📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

Maximize Your Warehouse Storage Without Expansion: The Definitive Guide to Mezzanine Racking for Warehouses

The universal challenge confronting warehouse managers and logistics directors from Mexico to Malaysia, from Dubai to Durban, is a relentless pressure to do more within the same four walls. Supply chains demand greater throughput, product portfolios diversify into thousands of SKUs, and the physical footprint of the warehouse remains a fixed, constricting barrier. The conventional reflex—to construct an addition or lease additional space—is often a capitulation to exorbitant costs, protracted timelines, and operational fragmentation. However, a paradigm shift is redefining warehouse optimization, moving from a horizontal mindset to a vertical strategy.

The solution lies not in expanding outwards, but in building upwards, into the vast, untapped vertical airspace that exists in virtually every storage facility. This comprehensive guide delves into the engineering, economics, and strategic implementation of mezzanine racking for warehouses, the single most effective method to maximize warehouse storage capacity without a single brick being laid for expansion. It explores how this transformative approach can double usable floor area, streamline workflows, and deliver an unparalleled return on investment, solidifying its status as a cornerstone of modern warehouse storage systems.

The Vertical Imperative: Unlocking the Cubic Potential of Your Warehouse

Traditional warehouse management has often been guilty of two-dimensional thinking, focusing solely on length and width while ignoring the critical third dimension: height. Modern logistics facilities, particularly those constructed in the last two to three decades, are engineered with substantial clear heights, frequently ranging from 8 to 12 meters or more. The space between the top of the highest storage unit and the ceiling roof deck represents a massive, underutilized asset—a veritable goldmine of potential storage volume. This is the core problem that mezzanine racking for warehouses is designed to solve.

It is a systematic approach to capitalizing on this cubic potential, transforming empty air into high-value, functional space. For rapidly industrializing regions across Southeast Asia, Africa, and Latin America, where speed-to-market and capital efficiency are paramount, mastering this vertical imperative is a critical competitive advantage. The strategic deployment of a warehouse mezzanine floor allows businesses to scale operations dynamically, accommodating growth precisely where it occurs.

<h3>The Multifunctional DNA of Modern Mezzanine Solutions</h3>

While the term mezzanine racking for warehouses inherently suggests a storage function, its application spectrum is remarkably broad. This inherent versatility is what elevates it from a simple storage product to a core operational strategy. A well-planned system does more than just store goods; it rearchitects the entire workflow.

Strategic Inventory Stratification: A highly effective application involves using the mezzanine level to house slow-moving inventory, seasonal items, or raw material buffer stocks. This liberates the precious ground-floor space for high-velocity picking, value-added services, and shipping operations, dramatically reducing picker travel time and accelerating order cycle times.

Integrated Production and Assembly Platforms: The elevated deck provides an ideal, segregated environment for light manufacturing, product kitting, custom assembly, or packaging lines. By moving these processes off the main floor, a warehouse mezzanine floor reduces congestion, minimizes cross-contamination of workflows, and enhances overall safety and supervision.

Administrative and Supervisory Oversight: In many industrial parks in emerging markets, the cost and convenience of constructing separate office spaces are prohibitive. A mezzanine racking for warehouses solution can incorporate secure, enclosed office spaces, control rooms, or quality assurance labs that offer a direct, panoramic view of the warehouse floor, fostering better management and real-time oversight.

Secure and Controlled Access Areas: The platform can be easily configured with full-perimeter caging and secure access gates to create a highly protected enclosure for high-value goods, sensitive documents, or controlled substances, seamlessly integrating security into the storage matrix.

<h2>The Structural Blueprint: Deconstructing Mezzanine Racking Systems</h2>

The efficacy, safety, and longevity of any mezzanine racking for warehouses installation are rooted in its structural engineering. A one-size-fits-all approach is a recipe for failure. Therefore, a deep understanding of the different system typologies is essential for selecting the optimal solution for a specific warehouse environment and operational requirement.

