📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

The contemporary manufacturing landscape is defined by volatility, customization, and the relentless pursuit of efficiency. In this environment, the traditional conveyor belt, a symbol of rigid, linear production, has become an impediment to progress. Forward-thinking operations are now looking Beyond Conveyors toward a more adaptive, intelligent, and resilient solution. The future of material handling lies in the Integrated AGV & Rack Modular Platform.

This sophisticated system represents a fundamental re-engineering of internal logistics, creating a truly modular platform for manufacturing lines that is dynamic by design. By fusing intelligent Automated Guided Vehicles (AGVs) with reconfigurable storage racking, all under the command of a central software intelligence, this approach delivers unprecedented flexibility.

It is the ultimate answer for dynamic lines that must pivot quickly, scale efficiently, and optimize continuously. This comprehensive exploration delves into the mechanics, benefits, and implementation strategies of this transformative modular platform for manufacturing lines, providing a blueprint for manufacturers ready to embrace the next industrial evolution.

(H2) The Conveyor Conundrum: Why Fixed Automation Fails the Modern Manufacturer

For decades, the conveyor was the backbone of factory automation. Its continuous motion promised streamlined production, but this promise was built on a foundation of inflexibility. The modern market, characterized by high-mix, low-volume production runs and frequent product changeovers, has exposed the critical flaws of this fixed-path technology. A conveyor system is a monumental capital investment that physically hardcodes material flow routes into the factory floor. Any alteration to the product, process, or layout necessitates a costly, time-consuming, and disruptive re-engineering project. This rigidity is a significant liability in an era where agility is a primary competitive advantage.

The operational drawbacks are extensive. Conveyors create single points of failure; a malfunction in one section can halt the entire production line, leading to catastrophic downtime. They consume a vast footprint of valuable floor space, often creating inefficient, fixed layouts that hinder future expansion or reconfiguration. Moreover, they offer zero data granularity on the movement of individual items, operating as a “dumb” river flow rather than an intelligent, addressable network. This lack of traceability and control is unacceptable in industries requiring strict lot tracking and quality control. These limitations collectively underscore the urgent need for a new paradigm—a responsive and intelligent modular platform for manufacturing lines that can evolve at the speed of business.

(H2) The New Paradigm: Deconstructing the Integrated AGV & Rack Modular Platform

The successor to the conveyor is not a single piece of equipment, but a synergistic ecosystem. An Integrated AGV & Rack Modular Platform is a holistic material handling architecture where autonomy, structure, and intelligence converge. This sophisticated modular platform for manufacturing lines is composed of three core, interconnected elements that work in concert to create a “living” logistics environment.

The Mobility Engine: Advanced AGVs and Unmanned Forklifts: This component provides the dynamic movement. Unlike their primitive ancestors, modern AGVs are intelligent, autonomous robots. They utilize technologies like Natural Feature Navigation (NFN) or LiDAR-based SLAM to navigate freely, using the existing environment—walls, columns, and the racking itself—as reference points. This eliminates the need for costly and permanent floor guides, tapes, or wires. The fleet can include pallet-stacking AGVs, unit-load carriers for totes, and heavy-duty unmanned forklifts capable of handling full pallet loads. Their paths are not fixed; they are digital and can be optimized or altered in real-time through software.

