📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

In the relentless ecosystem of modern industry, where vertical space is a premium asset and operational uptime is the lifeblood of profitability, access is not merely a convenience—it is a critical component of the workflow. The challenge of safely and efficiently reaching elevated storage areas, mezzanine workstations, and machinery platforms is a universal pain point in warehouses, distribution centers, and manufacturing plants.

Traditional solutions, such as fixed weldments and rudimentary ladders, consistently reveal their shortcomings: they are inflexible, often unsafe, and ill-suited for the punishing demands of 24/7 operation. This operational gap is precisely where the heavy-duty modular stair platform system establishes its dominance. This system represents a paradigm shift in industrial access, moving away from permanent, single-purpose structures toward intelligent, adaptable, and engineered solutions. A superior modular stair platform system is meticulously designed to deliver uncompromising safety, robust durability in the face of harsh environmental challenges, and unparalleled flexibility to evolve alongside a dynamic facility.

This comprehensive analysis delves into the engineering principles, configurable components, and tangible economic benefits that make this system an indispensable investment for any organization serious about optimizing its vertical logistics and safeguarding its personnel.

The Access Dilemma: Why Conventional Solutions Fail and the Modular Stair Platform System Succeeds

To fully appreciate the innovation of a heavy-duty modular stair platform system, one must first understand the operational and safety deficits created by traditional access methods. Many facilities remain tethered to outdated approaches that introduce significant risk and inefficiency.

Fixed staircases, while common, represent a permanent and often problematic commitment. Their on-site fabrication is disruptive, time-consuming, and costly. Once the final weld cools, the structure becomes an immovable fixture. Any future change in warehouse layout, storage rack configuration, or mezzanine expansion turns this fixed staircase into a formidable obstacle, often requiring expensive demolition and reconstruction. Furthermore, many fixed designs lack the sophisticated engineering needed for sustained heavy-use, leading to unsettling flex, vibration, and long-term structural fatigue.

Ladders represent an even greater liability. They necessitate a three-point climbing technique, rendering the safe transport of tools or inventory impossible. They are a leading contributor to fall-related incidents and are fundamentally inadequate for the rapid, repeated access required in a fast-paced storage environment. They fail to provide a stable, standing platform for tasks performed at height, forcing workers into unstable and hazardous positions.

The modular stair platform system is the engineered answer to these systemic failures. Its core philosophy is rooted in modularity and precision. Instead of a single, welded monolith, the system comprises a series of pre-engineered, standardized components that integrate via a high-strength bolting system. This approach transforms industrial access from a static problem into a dynamic solution. It is, in essence, a toolkit for constructing the ideal access pathway tailored to a facility’s unique requirements.

This foundational flexibility is the key differentiator. Whether the need is to create access to a new pick module, adapt to a reconfigured warehouse footprint, or expand an existing platform, the modular stair platform system can be disassembled, relocated, and reconfigured with minimal downtime and capital expenditure. This inherent adaptability future-proofs the investment, ensuring the access infrastructure remains perfectly aligned with evolving operational needs.

An Anatomical Breakdown: The Core Components of a Superior Modular Stair Platform System

The unparalleled performance of a best-in-class modular stair platform system is a direct result of the meticulous engineering applied to every constituent part. Each component is purpose-built to contribute to the system’s overall strength, safety, and longevity.

<h3>**The Structural Backbone: Engineered Stringers and Platform Frames**</h3>

The stringers—the primary load-bearing members that cradle the treads—form the very spine of the staircase. In a high-caliber modular stair platform system, these are not simple, off-the-shelf C-channels. They are fabricated from high-grade, commercial-weight structural steel, often formed into a robust, box-section design that provides exceptional resistance to torsion and bending forces far beyond the capacity of standard profiles.

The specific steel gauge and alloy are meticulously selected to exceed recognized industry standards for load capacity. Each stringer is pre-drilled with a precision laser-cut bolt-hole pattern, guaranteeing swift, secure assembly and perfect alignment across the entire structure. The main platform frames adhere to the same rigorous principle, utilizing heavy-duty rectangular tubing to create a rigid, unwavering base that eradicates any perceptible flex or bounce, even when subjected to the system’s maximum rated load.

<h3>**The Critical Interface: Advanced Tread and Decking Solutions**</h3>

The walking surface is the most frequent point of contact between personnel and the modular stair platform system, making its design a paramount safety consideration. Leading manufacturers offer a range of industry-proven tread and decking options, each engineered for specific environmental and operational demands.

