📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Optimizing Industrial Storage: The Strategic Imperative of Heavy-Duty Adjustable Pallet Racking

In the fast-paced industrial corridors of Southeast Asia and the Middle East, operational leaders face a relentless equation: storage space is finite, but inventory and throughput demands are not. The bridge between these competing realities is a system whose importance is often underestimated—the heavy-duty adjustable pallet racking system. Far more than passive steel shelving, this engineered framework is the foundational grid upon which warehouse efficiency, safety, and scalability are built.

This definitive resource delves beyond product specifications, providing a masterclass in leveraging adjustable pallet racking as a dynamic tool to achieve unparalleled storage density and drive down long-term operational costs. It addresses region-specific challenges, explores advanced high-density configurations, and outlines a rigorous procurement framework, empowering decision-makers to transform their storage infrastructure into a competitive asset.

The Engineered Backbone of Modern Warehousing

For any facility storing palletized goods, the choice of storage system is a primary strategic decision. Adjustable pallet racking represents the industry standard for a compelling reason: it offers an optimal balance of accessibility, density, and flexibility. Its design, comprising upright frames and load beams, creates a three-dimensional storage matrix that can be precisely tuned to the size and weight of the load unit.

The “adjustable” nature of this racking system is its core strength; beam levels can be reconfigured in minutes without tools to accommodate changing pallet heights or to optimize vertical space utilization as inventory profiles evolve. This inherent adaptability makes adjustable pallet racking a future-proof investment in regions characterized by rapid market shifts and business growth.

However, not all adjustable pallet racking is conceived for the demands of heavy industrial use. The designation “heavy-duty” signifies a product engineered for higher load capacities, greater impact resistance, and longer service life. It involves thicker steel gauges, robust connection designs, and often, enhanced protective finishes. Selecting a heavy-duty adjustable pallet racking system is a commitment to operational resilience, minimizing the risk of costly downtime or safety incidents while maximizing the return on every square meter of floor space.

Decoding the Components: What Defines a Superior System

Understanding the anatomy of adjustable pallet racking is crucial for informed specification. A high-performance system is the sum of its meticulously engineered parts.

Upright Frames: The Vertical Load-Bearing Pillars

Upright frames form the vertical backbone. Their design dictates the system’s overall stability and capacity.

Steel Grade and Thickness: Premium adjustable pallet racking utilizes high-tensile, hot-rolled steel (e.g., S355JR). The column’s gauge—often varying within the same frame for optimized strength-to-weight ratio—must be specified based on height and load requirements.

Footplate and Anchoring: A large, reinforced footplate ensures stable load transfer to the concrete floor. The anchoring system—typically mechanical expansion bolts or chemical anchors—must be specified to withstand both vertical and seismic or impact-induced lateral forces, a critical consideration for racking in volatile regions.