<h3>Structural Shelving Mezzanines: The Engine of High-Density Storage</h3>

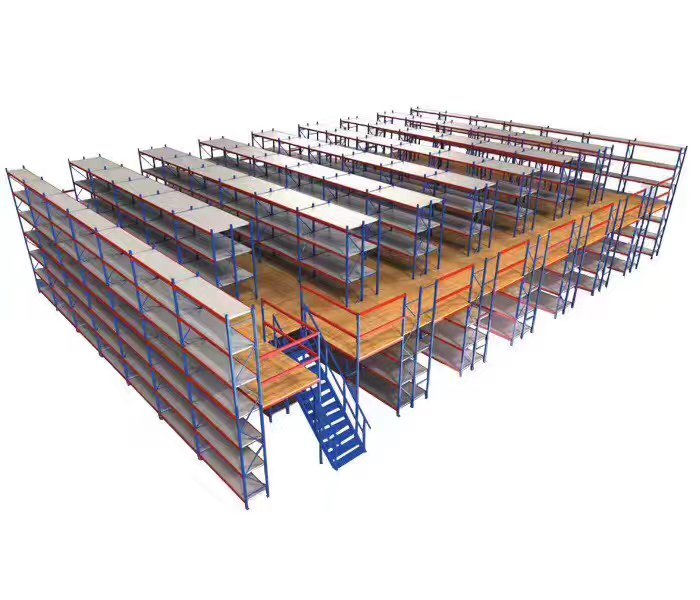

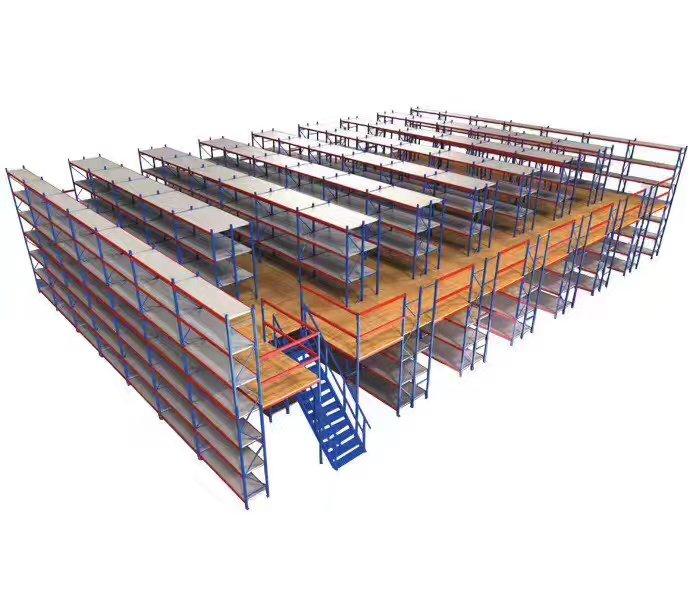

This configuration represents the pinnacle of integrated storage density. In a structural shelving mezzanine, the shelving or pallet racking itself is not merely placed beneath the structure; it is engineered to be the primary load-bearing support for the deck above. This creates a seamless, ultra-efficient storage continuum from the warehouse floor to the overhead platform.

Engineering Principle: Heavy-duty steel uprights and beams, designed for far greater loads than standard shelving, are assembled into a rigid grid. This grid supports the primary and secondary beams upon which the decking surface is laid. The result is a unified structure where the storage system and the mezzanine are one and the same.

Operational Ideal: This type of mezzanine racking for warehouses is the undisputed champion for creating ultra-high-density storage zones for bulk items, palletized goods, and components. It is designed to handle significant distributed and concentrated loads, often exceeding 1,500 kg/m², making it a workhorse for industrial storage.

Critical Design Insight: While shelving levels are adjustable, the overall layout is more permanent than a free-standing system. Consequently, the initial planning phase—mapping out future needs for load, access, and workflow—is absolutely critical for a successful structural shelving mezzanine project.

<h3>Free-Standing Mezzanines: The Paradigm of Layout Flexibility</h3>

A free-standing mezzanine is an entirely self-supporting structural entity. Its independent framework of columns, beams, and bracing does not rely on any other storage equipment, granting unparalleled freedom for the use of the space both on the deck and, just as importantly, on the ground floor beneath it.

Engineering Principle: The system is built around robust upright columns that transfer the load directly to the warehouse slab. Horizontal beams and often diagonal cross-bracing provide stability, forming a rigid box structure that is completely self-reliant. The deck is then installed atop this independent frame.

