📐 "First 50 Enterprise Queries Get Custom 3D Warehouse Design" Plan

For decades, the fundamental response to spatial constraints in industrial operations was a binary and brutal choice: endure the inefficiency or endure the monumental cost and disruption of relocation. This paradigm, however, has been fundamentally overturned. The most strategic and financially astute solution for a growing business no longer lies in expanding its footprint outwards, but in capitalizing on the most underutilized asset within its existing four walls: vertical air space. A modular mezzanine platform represents this paradigm shift.

It is a sophisticated, engineered solution that systematically transforms unused cubic volume into high-value, operational square footage, all without a single brick being laid or a lease being renegotiated. This comprehensive exploration delves beyond the sales pitch, offering a masterclass in how a modular mezzanine platform operates as a strategic lever for operational excellence, financial prudence, and competitive agility. The central question for modern warehouse and operations managers is not if they should consider this solution, but how quickly they can deploy a modular mezzanine platform to secure a decisive market advantage.

Deconstructing the Modern Marvel: What Exactly is a Modular Mezzanine Platform?

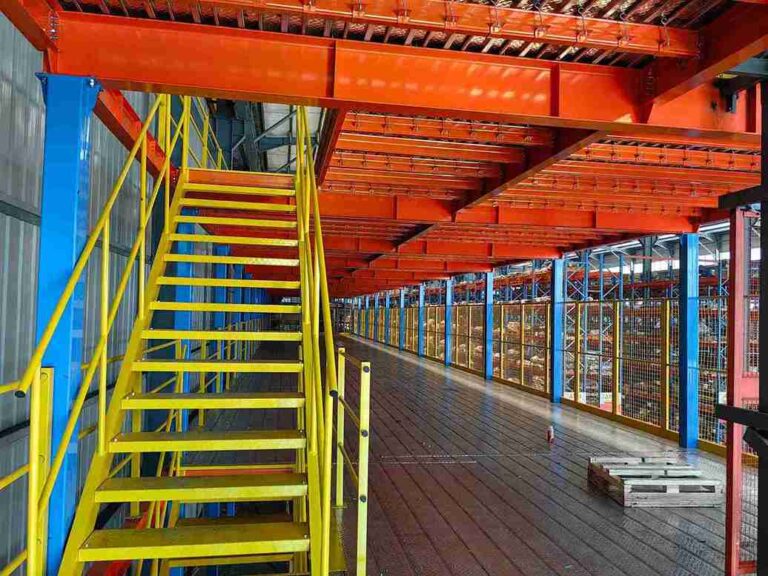

At its core, a modular mezzanine platform is a semi-independent, free-standing structural system installed within an existing building to create one or multiple additional working levels. The critical distinction lies in the term modular. Unlike a permanent, welded-in-place structure, a true modular mezzanine platform is composed of precision-engineered, prefabricated steel components—primarily columns, beams, and decking—that are bolted together on-site.

This bolted modular mezzanine platform design is not merely a convenience; it is the source of the system’s immense strength, inherent flexibility, and future-proof value. The engineering philosophy behind a modern modular mezzanine platform treats it as a dynamic component of the material handling ecosystem, capable of supporting everything from static storage to dynamic, automated systems. When professionals assess the feasibility of a modular mezzanine platform, they are evaluating it as a capital investment in vertical density, a concept that is redefining warehouse and factory design worldwide.

The Anatomy of Strength: Core Components of an Industrial-Grade Modular Mezzanine Platform

To truly appreciate the value and versatility of a modular mezzanine platform, one must understand its fundamental anatomy. Each component plays a critical role in ensuring the structure’s safety, durability, and performance, transforming the abstract concept of a “second floor” into a tangible, industrial-strength asset.

Primary Structural Framework: The Backbone of the System

The integrity of any modular mezzanine platform rests on its primary framework. This includes the heavy-duty steel columns, which are the vertical members transferring the entire load to the building’s slab, and the primary beams, which are the main horizontal support members. These components are typically fabricated from rolled structural steel I-beams or custom-built box sections, chosen for their optimal strength-to-weight ratio. The design of this framework for a modular mezzanine platform is precisely calculated to handle both the dead load (the weight of the structure itself) and the intended live load (the weight of stored goods, equipment, and personnel).

Decking and Surface Solutions: The Working Landscape

The decking is the functional “floor” of the modular mezzanine platform, and its selection is paramount to the system’s application. Options are diverse and purpose-driven:

Heavy-Gauge Steel Plate: The industry standard for most storage applications, offering durability and a solid walking surface.

