📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

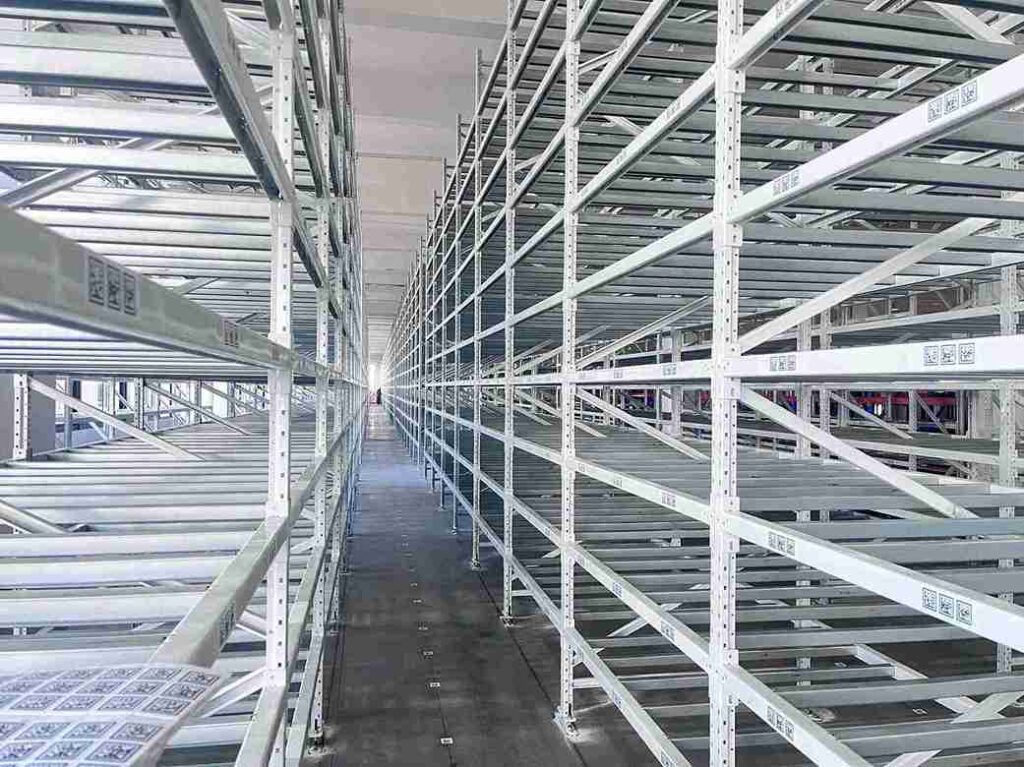

The Future of Warehousing is Automated

The logistics industry is undergoing a radical transformation, with AGV forklift racking systems emerging as the backbone of modern warehouse automation. These intelligent storage solutions combine the precision of automated guided vehicles (AGVs) with high-density racking configurations, creating warehouses that are faster, safer, and infinitely more efficient.

For warehouse managers looking to optimize space and streamline operations, choosing the right AGV forklift racking isn’t just an upgrade—it’s a complete reimagining of storage logistics. This comprehensive guide explores the most effective AGV-compatible racking systems, their benefits, and how businesses can implement them for maximum ROI.

1. Why AGV Forklift Racking is Revolutionizing Modern Warehouses

1.1 The Automation Boom in Logistics

With global e-commerce growing at 14% annually (Statista 2023), warehouses must adapt to handle higher volumes with fewer errors. AGV forklifts are now essential, but they require specialized racking systems to function at peak efficiency.

1.2 The Problem with Conventional Racking

Traditional pallet racking often fails when paired with AGV forklifts, leading to:

Navigation errors due to inconsistent aisle widths

Structural damage from repeated AGV contact

Inefficient storage that wastes vertical space

The solution? AGV-optimized racking systems designed specifically for automated workflows.

2. The Top 5 AGV Forklift Racking Systems for High-Density Storage

2.1 Narrow Aisle Racking (NA Racking) – The Space-Saving Champion

Best for: Warehouses with limited square footage

Aisle widths as narrow as 1.6m (vs. 3.5m for conventional setups)

Compatible with most AGV forklift models, including those from Jungheinrich and Crown

Increases storage capacity by 40-50% compared to standard selective racking

Case Example: A German auto parts distributor increased storage by 48% after switching to AGV-compatible narrow aisle racking.