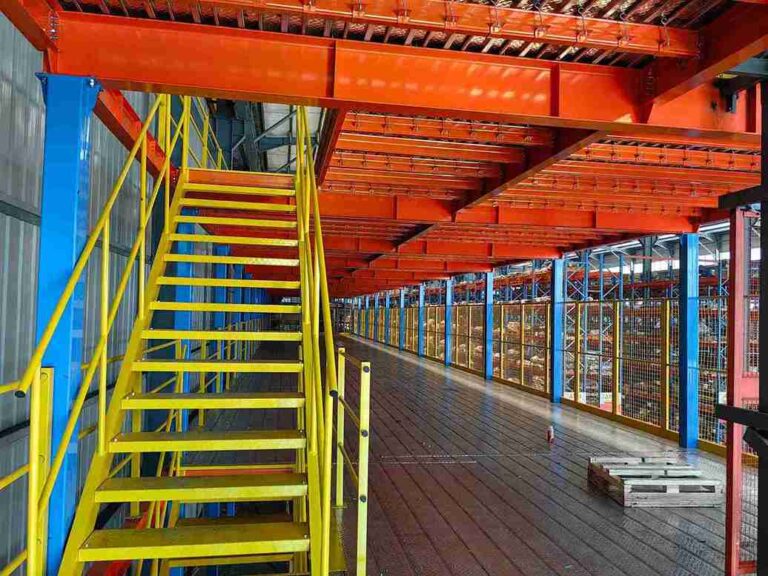

The Adaptive Skeleton: Modular Storage Racking: This is the physical framework of the modular platform for manufacturing lines. It is the antithesis of static, welded storage structures. Engineered for flexibility, this racking is designed to be easily reconfigured, disassembled, expanded, or relocated with minimal effort and downtime. When this adaptable storage infrastructure is paired with the precision of AGVs, new design possibilities emerge. Aisles can be narrowed to the vehicle’s exact clearance requirements, dramatically increasing storage density. The racking becomes a dynamic canvas upon which the AGVs paint an ever-changing picture of material flow.

The Central Nervous System: Integration and Control Software: The magic of this system lies in the seamless orchestration of its physical components. A robust Warehouse Execution System (WES) or Fleet Management System acts as the brain. This software platform integrates directly with the company’s ERP or MES, translating high-level production orders into discrete, optimized tasks for the AGV fleet. It manages traffic, assigns priorities, optimizes travel paths to minimize empty miles, and provides a continuous stream of performance data. This intelligence layer transforms a collection of vehicles and racks into a cohesive, self-optimizing modular platform for manufacturing lines.

(H3) The Core Synergy: Creating a Living, Breathing Logistics Organism

The transformative power of this modular platform for manufacturing lines is not merely the substitution of AGVs for conveyors. It is the profound synergy created between the mobile robots and the adaptive infrastructure. In a traditional system, storage is a passive destination. In this integrated model, the entire storage and buffer system becomes an active, dynamic participant in the material flow.

AGVs can be tasked with physically reconfiguring supermarket and buffer zones in real-time to match the production schedule. Before a shift producing a specific product model, the AGV fleet can autonomously stage the required kits and components at the precise line-side locations. When the production order changes, the AGVs can dismantle that setup and construct a new one, all without human intervention. The modular platform for manufacturing lines enables this fluid re-allocation of space and inventory, creating a logistics environment that breathes in sync with the pulse of production. This living system is the hallmark of a truly modern, adaptable modular platform for manufacturing lines.

(H2) Unpacking the Tangible Benefits: The Strategic Advantages of a Modular Platform

Adopting this integrated approach yields a cascade of operational and strategic benefits that deliver a compelling return on investment and a durable competitive edge.

(H3) Radical Flexibility and Unmatched Scalability

This is the defining benefit of this modular platform for manufacturing lines. The system’s digital heart means that change is simple and cheap. Altering a material delivery route is a software update, not a construction project. Expanding capacity is a matter of adding more modular racking bays and integrating additional AGVs into the existing fleet management system. This inherent scalability allows companies to start with a pilot project in a critical area and expand the modular platform for manufacturing lines throughout the facility as ROI is demonstrated. This “start small and scale” philosophy de-risks the investment and aligns perfectly with the growth trajectory of agile businesses.

(H3) Maximizing Floor Space and Storage Density

The precision and consistency of AGVs allow for a radical rethinking of storage layout. Without the need for wide aisles to accommodate human operators, aisles can be compressed to the minimum safe operating width for the vehicles. This immediate spatial compression can increase storage density by 20% or more, effectively adding significant capacity within the same four walls. The reclaimed floor space is valuable real estate that can be repurposed for additional production cells, kitting areas, or other value-added operations, maximizing the utility of the entire facility—a key advantage of this sophisticated modular platform for manufacturing lines.

