📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The Definitive Guide to Adjustable Mezzanine Racking: Engineering Warehouse Agility for Dynamic Markets

In the fast-paced world of global logistics and manufacturing, stagnation is not an option. The ability to pivot, scale, and optimize operations in real-time separates industry leaders from the rest. For warehouses and distribution centers across Southeast Asia, the Middle East, Africa, and Latin America, the greatest challenge is no longer just finding space—it’s creating intelligent, adaptable space. Enter the transformative power of adjustable mezzanine racking.

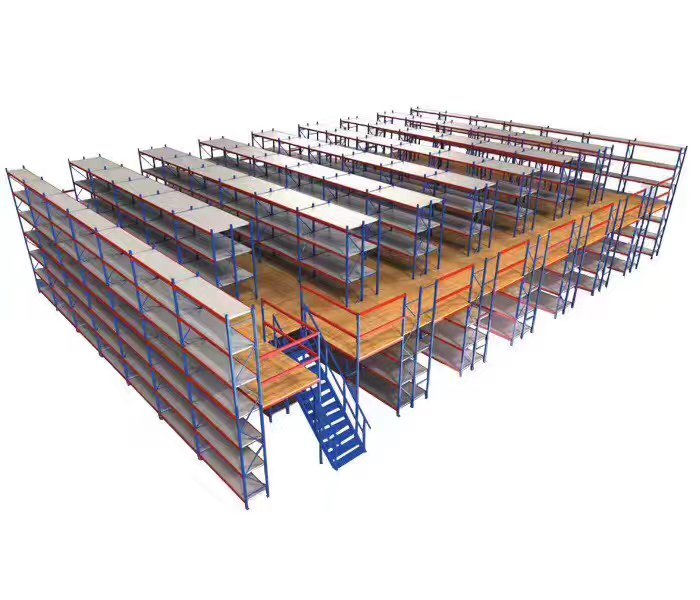

This is not merely a storage product; it is a comprehensive, strategic approach to volumetric space utilization. An adjustable mezzanine racking system is a multi-level structural platform, engineered with inherent flexibility, designed to evolve alongside a business. It empowers operations to seamlessly adapt to changing SKUs fast, reconfigure layouts with minimal downtime, and future-proof their most valuable asset: their facility’s cubic airspace. This definitive guide explores how investing in a sophisticated adjustable mezzanine racking solution is the most impactful decision a company can make to build a resilient, efficient, and supremely agile operation.

H2: The Inflexibility Trap: How Static Storage Stifles Growth and Profitability

Many operations managers confront daily bottlenecks without realizing the root cause lies in their fundamental storage infrastructure. Traditional, fixed storage solutions create a cascade of inefficiencies that silently erode the bottom line. The core failure is an inability to dynamically respond to market demands.

H3: The Crippling Cost of Wasted Vertical Airspace

Look upward in any warehouse plagued by clutter and congestion. The vast volume of air between the top of the highest shelf and the ceiling represents a colossal, pre-paid asset lying dormant. Static shelving and single-level layouts are inherently two-dimensional, forcing an operation to expand outwards, often necessitating costly relocations or construction. This inefficient cube utilization is a direct tax on profitability. A well-engineered adjustable mezzanine racking system directly attacks this problem by creating a fully functional second or even third level, effectively doubling or tripling the operational floor area without pouring a single square foot of new concrete.

H3: Labor Drain and Productivity Loss in Constant Reconfiguration

Every product line change, seasonal shift, or market pivot becomes a logistical nightmare with fixed storage. The labor hours required to dismantle shelving, relocate inventory, and retrain staff on new pick paths are immense. This operational rigidity means skilled workers spend their time on unproductive tasks instead of value-added activities. The fundamental design of adjustable mezzanine racking is to mitigate this drain. By allowing for the modular reconfiguration of decking, shelving, and access points, these systems enable swift adaptations, keeping the workforce focused and productive.

H2: Deconstructing the Solution: The Core Components of Advanced Adjustable Mezzanine Racking

Understanding what makes adjustable mezzanine racking “adjustable” is key to appreciating its value. It is a system built on the principles of modular engineering, structural integrity, and long-term adaptability.

H3: The Structural Backbone: Engineered for Strength and Flexibility

The foundation of any superior system is its frame. High-grade, hot-rolled structural steel forms the primary columns and beams. Unlike basic bolt-together kits, professional-grade adjustable mezzanine racking is designed with future reconfiguration in mind. The connection points, beam lengths, and column designs are standardized to allow for lateral expansion, height adjustments, and the integration of various accessories. This robust skeleton is non-negotiable for safety and forms the platform upon which all flexibility is built.