Grip Strut Safety Tread: Widely regarded as the industry standard, this tread features a raised, diamond-shaped pattern that delivers exceptional slip resistance, even when contaminated with oil, grease, or water. The open-grid design allows dirt, debris, and liquids to pass through, maintaining a clean and secure walking surface. The serrated edges provide positive footing, enhancing confidence with every step.

Solid Serrated Tread with Abrasive Nosing: For applications involving small parts or tools, a solid tread with a deeply serrated surface and a prominent abrasive nosing is the optimal choice. This design prevents items from rolling off the steps while providing a highly slip-resistant leading edge, a critical feature for preventing missteps.

Heavy-Duty Grating Systems: For expansive platform areas, a modular stair platform system often employs steel grating with a high density of bearing bars. This offers the same self-cleaning, open-grid benefits as grip strut tread but in large-format panels, ideal for creating spacious, secure work platforms at the summit of the stair ascent.

<h3>**The Guardian System: Industrial-Grade Handrails and Guardrails**</h3>

Fall protection is not an optional add-on; it is an integral, non-negotiable element of a safe modular stair platform system. The handrails and guardrails are engineered to withstand immense impact forces, complying with and often surpassing OSHA, IBC, and other international safety regulations. The posts are constructed from substantial steel tubing, securely through-bolted to the stringers and platform frame at code-compliant intervals.

The inclusion of mid-rails and toe-kicks is standard, forming a comprehensive barrier system that proactively prevents falls. The handrails themselves are ergonomically designed to offer a comfortable and secure grip, promoting consistent use during every ascent and descent.

<h3>**The Nexus of Modularity: High-Strength Bolting Systems**</h3>

The revolutionary flexibility of a modular stair platform system is wholly dependent on the integrity of its connections. These systems do not rely on generic hardware. Instead, they utilize high-tensile, grade-8 or equivalent bolts, paired with precision-matched lock nuts and hardened washers. The bolt holes are engineered to a specific diameter to eliminate shear movement, and the entire assembly process is designed for intuitive execution with standard tools. The result is a series of connections that rival the strength of a welded joint while providing the transformative flexibility that welding permanently negates.

<h2>**Forged for Adversity: The Performance of a Modular Stair Platform System in Harsh Environments**</h2>

The term “durable” is often used loosely, but for a modular stair platform system destined for harsh environments, it is a measurable performance metric. The system is engineered not just to endure but to perform reliably under extreme conditions.

<h4>**Superior Corrosion Defense: A Multi-Layered Approach**</h4>

Corrosion is the relentless enemy of structural steel in industrial settings. A simple painted finish is a temporary and inadequate defense. The standard protection for a quality modular stair platform system is a robust Hot-Dip Galvanized finish. This intensive process involves the complete immersion of each fabricated component into a bath of molten zinc, resulting in a metallurgical bond that provides a total, 360-degree barrier against rust and corrosion.

The zinc coating sacrificially protects the underlying steel, even if the surface is gouged or scratched. For exceptionally aggressive environments—such as cold storage facilities with persistent humidity, chemical processing plants with acidic vapors, or coastal installations with salt-laden air—manufacturers offer upgraded protection systems like powder coating over the galvanized substrate or specialized industrial epoxy coatings that provide extended resistance to chemical attack.

<h4>**Uncompromising Structural Integrity and Load Capacity**</h4>

A reputable manufacturer will rate its modular stair platform system with realistic, industrial-scale load capacities. Standard systems are typically engineered to support concentrated loads of up to 1,000 pounds and live loads of 150 pounds per square foot, with higher capacities available for specialized applications. This engineering accounts for more than just static weight; it incorporates dynamic loading—the additional forces imparted by walking, running, or the occasional impact from material handling equipment. The result is a modular stair platform system that feels profoundly solid and permanent, instilling confidence in users and ensuring long-term structural reliability.

The Art of Configuration: Tailoring the Modular Stair Platform System to Your Facility

The defining characteristic of a modular stair platform system is its inherent configurability, allowing it to provide bespoke solutions for a vast array of industrial access challenges.

<h3>**Straight-Run Systems for Direct Vertical Access**</h3>

The most straightforward configuration is the straight-run stair with an integrated top platform. This design is the ideal solution for providing direct access to a single, elevated point, such as a mezzanine floor, a fixed control station, or the first tier of high-bay shelving. A proficient supplier will customize the rise and run to meet the exact height requirements and spatial constraints of the installation, ensuring optimal ergonomics and user safety.