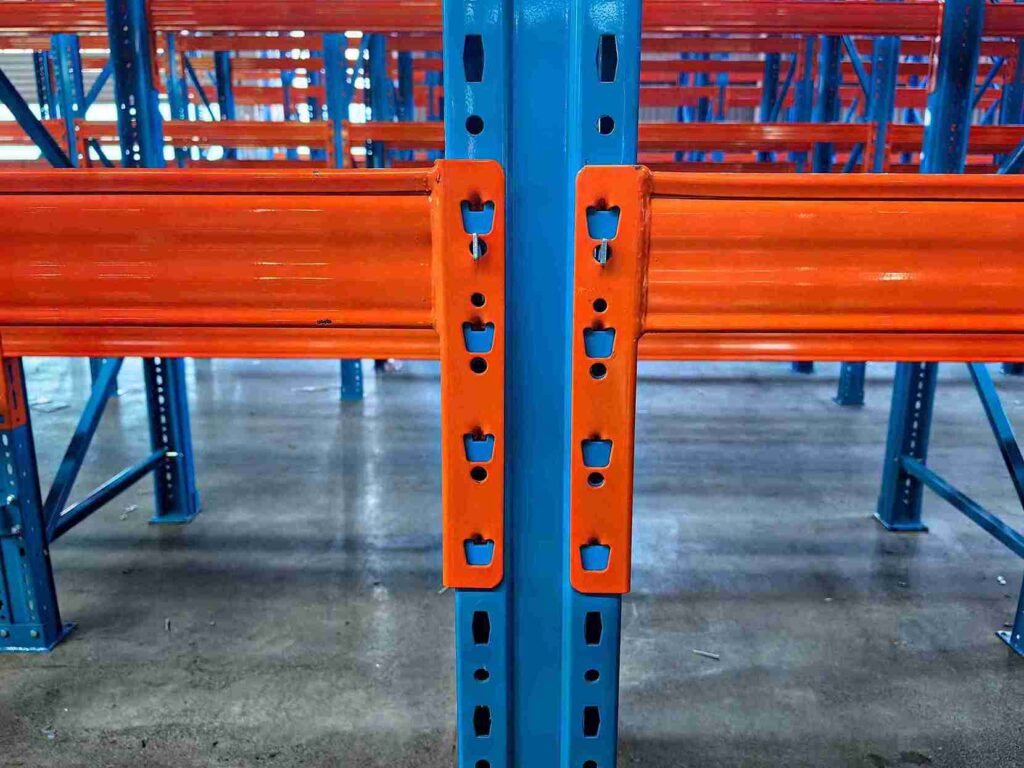

Connector Hole Pattern: The patented teardrop or oval holes allow for secure beam connection and easy height adjustment. The consistency and precision of this punching directly affect installation speed and long-term reliability.

Load Beams: The Critical Horizontal Support

Beams directly carry the palletized loads. Their integrity is non-negotiable.

Beam Profile: Heavy-duty adjustable pallet racking typically employs closed tubular or box beams. This design offers superior torsional stiffness and resistance to forklift impact compared to open-step beams, essential for maintaining alignment in high-traffic environments.

Safety Lock Mechanism: A positive, mechanical locking device—often a welded or bolt-on safety clip—is mandatory. This feature prevents beams from becoming accidentally dislodged by forklift contact, a fundamental safety requirement in any pallet racking installation.

Essential Accessories for Enhanced Function and Safety

Accessories transform a basic adjustable pallet racking structure into a tailored, high-performance system.

Wire Mesh Decking: Provides a secure surface for storing smaller items or unstable loads, improves fire safety by limiting sprinkler obstruction, and enhances worker safety.

Column Guards and Post Protectors: Installed at the base of uprights in high-risk traffic aisles, these absorb kinetic energy from impacts, protecting the structural integrity of the racking system. This is a cost-effective form of insurance.

Row Spacers and Braces: Ensure consistent aisle widths and provide essential lateral stability, especially for taller systems or those in seismically active zones. The configuration of bracing is a key part of the structural engineering for any adjustable pallet racking layout.

Confronting Regional Operational Realities

A heavy-duty adjustable pallet racking system designed for a temperate climate will underperform—and potentially fail—in the demanding environments of Southeast Asia and the Middle East. Proactive engineering is required.

Combating Corrosion in Humid and Coastal Climates

The combination of high humidity, seasonal monsoons, and coastal salt spray presents a relentless assault on steel. A standard powder coat is insufficient. For long-term asset protection, a heavy-duty adjustable pallet racking system destined for such environments should specify hot-dip galvanizing (HDG). The process involves submerging fabricated components in molten zinc, creating a metallurgical bond that provides sacrificial protection even if scratched. For less aggressive indoor environments, a robust alternative is pre-galvanized steel with a supplementary polyester powder coating. This dual-layer defense is critical for the longevity of adjustable pallet racking in countries like Vietnam, Indonesia, or the UAE.

Engineering for Seismic and Wind Loads

Geological activity in parts of Indonesia, the Philippines, and Iran, alongside high wind loads in certain Gulf regions, necessitates specialized design. Standard adjustable pallet racking is not inherently seismic-resistant. Seismic-rated racking involves:

Increased brace density and capacity.

Moment-resistant connections that can handle dynamic forces.

Strict adherence to local building codes and international standards like FEM 10.2.08.

A rigorous anchoring plan, often requiring pull-out testing. Specifying this level of engineering for adjustable pallet racking is a non-negotiable aspect of risk management.

Adapting to Variable Infrastructure and Labor Practices

Warehouse floor flatness can be inconsistent, and forklift operator training standards may vary. A robust adjustable pallet racking strategy accounts for this:

Floor Tolerance and Shimming: Laser-leveled installation and the use of steel shims ensure uprights are perfectly plumb, preventing dangerous pre-load stresses.