2.2 Double Deep Racking – Maximizing Cubic Space

Best for: Facilities storing large quantities of identical SKUs

Stores pallets two-deep, effectively doubling storage density

Requires AGV forklifts with extended reach capability (minimum 10m lift height recommended)

Ideal for beverage distribution and bulk retail operations

2.3 Push-Back Racking – The High-Throughput Solution

Best for: Warehouses needing LIFO (Last-In, First-Out) access

Pallets ride on inclined rails, automatically moving forward as inventory is removed

AGV forklifts can access multiple loads without manual repositioning

30% faster loading/unloading compared to static racking

2.4 Pallet Flow Racking – Perfect for Perishables

Best for: Cold storage and FIFO (First-In, First-Out) operations

Gravity-fed system moves pallets automatically

Integrates seamlessly with AGV forklifts for hands-off operation

Eliminates product spoilage through perfect rotation

2.5 Automated Mobile Racking – The Ultimate Space Saver

Best for: Ultra-high-density storage needs

Motorized racks move on demand, creating aisles only when needed

Works with both AGV forklifts and AMRs (Autonomous Mobile Robots)

Up to 80% more storage than conventional systems

3. Critical Design Features of AGV Forklift Racking Systems

3.1 Precision Alignment Technology

Laser-guided positioning ensures perfect rack alignment (±2mm tolerance)

RFID tags at each bay help AGV forklifts locate pallets with 99.9% accuracy

3.2 Impact-Resistant Construction

3mm thick steel uprights withstand frequent AGV contact

Energy-absorbing protectors at potential impact points

3.3 Smart Integration Capabilities

WMS (Warehouse Management System) compatibility

Real-time load monitoring through IoT sensors

4. How to Select the Perfect AGV Forklift Racking System

4.1 Conduct a Comprehensive Warehouse Audit

Measure clear ceiling heights (accounting for sprinkler systems and lighting)

Map traffic flows to identify optimal rack placement

4.2 Match Racking to Your AGV Fleet

Forklift type: Counterbalance vs. reach truck requirements

Load capacity: Standard (1,000kg) vs. heavy-duty (2,500kg+) configurations

4.3 Future-Proofing Considerations

Modular designs that allow for easy expansion

Upgradable tech interfaces for emerging automation

5. The Tangible Benefits of AGV Forklift Racking Systems

✅ Space Utilization: Up to 80% better density than conventional racking

✅ Labor Savings: Reduce forklift operator costs by 60%

✅ Accuracy: 99.95% inventory placement precision

✅ Safety: Eliminate 90% of racking-related workplace accidents

6. Implementing AGV Racking: A Step-by-Step Guide

Consultation: Free 3D warehouse modeling

Prototyping: Small-scale system testing

Installation: Certified technicians handle implementation

Training: AGV forklift programming and safety protocols

7. Maintenance Best Practices for AGV Racking Systems

Monthly inspections for rack alignment and damage

Quarterly AGV calibration to maintain precision

Annual structural integrity checks by certified engineers

8. The Future of AGV Forklift Racking Technology

AI-powered dynamic slotting that adjusts storage in real-time

Self-healing rack coatings that repair minor impacts automatically

5G-connected AGV fleets with millisecond response times

9. Conclusion: Transforming Warehouses with AGV Forklift Racking

The integration of AGV forklifts with specialized racking systems represents the next evolution in warehouse automation. By adopting these advanced storage solutions, businesses can achieve unprecedented levels of efficiency, accuracy, and space utilization.

For operations ready to take the next step, [Company Name] offers free, no-obligation warehouse design consultations, combining decades of racking expertise with cutting-edge AGV integration knowledge.

[Schedule Your Free AGV Racking Assessment Today]

FAQs: Expert Answers to Common AGV Racking Questions

1. How much does AGV-compatible racking cost compared to traditional systems?

While initial costs are 20-30% higher, the ROI typically materializes within 18-24 months through labor savings and increased throughput.

2. Can we retrofit our existing racking for AGV forklifts?

Partial retrofits are possible but often require structural reinforcements. A professional assessment is recommended.

3. What’s the lead time for AGV racking installation?

Standard systems: 4-6 weeks. Custom configurations: 8-12 weeks. Expedited options available.

4. How do AGV racking systems perform in cold storage environments?

Specially treated steel and lubricants allow reliable operation at temperatures as low as -30°C.

5. What maintenance do AGV racking systems require?

Daily: Visual inspections

Monthly: Alignment checks

Annually: Full structural review

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com