Operational Ideal: This is the go-to solution for multi-purpose applications that transcend pure storage. When the requirement is for office space, employee break rooms, production lines, maintenance areas, or even showroom floors, the free-standing mezzanine is the optimal choice. It allows for clear, unobstructed space underneath, perfect for wide aisles for forklifts or AGVs, receiving docks, or staging areas.

Critical Design Insight: The columns of a free-standing mezzanine will occupy some floor space, which must be factored into the operational planning. However, the strategic benefit of having a completely flexible ground floor layout almost always outweighs this minor spatial concession.

<h3>Catwalks, Stairs, and Lifts: The Circulatory System of the Mezzanine</h3>

An elevated platform is inert without safe, efficient, and appropriately scaled access. The design of the access systems is not an afterthought; it is a fundamental component that dictates the flow of personnel and materials, directly impacting productivity and safety compliance.

Industrial Staircases: These are the primary conduit for personnel. Best practices mandate wide treads, anti-slip surfaces, and intermediate landings for every 1.2 to 1.5 meters of vertical rise to prevent fatigue and ensure safety. The placement of staircases is strategic, designed to integrate with natural traffic patterns.

Full-Perimeter Safety Systems: Compliance with OSHA, ISO, and other local safety standards is non-negotiable. This includes robust handrails, mid-rails, and toe-kicks around the entire deck edge. Self-closing safety gates are installed at all staircase and lift access openings.

Material Handling Lifts and Vertical Conveyors: For the movement of pallets, carts, or totes between levels, a dedicated material lift is indispensable. These can range from simple hydraulic scissor lifts to fully automated systems that integrate with automated conveyor systems and AGV pathways. This integration is what transforms a static mezzanine racking for warehouses into a dynamic component of an automated storage and retrieval system (ASRS/ASRS), enabling seamless material flow across multiple vertical levels.

<h2>The Investment Thesis: A Rigorous Financial Analysis of Mezzanine Racking</h2>

The decision to proceed with a mezzanine racking for warehouses project must be underpinned by a compelling and rigorous financial rationale. The return on investment (ROI) is not merely a calculation; it is a demonstration of strategic capital allocation.

<h3>A Comparative Cost Analysis: Mezzanine vs. Physical Expansion</h3>

The financial disparity between adding a mezzanine level and constructing a new building is not merely significant; it is often decisive. The cost structures of the two approaches are fundamentally different.

The Cost Profile of Mezzanine Racking for Warehouses: This investment is primarily confined to the cost of manufactured materials (structural steel, decking), professional engineering, and installation labor. It is a concentrated capital expenditure within an existing asset. There are no costs for land, site preparation, foundational concrete, or new roofing.

The Cost Profile of New Construction: This path is laden with extensive, variable costs: land acquisition, architectural and civil engineering fees, site works, utilities extension, and the construction of the building envelope itself. The timeline is long, and soft costs accumulate over a period of 12 to 24 months.

The Inescapable Conclusion: In a vast majority of cases, the cost per square meter of usable space gained through mezzanine racking for warehouses is 40% to 60% lower than the cost of acquiring and developing new greenfield or expansion space.

<h3>Quantifying the Tangible and Intangible Returns</h3>

The ROI of a warehouse mezzanine floor extends far beyond the simple metric of added square meters. It generates a cascade of operational efficiencies that compound over the system’s lifetime.

Direct Capacity Multiplication: The most immediate benefit is the creation of a second or third operational level. A single-tier mezzanine racking for warehouses system can typically increase storage capacity by 80% to 100%, effectively doubling the functional area of the facility.

Labor Productivity Enhancements: By enabling process segmentation—such as dedicating the mezzanine to bulk storage and the ground floor to order fulfillment—travel time for warehouse personnel is drastically reduced. Documented case studies frequently show a 15% to 30% improvement in picking and put-away productivity post-installation.

Operational Consolidation and Cost Avoidance: Companies can avoid the significant ongoing expenses of managing a separate satellite warehouse, including duplicate rental, utilities, security, and management overhead. Consolidating into a single, vertically expanded facility simplifies logistics and reduces inter-site transportation costs.

Enhanced Capital Agility: The capital preserved by opting for mezzanine racking for warehouses over new construction can be strategically redeployed into revenue-generating activities such as market expansion, technology upgrades, or inventory investment, providing a significant boost to the company’s overall financial health and competitive positioning.

