📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Strategic Integration of Mezzanine Racking for Automotive Parts: A Guide to High-Density Storage Optimization

In the high-stakes, fast-paced world of automotive manufacturing and distribution, efficient storage is not a passive activity—it is a critical component of the supply chain that directly impacts production lines, order fulfillment rates, and overall profitability. The unique storage challenges presented by mezzanine racking for automotive parts demand a specialized, engineered solution.

This comprehensive resource delves deep into the strategic application of mezzanine racking for automotive parts storage, moving beyond basic concepts to explore the engineering principles, layout configurations, and operational workflows that make it an indispensable asset for warehouses storing everything from bulky bumper fascias and delicate electronic control units to heavy engine blocks and extensive wiring harnesses.

The focus is squarely on creating a high-density, highly accessible, and utterly safe storage environment specifically tailored for the automotive industry’s demands. For any logistics manager or operations director overseeing mezzanine racking for automotive parts, this guide provides the granular detail necessary to specify, implement, and optimize a system that delivers decades of reliable performance.

Understanding the Automotive Parts Storage Challenge

The storage profile of automotive components is uniquely complex, characterized by an extreme variance in size, weight, and handling requirements. A facility might simultaneously manage small, high-value sensors and expansive, fragile windshields. This diversity makes conventional shelving or single-level pallet racking profoundly inefficient.

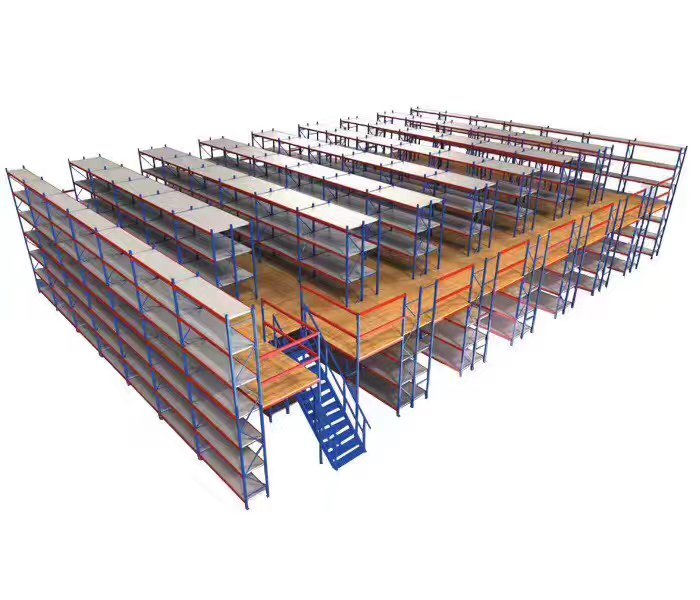

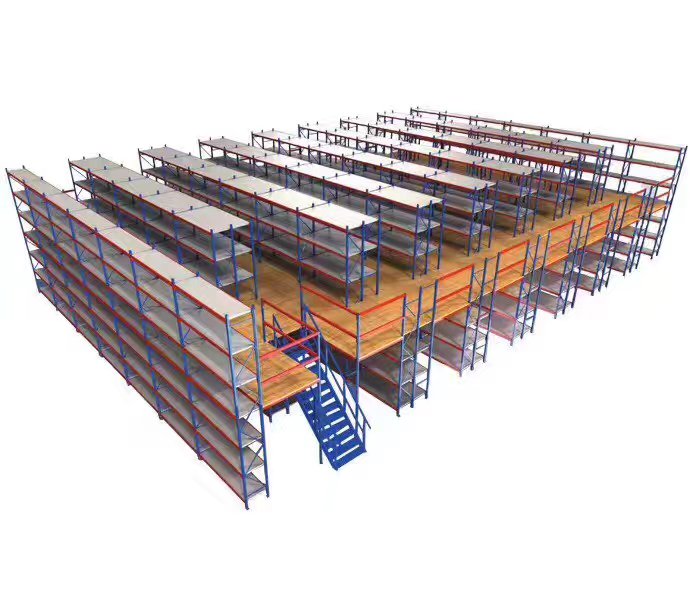

The primary challenge is volumetric: maximizing the use of the warehouse’s vertical cube without sacrificing selectivity or throughput. This is precisely where the concept of mezzanine racking for automotive parts demonstrates its profound value. By effectively creating a second or even third level within the existing building envelope, a mezzanine racking for automotive parts system doubles or triples the available floor space without the exorbitant cost of constructing a new facility.