(H3) Enhanced Resilience and Continuous Uptime

A conveyor is a single point of failure. An integrated AGV system is a networked fleet, embodying built-in redundancy. If one vehicle requires maintenance or charging, the central intelligence system dynamically redistributes its tasks among the remaining operational units. Material flow continues uninterrupted. This resilience is critical for maintaining service levels in high-throughput environments and protecting against costly production stoppages. The robust nature of this modular platform for manufacturing lines ensures operational continuity.

(H3) Data-Driven Optimization and Granular Traceability

Every task executed within this modular platform for manufacturing lines generates valuable data. The system captures metrics on travel times, task completion rates, wait times at pick-up/drop-off points, and vehicle health. This data is a goldmine for continuous improvement. Operations managers can move from reactive fire-fighting to proactive optimization, identifying hidden bottlenecks, refining replenishment triggers, and gaining complete traceability for every component from raw material staging to finished goods. This data-centricity transforms the logistics function from a cost center into a strategic source of intelligence.

(H2) Real-World Applications: The Modular Platform in Action

The versatility of the Integrated AGV & Rack system makes it a powerful solution across a diverse industrial spectrum. These are not theoretical benefits but proven results.

(H3) Automotive Sub-Assembly: Mastering Complexity and Changeover

A tier-1 automotive supplier faced crippling changeover times when switching between complex sub-assembly lines for different vehicle platforms. Their legacy system was rigid and slow. The implementation of a tailored modular platform for manufacturing lines was transformative. AGVs were integrated with modular racking to create mobile staging areas. Components are kitted and delivered directly to the AGV, which then navigates to the specific assembly line as required. The modular platform for manufacturing lines allows the AGVs’ destinations and loaded components to be reconfigured digitally in minutes, slashing changeover time by over 80% and dramatically increasing overall equipment effectiveness (OEE).

(H3) Electronics Manufacturing: Agile Material Handling for High-Mix Environments

An electronics contract manufacturer grappling with thousands of components and rapid product lifecycles needed to ensure flawless feeding of their SMT lines. The solution was a precision modular platform for manufacturing lines. A fleet of compact, agile AGVs manages the movement of component reels from a high-density modular racking system to the programming and loading stations. The software intelligence ensures the right reel arrives at the precise machine and time, eliminating setup errors and component mis-loads. This high-precision modular platform for manufacturing lines provides the agility needed to thrive in the fast-paced electronics industry.

(H3) Food and Beverage: Synchronizing Packaging and Palletizing

A large beverage company with numerous packaging formats and promotional SKUs required a flexible link between their filling lines, staging areas, and palletizers. A fleet of unmanned forklifts, serving as the core of a new modular platform for manufacturing lines, now orchestrates this flow. The vehicles transport pallets of empty and filled containers, with their routes and priorities dynamically adjusted by the software based on real-time production data from each line. This creates a perfectly synchronized, responsive flow that maximizes equipment utilization and adapts seamlessly to shifting production priorities, showcasing the power of a dynamic modular platform for manufacturing lines.

(H2) The Nuts and Bolts of Implementation: A Phased, Professional Approach

Deploying a sophisticated modular platform for manufacturing lines is a significant undertaking that requires meticulous planning and expert execution. A phased, professional methodology is critical to success.