<h3>**Multi-Turn and Switchback Stairs for Space Optimization**</h3>

In facilities where floor space is a critical constraint, a straight-run modular stair platform system may not be feasible. This is where the modular design truly excels, enabling the creation of multi-turn or switchback staircases. These systems utilize intermediate landings to change direction, effectively reducing the structure’s overall footprint while maintaining a safe and comfortable climbing angle. This configuration is a perfect solution for installing efficient access in tight aisles, corners, or against walls without sacrificing functionality or safety.

<h3>**Complex Platforms and Seamless Storage Integration**</h3>

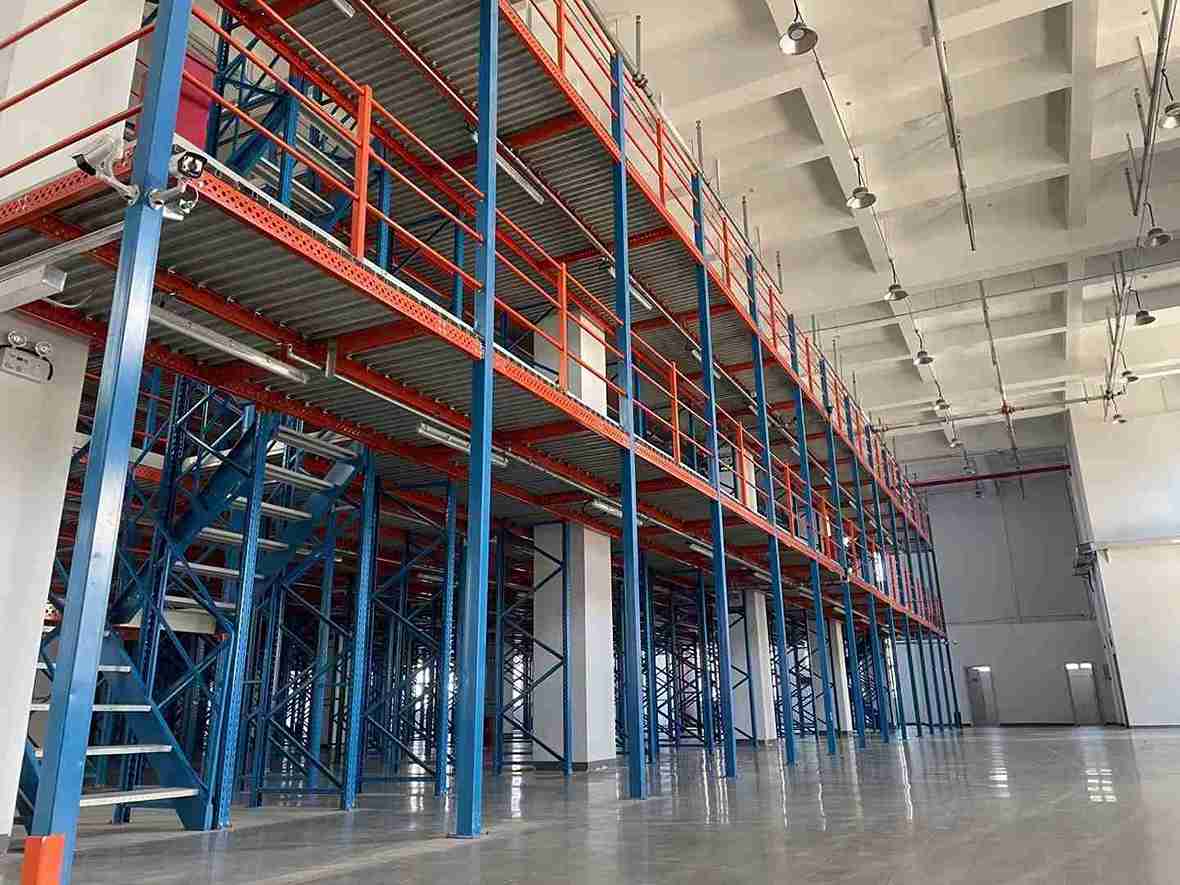

The staircase itself is often just the initial element of a larger access solution. A sophisticated modular stair platform system can be the building block for extensive, multi-level platforms that integrate flawlessly with existing or new industrial storage infrastructure. This includes:

Overhead Catwalk Systems: Creating safe and efficient elevated pathways connecting different sections of a large facility, freeing up valuable floor space for production or storage.