Aisle Width Optimization: While narrow aisles maximize density, they require precision driving. Design must balance storage goals with realistic operational skill levels, sometimes opting for slightly wider aisles to reduce collision risk and improve throughput.

Clear and Durable Labeling: Load capacity signs, bay identification, and directional markings must be prominent and durable, serving as constant guides for operational staff interacting with the pallet racking system.

Advanced Configurations: Maximizing Cubic Space Utilization

While selective adjustable pallet racking (single-deep storage) offers 100% accessibility, achieving maximum density often requires more sophisticated configurations built upon the same adjustable principle.

Double-Deep Racking: A Significant Density Increase

This system stores pallets two-deep on each side of an aisle, utilizing deep-reach forklifts. It effectively eliminates every other aisle, increasing storage density by 40-50% compared to selective adjustable pallet racking. It is ideal for bulk storage of medium-slow moving SKUs with good inventory rotation discipline.

Push-Back Racking: Dynamic Storage for High-Throughput

Push-back racking, a derivative of the adjustable pallet racking family, stores pallets 2-5 deep on inclined rails on each side of an aisle. It operates on a Last-In, First-Out (LIFO) basis within each lane, offering excellent density with good selectivity. This makes it a premier choice for adjustable pallet racking solutions in beverage, FMCG, or cooler storage environments where space is at a premium.

The Role in Supporting Automation and Mezzanines

Modern adjustable pallet racking is rarely an island. It is the critical infrastructure for automation:

AGV/AMR Integration: Automated vehicles require millimeter-precision for pallet pickup and deposit. The racking must be installed with exceptional accuracy—perfectly plumb, level, and dimensionally consistent.

Mezzanine Floors: The upright frames of a heavy-duty adjustable pallet racking system can be designed to structurally support a mezzanine deck, creating a second operational level and effectively doubling the usable footprint within the same building envelope.

The Procurement Blueprint: A Methodical Approach to Investment

Acquiring a heavy-duty adjustable pallet racking system is a capital project requiring due diligence. A structured process mitigates risk and ensures optimal outcomes.

Phase 1: Comprehensive Discovery and Data Audit

Success begins with data. Before any layout is drawn, information must be gathered:

Pallet Data: Dimensions, type, condition, and maximum loaded weight and dimensions.

Inventory Analysis: SKU velocity (ABC classification), seasonality, and growth projections.

Facility Constraints: Detailed building drawings with column locations, door clearances, sprinkler head positions, and clear ceiling height.

Equipment Audit: Specifications of all material handling equipment (forklifts, reach trucks).

Phase 2: Conceptual Design and Simulation

Using advanced warehouse design software, engineers create multiple adjustable pallet racking layout options. These are not just drawings; they are data models that can be simulated to test throughput, identify potential bottlenecks, and provide a quantifiable comparison of different racking configurations and their impact on operational metrics.

Phase 3: Detailed Engineering and Load Notices

This technical phase transforms a concept into a safe, executable plan. It produces:

Detailed Layouts and Bills of Material: Every component is specified.

Structural Calculations and Load Application & Racking Configuration (LARC) Notices: Each upright frame is analyzed for its specific load. A LARC notice, which must be permanently displayed, provides operators with unambiguous instructions on the allowable pallet configuration and weight for each bay. This is the cornerstone of safe adjustable pallet racking operation.

Phase 4: Professional Installation and Commissioning

Precision installation is paramount. Certified crews use laser levels and calibrated torque wrenches to ensure the adjustable pallet racking system is erected according to engineered drawings. The final step is a formal commissioning and handover, including all safety documentation and as-built drawings.

Sustaining Performance: The Imperative of Inspection and Maintenance

A heavy-duty adjustable pallet racking system is a dynamic asset that experiences daily stress. A proactive maintenance regime is essential to preserve its safety and functionality.

Establishing a Rigorous Inspection Schedule

Inspections should be tiered:

Operator Visual Checks: Forklift drivers should be trained to report any visible damage immediately.

Formal Inspections: Conducted quarterly or annually by a “competent person,” following a checklist that includes measuring column deflection, checking for beam engagement, and inspecting for damage or corrosion. All findings related to the adjustable pallet racking must be documented and acted upon.

Implementing a Damage Protocol and Repair Standard

A clear process must be in place for when damage to the adjustable pallet racking is identified. This includes immediate quarantine of the affected bay, assessment by a qualified engineer, and repair using manufacturer-approved parts and methods. Never allow unapproved modifications or makeshift repairs to a heavy-duty adjustable pallet racking system.