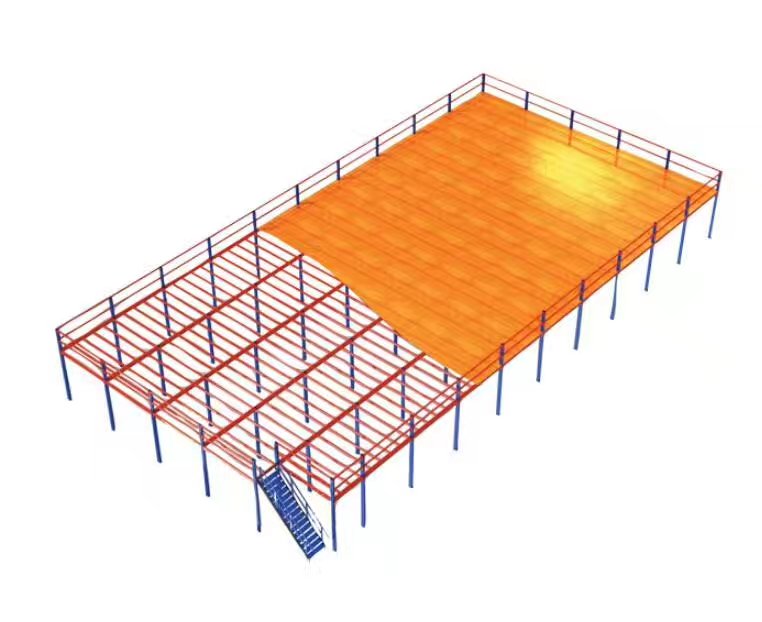

(H3) Phase 1: Deep-Dive Consultation and Digital Twin Simulation

The journey begins with a comprehensive operational analysis. Experts immerse themselves in the client’s facility, mapping material flows, quantifying pain points, and defining key performance indicators (KPIs). The most critical step in this phase is the creation of a digital twin—a high-fidelity simulation model of the proposed modular platform for manufacturing lines. This virtual environment allows engineers to run thousands of simulated production cycles, stress-testing the design, optimizing fleet size and racking layout, and validating the projected ROI before any physical installation begins. This de-risks the investment and builds confidence in the solution.

(H3) Phase 2: Physical Deployment and System Integration

With a proven digital model, the project moves to physical implementation. This phase is managed end-to-end to ensure minimal disruption:

Site Preparation: Requirements are minimal, often limited to ensuring floor flatness and installing necessary charging infrastructure.

Racking Installation: Certified technicians install the engineered modular storage racking according to the digital plan.

AGV Deployment and Mapping: The AGV fleet is deployed, and their navigation maps are built using the facility’s natural features.

Software Integration: The WES is seamlessly integrated with the host ERP/MES, creating a closed-loop information system that drives physical execution. This integration is the cornerstone of a successful modular platform for manufacturing lines.

(H3) Phase 3: Ongoing Support and Continuous Optimization

The partnership extends long after the system goes live. Comprehensive support agreements include remote system monitoring, proactive maintenance, and software updates. The operational data generated by the modular platform for manufacturing lines is continuously analyzed to identify new opportunities for performance tuning and process improvement, ensuring the system delivers maximum value throughout its lifecycle.

(H2) Addressing the Skeptics: Overcoming Common Objections

Despite its proven benefits, some misconceptions persist. Addressing them head-on is part of a thorough evaluation.

“The Capital Outlay is Prohibitive.” While the initial investment can be significant, the analysis must focus on Total Cost of Ownership (TCO). When the gains in flexibility, uptime, labor reallocation, space savings, and damage reduction are quantified, the ROI for a modular platform for manufacturing lines is often superior to that of a fixed conveyor system over a 3-5 year period. The ability to scale incrementally also improves cash flow management.

“Safety is a Concern with Mobile Robots.” Modern AGVs are engineered with multi-layered safety systems, including LiDAR, 3D cameras, and physical bumpers. They operate at controlled speeds and are programmed to slow, stop, or alter course when encountering obstacles or personnel. Their predictable patterns and constant vigilance often make them safer than human-operated industrial vehicles.

“The Technology is Not Yet Proven.” This objection is outdated. According to the Association for Advancing Automation (A3), the mobile robot sector has experienced explosive growth, with annual unit shipments increasing dramatically year-over-year. This market adoption is a direct reflection of the technology’s maturity and proven performance in demanding industrial environments worldwide. The modular platform for manufacturing lines is a present-day reality, not a future concept.

