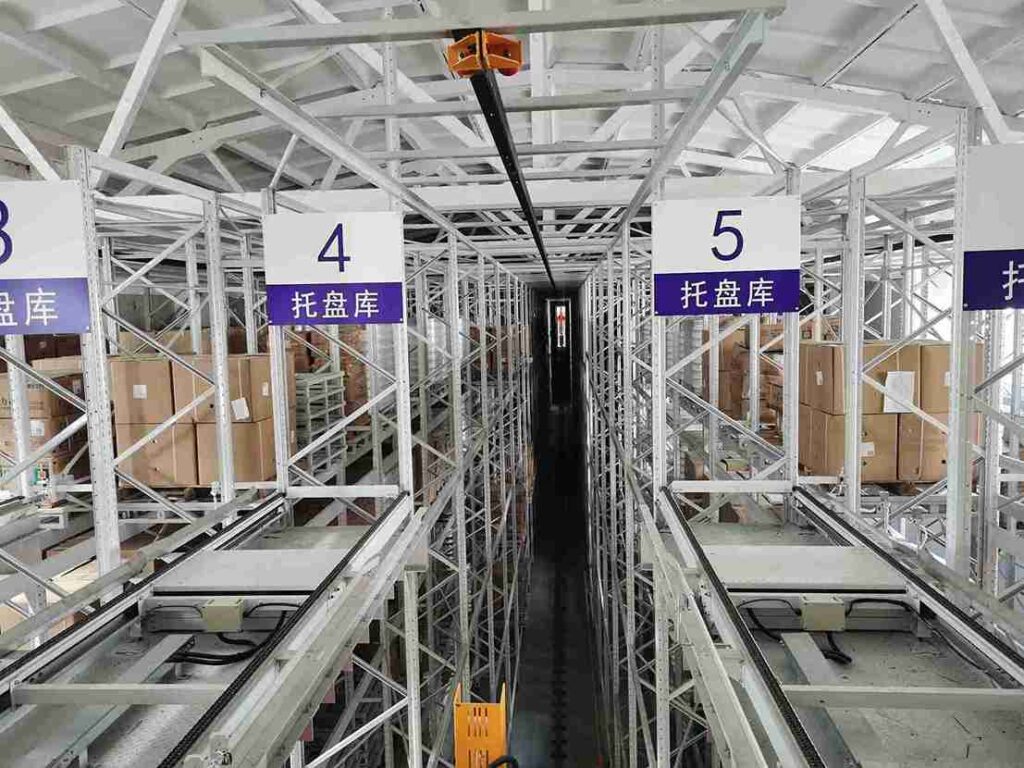

The Automated Storage and Retrieval System (ASRS) is the intelligent, automated actor that brings the dense storage structure to life. In the context of ASRS with narrow aisle racking, this typically manifests as a Unit Load ASRS—a robotic crane or shuttle system that operates on dedicated rails within the tight confines of the racking aisle. This machine is the tireless executor of all storage and retrieval commands.

The operational advantages conferred by integrating an ASRS with narrow aisle racking are profound and multi-dimensional:

Uninterrupted Operation: The system operates continuously across shifts, undeterred by breaks, shift changes, or absenteeism. It enables “lights-out” operation for certain processes, maximizing the utility of the capital asset.

Predictable, Optimized Throughput: An ASRS machine follows programmed, optimized acceleration and travel profiles. There is no variance from fatigue, caution, or inconsistency. This creates a reliable, calculable cycle time for every store and retrieve action, allowing for precise capacity planning.

Deterministic Accuracy: Governed by the Warehouse Management System (WMS) and guided by laser or barcode positioning, the ASRS within the narrow aisle racking retrieves the exact pallet from the exact location, every time. This eradicates mis-picks and the costly phantom inventory that haunts manual warehouses.

Inherent Safety: Removing manned vehicles from high-bay, dense storage aisles eliminates a major category of warehouse accidents. It also permits racking designs to extend safely to greater heights, as there is no need to accommodate an operator’s cabin at elevation.

Therefore, implementing ASRS with narrow aisle racking is not an exercise in placing a robot in a tight space. It is the creation of a unified, co-engineered storage cell. The narrow aisle racking is designed from the outset with the exact interface points, clearances, and load dynamics required by the specific ASRS model. The result is a high-density automated storage solution that performs with the relentless efficiency and precision of a machine, fully unlocking the spatial potential of the facility.