Conclusion: Building a Foundation for Scalable Efficiency

In the competitive landscapes of emerging global markets, warehouse infrastructure is a key determinant of supply chain agility and cost efficiency. Heavy-duty adjustable pallet racking is not a commodity purchase but a strategic, long-term investment in operational capacity. Its value is unlocked not just through the quality of its components, but through a holistic process encompassing meticulous planning, region-aware engineering, professional implementation, and diligent stewardship.

The journey to maximize storage density and minimize costs is a continuous one. It begins with selecting a heavy-duty adjustable pallet racking system engineered for the specific challenges of your region and operational profile. It is sustained through a partnership with providers who offer not just products, but engineering expertise, reliable installation, and ongoing support. By viewing adjustable pallet racking as the adaptable, robust, and intelligent backbone of the warehouse, businesses can construct a storage environment that is not merely a cost center, but a driver of resilience, growth, and competitive advantage.

(Article includes an audio transcription of critical safety inspection guidelines for warehouse managers.)

Frequently Asked Questions (FAQs)

1. What is the typical design life expectancy of a premium heavy-duty adjustable pallet racking system, and what factors most influence its longevity?

A properly specified, installed, and maintained heavy-duty adjustable pallet racking system can have a design life exceeding 25 years. The primary factors influencing longevity are: the corrosion protection system (hot-dip galvanizing dramatically extends life in harsh environments), the operational discipline in avoiding forklift impacts, the adherence to posted load capacities to prevent metal fatigue, and the quality of the initial installation and anchoring. Regular professional inspections are the single most effective practice for ensuring the adjustable pallet racking system reaches its full potential lifespan.

2. How does the procurement process for adjustable pallet racking differ from other warehouse equipment, and why is a “design-bid” model often risky?

Procuring adjustable pallet racking is more akin to a structural engineering project than buying equipment. The system must be custom-designed for the specific loads, building, and equipment. A traditional “design-bid” model, where detailed drawings are created and then sent for competing bids, is risky because it separates engineering responsibility from supply. Subtle changes in component sourcing or manufacturing tolerances by the low bidder can compromise the entire design’s integrity. An integrated “design-supply-install” model from a single responsible provider ensures accountability for the performance and safety of the entire pallet racking system.

3. Can existing adjustable pallet racking be safely reconfigured for a different use, such as supporting smaller carton flow systems or different pallet sizes?

Yes, one of the core advantages of adjustable pallet racking is its reconfigurability. Beams can be relocated to new heights to accommodate different load units. However, any reconfiguration must be preceded by a re-evaluation of the structural capacity. Adding beam levels for lighter loads is generally feasible, but significant changes to load distribution or the introduction of dynamic loads (like flow rails) require review by an engineer. The updated configuration must be documented in new Load Application notices posted on the racking.

4. What are the critical questions to ask a potential supplier when evaluating their heavy-duty adjustable pallet racking offering for a demanding application?

Beyond price, key questions include:

“Can you provide third-party certification of your beam and upright load capacities (e.g., from a recognized lab)?”

“What is your standard and optional corrosion protection process for my specific climate?”

“Do you provide detailed, project-specific engineering drawings and LARC notices, and are they sealed by a qualified engineer?”

“What is your installation methodology, and do you use your own certified crews or subcontractors?”

“What is your process for conducting a post-installation inspection and providing the as-built documentation for our adjustable pallet racking system?”

5. In a multi-level distribution center, how should the specification of adjustable pallet racking vary between bulk reserve storage and active picking areas?

The adjustable pallet racking specification should be task-appropriate. In bulk reserve areas (often high-bay), the focus is on maximizing cubic density and supporting very high uniform loads. Here, heavy-duty adjustable pallet racking with high capacity uprights and box beams is essential. In active pick zones, accessibility and speed are paramount. The racking may be configured for smaller, faster-moving units. While still robust, beam levels may be more numerous and lower capacity. Integration with pick modules, wire decking, and safety netting is more common in these zones, all of which must be factored into the design of the adjustable pallet racking structure from the outset.

If you require perfect CAD drawings and quotes for warehouse racking, please contact us. We can provide you with free warehouse racking planning and design services and quotes. Our email address is: jili@geelyracks.com