H3: The Heart of Adaptability: The Adjustable Decking and Support System

This is where the concept of a flexible mezzanine floor comes to life. The decking—the actual working surface—is not a permanent, poured concrete slab. Instead, it typically consists of:

Rolled Steel Decking: This corrugated steel sheeting rests on supporting beams that can be repositioned at various heights along the mezzanine’s primary structure. This allows for fine-tuning the clearance between deck levels or creating varying ceiling heights for different applications.

Modular Grid Systems with Open Grid Decking or Solid Plate: A matrix of primary and secondary beams allows for decking panels to be easily removed, swapped, or relocated. This is critical for creating new access points for vertical lifts, conveyor pass-throughs, or stairwells without compromising the structure’s integrity. This modularity is the defining feature of best-in-class adjustable mezzanine racking.

H3: Integrated Access, Safety, and Material Flow

Agility must never come at the expense of safety. A truly adaptable adjustable mezzanine racking design incorporates relocatable and modular safety components:

Modular Staircases and Gates: Staircases and safety gates are designed as self-contained units that can be unbolted and moved to new optimal locations as the mezzanine’s layout evolves.

Pallet Gates and Vertical Lifts: For handling unit loads on the upper level, heavy-duty, bolt-on pallet gates and Vertical Reciprocating Conveyors (VRCs) can be repositioned to align with changing workflow patterns on the floor below.

Mezzanine Guard Railing and Toe-Kicks: Perimeter protection is integral and designed to be unbolted and reconfigured as the decking layout changes, ensuring continuous safety compliance.

H2: The Automation Synergy: Integrating Adjustable Mezzanine Racking with Smart Warehousing

The true potential of adjustable mezzanine racking is fully unlocked when it ceases to be an isolated structure and becomes the physical platform for a broader warehouse automation ecosystem.

H3: Creating Multi-Tiered AGV and AMR Workflows

Autonomous Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) can be programmed to operate seamlessly within a multi-level environment facilitated by adjustable mezzanine racking. By strategically positioning lifts or lightweight ramps, these robots can transport goods to and from the mezzanine level autonomously. This transforms the adjustable mezzanine racking structure into an active, automated storage and retrieval zone that functions 24/7, fully integrated with the ground-level workflow.

H3: Optimizing Conveyor, Sortation, and Pick-to-Light Systems

Automated conveyor equipment and sortation systems can be routed directly to and from the mezzanine level. The platform can serve as a high-density pick module, a buffering zone, or a consolidation area. The inherent flexibility of the adjustable mezzanine racking deck means that if the conveyor line needs to be extended or rerouted, the decking above can be modified to accommodate the change. This prevents a complete and costly system overhaul and exemplifies the ability to adapt to changing SKUs fast from a systemic perspective.

H2: Strategic Global Applications: Where Adjustable Mezzanine Racking Delivers Maximum ROI

The versatility of modern adjustable mezzanine racking means it provides immense value across a wide spectrum of industries and operational functions, particularly in high-growth emerging markets.

H3: The High-Density, Multi-SKU Storage Archive for Bulk Goods

For businesses with vast and fluctuating inventories, such as import/export distributors, the adjustable mezzanine racking system becomes a dynamic storage archive. Slower-moving items can be stored efficiently on the upper levels, accessed by order pickers, while fast-movers remain on the ground floor. The adjustability allows managers to re-categorize and re-slot this storage dynamically as product demand cycles change, a common scenario in the diverse markets of Southeast Asia and Latin America.

H3: The Dynamic E-Commerce and Omni-Channel Fulfillment Center

E-commerce is the ultimate test of warehouse agility. An adjustable mezzanine racking system can be configured as a high-density, multi-level pick module. As best-selling SKUs change seasonally—a constant reality for online retailers—the entire layout of the pick modules, including shelving, lighting, and pick paths, can be rapidly reconfigured. This maintains optimal pick rates and accuracy, directly impacting customer satisfaction and operational margins. This is the ultimate embodiment of a system built to adapt to changing SKUs fast.

H3: Scalable Production, Kitting, and Light Assembly Platforms

In manufacturing facilities, an adjustable mezzanine racking platform can host light assembly lines, kitting operations, or quality control stations. This frees up valuable floor space for heavier machinery or raw material storage. As production lines are redesigned for new products, the adjustable mezzanine racking platform can be adapted to suit the new workflow without disrupting core operations below, a critical advantage for the rapidly industrializing sectors in Africa and the Middle East.

H2: Deploying Agile Storage in Growth Markets: The Global Standard of Adjustable Mezzanine Racking

Experience across diverse global landscapes has proven that the need for operational agility is universal. However, local conditions in emerging economies demand specific considerations that a flexible system is uniquely suited to address.