The key to success, however, lies in a system engineered not as a generic platform, but as a structure purpose-built for the specific load dynamics and material handling flows inherent to the automotive sector. Every decision, from the steel gauge to the decking type, must be made with the unique profile of mezzanine racking for automotive parts in mind.

The Engineered Anatomy of a Automotive-Grade Mezzanine Racking System

A robust mezzanine racking for automotive parts is more than a raised platform; it is a fully integrated structural system. Understanding its core components is essential for specifying a solution that guarantees safety and longevity.

Primary Support Structure: Upright Frames and Beams

The foundation of any mezzanine racking for automotive parts system is its primary support structure, which typically consists of heavy-duty selective pallet racking. The upright frames for the lower level must be engineered to bear not only the direct pallet loads but also the cumulative dead load of the entire mezzanine structure and its live inventory. For a mezzanine racking for automotive parts application, these frames are often constructed from 7-gauge or thicker steel, with reinforced column profiles to resist impact and sustain heavy point loads. The load beams that form the base of the mezzanine deck must have capacities that far exceed standard requirements, as they become the primary support for the working level above.

The Mezzanine Deck: Choices for Performance and Safety

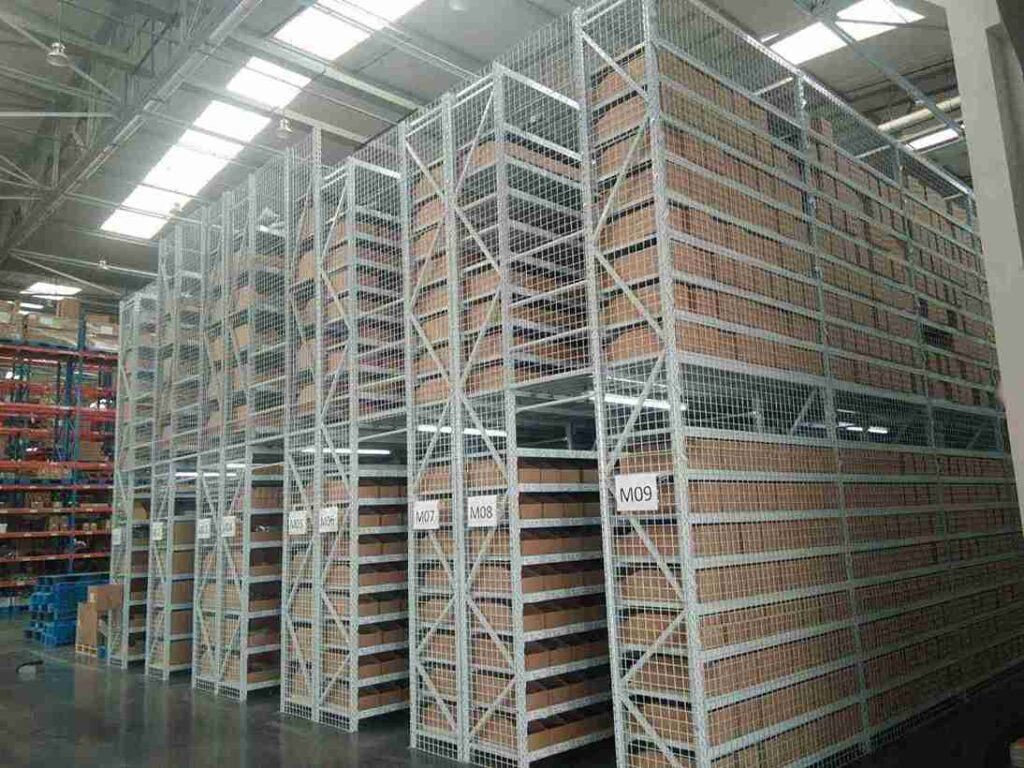

The decking material chosen for a mezzanine racking for automotive parts installation is a critical safety and operational decision.