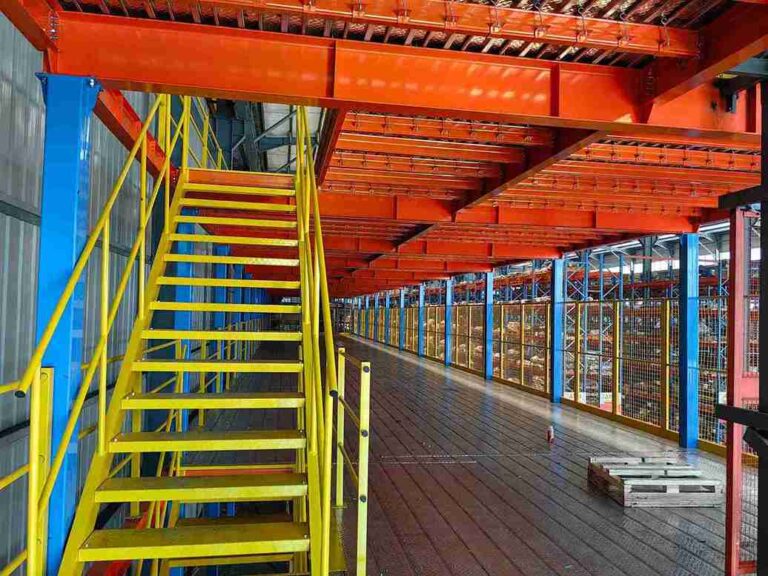

Order Fulfillment Platforms (Pick Modules): Designing comprehensive platforms that allow workers to safely and efficiently access multiple levels of shelving or pallet racking for rapid order picking, dramatically improving fulfillment cycle times.

Machine Maintenance and Access Platforms: Providing stable, secure, and guarded access for the routine maintenance, operation, and monitoring of large machinery, conveyor systems, or industrial HVAC units.

<h2>**Calculating the Return: The Tangible and Intangible ROI of a Modular Stair Platform System**</h2>

Investing in a high-performance modular stair platform system yields a demonstrable return on investment across several key business metrics, transforming it from a capital expense into a strategic asset.

<h3>**A Proactive Investment in Workplace Safety and Risk Mitigation**</h3>

This is the most significant and non-negotiable benefit. By systematically replacing ladders and inferior stairs with a stable, guarded, and slip-resistant modular stair platform system, organizations directly and dramatically reduce the risk of slips, trips, and falls—a category that consistently ranks among the most common and costly workplace injuries.

This proactive approach not only protects a company’s most valuable asset—its employees—but also leads to a substantial reduction in workers’ compensation claims, associated insurance premiums, and the costly operational downtime that follows an accident. A safer work environment also fosters a more positive and productive culture, as employees can perform their duties with confidence and without apprehension.

<h3>**A Catalyst for Operational Efficiency and Productivity Gains**</h3>

In logistics and manufacturing, time is a direct proxy for money. A well-designed modular stair platform system facilitates rapid, fluid, and unimpeded movement between different working levels. Personnel can ascend and descend quickly while carrying tools, instruments, or products, a task that is inefficient and hazardous with a ladder.

This efficiency translates into reduced time required for critical tasks such as inventory cycle counts, order picking, and equipment servicing. The ease and safety of access also encourage more frequent and thorough inspections of elevated areas, leading to improved overall facility management and proactive maintenance.

<h3>**Long-Term Value and Unmatched Adaptability**</h3>

While the initial investment in a premium modular stair platform system may be higher than a low-cost, welded alternative, the total cost of ownership is unequivocally lower. The exceptional durability of the materials and protective finishes ensures the system will provide decades of reliable service with minimal maintenance. Crucially, its modular nature means it is not a disposable asset. When operational needs shift, the modular stair platform system is not scrapped; it is reconfigured, repurposed, or expanded. This inherent adaptability protects the capital investment for the long term and guarantees that a company’s access solutions never become obsolete.

From Concept to Completion: The Process of Specifying and Installing a Modular Stair Platform System

Engaging with a reputable supplier for a modular stair platform system is a collaborative partnership, designed to ensure a seamless journey from initial inquiry to final installation.