Open-Grid Bar Grating: Ideal for areas where ventilation, light penetration, or debris fall-through is required.

Concrete-Filled Decking: Provides a solid, fire-resistant surface often used in office build-outs or areas requiring a high degree of stability.

The choice of decking directly impacts the functionality and safety of the modular mezzanine platform.

Safety and Access Integration: Non-Negotiable Essentials

A modular mezzanine platform is an industrial workplace, and its design must integrate safety from the ground up. This includes full perimeter guarding with robust handrails and toe-kicks, compliant industrial staircases with safety gates, and strategically placed column guards. Furthermore, access for goods is a critical design consideration. This can range from simple pallet drop-gates to fully integrated custom mezzanine lifts and Vertical Reciprocating Conveyors (VRCs). The safe and efficient flow of both people and materials is a hallmark of a well-executed modular mezzanine platform installation.

The Compelling Financial Calculus: Quantifying the ROI of a Modular Mezzanine Platform

The decision to invest in a modular mezzanine platform is, at its heart, a financial one. When analyzed against the traditional alternative of relocation or new construction, the return on investment (ROI) is often staggering. The financial argument for a modular mezzanine platform is built on both direct cost avoidance and significant operational gains.

A Direct Cost Analysis: Mezzanine vs. The Costly Move

Consider a scenario requiring an additional 5,000 square feet of operational space. The cost comparison is revealing:

The Relocation/Build-Out Path:

Exorbitant Real Estate Costs: Significantly higher lease rates for a larger facility or the immense capital outlay for new construction.

Massive Construction/Build-Out: Costs for new offices, utilities, and specialized infrastructure.

Catastrophic Relocation Expenses: Hiring professional movers, disassembling and reassembling existing systems, and the immense, often underestimated, cost of operational downtime and lost productivity.

The Modular Mezzanine Platform Path:

Predictable Capital Investment: A single, defined cost for the engineered structure, decking, and access.

Minimal Site Preparation: Often limited to ensuring a sound concrete slab.

Installation with Minimal Disruption: Expert installation teams can often erect the modular mezzanine platform with negligible impact on ongoing operations.

Zero Increase in Ongoing Real Estate Costs: The existing lease or mortgage payment remains unchanged.

In this light, the cost per square foot of a modular mezzanine platform frequently represents a 70-90% saving compared to the cost of new physical space. It is, effectively, the creation of new space at a profound discount.

The Value Beyond Cost Savings: Intangible Returns

The financial benefits of a modular mezzanine platform extend far beyond simple square-footage economics.

Radical Operational Flow Improvement: A modular mezzanine platform enables vertical workflow organization. Imagine raw materials stored on the upper level, feeding directly to assembly lines below via gravity conveyors, with finished goods moving to a dedicated packaging area. This vertical integration, facilitated by the modular mezzanine platform, slashes material handling travel time and streamlines processes.

Enhanced Inventory Control and Organization: This system allows for strategic SKU segregation. Slow-moving inventory can be housed on the modular mezzanine platform, while fast-moving goods remain at ground level. High-value items can be secured in caged areas on the platform, improving inventory accuracy and security.

Reclamation of Premium Floor Space: By moving storage, offices, or workstations to the upper level of a modular mezzanine platform, the main floor is liberated for higher-value activities like manufacturing, cross-docking, or value-added services. This main floor real estate is the most valuable; a modular mezzanine platform allows a company to optimize its use.

The Critical Suitability Checklist: Is Your Facility a Candidate for a Modular Mezzanine Platform?

While a powerful solution, a modular mezzanine platform is not a universal panacea. Its successful implementation hinges on a set of concrete, measurable site conditions. This five-point checklist provides a foundational guide for any feasibility assessment.

1. Vertical Clearance: The Non-Negotiable Spatial Requirement

The single most critical determinant is available clear height. A general rule of thumb suggests a minimum of 15-16 feet from the finished floor to the lowest overhead obstruction (sprinklers, lights, ductwork). This allows for a functional deck height (e.g., 10 feet clearance underneath), the structure’s depth (~1-2 feet), and comfortable, code-compliant headroom on the upper level (at least 7-8 feet). A professional site survey is essential to model this precisely for a proposed modular mezzanine platform.

2. Floor Slab Capacity: The Unseen Foundation

The concrete slab must be capable of supporting the significant point loads imposed by the modular mezzanine platform columns. This requires a professional structural analysis to determine the existing slab’s capacity (in pounds per square foot, PSF) and verify it can handle the combined dead and live loads. In cases where capacity is insufficient, a modular mezzanine platform can still be feasible through engineering solutions like spreader plates or designated slab reinforcement.