Part 3: Engineering for Reality: Tailoring ASRS with Narrow Aisle Racking for Regional Success

Proven Adaptations for Infrastructure and Environment

A primary concern for engineers in markets like Angola, Colombia, or Kenya is practical viability. Skepticism often arises: “Can such an advanced system as ASRS with narrow aisle racking function reliably here?” The answer, proven in countless installations, is a definitive yes—provided the system is conceived and engineered with these realities as core design parameters. A competent partner does not supply an off-the-shelf European solution; they engineer for resilience from the ground up.

Power Management Intelligence: Robust ASRS with narrow aisle racking systems incorporate sophisticated power handling. Features like regenerative drives that capture braking energy, ultra-capacitors to handle peak traversing loads, and seamless fail-over to backup generator systems are not optional extras but standard requirements. Electrical systems are hardened against voltage sags and surges common in developing grids.

Robust Control Architecture: While integrated with a central WMS, the ASRS machines themselves operate with a high degree of autonomous intelligence. They should execute sequences of tasks based on localized command batches, ensuring operations continue even during brief network interruptions. This decentralized control logic is critical for uptime.

Localized Support Ecosystem: Perhaps the most vital differentiator is the post-installation framework. Success hinges on establishing a network of locally based, trained technical partners for first-line response, supported by a strategically located regional spare parts hub (e.g., in South Africa for the SADC region, in Panama for Central America). Furthermore, system design prioritizes the use of standardized, globally available industrial components (ISO metric bearings, common PLCs, standard sensors) to avoid crippling dependencies on proprietary, long-lead parts.

The Compelling Financial Narrative: ROI in Focus

The business case for investing in ASRS with narrow aisle racking must be ironclad, particularly in regions where capital allocation is scrutinized. The Return on Investment (ROI) model is robust and extends far beyond simple labor savings.

Real Estate Monetization: The most impactful financial benefit. By storing up to 50% more goods in the same building, companies avoid the multi-million dollar expense of constructing or leasing additional space. In high-cost urban corridors, this benefit alone can justify the entire project.

Labor Productivity Transformation: The system reallocates human capital from repetitive, physically taxing roles to higher-value functions in system supervision, quality assurance, and process optimization. It reduces dependency on a scarce pool of certified narrow-aisle forklift operators, mitigating a significant operational risk and often improving workforce stability.

Working Capital Liberation: With inventory accuracy exceeding 99.99%, the requirement for safety stock can be dramatically reduced. For a facility holding millions of dollars in inventory, this can free substantial working capital—a crucial advantage in any market, but particularly valuable where cost of capital can be elevated.

Cost of Error Elimination: Quantifying the hard and soft costs of shipping errors, expedited freight charges for corrections, and lost customer trust provides a powerful component of the ROI model. The reliability of ASRS with narrow aisle racking directly safeguards revenue and brand reputation.

Developing a detailed, customized financial model is a critical first step. By inputting local data on space costs, labor rates, current error rates, and growth projections, the true payback period for ASRS with narrow aisle racking often proves to be remarkably short, frequently under three years for high-activity facilities.

Part 4: The Implementation Journey: From Vision to Operational Asset

Phase 1: Collaborative Design and Data-Driven Engineering

Deploying ASRS with narrow aisle racking is a consultative engineering partnership, not a transactional sale. It commences with a deep forensic analysis of the operation’s data: SKU cube and weight profiles, velocity analysis (ABC classification), inbound/outbound flow patterns, and future business projections. This intelligence directly dictates the custom engineering of the solution:

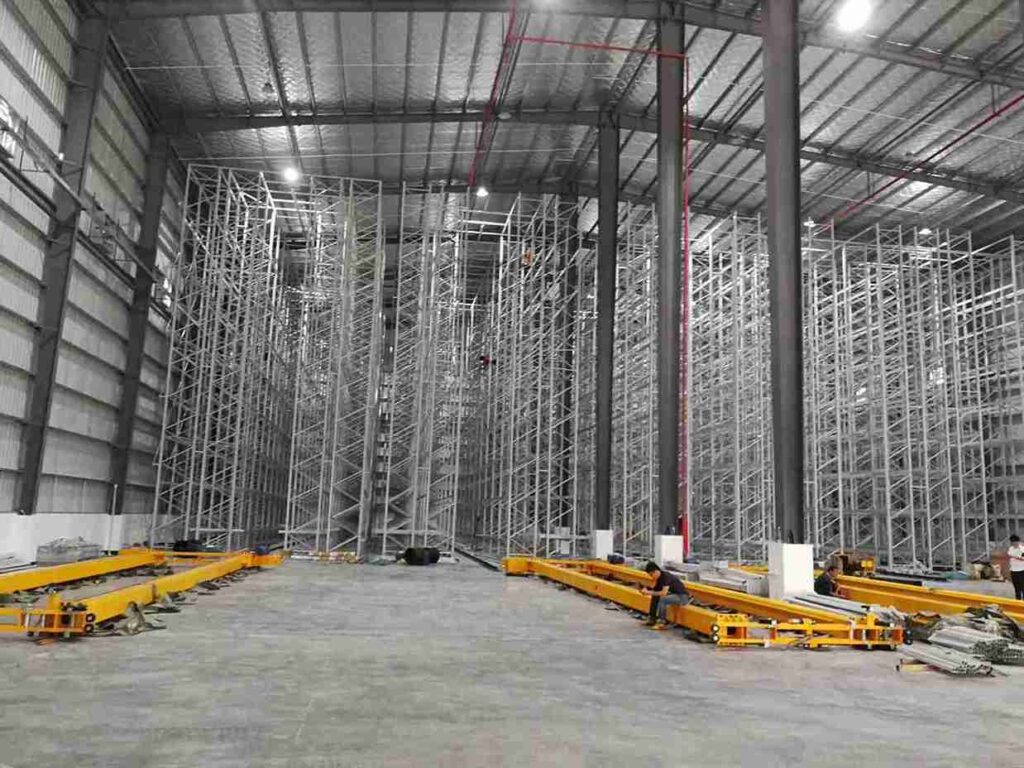

Racking Configuration & Seismic Design: Determining beam levels, bay depths, and overall system height, which must be optimized for the building’s clear height and comply with local seismic codes, which are particularly relevant in regions like Chile and parts of Central America. The racking for ASRS with narrow aisle racking must account for dynamic loads imposed by the moving machine.

ASRS Technology Selection: Choosing the optimal automated mechanism—single-mast crane, double-mast crane, or a satellite-based pallet shuttle system—based on required throughput (cycles per hour), building height, and load handling specifications. For end-to-end automation, this ASRS with narrow aisle racking cell can be seamlessly interfaced with Automated Guided Vehicles (AGVs) or Autonomous Mobile Robots (AMRs) for transport to packing stations, or with automated conveyor and sortation systems for parcel handling.

Software Integration Mastery: The Warehouse Management System (WMS) is the strategic brain, while the Warehouse Control System (WCS) is the tactical nervous system. Their seamless integration is non-negotiable. The WCS directly orchestrates the ASRS with narrow aisle racking, executing the WMS’s commands for put-away, retrieval, and inventory cycling with millisecond precision. This software layer also manages interfaces with any peripheral automation, creating a cohesive, intelligent material flow.

Phase 2: Phased Deployment and Organizational Change Management

A successful implementation respects the imperative of business continuity. A phased, disciplined approach minimizes risk and builds internal competency:

Site Preparation & Parallel Build: Civil and electrical site preparations are completed. The ASRS with narrow aisle racking structure is erected in a designated zone, often while existing manual operations continue nearby.

Pilot Migration & Stress Testing: A controlled subset of inventory, such as a specific high-turnover product line, is migrated into the new system. This period is used to validate all software interfaces, fine-tune operational workflows, and train super-users in a real-world but contained environment.

Full Cut-Over & Performance Ramp-Up: Following successful piloting, inventory migration proceeds systematically. Intensive, role-based training programs are conducted for operators, maintenance technicians, and system administrators, fostering internal ownership and expertise.

Phase 3: Lifecycle Performance and Continuous Optimization

The partnership extends for the decades-long lifespan of the system. To protect the investment and ensure sustained performance, a proactive lifecycle support program is essential. This includes remote system health monitoring (telematics), predictive maintenance alerts based on actual component usage, and scheduled preventative maintenance visits. This approach ensures the dramatic productivity gains achieved at commissioning are not only maintained but optimized over time, delivering an outstanding total cost of ownership (TCO).