<h4>**Phase 1: Comprehensive Consultation and Technical Site Assessment**</h4>

The process is initiated with a detailed discovery session to understand the specific application, anticipated traffic volume, load requirements, and unique environmental challenges. Suppliers often work from facility blueprints or CAD drawings and may conduct an on-site visit to gain an intimate understanding of the spatial and operational context.

<h4>**Phase 2: Custom Engineering and Detailed Design Proposal**</h4>

Leveraging the data collected, the supplier’s engineering team develops a custom design and a comprehensive proposal. This package typically includes detailed layout drawings, structural load calculations, a complete bill of materials, and a clear project timeline. The design is rigorously vetted to ensure compliance with all applicable local and international safety codes.

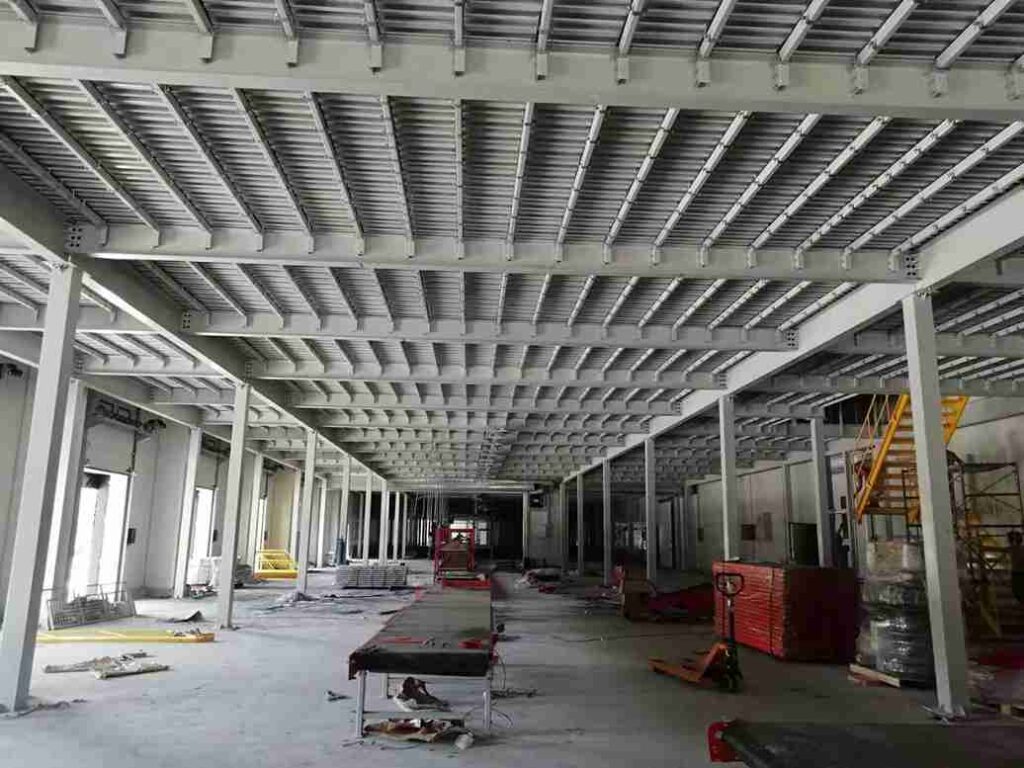

<h4>**Phase 3: Precision Fabrication and Managed Logistics**</h4>

Upon project approval, the fabrication phase commences. State-of-the-art manufacturing facilities utilize CNC machinery to ensure every component of the modular stair platform system is produced to exact tolerances. All parts are pre-drilled, pre-cut, pre-punched, and finished before being systematically packaged and shipped to the site with comprehensive, easy-to-follow assembly documentation.

<h4>**Phase 4: Streamlined On-Site Assembly and Commissioning**</h4>

A paramount advantage of a true modular stair platform system is the simplicity of its installation. The bolt-together methodology means that a facility’s own maintenance crew can often handle the assembly, generating significant savings on external contractor costs. For larger or more complex installations, the supplier can typically recommend or provide experienced installation teams. The process is designed to be swift, clean, and cause minimal disruption to ongoing operations.

Proven in the Field: Diverse Applications for the Modular Stair Platform System

The versatility of the modular stair platform system is evidenced by its widespread adoption across a diverse spectrum of industries, where it solves unique and demanding access challenges.

Warehousing and Distribution Centers: Serving as the primary access for mezzanine offices, multi-level pick modules, and for the maintenance of high-level pallet racking.