<h2>The Anatomy of a Flawless Installation: Critical Design and Planning Parameters</h2>

The successful implementation of a mezzanine racking for warehouses system is a meticulous process of engineering and planning. It is a custom-tailored solution, not an off-the-shelf commodity. Overlooking key parameters can compromise the entire investment.

<h3>Load Capacity Engineering and Decking Selection</h3>

Accurate load calculation is the non-negotiable foundation of the design. Engineers must account for both uniformly distributed loads (UDL) across the entire deck and critical point loads (CPL) imposed by pallet racking legs or heavy machinery.

Light-Duty Applications (150-400 kg/m²): Suitable for document archives, light retail parts, or office environments. Decking options typically include 38mm resin-coated particle board or light-duty steel bar grating.

Medium-Duty Applications (400-800 kg/m²): The standard for most storage applications, including manual pallet handling and bulk storage of medium-weight items. Decking often consists of 6-gauge or 4-gauge heavy-duty steel bar grating or laminated hardwood.

Heavy-Duty Applications (800+ kg/m²): Engineered for supporting active pallet racking systems on the deck and for use with powered industrial trucks. This requires the strongest decking solutions, such as 10-gauge or 12-gauge steel plate or ultra-heavy-duty grating, and is a hallmark of a robust structural shelving mezzanine.

<h3>Navigating the Regulatory Landscape: Codes, Permits, and Compliance</h3>

This is the stage where professional expertise proves its worth. A mezzanine racking for warehouses is a structural modification and is subject to a web of local building codes, fire safety regulations, and occupational health standards.

Building Permits and Structural Seals: Virtually all municipal authorities require a building permit for the installation. Reputable providers of mezzanine racking for warehouses will supply a full set of engineer-stamped structural drawings and calculations for submission to the local building department.

Seismic and Wind Load Considerations: In geographically active regions like parts of Central Asia, the Caribbean, and the Pacific Rim, the structural design must incorporate specific dynamic load calculations and specialized bracing to withstand seismic events or high wind loads, a critical aspect of the engineering for mezzanine racking for warehouses in these zones.

Comprehensive Fire Safety Integration: Building codes universally require that the mezzanine deck be protected by the warehouse’s fire sprinkler system. This necessitates extending sprinkler lines and heads to provide adequate coverage above and below the deck. Egress plans, defining the number, width, and location of staircases, must be meticulously planned to meet life-safety requirements.

<h2>The Future-Proof Warehouse: Integrating Mezzanine Racking with Automation</h2>

To remain competitive, a warehouse must be more than just a storage shed; it must be a dynamic, responsive logistics hub. A mezzanine racking for warehouses system, when conceived as part of an integrated automation strategy, becomes a powerful platform for technological advancement.

<h3>Seamless Interfacing with AGVs and Automated Forklifts</h3>

The challenge of automated material transport between floors is solved through deliberate design integration. A modern mezzanine racking for warehouses project can be engineered with specific interfaces for robotics.

AGV-Compatible Lifts and Transfer Cars: Dedicated, automated lifts can be installed that allow AGVs or automated forklifts to drive on, be transported to the mezzanine level, and then continue their assigned task autonomously. This creates a truly continuous, hands-off material flow across multiple vertical levels.

Conveyor System Integration: Automated conveyor systems can be designed with spiral elevators, vertical reciprocating conveyors (VRCs), or inclined belts that rise to meet the mezzanine deck. This creates a seamless river of goods, connecting receiving, storage, picking, and shipping processes in a multi-level, automated loop.

<h3>The Central Role in Multi-Tier Automated Storage and Retrieval Systems (ASRS)</h3>

For the ultimate expression of high-density storage, the mezzanine racking for warehouses structure itself can form the foundational framework for a multi-level automated storage and retrieval system. Mini-load or shuttle-based ASRS cranes can operate on the mezzanine deck, accessing a dense matrix of bins or totes stored in racking that extends from the slab through the mezzanine level.

This approach maximizes storage density to an extreme degree, creating a “storage cube” that is simply unattainable through any form of horizontal expansion, positioning mezzanine racking for warehouses as a key enabler of the most advanced warehouse storage systems.

<h2>Case Study: Transforming an E-Commerce Logistics Hub in Southeast Asia</h2>

A concrete example illustrates the transformative power of this solution. A major e-commerce logistics provider in Thailand was facing a critical space constraint during a period of 50% annual growth. Their facility in Bangkok was at absolute capacity, and the lead time for a new build was 24 months. The solution was a custom-engineered, two-tier structural shelving mezzanine that leveraged the building’s 9-meter clear height.