Part 5: Advanced Configurations and Strategic Evolution

The platform of ASRS with narrow aisle racking is inherently versatile and future-proof. It serves as the foundational storage layer for more advanced logistics architectures:

Multi-Shuttle Systems for Case Handling: Within the dense framework of narrow aisle racking, multi-level shuttle systems can be deployed for high-speed handling of smaller totes or cases, ideal for e-commerce fulfillment centers serving Africa’s growing online retail sector or for pharmaceutical distribution in Latin America requiring high throughput and traceability.

The Engine for Goods-to-Person (G2P): The ASRS with narrow aisle racking acts as the high-density reserve, automatically delivering items to ergonomic, stationary pick stations. This can increase pick rates by 400-600% compared to traditional walking, a transformative advantage for order fulfillment operations.

The Intelligent Data Foundation: Every transaction within the ASRS with narrow aisle racking is a data point. This transforms the storage system into a powerful analytics engine, providing insights into inventory trends, optimizing replenishment, and offering complete audit trails for compliance—increasingly critical in regulated industries across these regions.

Conclusion: Forging a Durable Competitive Advantage

In the competitive arenas of Africa and Latin America, where growth and constraint exist side-by-side, operational excellence in logistics is a primary and defensible competitive advantage. The strategic decision to implement a smarter automation core based on ASRS with narrow aisle racking is an investment in building that advantage. It is a decisive move to lead on the critical metrics of cost-per-unit-handled, order accuracy, and scalable agility.

This journey necessitates a partner with profound technical expertise, deep regional understanding, and a commitment to long-term success. It requires a partner who views ASRS with narrow aisle racking not as a commodity, but as a customizable tool for solving your unique operational puzzle. For leaders who envision a warehouse that is not merely a repository, but a dynamic, responsive, and potent engine for market growth, the conversation begins with a detailed exploration of how ASRS with narrow aisle racking can be engineered for your specific success. The path to definitive market leadership is clear.

Frequently Asked Questions (FAQs)

1. How does the system handle pallets with overhanging loads or non-standard dimensions, which are common in our supply chain?

The design phase for ASRS with narrow aisle racking explicitly accounts for load dimensions. Clearances are engineered based on your specific pallet and load profiles. For non-standard situations, customizable adaptations are available, such as adjustable fork widths, specialized load-handling attachments, or designated storage lanes within the racking for oversize items. A detailed load audit is always the first step to ensure the system design accommodates your real-world inventory.

2. What is the typical energy consumption profile of an ASRS with narrow aisle racking system, and how can we mitigate this operational cost?

Modern ASRS with narrow aisle racking systems are designed for energy efficiency. Key features include regenerative drives that feed energy back into the system during deceleration, high-efficiency motors, and intelligent sleep modes during idle periods. A detailed energy consumption analysis can be provided during the project planning phase. Furthermore, the system’s ability to operate in darkness (no lighting required in the aisles) and the reduced need for climate control in a densely packed, unmanned storage area contribute to significant overall facility energy savings.

3. Can the system be expanded or reconfigured in the future if our business needs change?

A core principle of a well-designed ASRS with narrow aisle racking installation is modular scalability. The system can often be extended in length by adding additional racking bays and extending the crane rail. In some configurations, height can also be increased. Software is designed to accommodate such expansion. Reconfiguring storage lane depths or adjusting for new SKU profiles is also possible, though it requires careful planning. This inherent flexibility protects your long-term investment against business evolution.

4. What kind of fire protection and safety systems are integrated with such a high-density automated storage environment?

Safety is paramount. ASRS with narrow aisle racking installations adhere to stringent international and local safety codes. Integrated systems typically include: dedicated in-rack sprinkler systems designed for high-density storage hazards, early smoke detection apparatus (ESD) at the ceiling and within the racking, physical safety fences and light curtains at access points, and comprehensive emergency stop circuits. The automated nature of the system itself enhances safety by removing personnel from active storage aisles.

5. How does the system manage inventory cycle counting and reconcile physical stock with system records?

The ASRS with narrow aisle racking system revolutionizes inventory control. Cycle counting can be performed continuously and unobtrusively. The WMS can automatically schedule specific locations for verification during low-activity periods. The ASRS machine can retrieve pallets for visual inspection or barcode scanning at a dedicated station without disrupting main operations. The pinpoint accuracy of the system drastically reduces discrepancies, and the process of reconciling any variance is vastly accelerated due to the absolute certainty of location provided by the ASRS with narrow aisle racking control software.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com