Heavy Manufacturing and Assembly Plants: Providing safe and stable access to large machinery, overhead crane control stations, and assembly jigs.

Food and Beverage Processing Facilities: Utilizing corrosion-resistant models with finishes that meet stringent USDA, FDA, and HACCP hygiene protocols.

Chemical and Pharmaceutical Industries: Featuring specialized coatings and stainless-steel options to resist aggressive chemical solvents and meet cleanroom requirements.

Automotive and Aerospace Sectors: Supporting the weight of heavy tools and providing ergonomic access to complex assemblies on production lines.

Mining and Mineral Processing Plants: Engineered with extra-heavy-duty components to withstand extreme abrasion, constant impact, and corrosive slurry environments.

Conclusion: Strategic Elevation Through Engineered Access

In the competitive landscape of global industry, the optimization of space, time, and safety is not merely an objective—it is a fundamental requirement for sustained success. Compromising on the quality and intelligence of industrial access solutions introduces unacceptable levels of risk and operational friction. The heavy-duty modular stair platform system stands as the culmination of advanced engineering in this field—a solution that synthesizes immense strength, proactive safety, and foundational flexibility into a single, cohesive asset.

It is an investment that delivers continuous returns through enhanced productivity, mitigated risk, and long-term operational agility. For facility managers, plant engineers, and safety professionals dedicated to excellence, the question is no longer whether to upgrade, but how quickly they can integrate a superior modular stair platform system into their operations. The path to a safer, more efficient, and fully optimized facility begins with a single, well-engineered step.

Frequently Asked Questions (FAQs)

Q1: How does the load capacity of your modular system compare to a traditional, welded-in-place staircase?

A properly engineered and assembled modular stair platform system possesses a load capacity that is structurally equivalent to, and frequently exceeds, that of a custom-welded staircase. The critical factors are the engineering design of the individual components and the use of high-strength, certified bolted connections. Reputable manufacturers subject their modular stair platform system designs to rigorous testing and analysis, certifying that they meet or exceed all relevant OSHA and IBC standards for industrial stairs. This ensures the system can reliably handle the concentrated and distributed loads encountered in demanding industrial settings.

Q2: Can your stair systems be outfitted with special features like gates or privacy screens?

Absolutely. The inherent modularity of the modular stair platform system makes it exceptionally well-suited for customization. Manufacturers can seamlessly integrate self-closing safety gates at the top or bottom of the stairway to control access to restricted areas. They can also add mid-rail to toe-kick solid paneling (often called kick-plates) for privacy, wind protection, or to prevent small items from falling off the platform. Other common customizations include wire mesh infill panels, integrated lighting conduits and fixtures, and custom caster bases for creating fully mobile access units.

Q3: We have a very specific height requirement that doesn’t match a standard stair run. Can you accommodate this?

Yes, this capability is a primary advantage of opting for a engineered modular stair platform system. Because the components are fabricated to order based on specific project parameters, manufacturers are not constrained by standard rise dimensions. Engineers can calculate the exact number of treads and the precise rise and run measurements needed to fit the exact floor-to-platform height, guaranteeing a comfortable, ergonomic, and code-compliant climbing experience without any awkward or unsafe step variations.

Q4: What kind of maintenance should we expect after installation?

The maintenance requirements for a hot-dip galvanized modular stair platform system are exceptionally low. The galvanization process provides long-term, sacrificial protection that requires no scheduled maintenance. A general recommendation is to conduct periodic visual inspections of the entire structure, checking for any loose bolts—which can be easily re-tightened with standard tools—and ensuring that treads and handrails are kept free of excessive debris, snow, or ice buildup. For powder-coated systems in highly corrosive environments, occasional washing with a mild detergent may be advised to preserve the aesthetic finish.

Q5: Are your systems compliant with international safety standards like OSHA (USA) and CE (Europe)?

Yes, leading manufacturers design their modular stair platform system products with global compliance as a core engineering principle. Standard configurations are meticulously designed to meet the stringent requirements of the U.S. Occupational Safety and Health Administration (OSHA), particularly standards 1910.24 (Fixed Stairways) and 1910.23 (Ladders). For the international market, these systems are engineered to satisfy the essential health and safety requirements of the European Machinery Directive and other pertinent local regulations, which can include CE marking. Reputable suppliers provide comprehensive documentation to support and verify compliance for their clients.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com