3. Application-Specific Live Load Engineering

The intended use of the modular mezzanine platform dictates its required live load capacity. This is not a one-size-fits-all metric:

Office/File Storage: 75-100 PSF (though often over-engineered for flexibility).

Light Storage/Bulk Shelving: 125 PSF.

Pallet Storage with Forklifts: 150-250+ PSF.

Industrial Manufacturing/Heavy Machinery: 300 PSF and above.

The entire modular mezzanine platform is engineered from the ground up based on this specific live load requirement, ensuring absolute structural integrity and safety.

4. Navigating the Regulatory Landscape: Permits and Codes

A modular mezzanine platform is a permanent structural addition and almost universally requires a building permit. The process involves submitting detailed engineering drawings that demonstrate compliance with local building codes, which govern egress, seismic design (in specific zones), and fire safety. A key consideration is sprinkler coverage; installation of a modular mezzanine platform will typically require extending the facility’s fire suppression system underneath the deck. Partnering with a provider experienced in this process is critical.

5. Material Handling Integration: The Circulation System

The efficiency of a modular mezzanine platform is determined by how seamlessly people and goods move to and from it. Planning for this integration is not an afterthought; it is a core part of the design phase. Solutions range from standard stairs and pallet gates to sophisticated, integrated systems like custom mezzanine lifts, vertical conveyors, and spiral chutes. The choice directly impacts the operational throughput of the modular mezzanine platform.

Beyond Storage: Innovative and Transformative Applications for a Modular Mezzanine Platform

The true potential of a modular mezzanine platform is unlocked when it is viewed not just as a storage shelf, but as a strategic tool for re-engineering operational workflows. Its applications are limited only by imagination and sound engineering.

Multi-Tiered Order Fulfillment and Pick Modules

In the fast-paced world of e-commerce and distribution, a modular mezzanine platform can be configured into a high-density pick module. By creating multiple levels of picking faces served by conveyors, the system creates a “goods-to-person” environment that dramatically reduces picker walk time and increases order throughput. This multi-level modular mezzanine platform design can effectively double or triple the picking density within the same building footprint.

The Integrated Office and Production Overlook

A modular mezzanine platform offers an ideal solution for housing administrative functions like offices, quality control labs, or employee break rooms. This “office-in-the-sky” approach liberates invaluable production floor space while providing management with a panoramic overview of the operation. This specific application of a modular mezzanine platform improves supervision, isolates personnel from production floor hazards, and optimizes the use of the entire facility’s cube.

The Structural Backbone for Automation (ASRS)

For the pinnacle of storage density and efficiency, a modular mezzanine platform can serve as the primary support structure for an Automated Storage and Retrieval System (ASRS). In this advanced configuration, the modular mezzanine platform provides the access aisles and support for the retrieval machines, while the storage racks themselves become an integral part of the overall structure. This symbiotic relationship between the modular mezzanine platform and automation technology represents the cutting edge of high-density warehousing.

A Partnership for Success: The Professional Journey of a Modular Mezzanine Platform Project

The journey from concept to a fully operational modular mezzanine platform is a meticulous, phased process that demands expertise at every step. Engaging with a specialist provider ensures a seamless, compliant, and successful outcome.

Phase 1: In-Depth Discovery and Strategic Feasibility

The process begins with a comprehensive consultation to understand not only the spatial challenge but the overarching business goals, workflow patterns, and long-term vision. This strategic alignment ensures the modular mezzanine platform solution is tailored for maximum impact.

Phase 2: Laser-Precise Site Survey and Structural Analysis

A professional site survey is conducted to capture precise measurements of the space, including all obstructions and critical details. Simultaneously, the facility’s structural drawings are reviewed, and slab capacity tests may be performed to gather all necessary data for the engineering phase.

Phase 3: Custom Engineering and Integrated Design

Using state-of-the-art CAD and modeling software, engineers create a custom design for the modular mezzanine platform. This phase produces the structural calculation reports, permit drawings, and detailed integration plans for any material handling equipment, ensuring the final modular mezzanine platform is both safe and perfectly suited to its operational role.

Phase 4: Quality Fabrication and Meticulous Project Management

All components for the modular mezzanine platform are fabricated to exacting standards in a controlled factory environment. A dedicated project manager oversees the entire timeline, coordinating fabrication, delivery, and installation, serving as a single point of contact for the client.

Phase 5: Expert Installation and Final Commissioning

Certified installation crews erect the modular mezzanine platform efficiently and with minimal operational disruption. The project culminates in a rigorous final inspection with the client to ensure every aspect of the modular mezzanine platform meets the agreed-upon specifications, safety standards, and performance expectations.