The Operational Design: The ground floor was entirely reconfigured for inbound receiving, cross-docking, and the high-speed picking of the top 20% of fastest-moving SKUs. The new mezzanine racking for warehouses system created two additional levels: the first mezzanine for slow-moving inventory and the second for returns processing and value-added services like gift wrapping. Two high-capacity material lifts facilitated the movement of pallets and carts between all three levels.

The Measurable Outcome: The project added 1,200 square meters of operational space (a 200% increase in functional capacity) within a 14-week project timeline. The segregation of workflows led to a 25% reduction in order cycle times for priority shipments and a 40% decrease in internal travel time for warehouse staff. The investment in mezzanine racking for warehouses was recouped in under 15 months through the avoidance of a much more expensive and time-consuming lease on a second facility, demonstrating a clear and compelling ROI.

Conclusion: The Strategic Ascendancy of Vertical Warehousing

The relentless pressure on global supply chains to become more efficient, responsive, and cost-effective will not abate. In this environment, the traditional, capital-intensive response of horizontal expansion is increasingly anachronistic. The future of warehouse optimization is vertical. The implementation of mezzanine racking for warehouses represents a sophisticated, financially astute, and operationally superior strategy for unlocking the latent potential within existing facilities.

It is a proven technology that transforms passive overhead space into a dynamic, multi-functional asset capable of driving significant gains in storage density, workflow efficiency, and overall productivity. From a simple storage add-on to the structural backbone of a fully integrated automated storage and retrieval system, the versatility and power of mezzanine racking for warehouses are undeniable. For any business serious about scaling its logistics capabilities in a competitive global market, the first step is to look up and recognize that the most valuable real estate in their warehouse may be the space they are currently not using.

Frequently Asked Questions (FAQs)

1. What is the typical project timeline from initial consultation to full operational readiness for a mezzanine racking for warehouses system?

A standard project for mezzanine racking for warehouses typically spans 10 to 16 weeks from concept to completion. This timeline encompasses a 2-4 week phase for detailed needs analysis and engineering design, a 5-8 week period for precision manufacturing and fabrication of all components, and a final 3-4 week window for on-site installation and commissioning by a certified technical team. Complex, multi-level, or highly automated integrations will naturally extend this timeline.

2. To what extent can an existing mezzanine racking for warehouses system be modified or expanded in the future?

The modular design philosophy behind modern mezzanine racking for warehouses inherently allows for a significant degree of future modification and expansion. Free-standing mezzanine systems are particularly adaptable, as bays can often be added laterally or even relocated. Even structural shelving mezzanine systems can be reconfigured, though this requires more extensive engineering review. A reputable provider will always design with future scalability in mind.

3. How does the installation of a warehouse mezzanine floor impact our existing warehouse management system (WMS) and inventory tracking?

A new level of storage introduces new locations that must be integrated into the WMS. Professional providers of mezzanine racking for warehouses understand this critical need. They will work with your team to define a logical location numbering scheme for the new mezzanine levels (e.g., Level M) and ensure the physical layout facilitates efficient scanning and picking, ensuring a smooth digital transition alongside the physical one.

4. What are the critical questions we should ask a potential supplier during the vetting process for a mezzanine racking for warehouses project?

To ensure expertise and reliability, key questions should include: “Can you provide engineer-stamped structural calculations for my local permit application?”, “What is your process for conducting a site-specific load capacity analysis of my concrete slab?”, “Can you show case studies of similar mezzanine racking for warehouses projects you have completed, particularly those integrated with automation?”, and “What are the specific safety standards and certifications (ISO, OSHA-compliant) built into your design and components?”

5. Beyond storage, what are some innovative applications of mezzanine racking for warehouses that you have seen in industrial settings?

Beyond standard storage, innovative applications for mezzanine racking for warehouses include creating multi-level maintenance platforms for servicing large machinery, building in-facility employee welfare centers with locker rooms and cafeterias, constructing elevated quality control laboratories with controlled environments, and even installing showroom spaces where clients can view large industrial products in a clean, segregated area. The versatility of mezzanine racking for warehouses is limited only by the imagination of the operational planner.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com