Heavy-Gauge Pressed Steel Decking: This is the premier choice for most mezzanine racking for automotive parts applications. It provides a solid, unwavering surface that can support the concentrated loads of pallet jacks or even light-duty forklifts. Its solid surface contains spills and prevents small parts from falling through, a significant consideration when storing small automotive components like bolts or electrical connectors.

Bar Grating: In areas where dust/debris management, ventilation, or light penetration is desired, bar grating is a viable alternative. However, for a mezzanine racking for automotive parts system storing small items, supplementary containment measures are often necessary.

Plywood or Particle Board: While sometimes used for light-duty office mezzanines, these materials are generally unsuitable for the demanding environment of mezzanine racking for automotive parts due to their susceptibility to wear, moisture damage, and lack of fire resistance.

Optimizing Layouts for Automotive Parts Workflow

The physical configuration of a mezzanine racking for automotive parts system must reflect the inventory velocity and picking strategies of the operation. A one-size-fits-all layout is a recipe for inefficiency.

High-Velocity Picking Module Configuration

For fast-moving components—filters, spark plugs, fluids—the mezzanine racking for automotive parts should be configured as a high-density picking module. The lower level utilizes carton flow lanes or static shelving for the fastest-moving SKUs, while the mezzanine level houses palletized reserve storage. Integrating a gravity-fed replenishment system from the mezzanine level down to the pick faces on the ground floor creates a seamless, efficient flow that minimizes labor and walking time. This specific application of mezzanine racking for automotive parts turns vertical space into a dynamic tool for accelerating order fulfillment.

Bulky and Oversized Parts Storage Strategy

Storing large, bulky items like bumper assemblies, doors, or exhaust systems requires a different approach. The mezzanine racking for automotive parts system for these components must feature wider bays, heavier beam capacities, and often, a cantilever racking system integrated onto the mezzanine level itself. This allows for the storage of long, awkwardly shaped items without the obstruction of front-column uprights. The structural design for this type of mezzanine racking for automotive parts must be meticulously calculated by a professional engineer to account for the significant moment loads and uneven weight distribution.

Material Handling Integration: The Lifeblood of the System

A mezzanine racking for automotive parts structure is inert without an efficient means of moving goods to and from the elevated levels. The choice of vertical transport is a cornerstone of the system’s design.

Conveyor Systems for Automated Throughput

In high-volume distribution centers, integrating a conveyor system with the mezzanine racking for automotive parts is a game-changer. Pallet lifts or vertical reciprocating conveyors (VRCs) can automatically transport full pallets to the mezzanine for put-away, while belt or roller conveyors can move case-level picks to and from the upper level. This level of automation transforms the mezzanine racking for automotive parts from a static storage area into a fully integrated, high-throughput element of the material handling system, drastically reducing manual labor and potential for injury.

Stair and Gate Access for Manual Operations

For facilities where manual picking on the mezzanine level is required, safe and compliant access is non-negotiable. Industrial-grade staircases with integrated landings must be provided. Safety gates at the top of all mezzanine access points are a mandatory safety feature to prevent falls. The placement of these stairs and gates within the layout of the mezzanine racking for automotive parts must be planned to optimize pick paths and avoid creating traffic bottlenecks.

Load Capacity and Safety: The Non-Negotiable Fundamentals

There is no room for compromise on the structural integrity of a mezzanine racking for automotive parts system. The consequences of failure are catastrophic.

Calculating Combined Live and Dead Loads

The engineering for a mezzanine racking for automotive parts system must account for a complex combination of loads. The dead load includes the weight of the structure itself—the beams, decking, and stairways. The live load encompasses the weight of the stored inventory, personnel, and any material handling equipment on the deck. For a typical mezzanine racking for automotive parts application, the designed live load often starts at 150 PSF (pounds per square foot) and can exceed 300 PSF for areas storing heavy engine or transmission assemblies. These calculations must be certified by a professional structural engineer.