Navigating Pitfalls: Common Misconceptions About Modular Mezzanine Platforms

Awareness of common misconceptions is key to a successful project. Over decades of observation, several persistent myths have been identified.

Myth: “Any Fabrication Shop Can Build One.” Reality: A modular mezzanine platform is a professionally engineered structural system, not a simple weldment. Its design involves complex load path calculations, dynamic load considerations, and compliance with stringent building codes.

Myth: “We Can Bypass the Permit Process.” Reality: This is a high-risk strategy that can result in severe fines, operational shutdowns, and voided insurance policies. A permitted modular mezzanine platform is the only safe and legal path.

Myth: “The Lowest Price is the Best Deal.” Reality: The integrity of the modular mezzanine platform is foundational to the safety of personnel and inventory. The lowest bid often correlates with inferior materials, less rigorous engineering, and inexperienced installation, representing a significant long-term liability.

The Future is Vertical and Automated: The Enduring Role of the Modular Mezzanine Platform

The trajectory of modern logistics and manufacturing is unequivocally towards greater density, vertical integration, and automation. In this future, the modular mezzanine platform is not obsolete; it is increasingly essential. It creates the multi-level, structured environment that technologies like Autonomous Mobile Robots (AMRs) and sophisticated conveyor systems require to function at peak efficiency. By investing in a modular mezzanine platform today, forward-thinking companies are not just solving a current space crunch; they are building the foundational infrastructure for the automated, high-throughput facilities of tomorrow. The modular mezzanine platform is, therefore, a critical component in the ongoing evolution of the smart warehouse.

Conclusion: The Strategic Imperative of Building Up

The evidence is overwhelming. In a competitive landscape defined by efficiency and agility, the ability to create new, high-value space within an existing footprint is a profound strategic advantage. A modular mezzanine platform is the key that unlocks this potential. It is a financially astute investment that pays for itself through avoided relocation costs, enhances operational throughput, and provides the flexibility to adapt to future challenges. The question for business leaders has evolved. It is no longer about whether you can afford to install a modular mezzanine platform, but whether you can afford the continued inefficiency and cost of ignoring the vast, untapped potential of your vertical cube.

Frequently Asked Questions (FAQs)

1. What is the typical lead time from project initiation to the completion of a modular mezzanine platform installation?

A typical project for a modular mezzanine platform spans 8 to 14 weeks, though complex designs can extend this. The timeline is generally divided as follows: 1-2 weeks for design and engineering, 2-6 weeks for the municipal permitting process (highly variable), 3-5 weeks for fabrication of the modular mezzanine platform components, and 1-3 weeks for on-site installation.

2. Can a modular mezzanine platform be disassembled and moved if our operational layout changes?

Yes, this is a primary advantage of the bolted, modular mezzanine platform design. Unlike a welded structure, it can be disassembled and reconfigured in a new layout or relocated to a different part of the facility. While there are costs associated with the labor for disassembly and reassembly, this feature provides unparalleled long-term adaptability and protects the initial investment.

3. How does the installation of a modular mezzanine platform affect our facility’s fire suppression system?

Building codes almost universally require that the entire space, including the area beneath the modular mezzanine platform, be protected by fire sprinklers. Therefore, installing a modular mezzanine platform will necessitate an extension of the existing sprinkler system to provide coverage underneath the new deck. A qualified provider will manage the coordination with a fire protection contractor to ensure full compliance.

4. What are the options for getting pallets and heavy goods onto the modular mezzanine platform level?

There are several safe and efficient solutions for vertical material transport with a modular mezzanine platform. For frequent or heavy lifting, a custom mezzanine lift or Vertical Reciprocating Conveyor (VRC) is the ideal solution. For less frequent use, a pallet gate with a manual or powered forklift may be sufficient. The best option is determined during the design phase based on workflow and volume.

5. We have unique challenges, such as irregular floor levels or critical overhead infrastructure. Can a custom modular mezzanine platform still be designed?

Absolutely. Expert providers specialize in designing custom modular mezzanine platform solutions for complex and challenging environments. This can include designing the structure to accommodate uneven floors with adjustable pedestals, creating clear-span bridges over production lines, or engineering the modular mezzanine platform to fit around and under existing cranes and utility runs. These challenges are where professional engineering expertise adds the most value.

Welcome to contact us, if you need warehouse rack CAD drawings. We can provide you with warehouse rack planning and design for free. Our email address is: jili@geelyracks.com