H3: Navigating Variable Building Standards and Infrastructural Challenges

In many growth markets, warehouse construction standards can be inconsistent. A rigid, ultra-heavy-duty storage system might be unsuitable for some older or lightly constructed buildings. The modular and distributable load nature of a professionally engineered adjustable mezzanine racking system can be designed to spread loads effectively, making it a safer and more viable option for a wider range of existing structures, a common challenge in many urban centers in Africa and Southeast Asia.

H3: Future-Proofing Investments Against Rapid and Unpredictable Scaling

Businesses in these regions often experience non-linear, explosive growth. Investing in a fixed storage system is a significant gamble. Adjustable mezzanine racking allows a company to start with a core structure and expand it laterally, vertically, or reconfigure it internally as storage needs skyrocket. This strategic approach protects capital investment and ensures seamless operational continuity during periods of intense change, providing a critical competitive edge.

H2: The Partner Difference: Expertise in Engineering and Lifecycle Support

Selecting and implementing a high-performance adjustable mezzanine racking system is a strategic decision that hinges on more than just product quality. It requires deep technical expertise and a partnership mindset.

H3: The Non-Negotiable First Step: Professional Site Analysis and Load Calculation

The “adjustable” nature of the system must be grounded in rigorous, site-specific engineering. The process must begin with a comprehensive analysis of existing floor load capacity, seismic considerations (where applicable), intended usage, and future growth projections. The design of the adjustable mezzanine racking is not a generic blueprint but a custom-engineered plan that ensures safety, compliance with local building and safety codes, and optimal performance for decades.

H3: Lifecycle Support, Reconfiguration Services, and Ongoing Optimization

A true partner provides support that extends far beyond installation. This includes offering ongoing consultancy, providing additional components, and executing reconfiguration services as the client’s business evolves. This long-term relationship ensures that the adjustable mezzanine racking system continues to function as a primary tool for operational agility and efficiency throughout its entire lifecycle, maximizing the return on investment.

Conclusion: From Static Storage to Dynamic Competitive Advantage

The central question for modern warehouse and operations managers has shifted. It is no longer about if you need to maximize space, but how you can do so in a way that embeds resilience and agility directly into your operational DNA. The era of the static, one-dimensional warehouse is conclusively over. By embracing the engineered flexibility of advanced adjustable mezzanine racking, a company makes a definitive strategic leap. It transitions from being a passive occupant of space to an active master of its volumetric potential.

This investment delivers a powerful, three-dimensional tool that empowers businesses to adapt to changing SKUs fast, integrate seamlessly with the future of automation, and scale with confidence in any global market. Ultimately, adjustable mezzanine racking is an investment that stores far more than goods; it stores potential—the potential for uninhibited growth, for superior efficiency, and for a future where the warehouse itself becomes a company’s most dynamic and adaptable competitive advantage.

Frequently Asked Questions (FAQs)

1. What is the typical lead time for the reconfiguration of an existing adjustable mezzanine racking system?

Lead times vary based on the complexity and scale of the reconfiguration. However, a significant advantage of a properly designed adjustable mezzanine racking system is that modifications like relocating a section of decking and shelving can often be completed by a professional crew in a matter of days, not weeks. This minimizes operational downtime to a fraction of what would be required for a fixed structure overhaul.

2. Our warehouse has a relatively low ceiling. Is adjustable mezzanine racking still a viable option for us?

Absolutely. While creating a full second level is common, an adjustable mezzanine racking system can be highly effective in spaces with ceilings as low as 4.5 to 5 meters. It can be designed as a single, elevated platform for specific functions like office space, packaging lines, or storing smaller, high-value items, still making excellent and efficient use of the vertical cube that would otherwise be wasted.

3. What are the typical weight capacities, and can these systems support integrated pallet racking?

Load capacities are always custom-engineered based on a professional site assessment. Industrial-grade adjustable mezzanine racking systems can typically handle uniform loads ranging from 300 kg/sqm to over 1,500 kg/sqm for heavier applications. Yes, they are specifically engineered to support integrated adjustable pallet racking on the upper level, creating a robust, high-density, multi-tiered storage solution.

4. How is fire safety and sprinkler system integration handled for a multi-level mezzanine structure?

This is a critical, non-negotiable part of the professional design process. A qualified installer will always conduct a review that includes fire safety compliance. The adjustable mezzanine racking design must integrate with the building’s existing sprinkler system, which typically requires extending sprinkler heads to the underside of the mezzanine deck and, depending on the platform’s size and use, installing a new, code-compliant sprinkler grid on the mezzanine level itself.

5. We have an uneven warehouse floor. Can an adjustable mezzanine racking system be installed safely?

Yes, it can. While a level floor is ideal, professional-grade adjustable mezzanine racking systems are engineered to compensate for minor floor irregularities through the use of adjustable base plates and shims. For more significant slopes, a custom structural solution would be designed during the engineering phase to ensure the entire structure is level, plumb, and stable, guaranteeing long-term safety and performance.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com