(H2) The Future is Already Here: AI and the Self-Optimizing Warehouse

The evolution of the modular platform for manufacturing lines is already underway, driven by advancements in Artificial Intelligence (AI) and Machine Learning (ML). The next generation of these systems will be predictive and prescriptive. AI algorithms will analyze historical and real-time data to forecast material flow bottlenecks before they occur.

The modular platform for manufacturing lines will then proactively dispatch AGVs to pre-position inventory, dynamically balance workload across the fleet, and continuously self-optimize for peak efficiency without human intervention. This journey from automated to autonomous logistics is the ultimate destination, and the integrated AGV and rack system provides the essential foundation.

(H2) Conclusion: Making the Strategic Leap Beyond Conveyors

The era of the fixed-path conveyor as the default solution for factory automation is over. Its inherent rigidity is fundamentally misaligned with the demands of modern manufacturing. The Integrated AGV & Rack Modular Platform represents the new standard—a dynamic, intelligent, and resilient ecosystem that provides the strategic agility required to compete and win in today’s volatile market.

This modular platform for manufacturing lines is more than a technological upgrade; it is a strategic imperative. It empowers manufacturers to build supply chain resilience from the inside out, turning internal logistics from a static cost center into a dynamic competitive weapon. The question for forward-thinking manufacturers is no longer if they will adopt this modular platform for manufacturing lines, but how quickly they can execute the transition to secure their position as the industry leaders of tomorrow.

(H2) Frequently Asked Questions (FAQs)

1. How does the navigation technology work, and what happens if we need to move a rack or a workbench?

The AGVs within this modular platform for manufacturing lines utilize advanced navigation like Natural Feature Navigation (NFN). They create a digital map by identifying permanent structural features. The beauty of this system is that the modular storage racking itself can be used as a navigation landmark. If a rack is moved, the digital map in the fleet management software is simply updated. The AGVs will then dynamically recalibrate their understanding of the environment, allowing the entire modular platform for manufacturing lines to adapt within hours, not days.

2. What is the typical ROI period for implementing such a system?

The return on investment for a modular platform for manufacturing lines is typically realized within 1 to 3 years, though this varies with scale and application. The calculation is driven by hard savings from labor reallocation, a dramatic reduction in product damage caused by vehicles, increased throughput from minimized stoppages, and the ability to defer costly facility expansions by maximizing existing space. The flexibility gains, while harder to quantify, often provide the most significant long-term strategic value.

3. Can this system integrate with our existing legacy equipment, like older conveyor sections or semi-automated palletizers?

Yes, a core strength of this modular platform for manufacturing lines is its ability to integrate with and enhance existing automation. The Warehouse Execution System (WES) is designed to act as a universal orchestrator. It can send and receive simple I/O signals to and from legacy equipment, allowing AGVs to seamlessly hand off loads to conveyors or service existing palletizers. This allows for a phased, capital-efficient implementation of the modular platform for manufacturing lines.

4. How do you handle the charging of the AGV fleet to ensure 24/7 operation?

These sophisticated fleets employ opportunistic, “sip” charging strategies. The central software continuously monitors the battery level of every vehicle. When an AGV’s charge drops below a threshold and it has a lull in its task schedule, it will autonomously navigate to a wireless or contact-based charging station for a quick top-up. This ensures the modular platform for manufacturing lines maintains near-continuous operation without requiring scheduled, lengthy charging breaks that would disrupt material flow.

5. What kind of maintenance do the AGVs and the overall system require?

The AGVs are designed for industrial durability and require minimal maintenance, primarily involving periodic checks of tires, sensors, and cleaning. The modular racking requires standard annual safety inspections. The most proactive maintenance is virtual. The system’s health is continuously monitored remotely by support teams who can often identify and resolve software-level issues or predict mechanical failures before they impact the operation, ensuring the modular platform for manufacturing lines maintains high levels of uptime.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com