Seismic and Vibration Considerations

In geographically active regions, or in facilities with heavy machinery that induces vibration, the mezzanine racking for automotive parts design must include specific seismic bracing and damping elements. The natural frequency of the structure must be analyzed to prevent harmonic amplification during an seismic event. This level of detailed engineering is what separates a generic platform from a truly resilient mezzanine racking for automotive parts system designed for a demanding industrial environment.

The Future-Proof Automotive Warehouse

Investing in a mezzanine racking for automotive parts system is a long-term strategic decision. The design must incorporate flexibility to adapt to future changes in product mix or operational technology.

Designing for Scalability and Reconfiguration

The best mezzanine racking for automotive parts systems are designed with modularity in mind. As storage needs evolve, the system should be capable of being reconfigured, expanded, or even relocated without requiring a complete tear-down and rebuild. This involves using standardized, commercially available components and a design that allows for the addition of more mezzanine levels or the extension of the deck area.

Laying the Groundwork for Automation (AGVs/AMRs)

Forward-thinking operations are already planning for increased automation. When specifying a mezzanine racking for automotive parts system today, considerations for future Automated Guided Vehicles (AGVs) or Autonomous Mobile Robots (AMRs) should be included. This can involve ensuring the lower level has clear, wide aisles for robot navigation, or that the structural design can support the eventual integration of a robotic pallet shuttle system on the mezzanine level itself. This foresight in planning a mezzanine racking for automotive parts system protects the capital investment and ensures the warehouse remains competitive for years to come.

Conclusion: Elevating Storage to a Strategic Advantage

The implementation of a well-conceived mezzanine racking for automotive parts system is one of the most impactful investments an automotive logistics facility can make. It transforms underutilized vertical air space into highly productive, organized, and safe storage real estate. By focusing on engineered integrity, workflow-optimized layouts, and seamless material handling integration, a mezzanine racking for automotive parts system ceases to be a mere storage platform and becomes a dynamic, profit-driving engine for the entire operation. It is the definitive solution for managing the vast and varied part universe of the modern automotive industry, ensuring that every component, from the smallest screw to the largest panel, is stored securely and available instantly.

Frequently Asked Questions (FAQs)

1. What is the typical weight capacity range for a mezzanine racking system designed for automotive parts?

The capacity is highly custom, but a robust mezzanine racking for automotive parts system is typically engineered for live loads ranging from 150 PSF to over 300 PSF. The specific capacity is determined by the stored components—a area for lightweight trim pieces will differ from one storing cast iron engine blocks. A professional load analysis is mandatory.

2. Can a mezzanine racking system be installed over existing production or assembly areas?

Yes, this is a common application. A mezzanine racking for automotive parts can be constructed over low-clearance areas like kitting zones, packaging lines, or quality control stations. The design must incorporate stringent safety measures like perimeter guarding, fire protection, and debris containment to protect the operations below.

3. How does the cost of a structural mezzanine compare to a rack-supported mezzanine for automotive parts storage?

A rack-supported mezzanine racking for automotive parts system, where the storage racking itself is the primary support, is generally more cost-effective and offers superior storage density for pure warehouse applications. A structural mezzanine, built with independent columns and beams, is used when the space below is needed for wide-open floor space, not storage. For dedicated storage, the rack-supported mezzanine racking for automotive parts is typically the preferred and more economical choice.

4. What fire protection measures are required for a large mezzanine racking system storing automotive parts?

Local building codes dictate requirements, but large mezzanine racking for automotive parts installations often require integration with the building’s sprinkler system, with sprinkler heads installed both above and below the mezzanine deck. Additional measures can include fire-rated decking and clearly marked, protected emergency egress routes.

5. Are there specific lighting considerations for a mezzanine level used for picking small automotive components?

Absolutely. Adequate, shadow-free lighting is crucial for accuracy and safety. The lighting plan for a mezzanine racking for automotive parts system should include dedicated LED fixtures mounted at the mezzanine level to ensure light is directed onto the pick faces, as overhead building lighting will be obstructed by the deck and the upper levels of racking.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com